Vine Filework for Knives

This instructable will focus on adding a simple decorative filework design on the spine of a knifeblade. Filework, for those of you who don't know, can be meant either as primarily aesthetic rather than functional or vice versa. In this case, we will be focusing primarily on improving the aesthetics of the blade in question.

There are many different filework designs, and those designs can be as simple and basic or as complicated and difficult as you wish.

I prefer to do my basic filework before I have heat treated, and then clean it up after I have hand rubbed the blade up to approximately 400 grit. Since I don't differentially heat treat the back edge, this is a necessity, as you need the spine to be pretty soft. Note: if you are using stainless you will have to do this before you heat treat.

While you can definitely do this at home using nothing but some round and triangle chainsaw files, I prefer to use power tools to reduce the work time and the wear and tear on my hands. This project was made at Techshop. Why Techshop? Simple. They have lots of great tools, lots of clean workspace, and great light. You will need all of that, and ESPECIALLY the light, to do this properly, regardless of the approach you take.

There are many different filework designs, and those designs can be as simple and basic or as complicated and difficult as you wish.

I prefer to do my basic filework before I have heat treated, and then clean it up after I have hand rubbed the blade up to approximately 400 grit. Since I don't differentially heat treat the back edge, this is a necessity, as you need the spine to be pretty soft. Note: if you are using stainless you will have to do this before you heat treat.

While you can definitely do this at home using nothing but some round and triangle chainsaw files, I prefer to use power tools to reduce the work time and the wear and tear on my hands. This project was made at Techshop. Why Techshop? Simple. They have lots of great tools, lots of clean workspace, and great light. You will need all of that, and ESPECIALLY the light, to do this properly, regardless of the approach you take.

Equipment, Tool, and Materials List

Knife:

So, clearly, in order to do this you need a blade upon which to put put your design. In this case, I am putting the filework on a pretty aggressive machete/chopper-style blade, based around a parang design. For those of you who are unaware of what that is, the short version is that it's a big hacking blade that incorporates a rounding swell toward the end of the blade. This allows for greater chopping power while not sacrificing too much balance. In my opinion, the parang is one of the absolute best blade designs for such a blade.

Equipment:

Vise

Dykem/Sharpie marker

Ruler

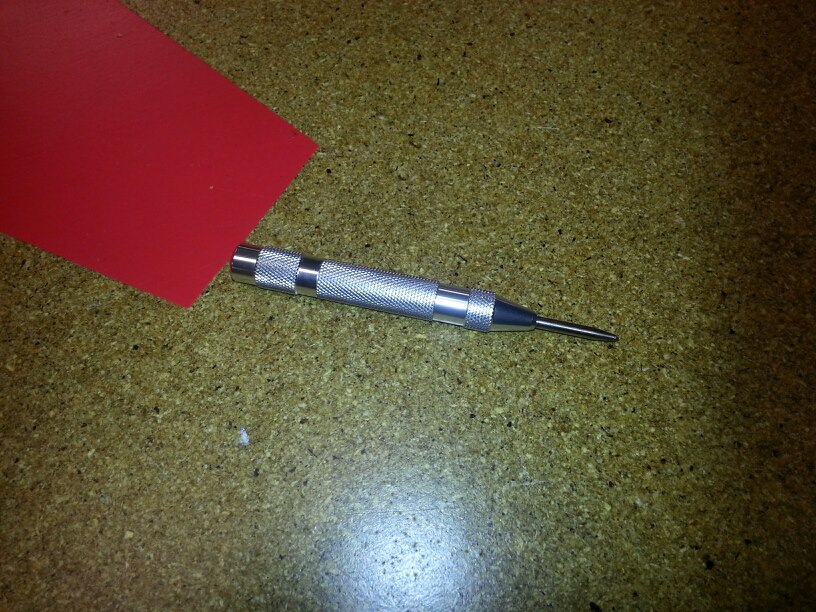

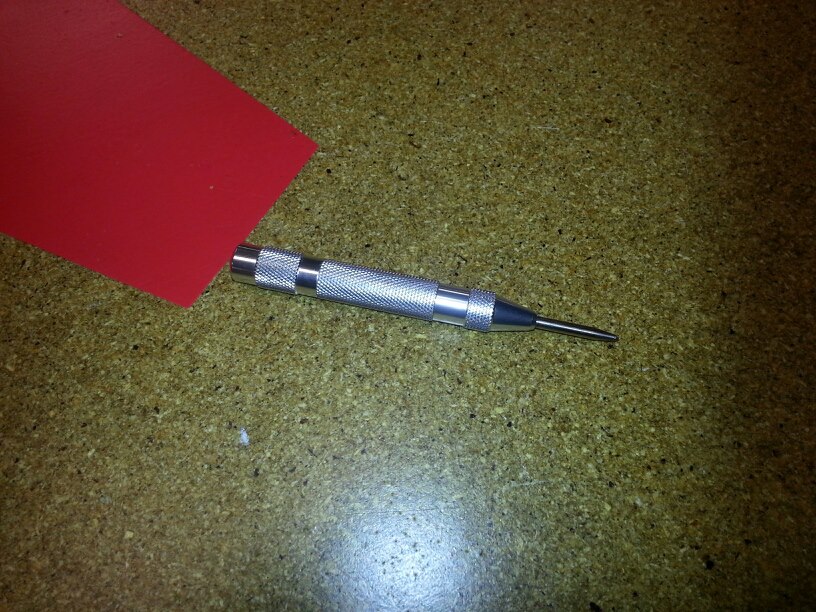

Scribe

Dremel with drum grinder tool

Chainsaw files

Eye protection

Sandpaper

Materials:

Wood, two pieces (1/4 - 1/2" thick x length of knife)

So, clearly, in order to do this you need a blade upon which to put put your design. In this case, I am putting the filework on a pretty aggressive machete/chopper-style blade, based around a parang design. For those of you who are unaware of what that is, the short version is that it's a big hacking blade that incorporates a rounding swell toward the end of the blade. This allows for greater chopping power while not sacrificing too much balance. In my opinion, the parang is one of the absolute best blade designs for such a blade.

Equipment:

Vise

Dykem/Sharpie marker

Ruler

Scribe

Dremel with drum grinder tool

Chainsaw files

Eye protection

Sandpaper

Materials:

Wood, two pieces (1/4 - 1/2" thick x length of knife)

Preparing the Knife

When doing filework, I prefer to use some sort of marking dye, in order to make the scribe marks I use more clearly visible. There are a couple of ways to do this.

One way is to spring for some Dykem, which is what machinists use for essentially the same purpose. It starts off as a liquid and you brush it onto the area on your piece that you wish to work on. It's messy, and once you get it on your skin it will remain until you grow new skin, but it really is the best out there. It typically requires a pretty decent scratch to make a mark, and it makes marks HIGHLY visible.

Another way to do this is to use a plain ol' Sharpie indelible pen. It tends to be less mess, but the mark comes off easier. So the tradeoffs are mostly cleanliness, availability, and cost. Dykem is not super easy to find, and it's not cheap, but I still prefer it.

Make sure you cover/coat the part of the blade you intend to file very well. That may involve two coats with the Dykem, but it may not. Either way, you want to make sure that you give yourself plenty of color to etch into with the scribe.

One way is to spring for some Dykem, which is what machinists use for essentially the same purpose. It starts off as a liquid and you brush it onto the area on your piece that you wish to work on. It's messy, and once you get it on your skin it will remain until you grow new skin, but it really is the best out there. It typically requires a pretty decent scratch to make a mark, and it makes marks HIGHLY visible.

Another way to do this is to use a plain ol' Sharpie indelible pen. It tends to be less mess, but the mark comes off easier. So the tradeoffs are mostly cleanliness, availability, and cost. Dykem is not super easy to find, and it's not cheap, but I still prefer it.

Make sure you cover/coat the part of the blade you intend to file very well. That may involve two coats with the Dykem, but it may not. Either way, you want to make sure that you give yourself plenty of color to etch into with the scribe.

Laying Out the Initial Scribelines

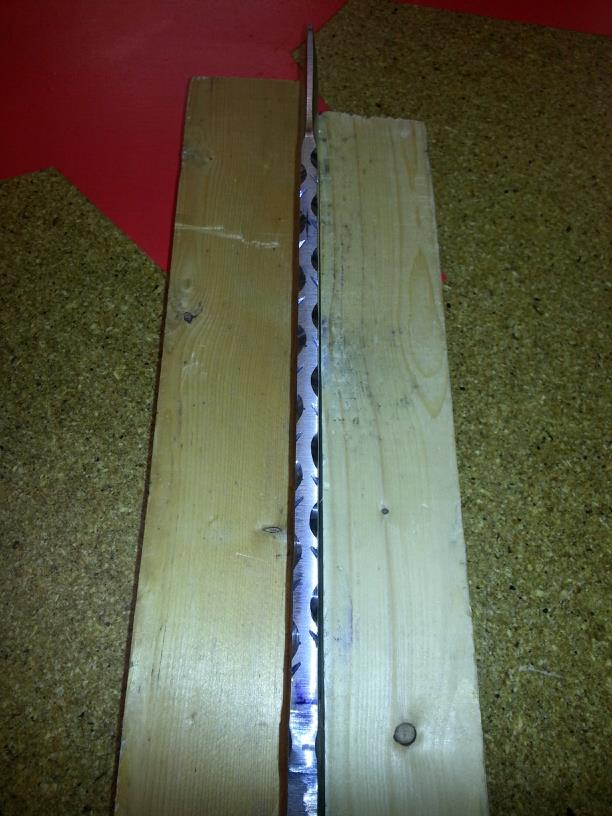

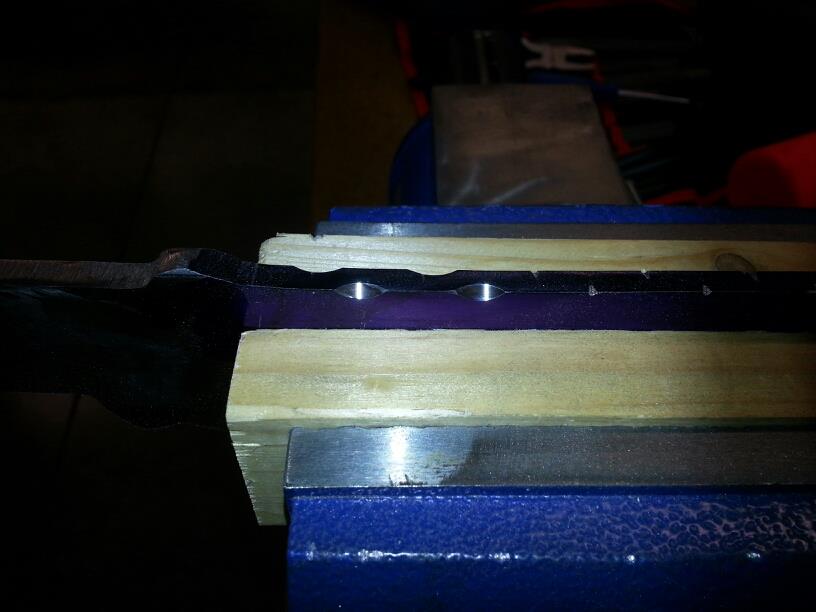

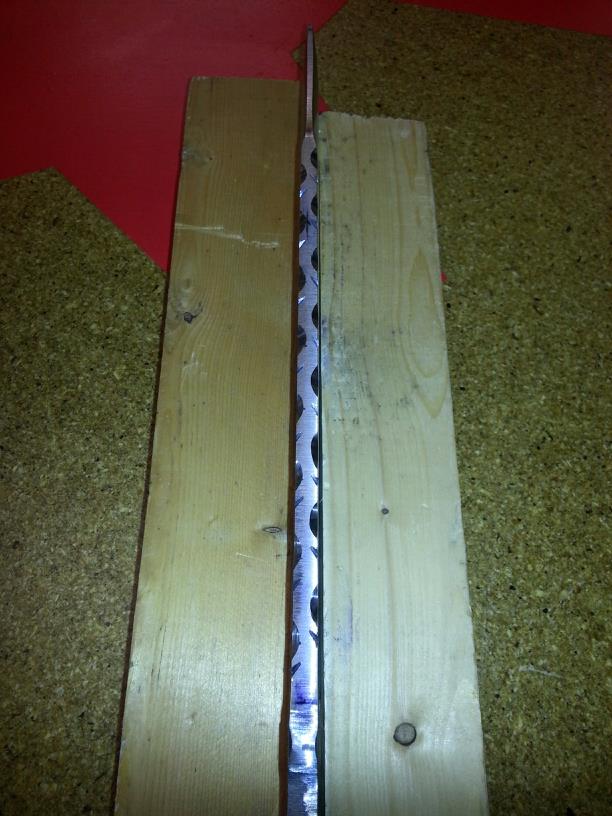

Once you have a sufficiently dark layer of layout dye on your piece, it's time to lay out your grind lines based on your design. In order to secure your piece properly, it's a good idea to chuck the work up into a vise so the workpiece won't migrate while you're filing. The best way to do that without either gouging the knife or making more work for yourself is to wedge the blade between two pieces of wood and tighten it down in a vice.

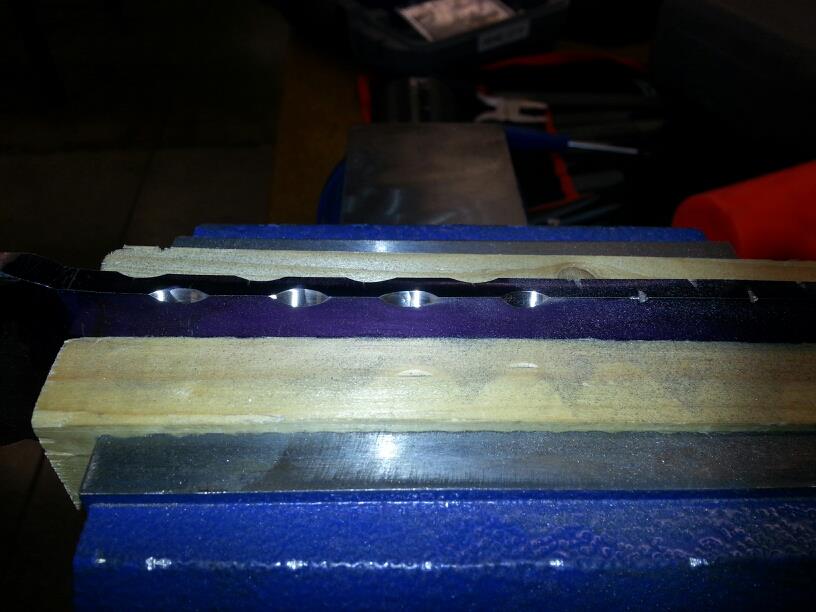

For a vinework design, I prefer to space my initial marks approximately 1cm from one another. Once you have measured out and scribed the appropriate lines on one side of the blade, do the other side as well. Just remember to offset the scribe marks such that each line falls directly between two marks on the opposite side. See pic #3 attached to this step to see what it looks like on a piece I recently did.

For a vinework design, I prefer to space my initial marks approximately 1cm from one another. Once you have measured out and scribed the appropriate lines on one side of the blade, do the other side as well. Just remember to offset the scribe marks such that each line falls directly between two marks on the opposite side. See pic #3 attached to this step to see what it looks like on a piece I recently did.

Initial Grinding

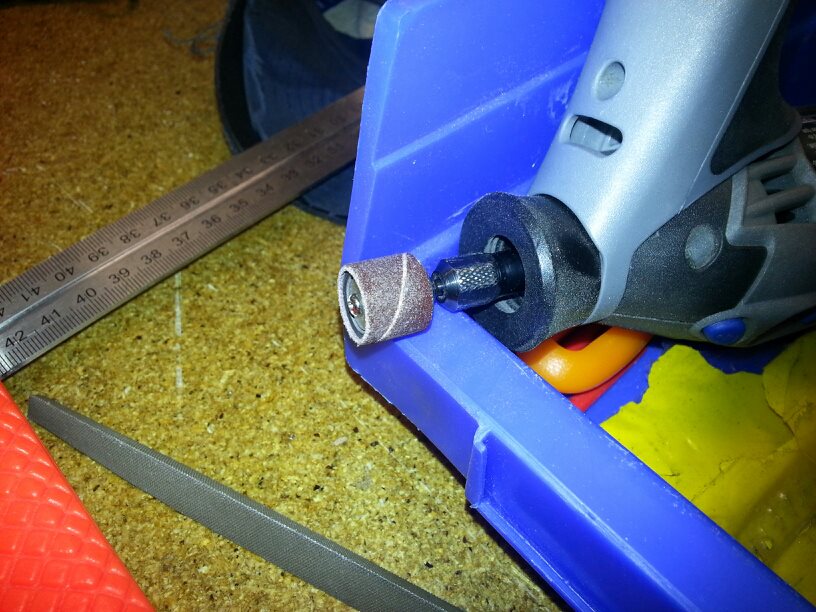

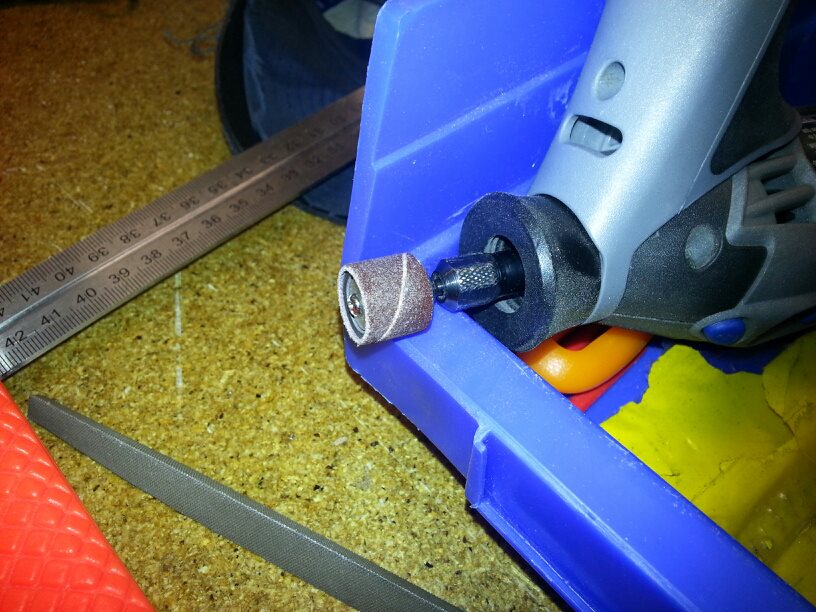

The next thing we'll be doing is grinding. Put your eye protection on.

Now, there are two ways to go about starting your round grinding. The first way is to use a round metal file and try to maintain the same angle for each hole, focusing on nice, slow, steady filestrokes.

The second way, which I prefer, is to use a Dremel with a drum grinder attachment. The It also helps to use a triangle file to start your grinds so that the Dremel has a place to "seat" the tool you'll be using. Since the Dremel is a high-rpm tool, it works using speed rather than power. In other words, you must be extremely careful, or the Dremel will run away from you, screwing up your work. It takes a very steady hand, but using a Dremel will cut out about 2/3s of the time that manual filing would take.

Start with the triangular file and score each scribe line deeper, and at a 45 degree angle, making sure to bite into the blade spine. Next, use your round file and make round cuts using the previous file cuts as a guide, at an angle 45 degrees to the blade. You will just barely start to see the zig zag pattern emerging after grinding a few of these.

\

___ \

| | \

| | \

| |

| |

| |

|__|

Next, use the Dremel to make each grind a scallop-shape. Be VERY careful here, because again, the Dremel can EASILY get away from you if you aren't careful. Actually, I prefer to use very low speeds (10-15k rpm to start) in order to get the really deep grind into the blade.

Now, there are two ways to go about starting your round grinding. The first way is to use a round metal file and try to maintain the same angle for each hole, focusing on nice, slow, steady filestrokes.

The second way, which I prefer, is to use a Dremel with a drum grinder attachment. The It also helps to use a triangle file to start your grinds so that the Dremel has a place to "seat" the tool you'll be using. Since the Dremel is a high-rpm tool, it works using speed rather than power. In other words, you must be extremely careful, or the Dremel will run away from you, screwing up your work. It takes a very steady hand, but using a Dremel will cut out about 2/3s of the time that manual filing would take.

Start with the triangular file and score each scribe line deeper, and at a 45 degree angle, making sure to bite into the blade spine. Next, use your round file and make round cuts using the previous file cuts as a guide, at an angle 45 degrees to the blade. You will just barely start to see the zig zag pattern emerging after grinding a few of these.

\

___ \

| | \

| | \

| |

| |

| |

|__|

Next, use the Dremel to make each grind a scallop-shape. Be VERY careful here, because again, the Dremel can EASILY get away from you if you aren't careful. Actually, I prefer to use very low speeds (10-15k rpm to start) in order to get the really deep grind into the blade.

Adding the Thorns...

Now that the scallops are mostly done, it's time to do grind the thorns in. This is slightly easier, as the thorns don't require removing as much material. The downside, though, is that the Dremel is really no use here. Your trusty triangle file will make short work of this, though.

Just as with the scallops, you need to mark your blade for the filework to be done. These cuts will be different, though. Whereas the scallops required a 45 degree angle to the blade in one dimension, the thorns need a 45 degree angle in the same dimension as the scallop cuts, as well as a 30 degree angle to the back of the blade, angled toward the tip of the knife. See the finished picture below to get a sense of the direction of the cut. The thorn cuts should start across from the opposing scallop, but instead of being at the midpoint, it should start at approximately the 2/3s point.

Using the triangle file, cut down and back. Again, the picture below should give you a sense of what you're going for.

Just as with the scallops, you need to mark your blade for the filework to be done. These cuts will be different, though. Whereas the scallops required a 45 degree angle to the blade in one dimension, the thorns need a 45 degree angle in the same dimension as the scallop cuts, as well as a 30 degree angle to the back of the blade, angled toward the tip of the knife. See the finished picture below to get a sense of the direction of the cut. The thorn cuts should start across from the opposing scallop, but instead of being at the midpoint, it should start at approximately the 2/3s point.

Using the triangle file, cut down and back. Again, the picture below should give you a sense of what you're going for.

Cleaning Up the Design

Once you have your filework design as well-developed as you like, it's time to clean things up a bit. Using sandpaper wrapped around the files or a dowel,start smoothing out all the file marks and round all edges.

That's really about it!

That's really about it!

Conclusion

Adding filework to your knife is not really that difficult. It's mostly just time consuming. With a bit of practice - on some scrap pieces of metal, for example - you can be doing some flework on a blade in a day or so. Remember: a pattern doesnt always have to be perfectly symmetrical to be beautiful. In fact, sometimes it looks better when it isn't. Filework is only limited to your imagination and can be as simple as just a few cuts or as complex and elaborate as you want, with many different cuts to make a design. If you have an idea but you aren't sure how you would do it or how it would look, just draw the back edge of a knife and draw different type cuts to make the pattern you want. Just have fun with it and don't be afraid to try something on a piece of scrap to see how it looks. And don't forget to ALWAYS BE CAREFUL.

I will post a picture of the finished knife once it's finally finished. That way, you can get a sense of how the filework looks on a fully completed blade.

I will post a picture of the finished knife once it's finally finished. That way, you can get a sense of how the filework looks on a fully completed blade.