Triangulum - 3D Printed 3-Hand Clock

by saulemmetquinn in Circuits > Clocks

14755 Views, 121 Favorites, 0 Comments

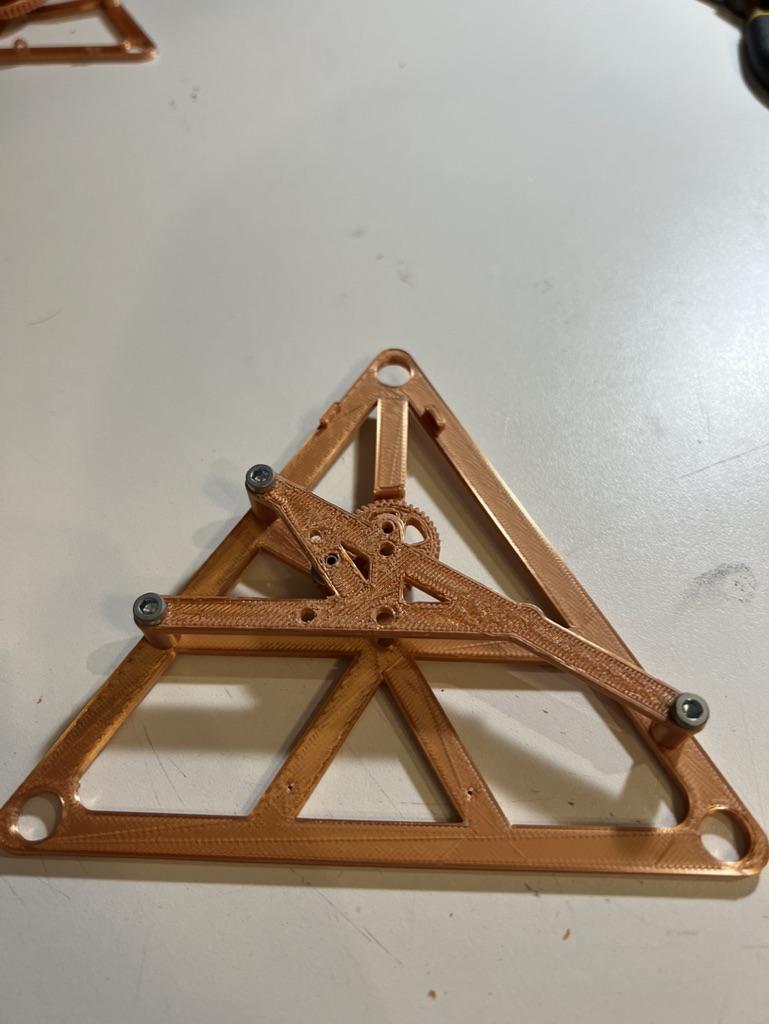

Triangulum - 3D Printed 3-Hand Clock

Hey!

So this is a project I started April 8 2021, and since then, it has changed quite a bit. The basic idea was to make a clock shaped like a triangle. This morphed into a 3-hand clock with a moon phase tracker.

The name Triangulum fits well because it is a triangular constellation, much like the shape of the clock.

This clock uses the same code as the Holo Clock with some minor improvements. You may find the use of both the imperial system and the metric system at the same time confusing, but this had to be done because the tubing is measured in imperial units and the clock was designed in metric units.

If you have any questions or comments, please let me know!

Supplies

If there are any missing materials, please let me know!

3D printer

3 colors of filament (Black pla, white pla, and silk copper pla were used in this model)

Masking tape

Super glue

Dremel with cutting disk bit (Or any tool that can cut brass tubing)

11/32" brass tube*

1/8" brass tube*

3/32" brass tube*

1/16" brass tube*

Arduino nano every (or standard version)

28byj48 stepper motor

Uln2003 driver case

6 male to female jumper wires

Small breadboard

Double-sided foam tape (3M brand was used here)

2 M1 screws

12 M4 screws

6 M3 washers

Sandpaper

Silicone or graphite lubricant

Flat black paint (optional)

9V battery

9V battery adapter (must connect to a breadboard)

Xacto knife

*All tubes are available in one pack here.

CAD and Mechanical Version

Before I begin the build, I'd like to show you the first vision of the clock.

Before I decided to use Arduino, it was going to be powered by a weight. This didn't work out that well because of friction and stability issues. The first picture above is of the original concept. As you can see, it has a weight train and an escapement. Had it not been for these problems, the clock wouldn't lack the one thing I hoped to include, ticking.

How It Works

The clock is powered by a stepper motor which turns 1/15 of a rotation each second. This 1:15 ratio is divided by four to create a 1:60 ratio, which is the seconds. The 1:60 ratio is then divided by 60 (the 60 is split into a 1:10 and a 1:6 ratio) to create a 1:3600 ratio, which is the minutes. The 1:60 ratio is then divided by 12 (the 12 is split into a 1:4 and a 1:3 ratio) to create a 1:43200, which is the hours.

60 seconds = 1 minute

3600 seconds = 1 hour

43200 seconds = 12 hours

1 rotation of the minute hand = 60 rotations of the second hand

1 rotation of the hours hand = 43200 rotations of the second hand

One of the harder parts of the gear train was the moon phase tracker. Its ratio is 99:2924 (it is split into a 1:4, a 9:17, and a 11:43 ratio), which produces a lunar month length of 29.53535 days. This is close to the actual length of the lunar month, 29.53059 days. It's not perfect, but it is accurate enough.

Print the Parts

All framework parts and gears should be printed in silk copper.

Hand parts and the moon phase tracker cover should be printed in Black

Number dial and moon disk have special printing processes which will be described in the next step.

Downloads

Special Part Printing

These two parts (moon frame.stl and number dial.stl) need to be printed in a different way than the other parts.

The print must be paused halfway through and the filament must be changed. There was a special setting for this in my slicer. I set moon frame.stl to pause at 0.6 mm and number dial.stl to pause at 1.5 mm. This creates a flawless dual colored part.

There is a second version of number dial.stl that uses IIII for 4 instead of IV.

Note:

Do not change filament type, but use the exact same brand and type (i.e. Sulnu Pla White to Sunlu Pla Black, not Sunlu Pla White to Hatchbox Pla Black).

Cutting the Brass Tubing Method 1

To cut the tubing to the proper lengths, you need to partially assemble the framework pieces and place a length of tubing into the hole. Next use an xacto knife to mark the place where you want to cut. Then remove the section of tube and cut it at the mark you just made. Use the pictures for an example of how to properly mark your tube sections.

For the 11/32" tube:

3x 43.7 mm

For the 1/8" tube:

1x 32.7 mm

For the 3/32" tube:

1x 41.7 mm

1x 21.4 mm

3x 17.4 mm

1x 13.7 mm

1x 12.5 mm

For the 1/16" tube:

1x 49.7 mm

1x 28.7 mm

Cutting the Brass Tubing Method 2

If you have calipers, I highly recommend that you use them for this step as it will be easier. For this method, you just have to sand down the tube until it is the correct length. If it's off ±0.2 mm, that is fine. As shown in the last step, you can use an xacto knife to make the cutting point on the tube.

As I do not have calipers, I don't have any photos for this method.

Assembly Part 1: First Layer of Gears

There are notes on the images. Refer to these for specific information.

Each photo has a note in the top left corner that shows which photo it is (i.e. Photo 1).

Step 1

Using photos 1 and 2 as a guide, insert the three tubes into their slots on frame a.stl and place washers over them. Dimensions of each tube are shown in notes on the image.

Step 2

Using photo 3 as a guide, glue each of the three gears to its corresponding shaft. The name of each gear is shown in the notes on the image.

Step 3

Using photos 4, 5, 6, and 7 as a guide, apply glue where indicated in the photo. Screw frame a3.stl into place with 2 4M screws. Remove the screws when the glue is done drying. The screw will come out even if a small amount of glue finds its way onto it. Place a washer over the tube protruding from frame a3.stl.

Step 4

Using photo 8 as a guide, insert the tube into 60t/12t.stl and glue it there. Make sure the underside of the gear is totally flat with no tube poking out. Dimensions of the tube are shown in a note on the image.

Step 5

Using photo 9 as a guide, take the part you made in Photo 8 and insert the smaller tube installed in Photo 2 into the bottom of it. Use the photo for guidance. Apply a small amount of lubricant to the inner tube to insure smooth rotation.

Step 6

Using photos 10 and 11 as a guide, place 40t.stl on the tube protruding from frame a3.stl. Glue it into place.

Step 7

Using photo 12 as a guide, insert a tube into 48t #1.stl and glue it into place. Make sure the underside of the gear is totally flat with no tube poking out. Dimensions of the tube are shown in a note on the image.

Step 8

Using photo 13 as a guide, place the part created in photo 11 into the position shown in photo 12.

Step 9

Using photos 14 and 15 as a guide, screw frame a2.stl into place with two 4M screws.

Assembly Part 2: Second Layer of Gears

There are notes on the images. Refer to these for specific information.

Each photo has a note in the top left corner that shows which photo it is (i.e. Photo 1).

Step 1

Using photos 1, 2, and 3 as a guide, insert the tube into the slot shown in the picture, then glue 32t/20t.stl onto it. Remove the part you just created from the slot. Dimensions of the tube are shown in a note on the image.

Step 2

Using photos 4 and 5 as a guide, attach frame a1.stl to frame a.stl with 3 4M screws.

Step 3

Using photo 6 as a guide, insert the part you created in photos 1, 2, and 3 into its slot.

Step 4

Using photos 7, 8, and 9 as a guide, place 12t.stl over the tube as shown in the photo.

Step 5

Using photos 10, 11, 12, and 13 as a guide, put 10t 28byj48.stl on the end of the stepper motor's shaft, and then screw the motor into place with 2 4M screws.

Assembly Part 3: Third Layer of Gears

There are notes on the images. Refer to these for specific information.

Each photo has a note in the top left corner that shows which photo it is (i.e. Photo 1).

Step 1

Using photos 1 and 2 as a guide, insert the tube into its slot and then put 17t/11t.stl on it. Make sure there is a washer on the tube as shown in the photo. Dimensions of the tube are shown in a note on the image.

Step 2

Using photos 3 and 4 as a guide, insert the tube into its slot and then put 43t.stl on it. Dimensions of the tube are shown in a note on the image.

Step 3

Using photos 5 and 6 as a guide, screw frame b1.stl onto frame b.stl with 3 4M screws as shown in the photo.

Step 4

Using photo 7 as a guide, make sure there is a about 2 mm of tubing protruding from the bottom of frame b.stl

Step 5

Using photos 8, 9, and 10 as a guide, insert tube 2, 9t.stl, and a washer into place as shown in the photos. You may have to use some masking tape on the tube to insure a tight fit with the gears. Dimensions of the tube are shown in a note on the image.

Step 6

Using photos 11 and 12 as a guide, put 48t.stl into place on tube 2.

Step 7

Using photos 13, 14, and 15 as a guide, put 40t/12t and its tube into place. Dimensions of the tube are shown in a note on the image.

Assembly Part 4: Wiring and Circuits

There are notes on the images. Refer to these for specific information.

Each photo has a note in the top left corner that shows which photo it is (i.e. Photo 1).

Step 1

Using photos 1, 2, 3, 4, and 5 as a guide, attach the uln2003 driver case onto frame a.stl with double-sided foam tape. Its placement does not have to be perfect, but make sure it is close to what is shown in the photo.

Step 2

Using photos 6, 7, and 8 as a guide, attach the mini breadboard onto frame a.stl with double-sided foam tape. Its placement does not have to be perfect, but make sure it is close to what is shown in the photo.

Step 3

Using photos 9, 10, and 11 as a guide, fasten the Arduino board to the breadboard with four male to female jumper wires. Connect the other ends to the uln2003 driver case. The connections are as follows: IN1 >>> D8, IN2 >>> D9, IN3 >>> D10, and IN4 >>> D11.

Step 4

Using photos 12, 13, and 14 as a guide, connect two wires to the Arduino board. One to the GND pin slot and one to the VIN pin slot. Connect the other ends to the uln2003 driver case. The connections are as follows: GND >>> - and VIN >>> +. There is an unfixable error in photo 13, refer to the note in the photo for more information.

Step 5

Using photos 15, 16, and 17 as a guide, connect the stepper motor's wire to the uln2003 driver case.

Assembly Part 5: Main Assembly

This process is pretty simple, just make sure all of the tube are properly connected. It took me a little while to figure it out, but the key is to be patient. Next, take the three large tubes and glue them into place to hold the clock together. Dimensions of the tubes are shown in a note on the image.

Assembly Part 6: Number Dial

Using two M1 screws, screw number dial.stl into place. You may have to widen the screw holes on frame b.stl as FDM printers struggle to print small holes such as these.

Assembly Part 7: Moon Phase Tracker and Hands

Moon dial.stl should be glued into place carefully so as not to glue it to the frame itself. Next, glue moon frame.stl into its place on top of moon dial.stl. Be very careful not to get any glue on frame b.stl when gluing moon frame.stl into place.

And now, it's finally time to put the hands on. This is a tedious process in which you must not get any glue on the inner tubes. I struggled with this until I used a small q-tip to apply the glue.

Arduino Code

Upload the code to the board via USB.

Downloads

Power

Connect the clock to the 9V battery using the adapter. The connections are made on the mini breadboard. Red wire >>> VIN and black wire >>> GND. Instructables users Jan5412 and parallyze (Thanks Jan5412 and parallyze!) provided helpful explanations for how to connect the battery to the VIN. Previously, I had incorrectly wired the battery to the 5V pin. The photo showing the diagram was created by instructables user parallyze (Thanks, parallyze!).

Conclusion

I hope you enjoyed reading this Instructable!

This project has been quite a journey and i'm very happy with how it turned out. There are a few thing that I would have liked to be different, but it's always like that. I love making clocks, so this won't be the last.

If you have any questions or comments, let me know!

Happy making,

saulemmetquinn

Updates:

2/8/22 - added photo to step 15

2/8/22 - added alternate version of number dial.stl to step 4

2/10/22 - moved battery connection to VIN