The Most Advanced Open-Source 3D Print Modular Block for STEM

by ArisBlocky in Workshop > 3D Printing

5707 Views, 59 Favorites, 0 Comments

The Most Advanced Open-Source 3D Print Modular Block for STEM

By making this project you should be able to understand how this block system works and create your own custom project using the framework.

This is my first tutorial ever shared, you can expect to be a lot more things to be shared every 3-4 days. so make sure you follow me. It's going to be a great addition to the world of STEM.

By the end of this tutorial, you should be able to create lots of cool projects on your own.

To support the continuity of this project you can Buy Me A Cofee Here

To know more about Blocky Codes, please check my website

Blocky Codes is still in its early version, any report bug or suggestion will help make Blocky Codes even better.

Introductions to Blocky Codes components.

I suggest you watch the video series below so you can understand the function of all the components. All the components are still in active development. So what you see on the video could be different from what you get.

We also have some others components that are still under development, such as bolts and screws, stackable LEDs, and lots more.

Supplies

Below are all the things you will need to make this project.

1. Sticks 7mm in diameter.

The holes on these blocks system are 7mm in diameter, so actually, you can use any cylinder that has 7mm in diameter. here some that I've been using for a while..

- Pencil (use holes on the blocks as a jig to make it round, it has good grip, I use only when I ran out of dowel)

- 7mm plastic straw (less friction, lightweight, but weak. Useful in some projects)

- Cheap bamboo chopstick (has good strength, but the diameter is not consistent in 7mm)

- 7mm wooden dowel (please search Amazon / eBay), it's cheap, comes in a variety of lengths, it's lightweight, easy to cut, has a good grip and if you want less friction, you can just use sandpaper. I will be using this

- If you have 7mm hollowed aluminum or steel, I think it can also be cool, I really want to try it sometimes when I have it.

Blocky Codes use all the above a lot, as it's a part of the system

2. Small Screw

A small tap screw (2x6mm), Here is a link to amazon. This screw will strengthen your structure. Actually, it's optional, but you'll see how the screw will fit in the project later.

These screws also become part of Blocky Codes and used a lot in making projects.

3. Cardboard for making the bird.

Here is the link to the template file, print it, glue it to the cardboard, and cut along the way, but feel free to make your own version of the bird, mine is not that pretty.

4. FDM printer with PLA filament.

Why FDM and PLA? because it's currently the only combination that I have and I've been using it. I will update this project once I have tried with a different material. Also a different type of 3D machine printing. I'm using PLA+ Filaments, but any kind of filament should work, just use the best one you have in stock.

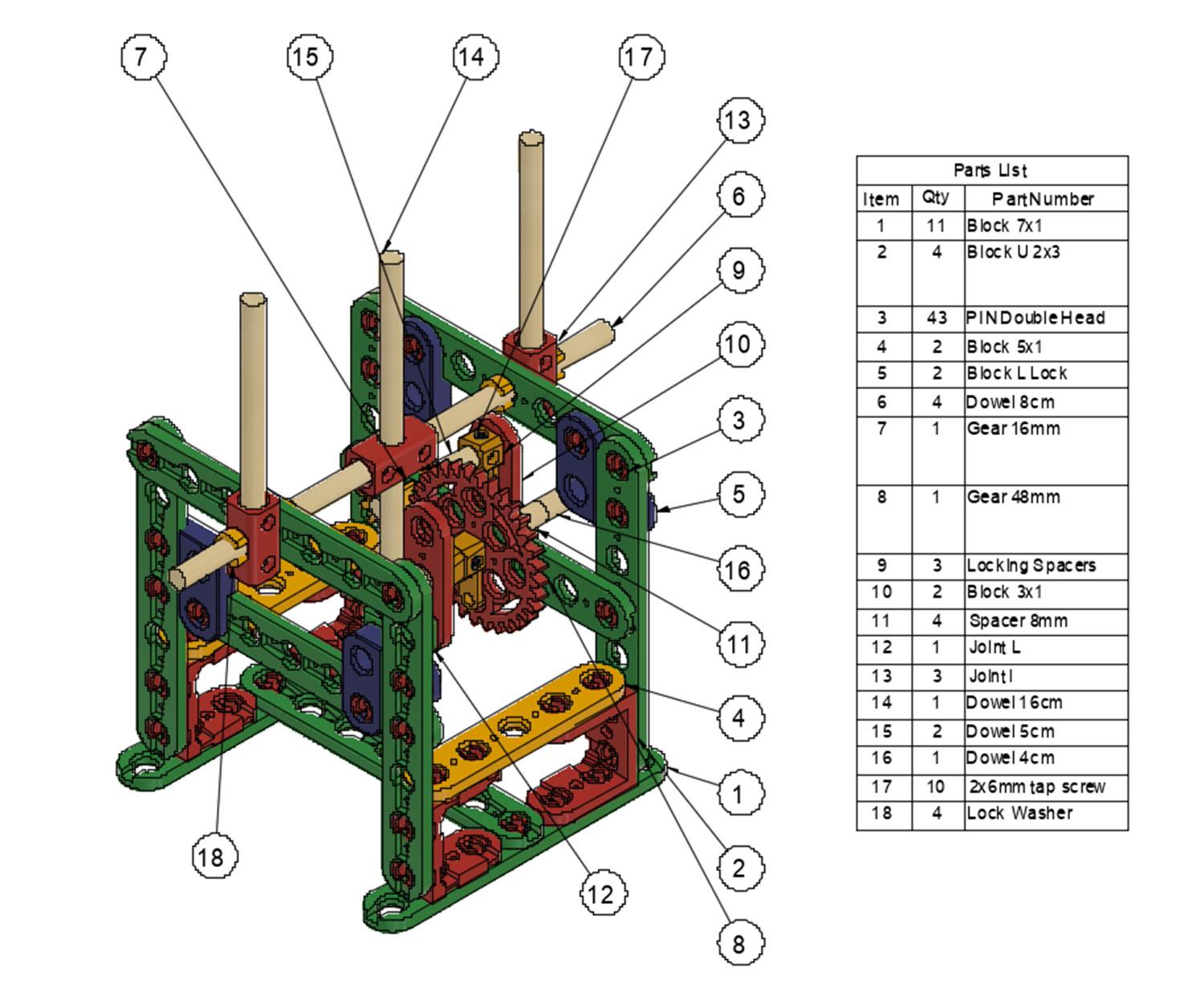

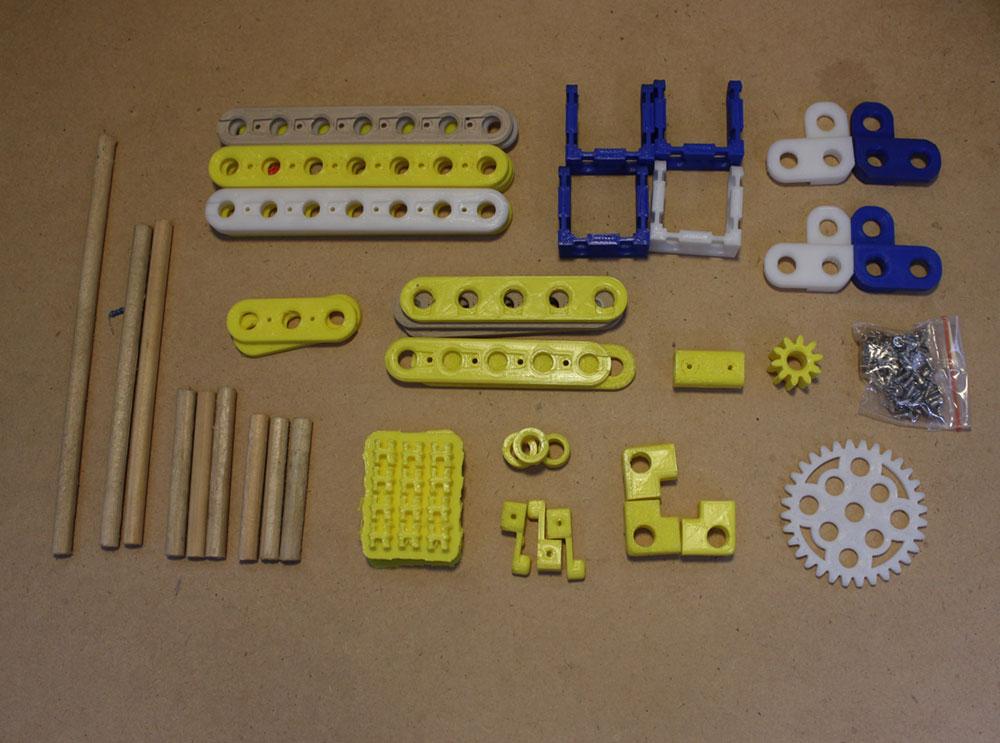

Print All the Files

All the things you have printed are re-usable for any other project, it's a modular system. So you can create another project with it.

Above is the list of components that I will be using to create this Automata bird. Since it's the first time I share this project.

You can download all the files from Thingiverse on this link :

To have the best experience using this system. make sure you have a calibrated 3D printer. Try to print the smallest block first. which is the 3x1 block, Measure the result using a caliper.

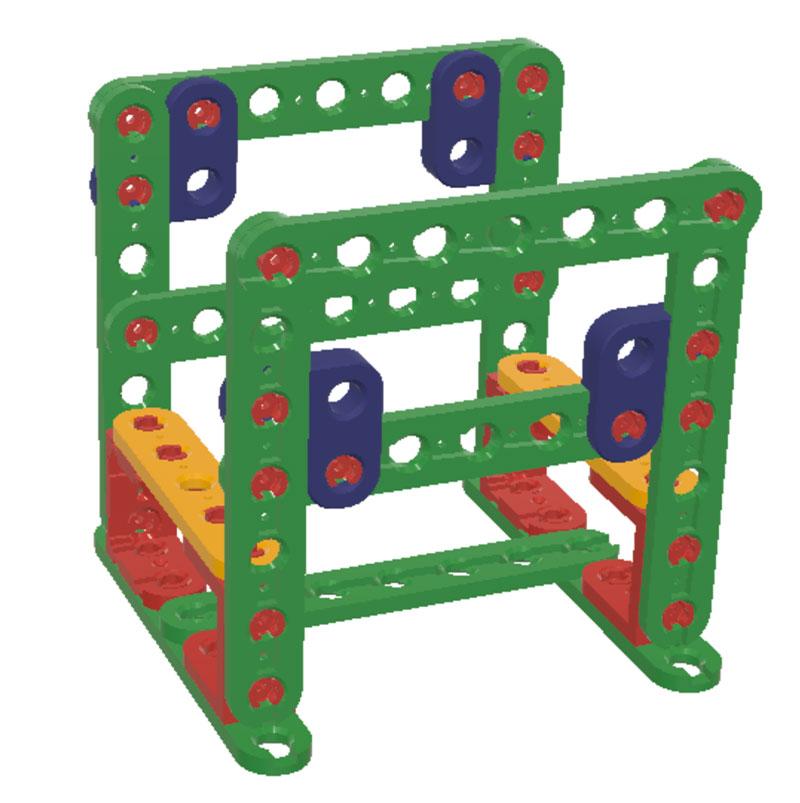

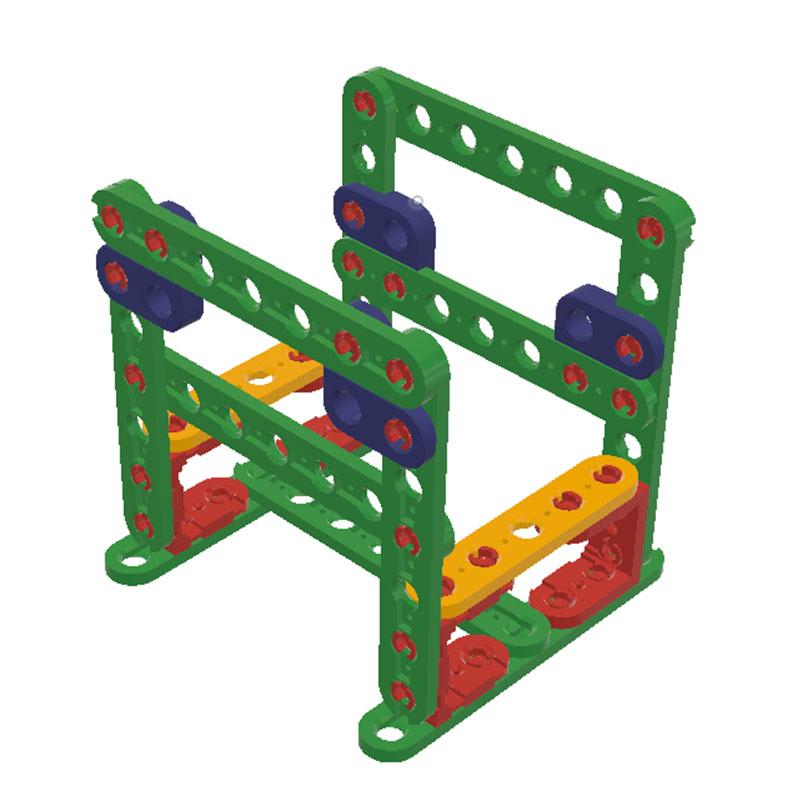

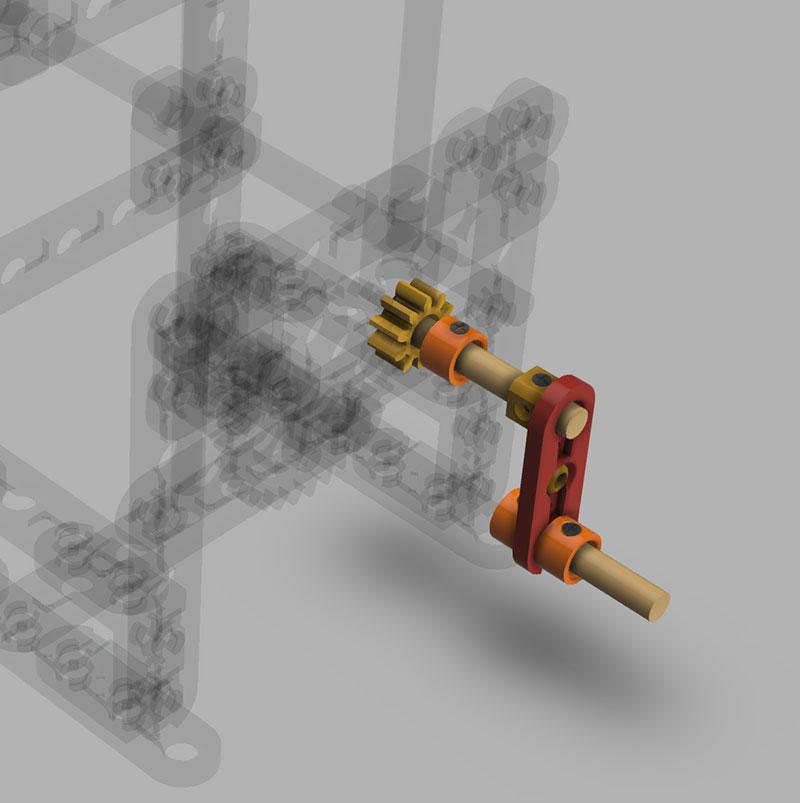

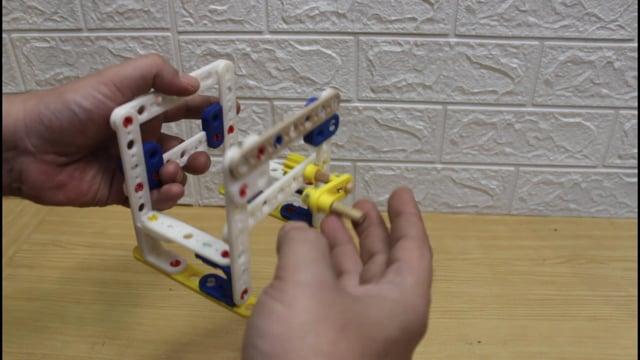

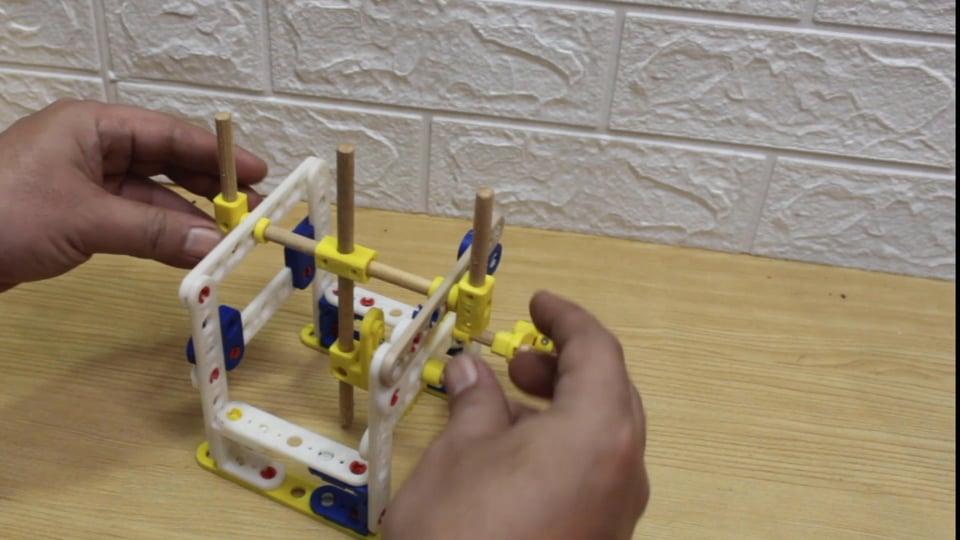

Assembly #1 Framework and Handle

Once all the parts are ready, Now it's time to put it all together, Please take a look at the Image steps above, If you having trouble with some parts, please make sure you have watched the video. For example, if you are having trouble with the PINS, make sure you already watch the video.

Use the blocks and pins to create something like the picture above, later on, you can create your own design, or add more connectors to make the structure stronger or bigger.

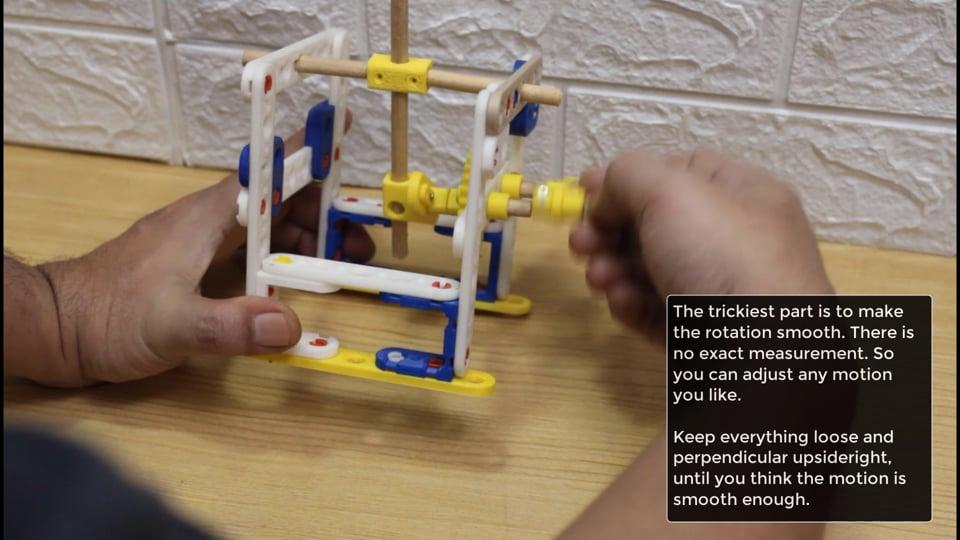

Final Asembly

Please watch the video above for final assembly instructions.

Challenge : Can You Upgrade the Framework More Bigger, Something Like This?