Wall Mounted Dream Desk

by diycreators in Workshop > Furniture

15225 Views, 215 Favorites, 0 Comments

Wall Mounted Dream Desk

This is the perfect dream desk for anyone looking to save space in a stylish fashion. This is wall-mounted, with a few built-in items.

Starting with the back panel, this is mounted to the wall with the French cleat system and wrapped with RF LED strip controlled by a remote. To the left corner, there’s a drink holder. In the middle section of the desk, there is an integrated power outlet with two USB ports. To the right of that, there’s a small desk grommet to pass wires through giving the desk a clean look. As a way to stay wire-free, there is a hidden wireless charger. The bottom is removable so if any electronics ever fail you can easily replace it. Last but not least the desk is designed as a two-part system to easily break down and transport.

GET THE PLANS HERE: https://gumroad.com/diycreators

FOR MORE AWESOME PROJECTS:

Subscribe to my YouTube channel: Click here

For daily inspiration follow me on Instagram: Click here

Visit my website: Click here

MATERIALS:

(1) Sheet of 3/4-inch plywood

(1) 8 x by 1 x 3 feet Select Pine

(2) 6 x 1 x 2 feet pine board

Black Wood contact paper: https://amzn.to/2Qfj0Jm

Marble Contact Paper: https://amzn.to/2xWX5PC

Smoothing tool: https://amzn.to/2xYHW0b

Outlet: https://amzn.to/2xXTEZ8

Desk grommet: Click here

USB LED Strip: https://amzn.to/2Oj2Xgs

Wireless Charger: https://amzn.to/2DGcKZG

Wood Glue

(18) 1 1/4 Wood Screw

(5) 1/4 -T-nuts

(5) 2-inch 1/4 bolts

TOOL USED:

Edge track Circular Saw: Click Here

Drill and Driver: Click Here

Heat Gun: Click Here

Clamps: Click Here

Getting Started

I began by cutting down a sheet of plywood. I ripped the plywood with a circular saw to a manageable size, and then made all the final cuts over at the table saw. You can find the plans HERE

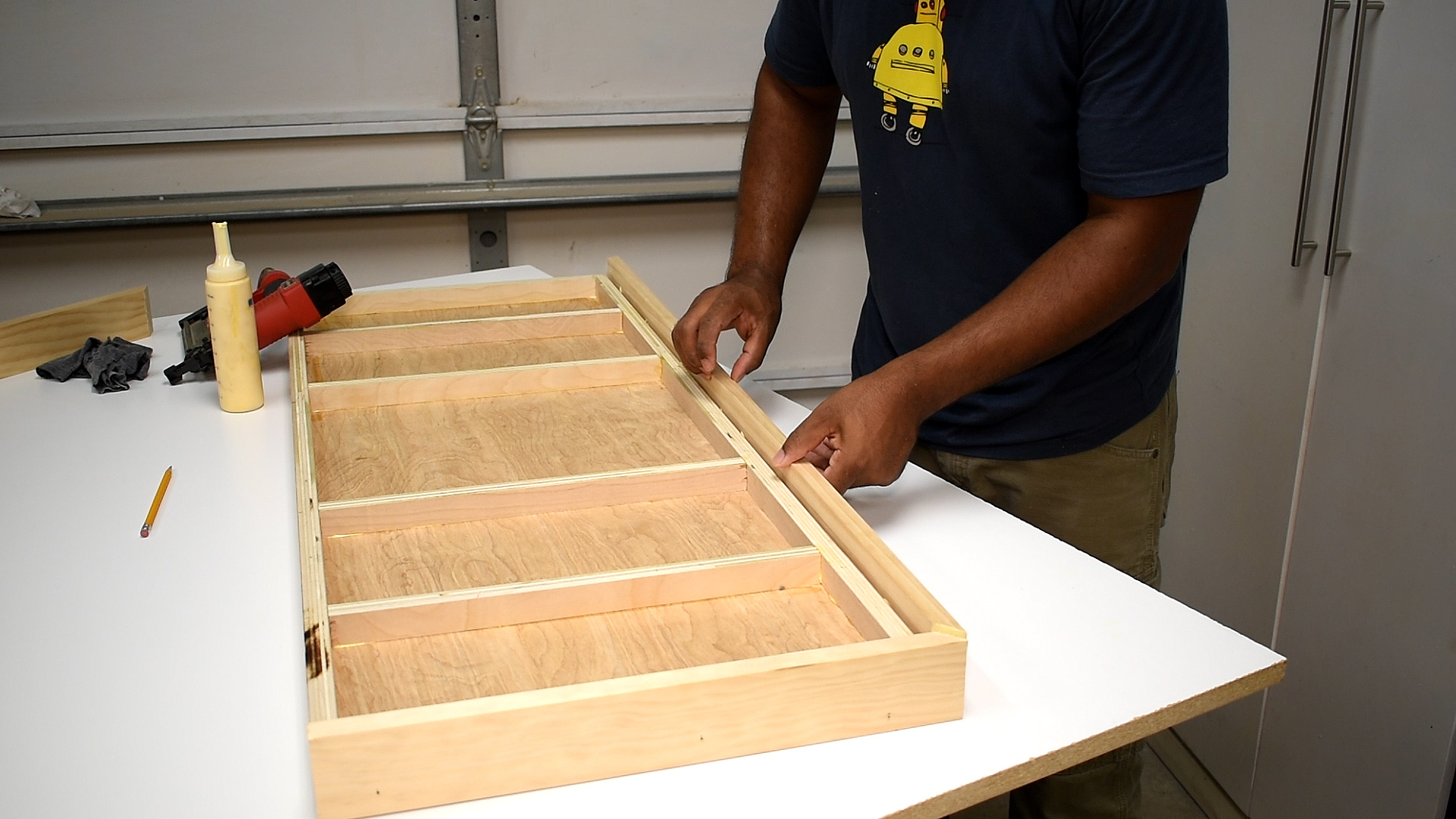

Attaching the Frame

With all the cutting being done, it’s time to start assembling. The frame was built first using wood glue and a nail gun. Next, attach the frame to the top of the desk. The overall frame needs to be the same size as the top for everything to line up. Now, attach all three of the trims. All of this can be glued and screwed for added strength.

Make a template:

To make it easy for the desk to line up with the back panel, I would suggest making a template. First, get a scrap piece of wood that matches the frame. Then, clamp that to the backside of the desk. You’ll need to drill out the pilot holes. I have one in each bay -- (5) total. After drilling through both the scrap wood and the frame set the template aside for now. I drilled out a larger hole in the frame to fit the t-nut. I used a 1/4-inch t-nut for every hole drilled. Make the pilot holes in the frame big enough to fit the t-nuts. Then, install the t-nut within the frame facing out.

Making the Back Panel

Let’s move our focus to the back panel. This part is quite simple. The back panel is a sheet of plywood with a frame attached to the back. To make the frame, I mitered the joints to give a clean look; butt joints or even half lamp joints could be used here. After the frame is complete, attach it to the plywood and center it up.

Now, locate the piece of scrap wood template. Place the French cleat piece on the back panel as it would be installed. Place the scrap wood template below the top French cleat, as shown. Next, drill the pilot holes and then open them to fit the 1/4-inch bolts. Use a countersink bit to recess head of the bolt.

Next, line up the desk and back panel. Drill out a 1 1/4-inch hole to pass the power plug through the back panel. Make sure the hole is centered and not above or below the desk.

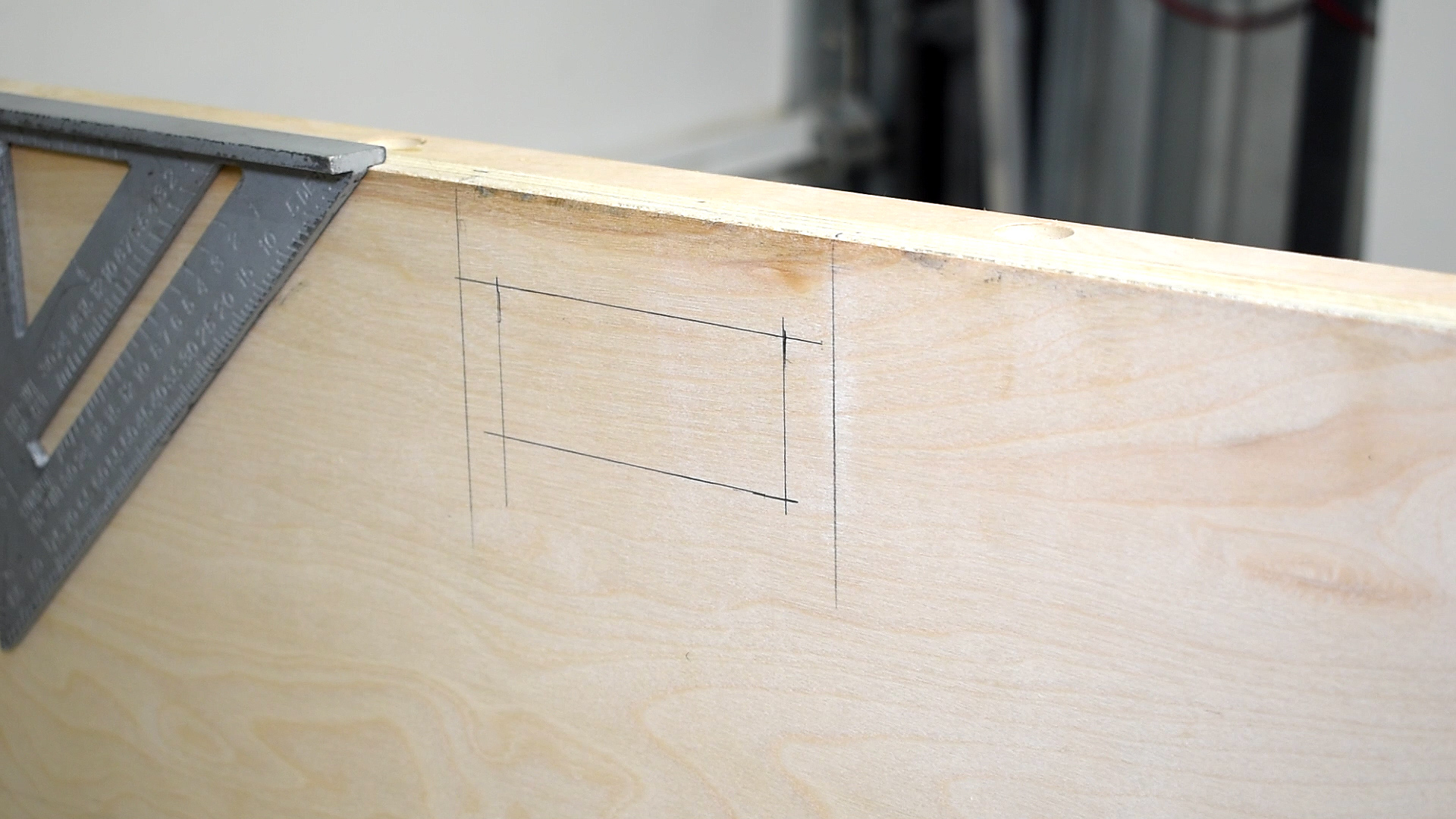

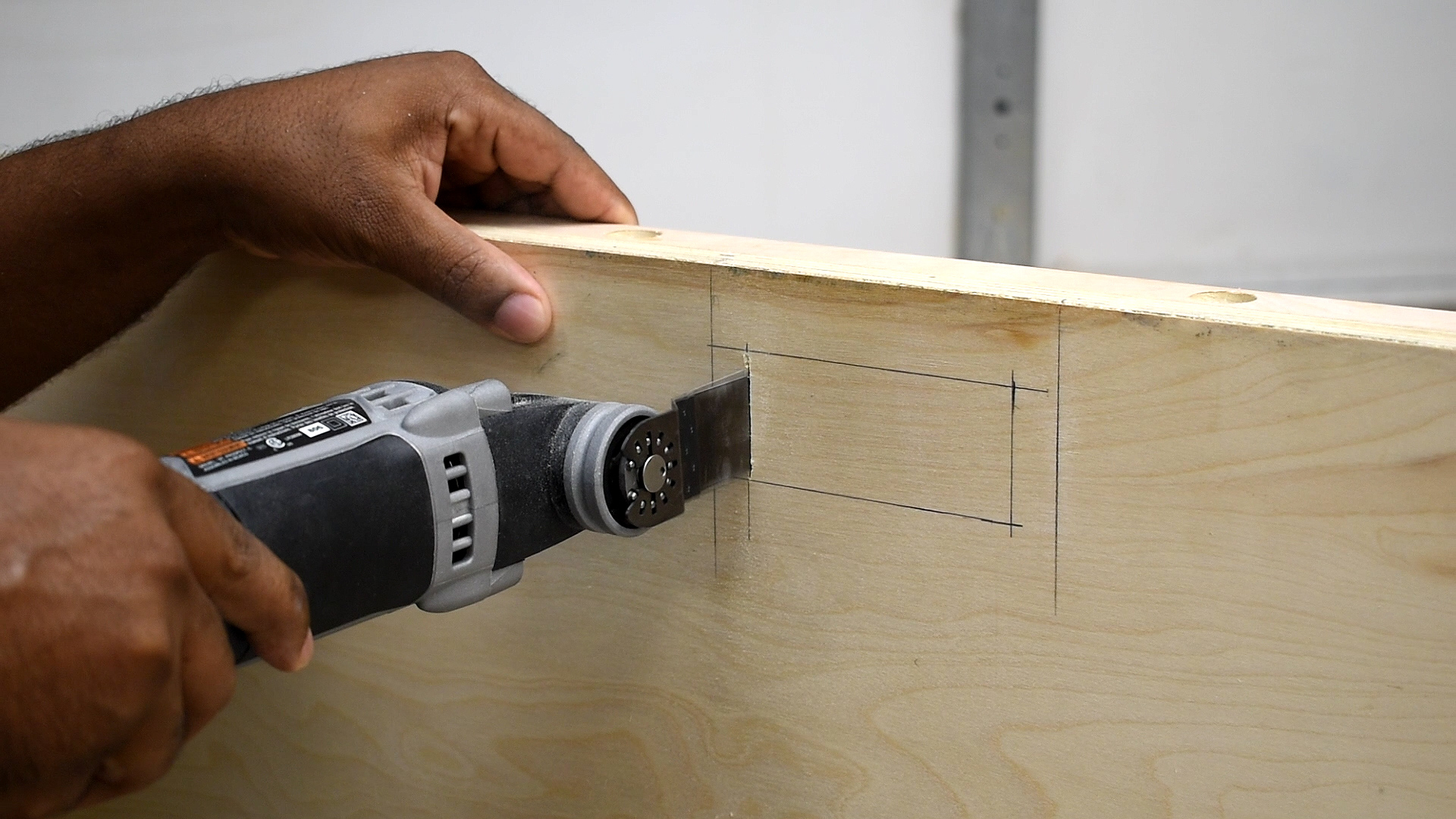

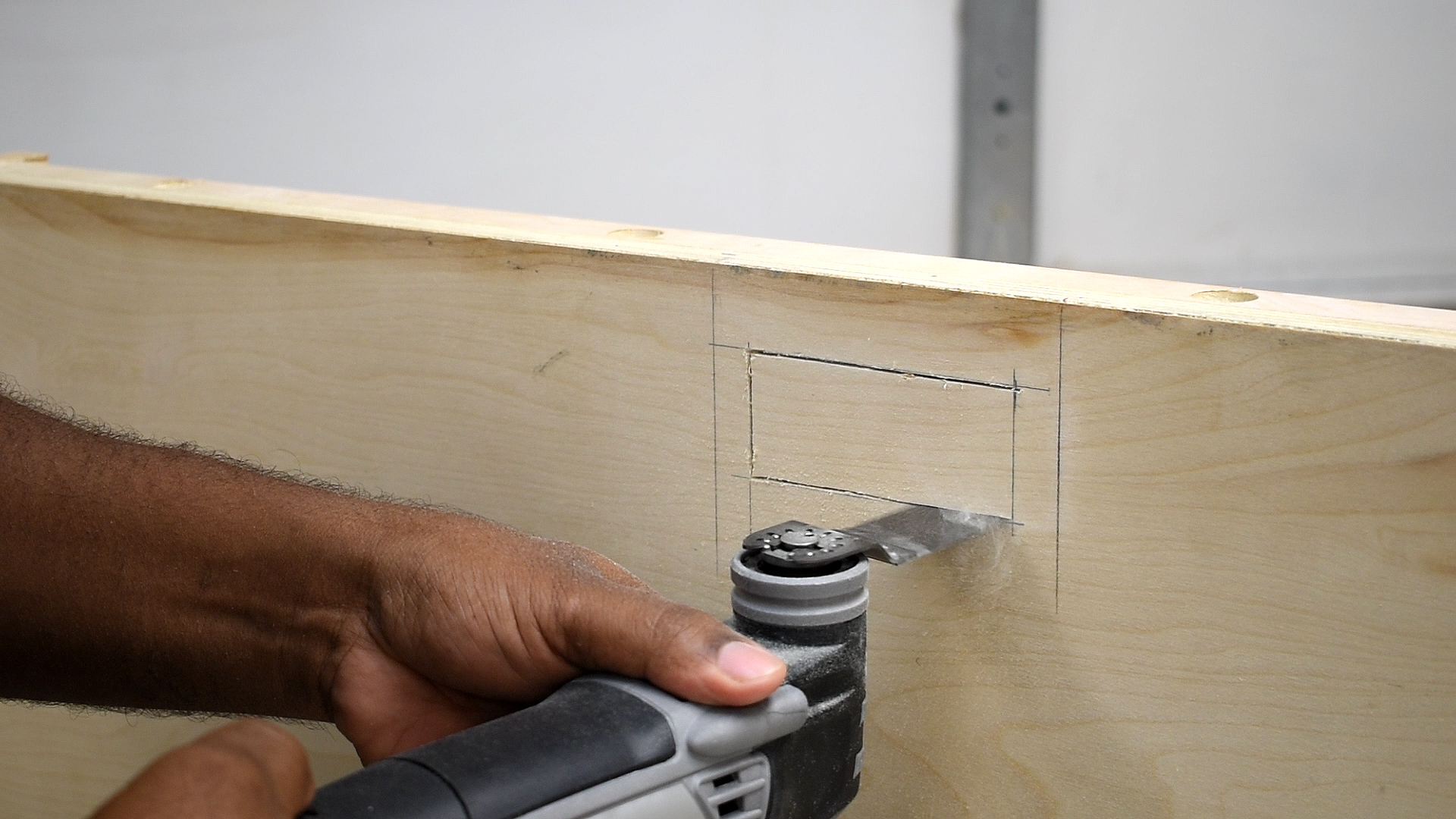

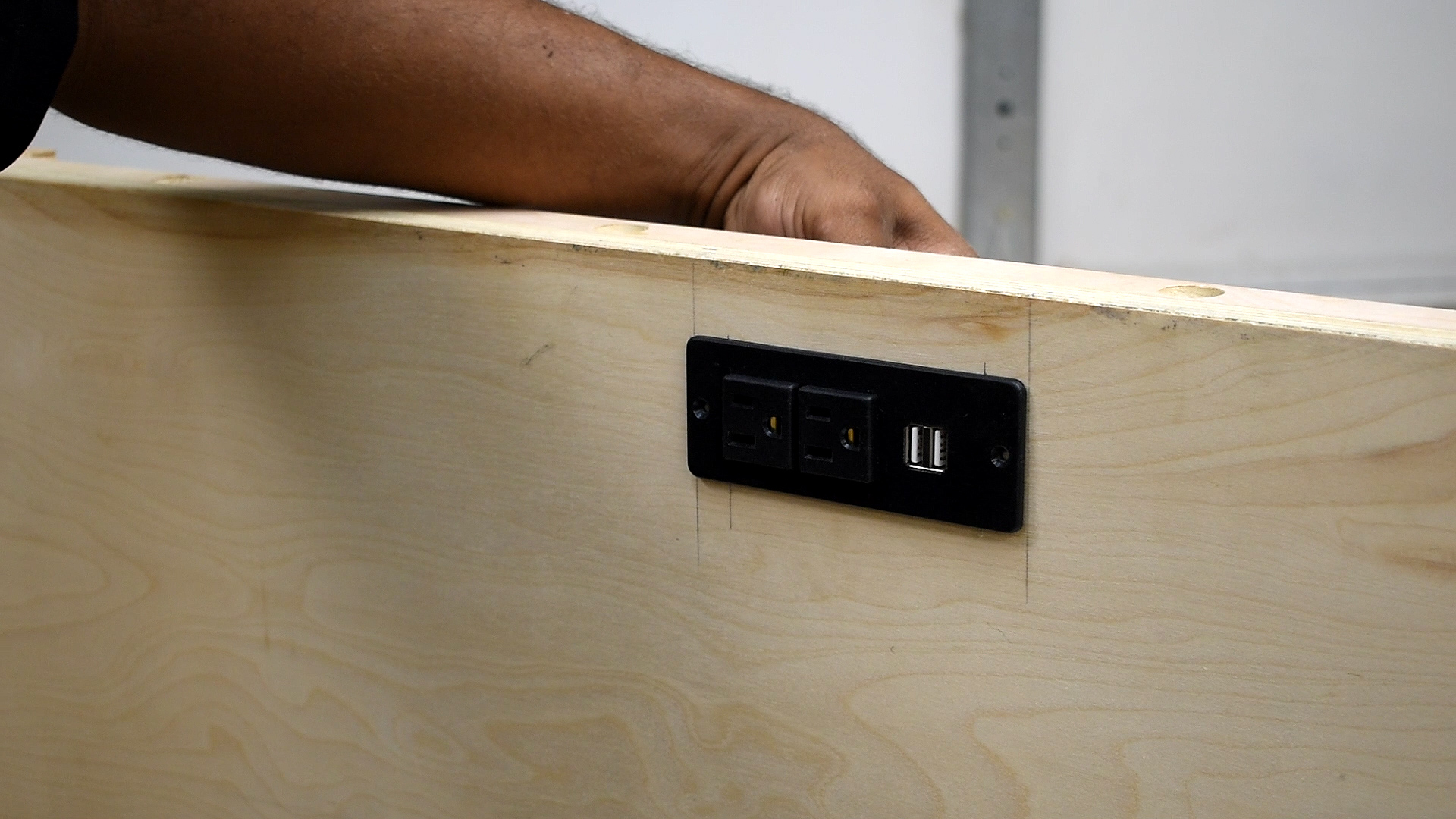

Adding the Cabinet Outlet

Mark and cut out the plywood for the cabinet outlet. You can use an oscillating tool like such or use a jigsaw. Try to make this a tight fit.

Making Room for the Drink Holder

Disregard the circle you see in the photo. I eyeballed it and it was a little off to the mark. The right way to go about this is to measure from the two sides and draw a line. Right where the lines intersect that’s where you drill. I measured 5 inches off both sides.

Use a hole saw or a jigsaw to cut out the hole.

The desk is 2.5-inches thick overall. I did a test fit and the bottom cover prevented the drink holder from sitting all the way down. To fix this, I routed out that area to remove the needed material for the drink holder to not sit.

Wireless Charger

As I stated in the video. It’s best to route this section for the wireless charger prior to attaching the frame. It was a challenge but I did manage to work in the tight area. I had to remove a lot of material to get the wireless charging to work. By the time I got done, there was about a 1/4-inch of material left. My suggestion is to test this while you are still building make sure it works well.

The one I used in the video had a transformer that plugged into the outlet. I later swapped it for one with a USB port. This way I can have one available outlet.

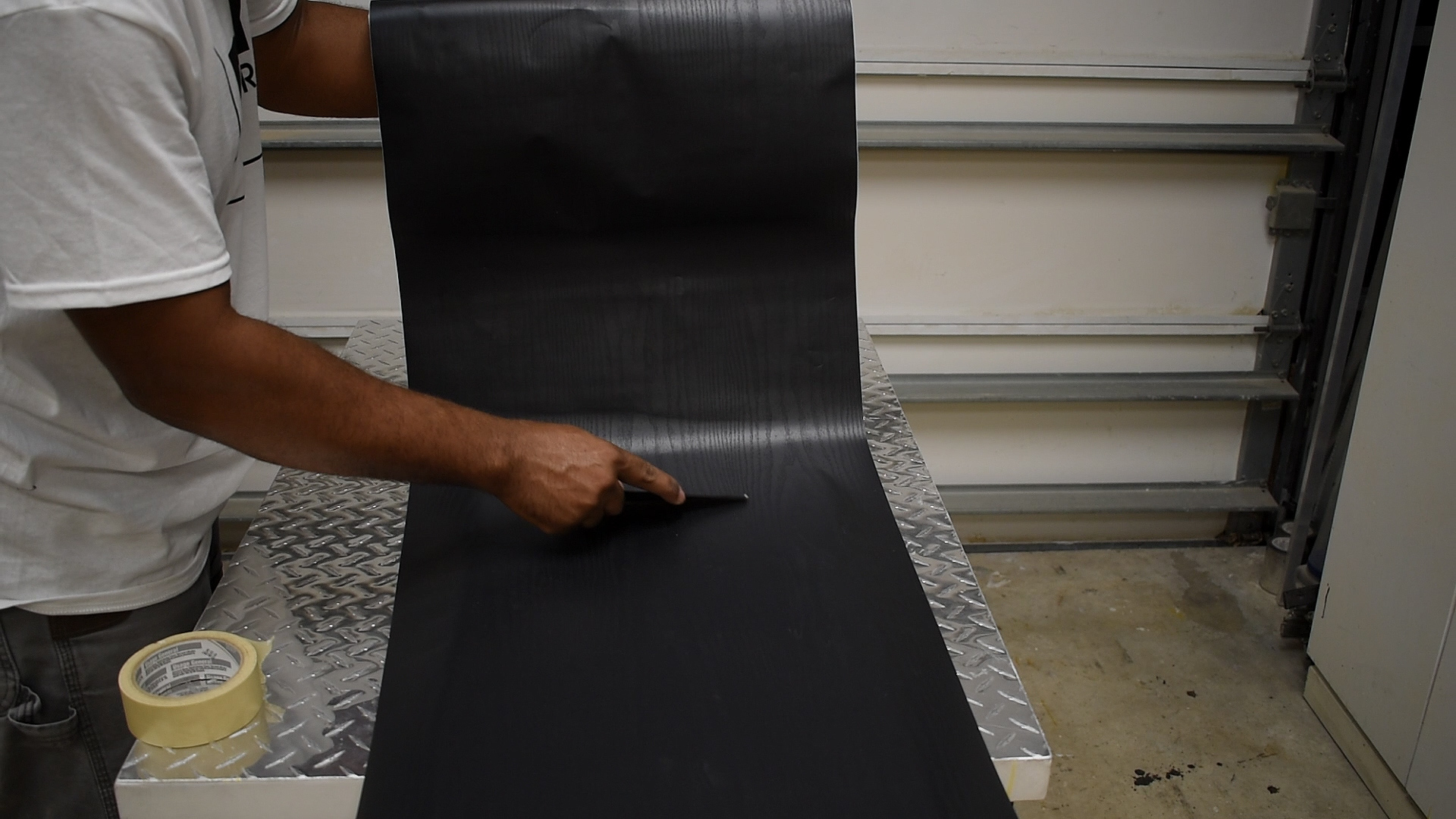

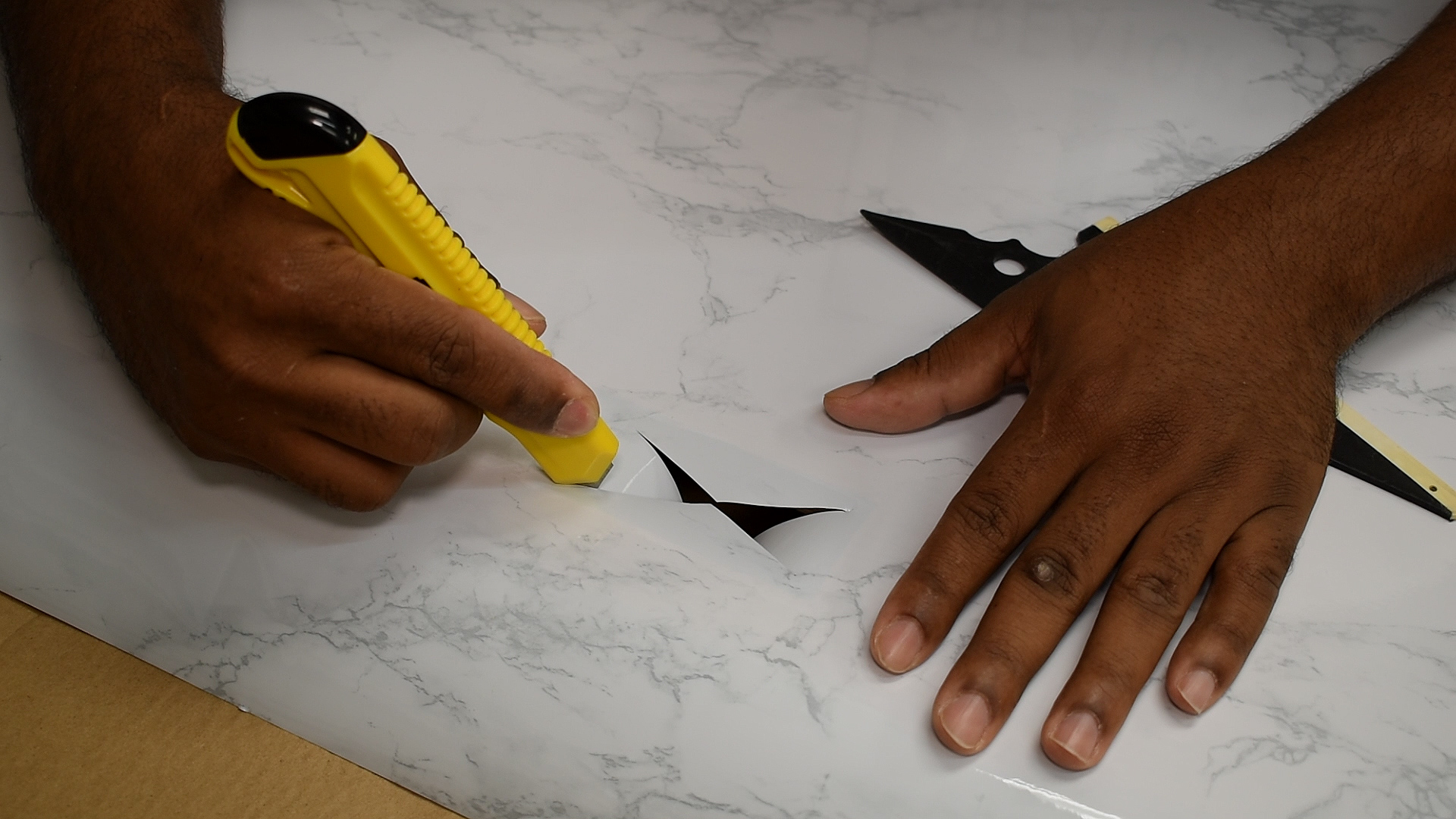

Sanding and Applying Vinyl Wrap

Before moving on, I sanded everything. This includes the back panel, desk and the cover to the bottom of the desk. I sanded with 120-grit, then 220-grit followed by 400-grit.

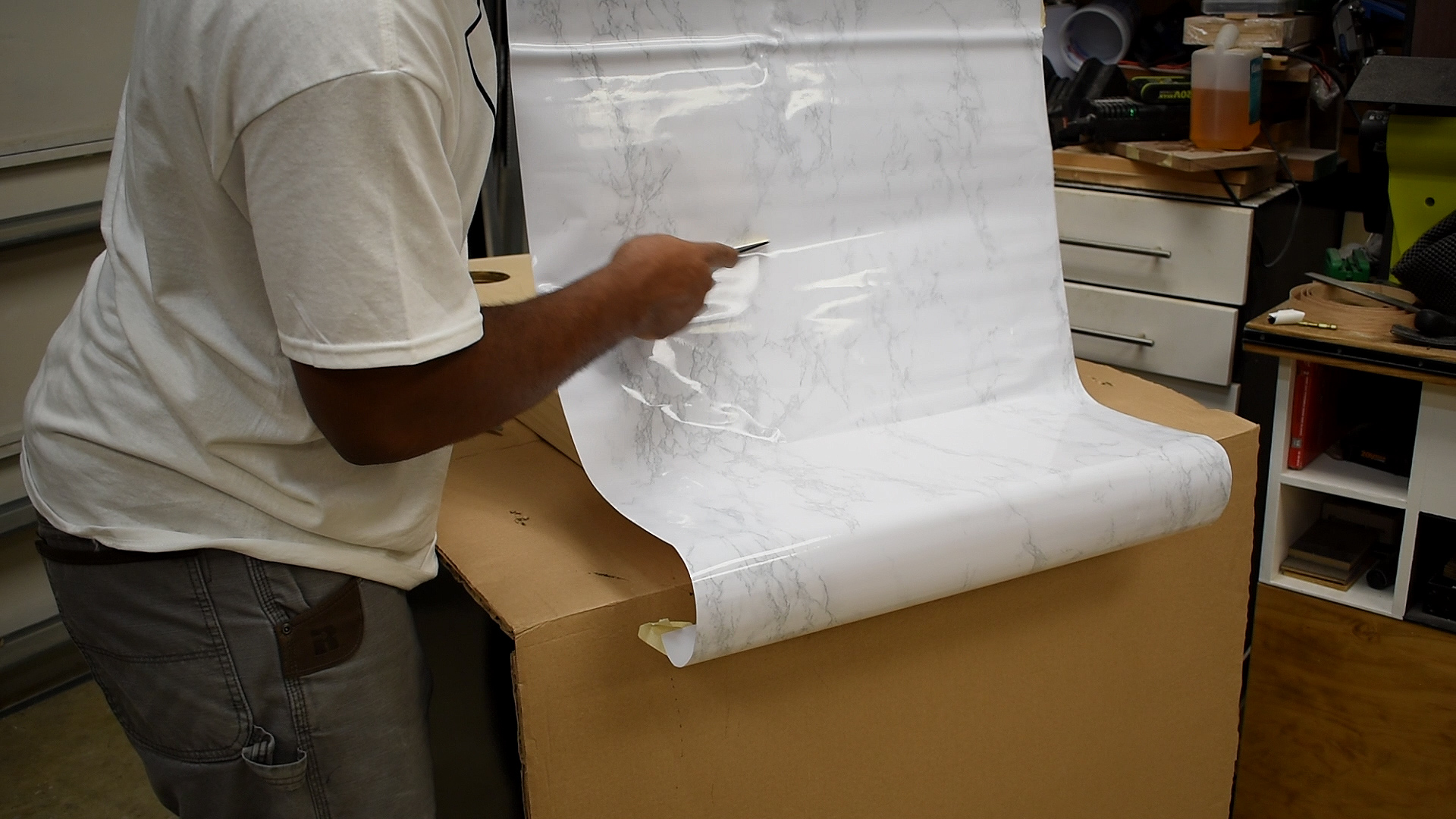

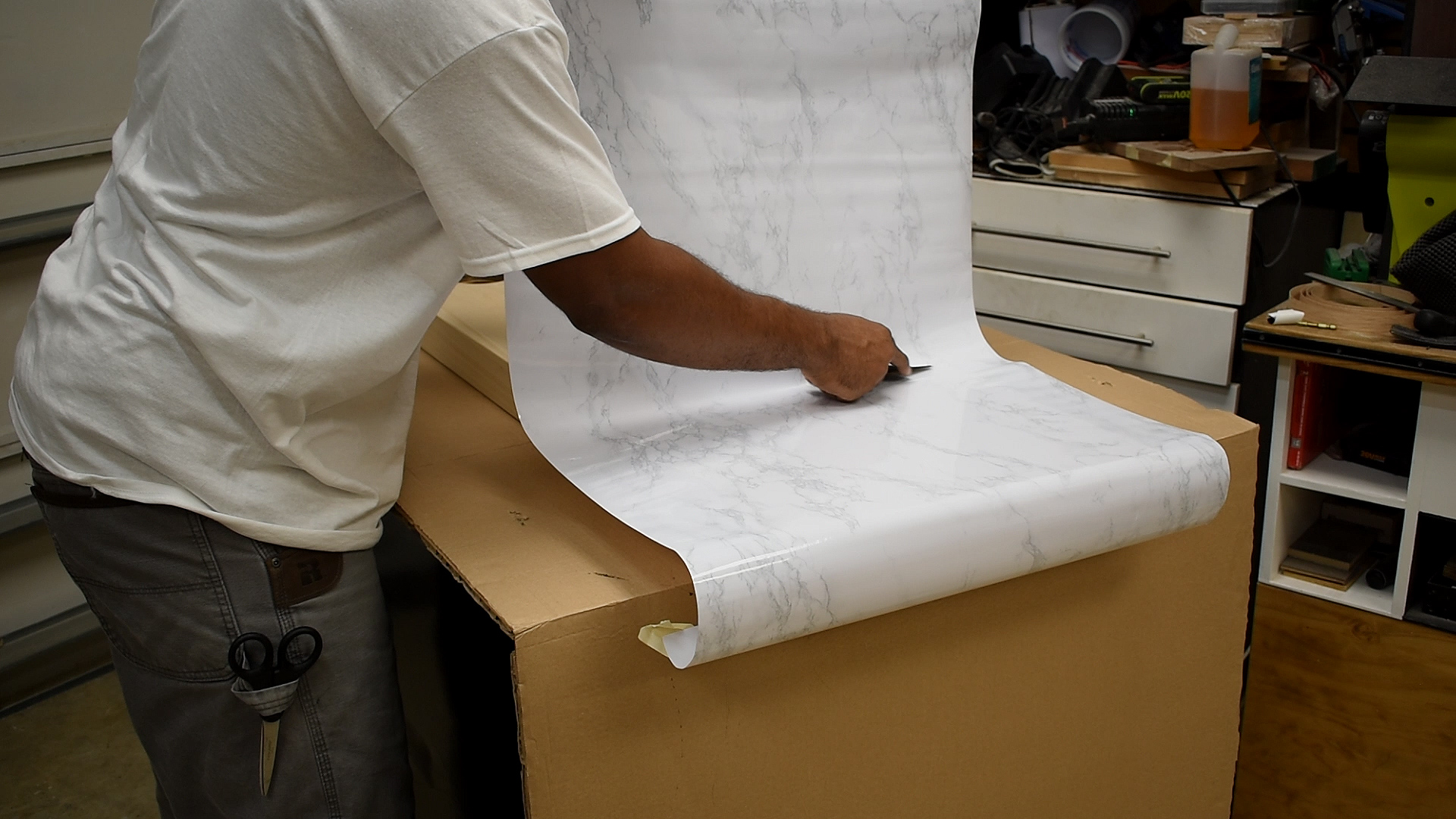

Working with contact paper was a new experience for me. So I did the best I could. I think it came out quite nice. For the back panel, I used a black contact paper. For the desk, I used a marble contact paper.

Laying out the paper was quite simple. Try lining it up the way you want it to be. Then, start from one end and layout the contact paper. Once you removed the backing paper and lay out the contact paper. Take a smoothing tool and push from the center out to the edge. Do this from one side to the other. Doing this should push out any air bubbles.

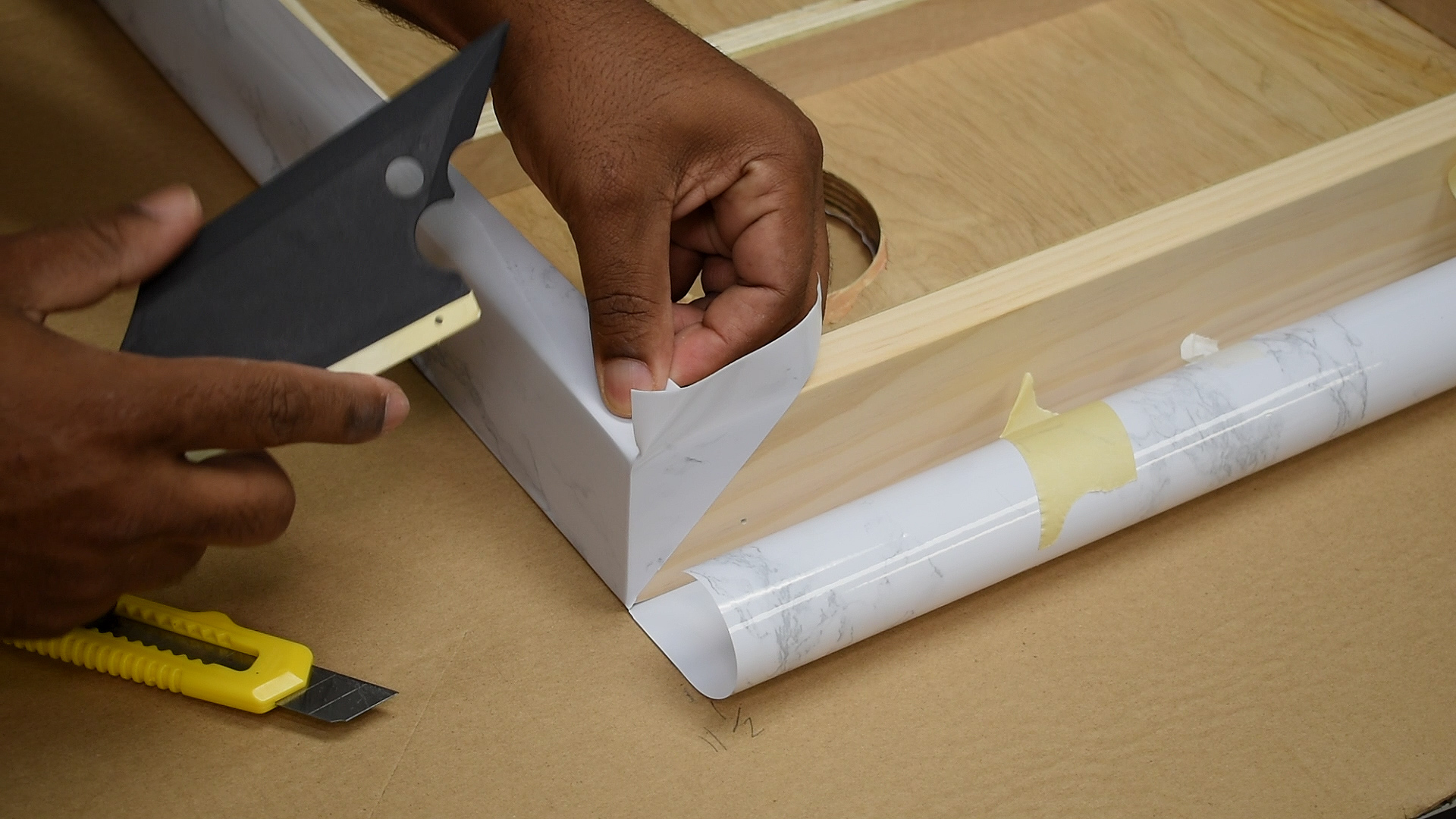

The corners were the fun part. After trying various techniques, I found that it worked out better if I just cut a triangle at each corner. For the corners, I wrapped and overlapped as shown in the photo.

Painting

I drilled out six mounting holes bottom cover. I then countersink the holes so the screw heads can sit flushed.

Then, I painted the bottom cover and the back of the panel black.

Add LED Strip

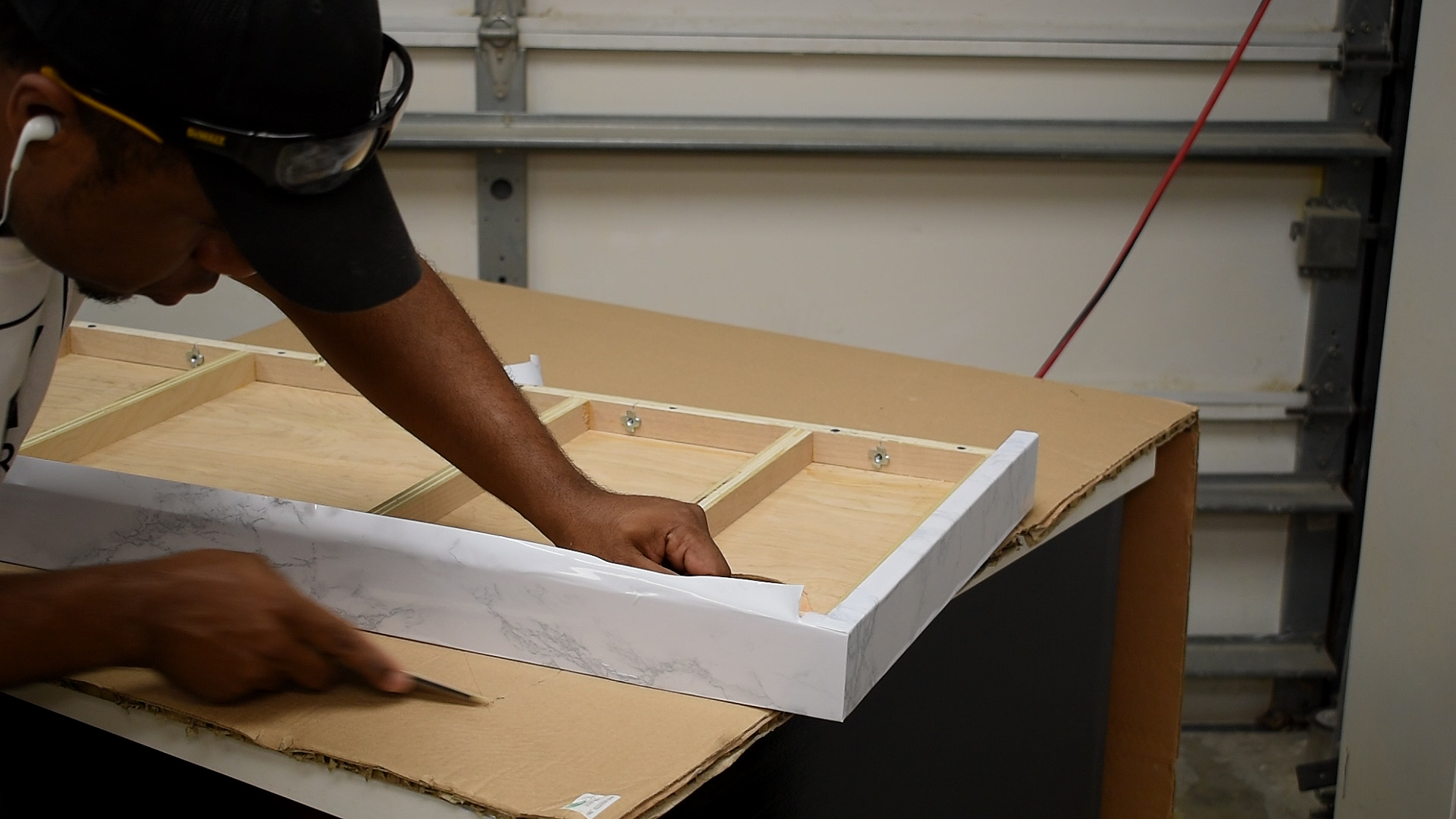

Attach the Desk to the Back Panel

I attached the French cleat to the back panel. Make sure the direction of the mitered edged is in the right position (as shown).

Right below the hole for the power cord to pass through, remove some of the material. This will allow the French cleat system to sit flat and not pinch the wires.

Finally, attach the back panel to the desk using the ¼-inch bolts.

Mounting the Desk

Drill a couple of holes in the frame to pass the power cable from the grommet hole to the wireless charger.

I added a couple of brackets in the corner of the frame for added strength.

The End

There is a lot to appreciate about this desk. Not only is it cool, it's also fun! I think it’s perfect for teens or anyone looking for a place to get some work done in style.

All there is left to do is plug it in, and enjoy!. Add some awesome artwork to your wall from Displate. They make all sorts of art on thin metal and mounted with a magnet. I like this concept, it's a neat way to add style or a cool gift to someone. Check them out here https://displate.com/?art=5b8c83f5e0050 If you find something use Promo code DIY20 for 20 percent-off everything.

GET THE PLANS HERE: https://gumroad.com/diycretors