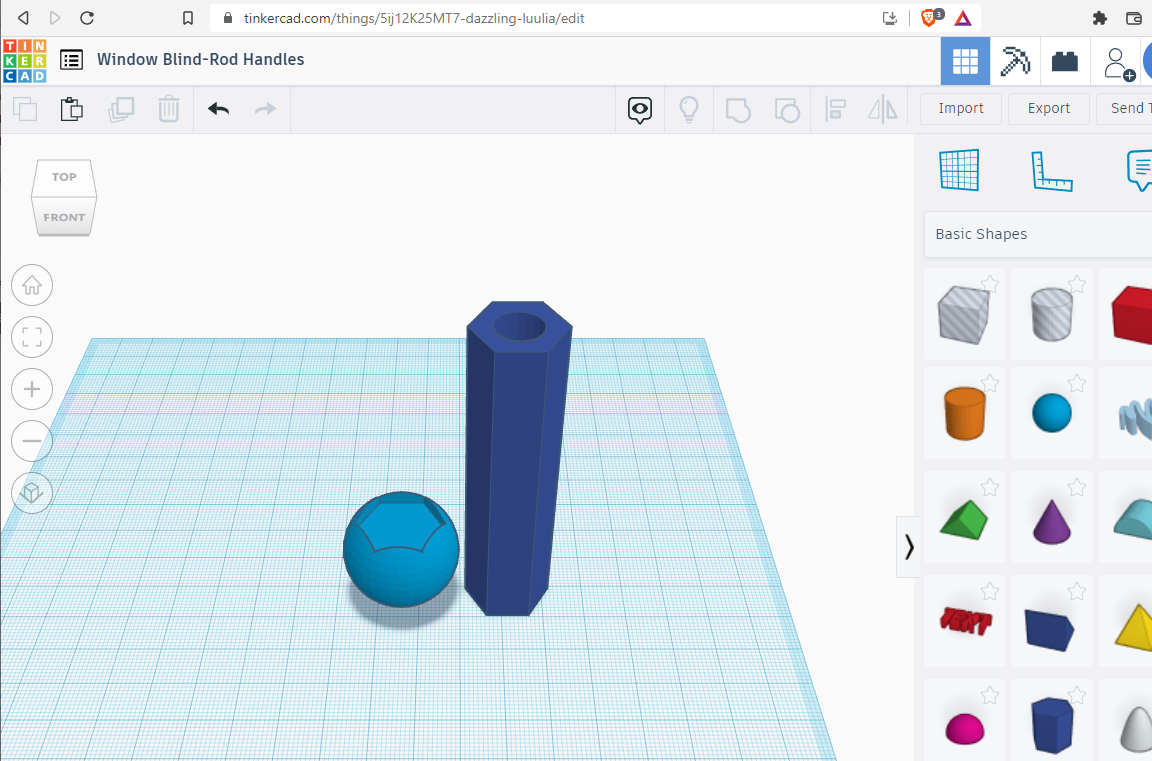

Window Blind Rod Handles

by TheOriginalNerd in Workshop > 3D Printing

2277 Views, 14 Favorites, 0 Comments

Window Blind Rod Handles

No more are the days of strings for the window blinds. These days window blinds come with rods to twist to open and twist to close. And to twist: pinch the rod between the finger and thumb and roll, roll, roll.

I twist the blind rods open every morning to let the sunshine in and twist them closed every night to keep the dark out. I love letting the day in when I twist the rods open. It allows the light and it’s friendly warmth to come on in and basically starts the day off with a nice start, but every evening, I have to twist those rods closed again to keep out the prying eyes and monsters of the night.

Only problem is… that is a lot of twisting and the twist and slip method of the pinch, isn’t the easiest way to do this, so I decided to add handles to the rods to increase their diameter and make a more comfortable grip.

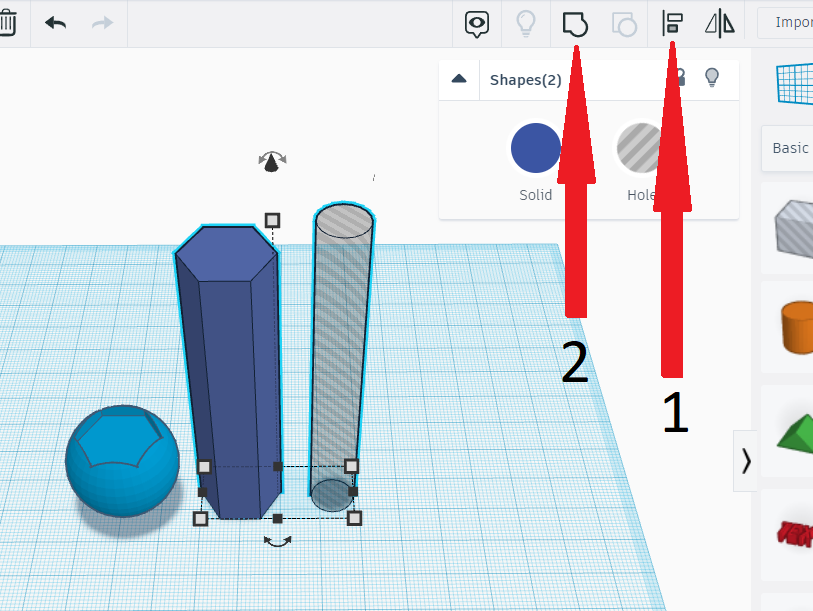

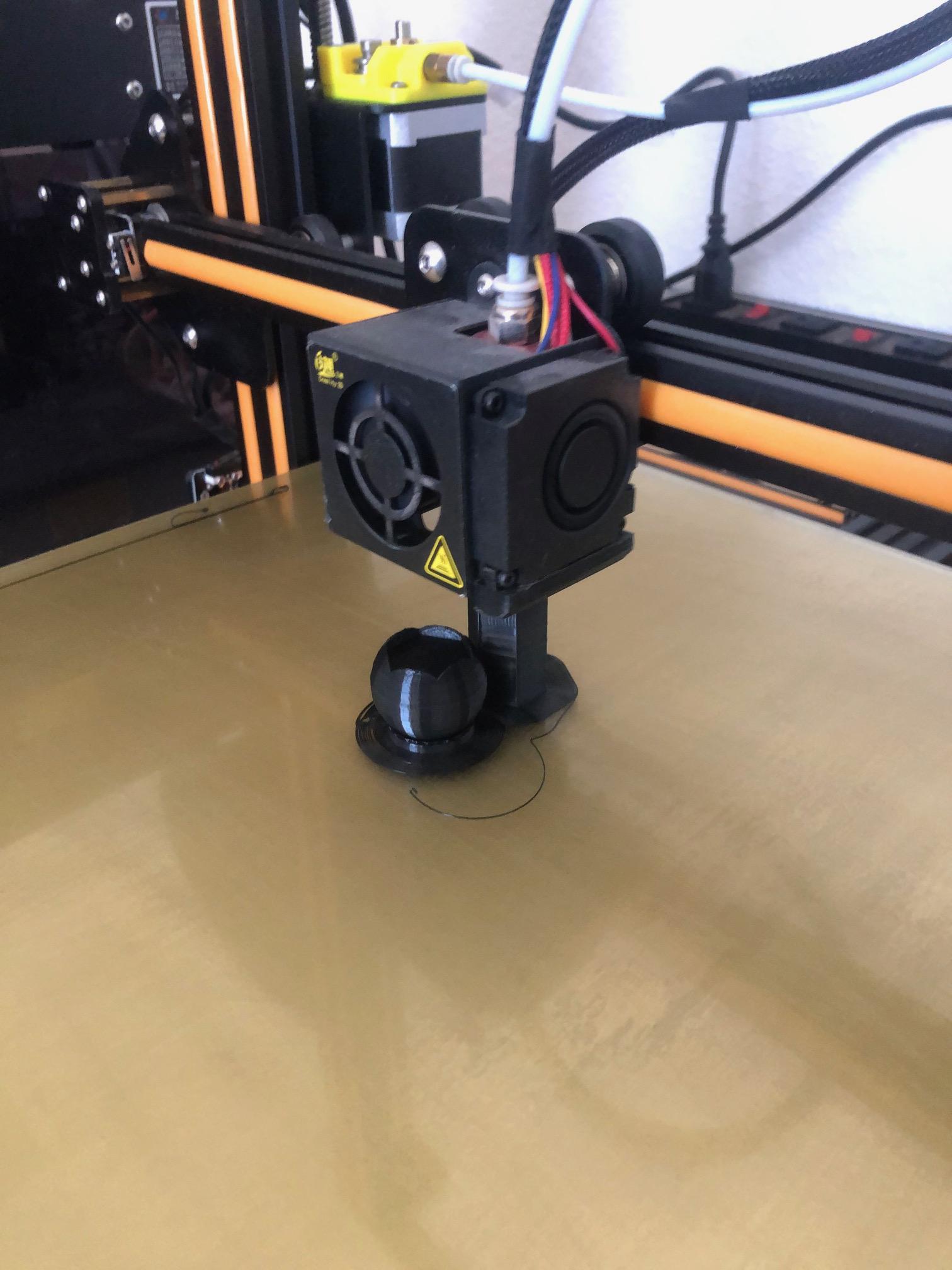

I 3D printed some handles for the blinds around my house. I used a hexagon shape for better grip and comfort when turning, but you can use whatever shape you feel works for you. I also added a ball at the bottom to help prevent slippage. I decided to print in 2 pieces and GLUE the 2 halves together, because I couldn't print the handle design laying down or I'd end up with supports in hard to remove place and standing up in either direction would make for an unbalanced print. Below how show you how to print the Hexagon Pillar and the "Ball" in two pieces and glue then together. I also show you how to separate the 2 pieces in a way that provides for good gluing surfaces.

Thank you for reading and I hope you enjoy making "the handles the window blind manufactures left off."

Supplies

Tools:

3D Printer (And Smart Phone or Computer)

CAD Software (I used TinkerCAD)

Calipers

Supplies:

Spool Of Plastic (I used PLA)

Silicon Adhesive (I used Clear Adhesive Sealant Silicon RTV)

Getting the Measurements

The ONLY real measurement needed is the diameter of the blind rods and the best way to get that measurement is to use calipers. BUT I’ve found the maker of the blinds in my house didn’t worry too much about a consistent diameter. This is good and bad, mostly bad. It means you’ll need to measure all of the rods you intend to add handles to and design more than one model OR design one model based on the largest diameter you measure and use adhesive on the rest.

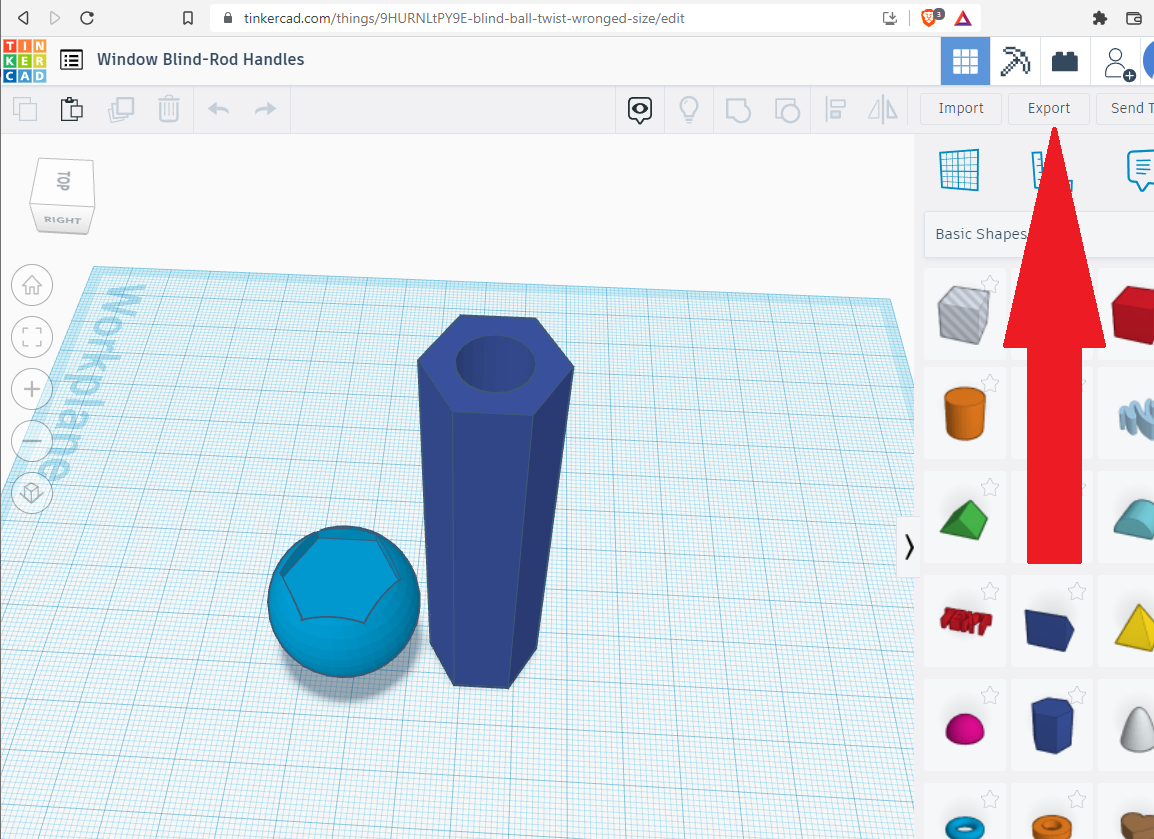

CAD Work (Or Use the Enclosed Files)

When designing your Blind Rod Handles, you’ll need to decide what length you’ll want and I suggest you add the spheres at the end for comfort.

I use many different CAD programs (of the FREE variety), but for quick and dirty designs, I use TinkerCAD. It’s not only easy and free, it does all you need a CAD program to do to create these Blind Rod Handles. It has basic shapes. It centers, combines and subtracts these shapes easily.

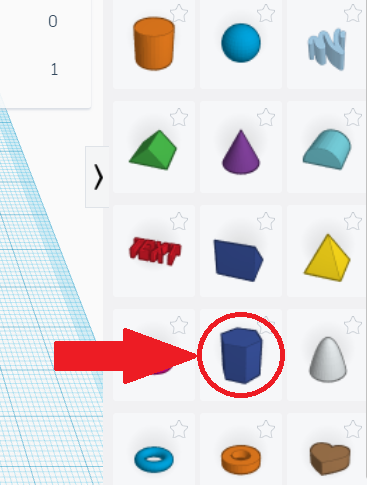

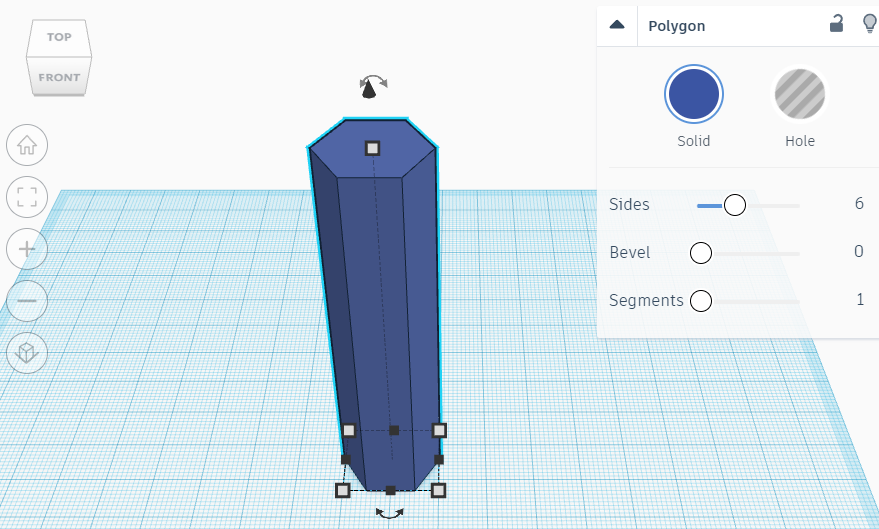

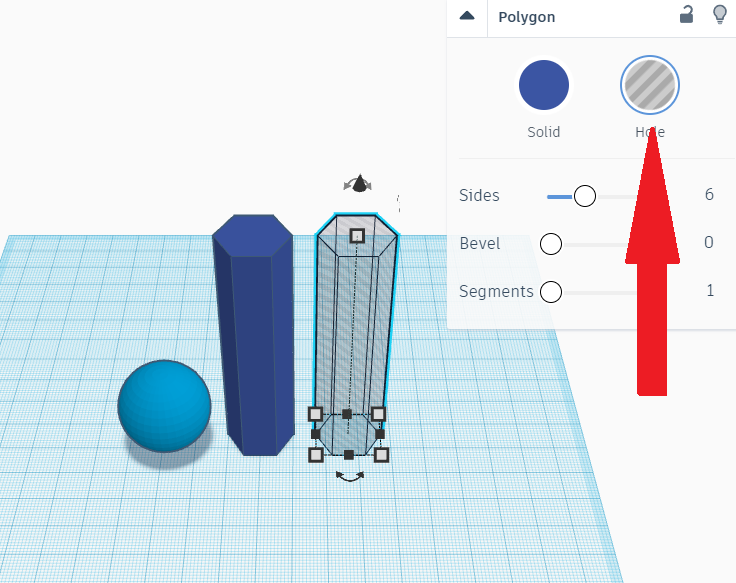

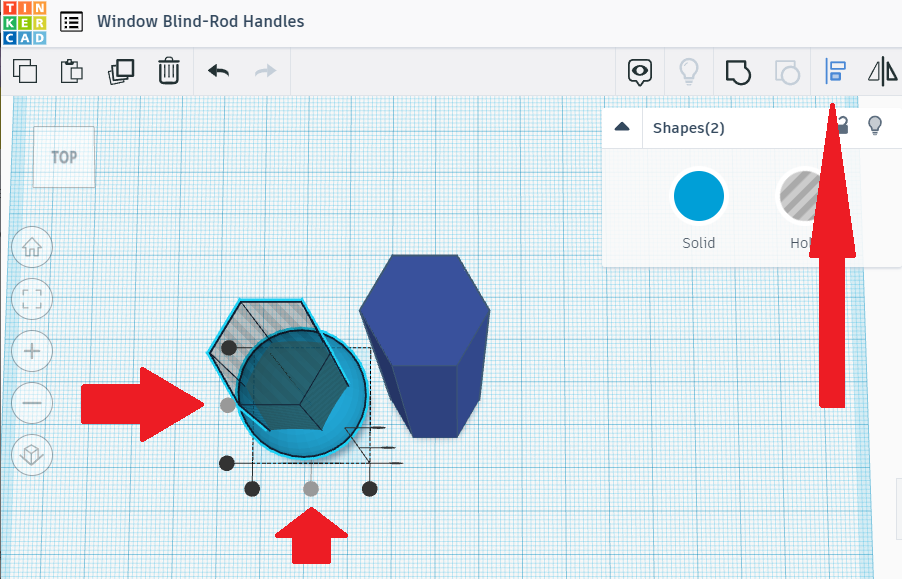

In TinkerCAD, choose the Hexagon Basic Shape and stretched it to match the length of the main handle you want. Also make sure the hexagons “diameter” is the size you’d like. [Tip: at this point, you can export the plain hexagon pillar shape to do a test print to see how it feels in your hand.] Next you’ll also need to create a copy of the hexagon pillar that is slightly larger (.01 or .02mm) than the original and turn that copy into a “ghost” (a negative or hole). Next use the sphere (ball) shape and stretched it so that the diameter is slightly larger than the Hexagon Pillar. Don’t worry about the exact size yet, just make sure it is has a larger diameter than the hexagon. You will be adjusting the diameter of the sphere as you move the “pieces” in order to combine them into their final shape.

At this point, move the Hexagon Pillar “Ghost” to the same location as the sphere, so that you can use the “Align” tool to center the Hexagon Pillar "Ghost" in the sphere. After you’ve center these two (2) pieces with each other, you’ll need to raise the hexagon “ghost” until it is just recessed in the top of the sphere. The little black cone shape above a selected object is how you raise and lower a it. [Tip: how tall the Hexagon "Ghost" is unimportant, so you can shorten the Pillar so that it is a more manageable size.]

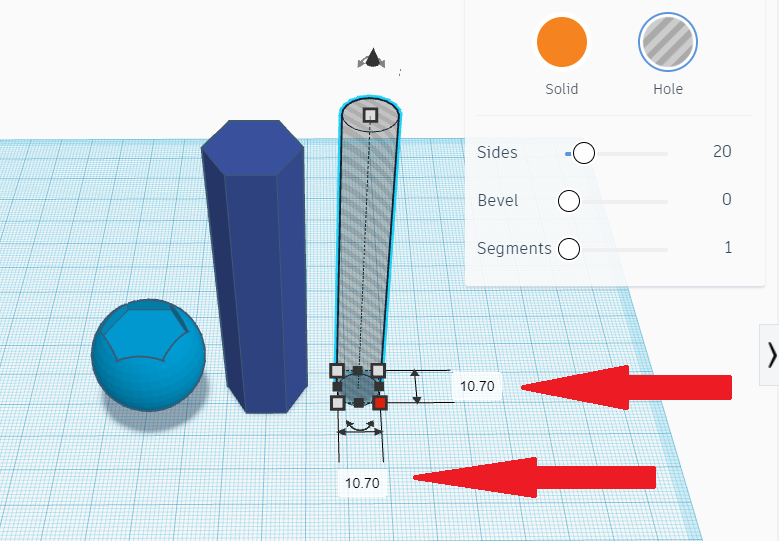

Next you’ll need to create a “ghost” or negative cylinder that represents the Window Blind Rods. Choose the Basic Cylinder Hole (“Ghost”) Shape and stretch it to a length longer than the Hexagon Pillar is tall. The exact length is not important as long as it is taller. To make the diameter of the Cylinder “Ghost”, click on it and then click on a corner selection square at the bottom. This will allow you to adjust the diameter equally in all directions at the same time. When it’s current dimensions are highlighted, you can type in the diameter of your Window Blind Rods plus a little to allow for printer accuracy (.01 to .02mm probably) and fit. After you’ve created a “Hole” for the Blind Rod you’ll center it with the Hexagon Pillar the same way you did for the sphere and the Hexagon Pillar "Ghost". Make sure the Rod “Ghost” extends through the bottom of the Pillar, if you want the Rod Hole in the Pillar to go all the way through the Hexagon Pillar Handle.

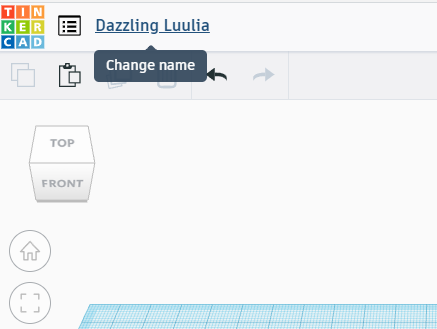

TinkerCAD generates a random name every time you open a new CAD design. At any point, if you want to give your Design a real name, click on the “random name” and you can then type in a name you want.

Exporting and the 3D Print

Export your TinkerCAD designed Window Blind Rod Handle design. When you click the Export button, a dialogue box will pop open asking you to choose what type of file you’d like the exported file to be. Most commonly you’ll choose “.STL” as that is what most 3D print slicers will use.

If you do not know what a 3D print slicer is, don’t give up even though I cannot walk you through the steps of using a slicer. It’s not hard, but there are many slicing programs and some 3D printers demand you use a particular slicer. So there are just to many slicers to give you an instructable for slicing your exported file. If you do not know how to slice a file for printing, there are many instructables and videos on it.

You'll need to 3D print one (1) handle set (Hexagon Pillar and Ball) for each window blind rod you wish to improve the grip of. In other words, you may only want to create a handle for the blinds you use frequently or you may wish to put a handle on every window blind set in your home.

For this step, you’ll need to slice and 3D print the first copy of your Blind Rod Handle. After printing, test fit the Hexagon “Ghost” to a Blind Rod. If it doesn’t fit, try it with other Blind Rods in your house. What you’re hoping for is a snug fit that’s snug enough to hold itself onto the rod, but if it’s loose, can it still be glued on? You will probably have to file and sand the printed pieces in order to remove supports from the sphere or remove any "Elephant Footing" (Printing too close to the bed produces a pressed look to the bottom of a print). Also "Elephant Footing" may cause the Rod Hole to be a little narrow at the opening. Filing can help widen the opening.

If you cannot fit it to any of the Blind Rods in your house, you’ll have to redesign the handle. BUT you don’t need to redesign the entire handle, just uncombine the Hexagon Pillar. That will separate the Pillar and the Cylinder Hole, so you’ll be able to resize the Cylinder Hole’s diameter.

I've included the .STL files for a variety of sizes, but there only a chance any of these sizes will fit the Window Blind Rods in your house.

Gluing the Pieces Together

There are many types of adhesives that will work with plastic, but here is what I’ve used…

I 3D printed the shapes using PLA plastic and Clear Adhesive Sealant Silicon RTV. Silicon makes a good plastic adhesive and it comes in multiple colors. Since I printed in Black PLA, I wanted to use black silicon, but it was unavailable at the time I made my purchase, so I used clear.

It works best if you apply the silicon to both pieces. I applied liberally to the top of the sphere and the bottom end of the pillar so that when I pressed the pillar into the sphere’s hexagon negative, some of the silicon oozed out the seam. I then wiped off the excess silicon. The silicon will have sort of a natural vacuum that holds the pieces together, but it helps to press the pieces together for a minute or so, while the silicon dries. Follow the directions on that come with the silicon for drying, but please wait 24 hours before fitting the new handles to the Blind Rods.