Sink Stopper Repair

My grandparents have a sink that is very old. A small plastic piece from the stopper had broken off. Replacements didn't exist and a new sink would have cost way too much money. So I decided to design and print the replacement.

Supplies

- CAD Software (I used Fusion 360)

- 3D Printer

- 3D Printer Filament (something durable like PETG)

- Calipers

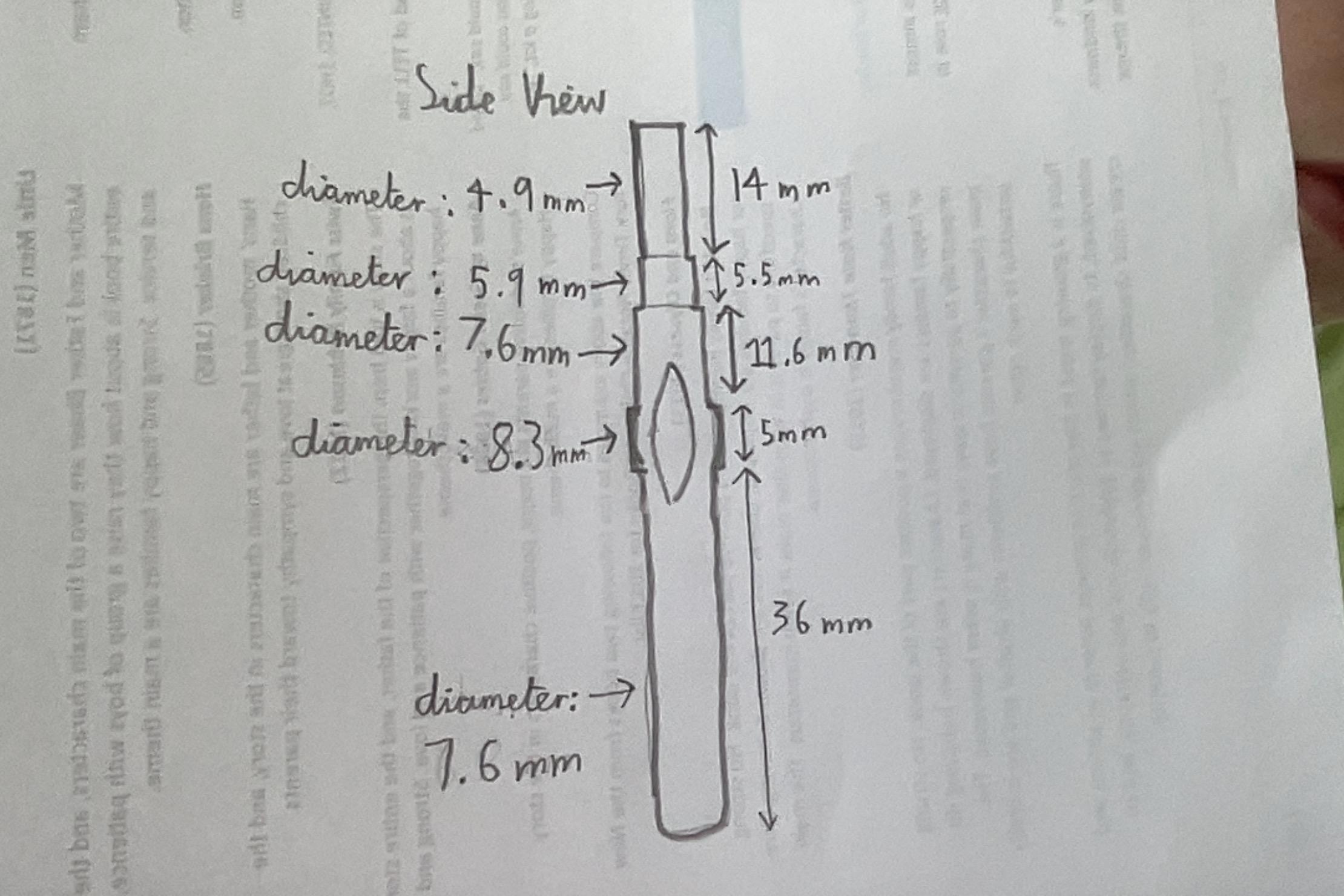

Measuring

First pull out you calipers and take some measurements. You can write them down on a sheet of paper or you can do it digitally.

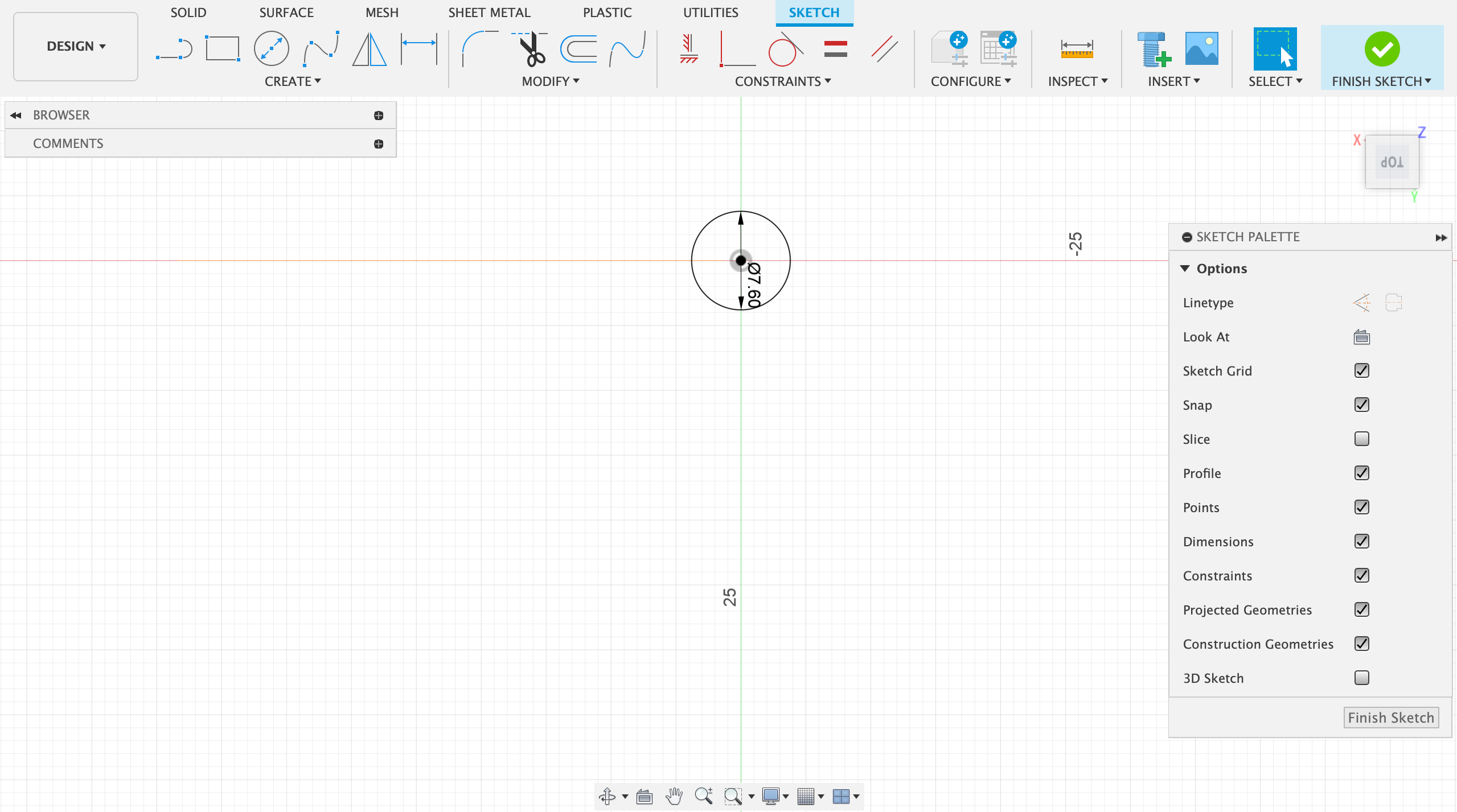

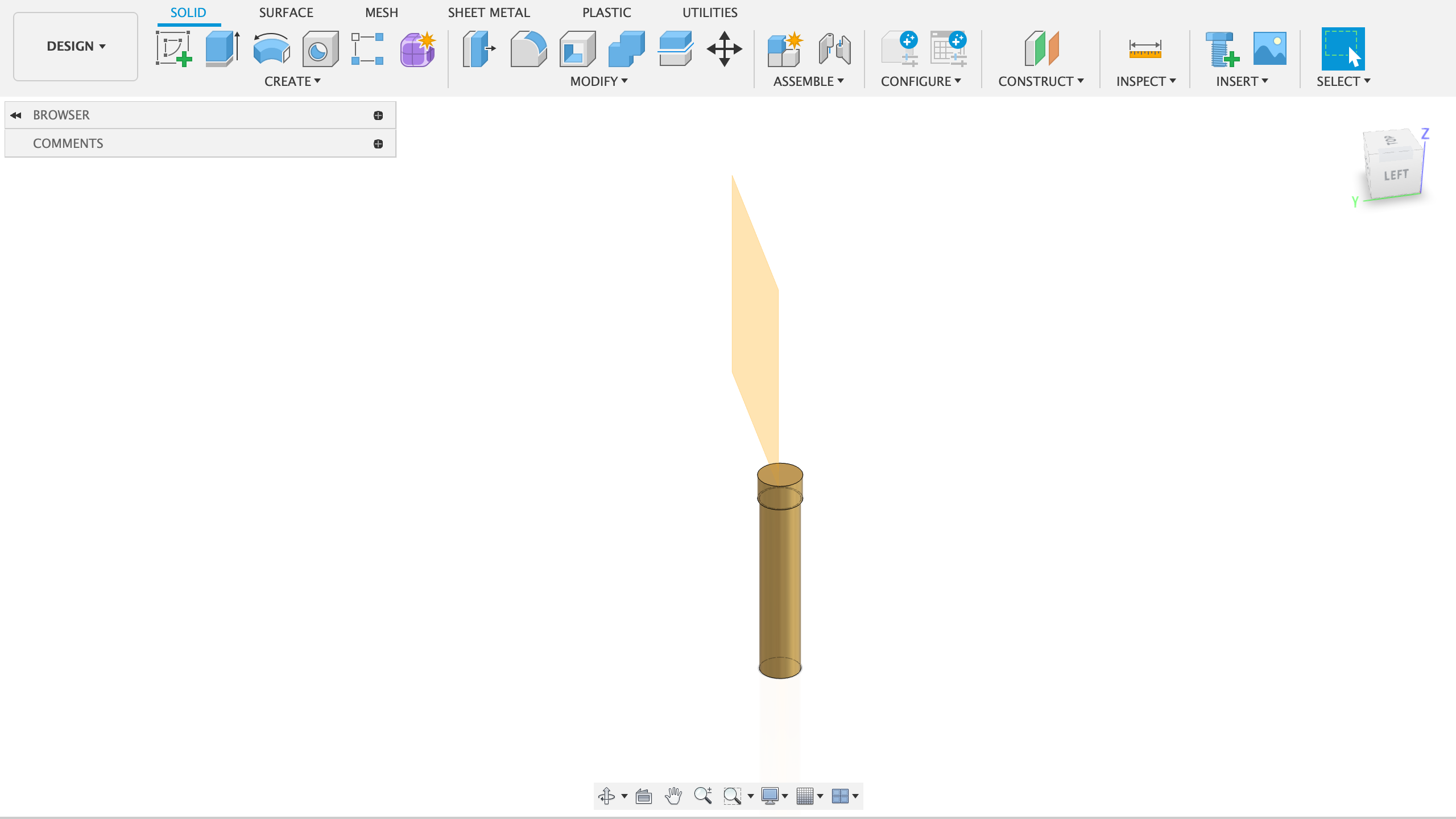

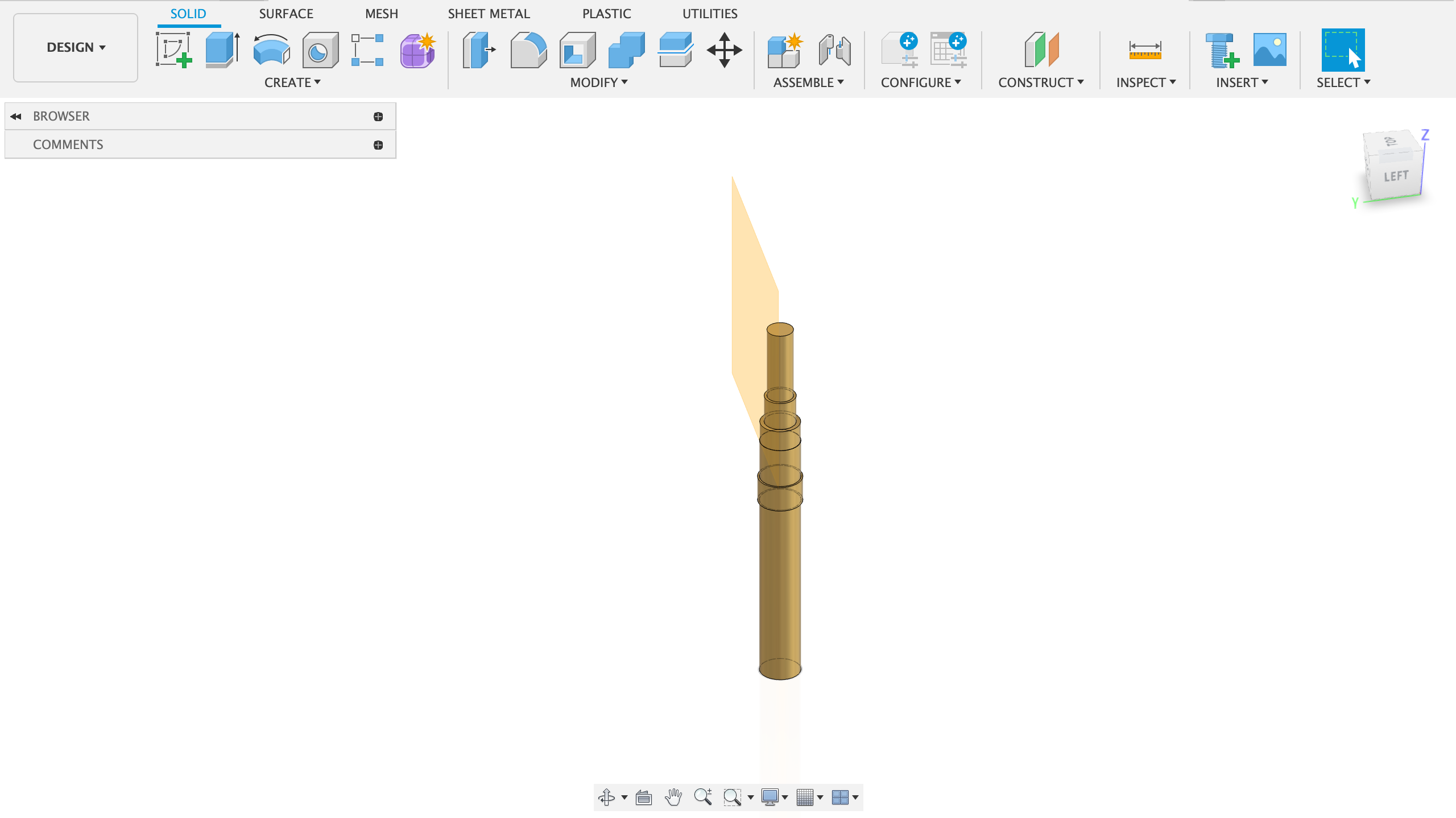

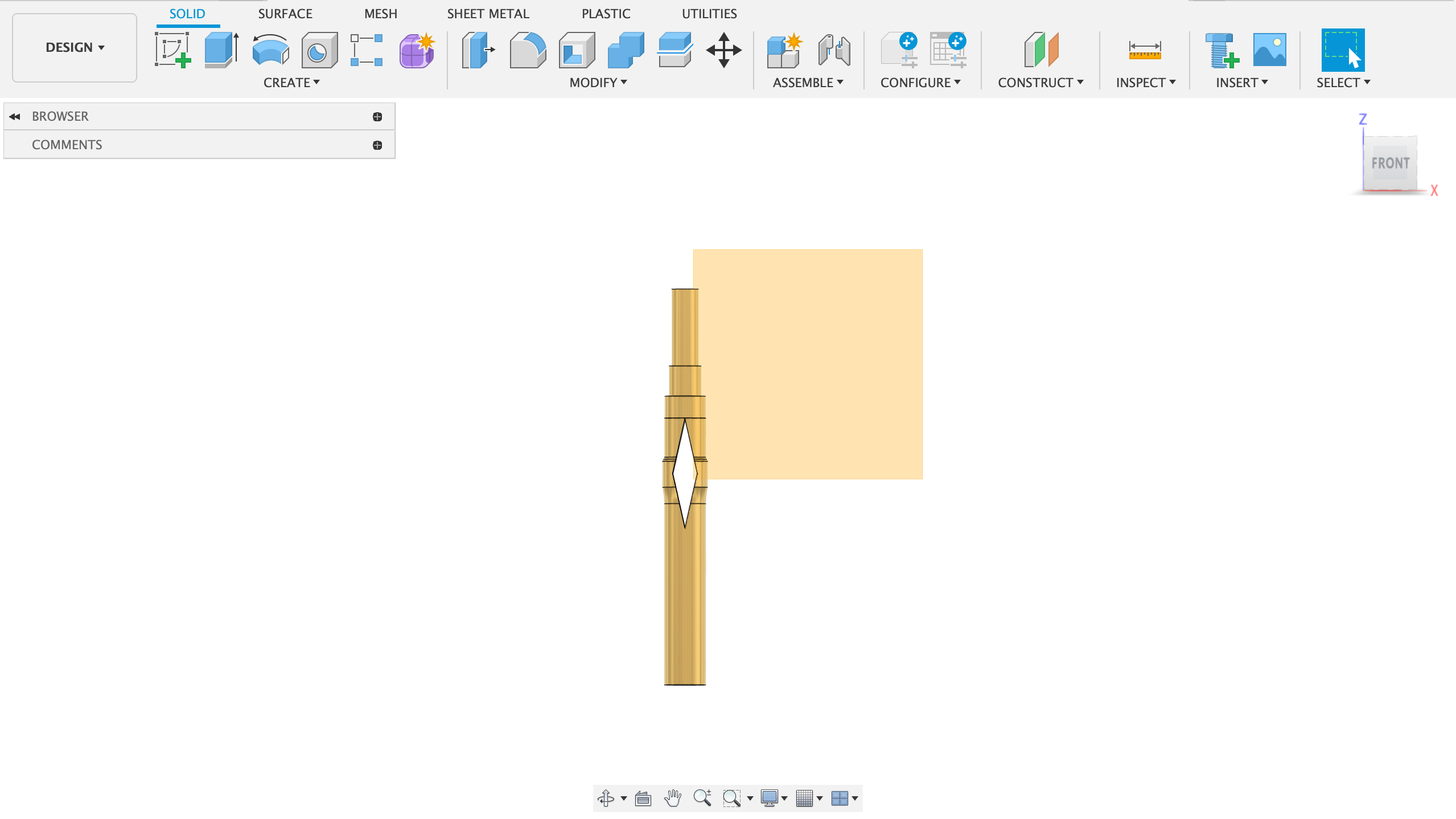

Designing the Base Structure

I started by basically stacking cylinders on top of each other.

- Create a sketch on the bottom / xy plane

- Draw a circle around the origin with the measured diameter from Step 1

- Extrude the circle the measured amount from Step 1

- Create another sketch on the top face of the cylinder just created

- Draw a circle around the z axis with the next measured diameter from Step 1

- Extrude this sketch the desired amount

- Repeat until the base structure is done

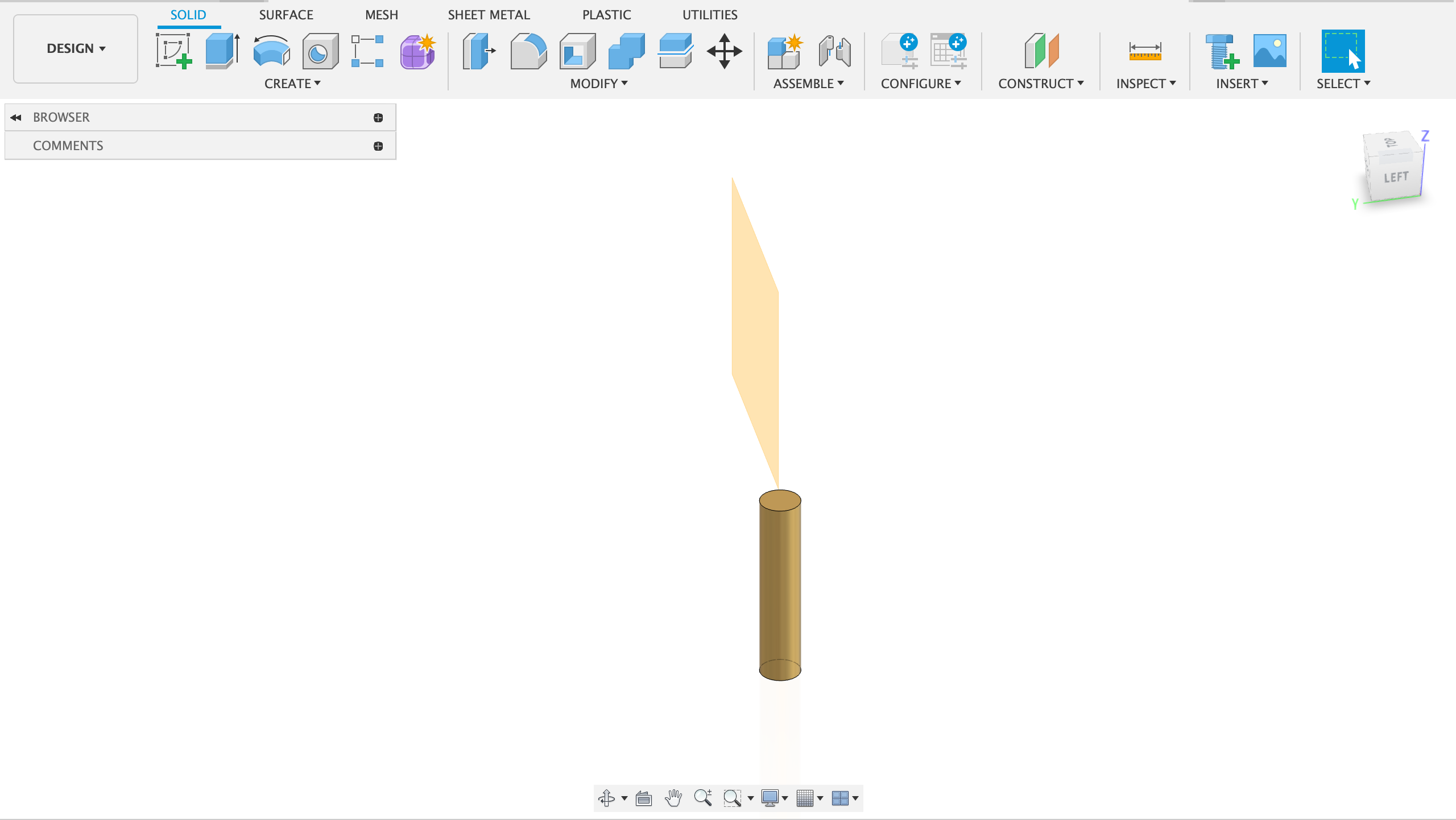

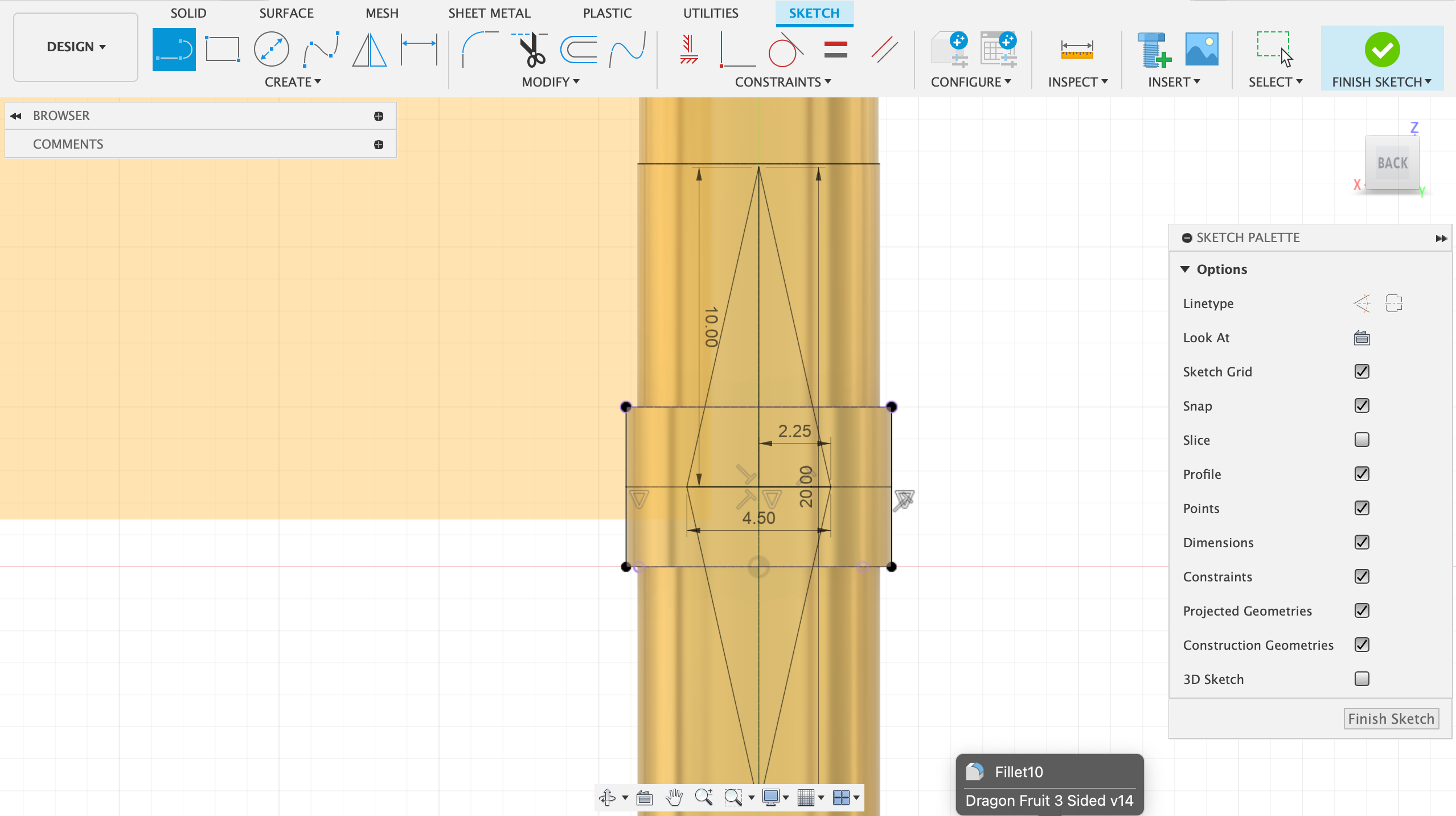

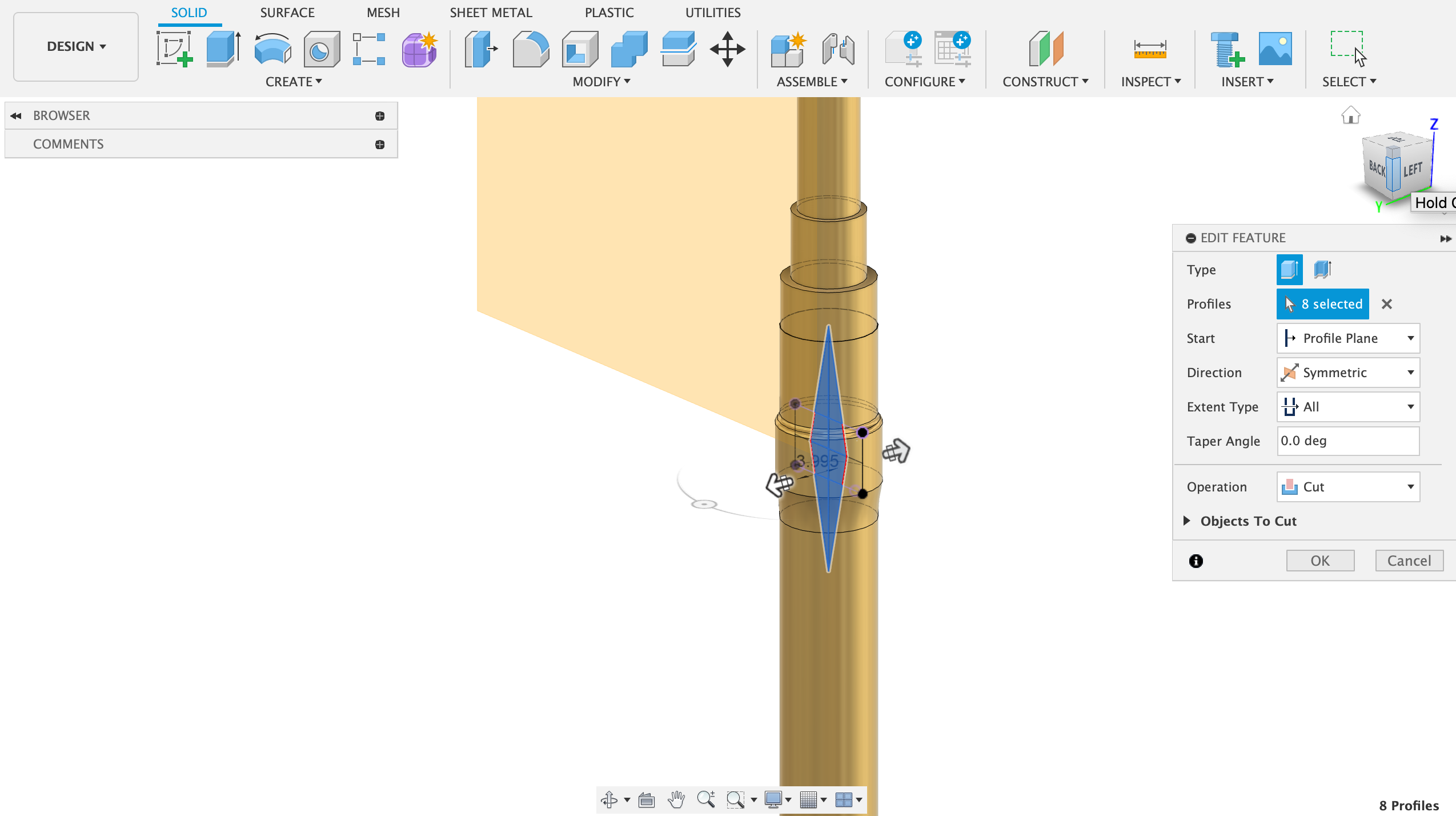

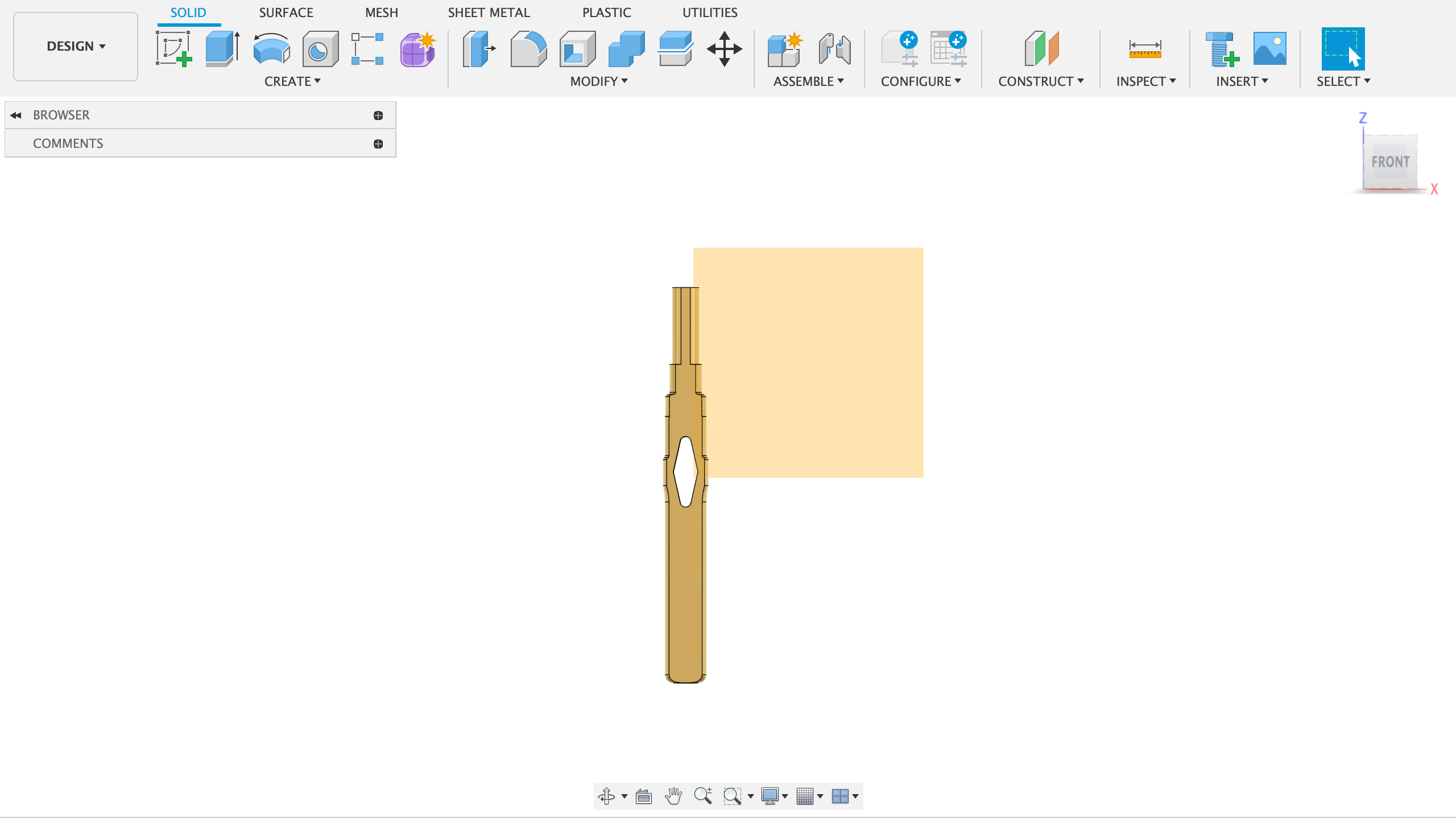

Cutout to Allow Flexibility of the Part

The injection molded piece had a hole to allow a portion of the part to flex in and out in order to open and close the sink-plug. I designed this cutout next:

- Create a sketch on the front plane

- Draw a point where the center of the cutout will be

- Draw two perpendicular lines and make sure that they cross in the point you created

- Draw a rhombus connecting these points

- Do a symmetrical cut through the entire part

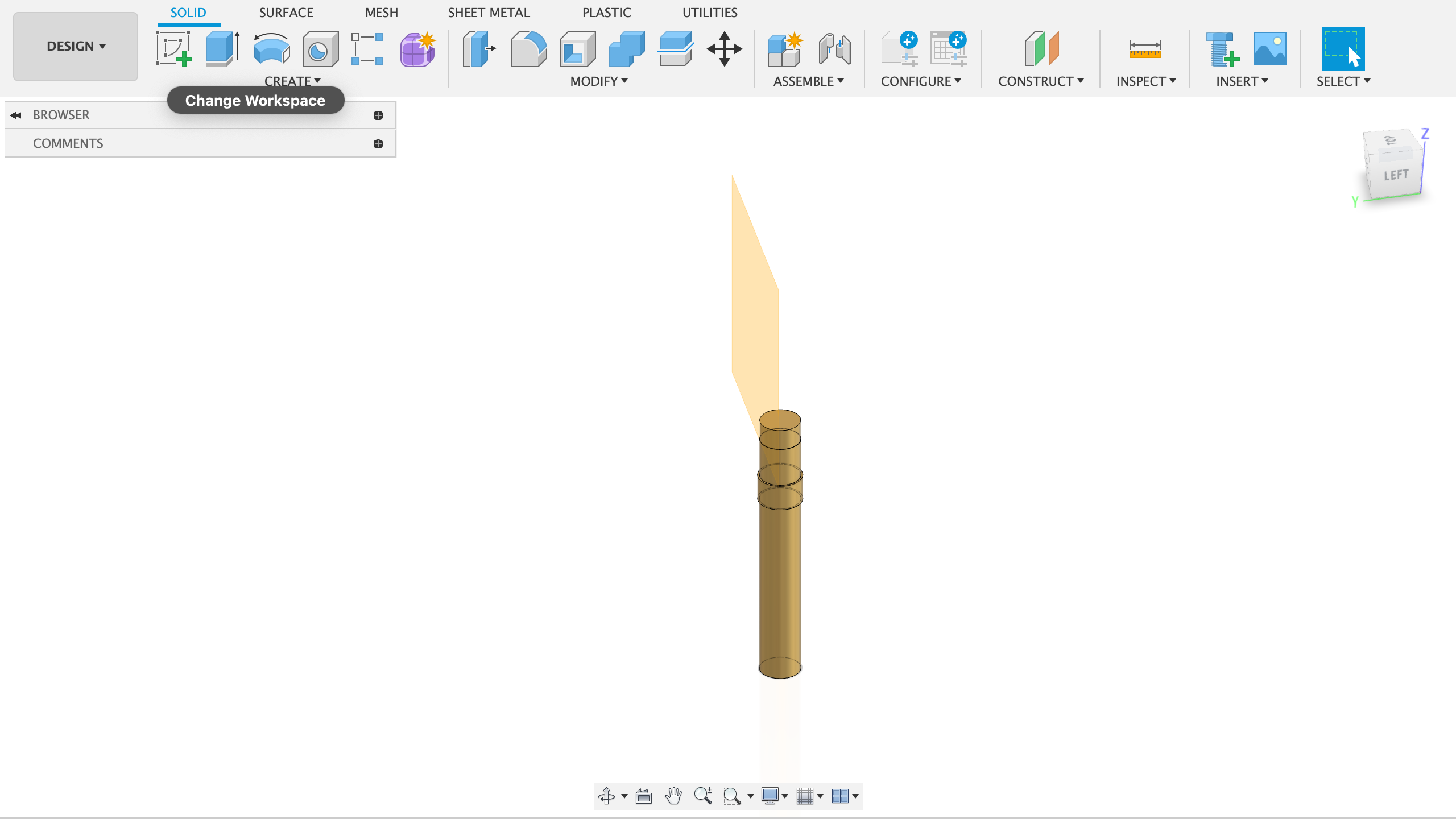

Details

- Add fillets near sharp corners for rigidity

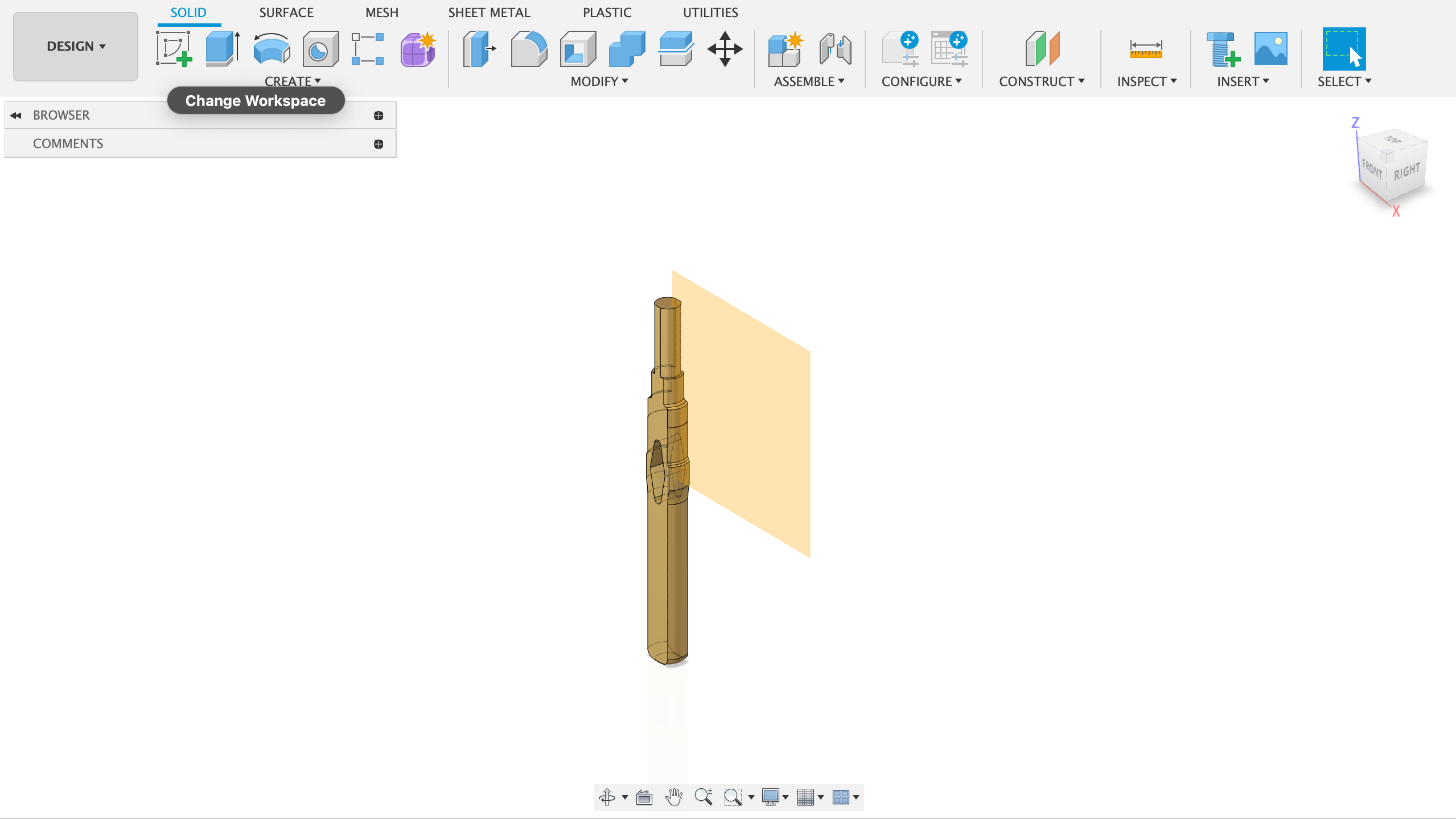

- (Optional) We will print the part on its side for optimum strength. This results in overhangs which need supports. You can cut off a portion of the cylinders (as seen in the picture) to make sure the part prints support-free

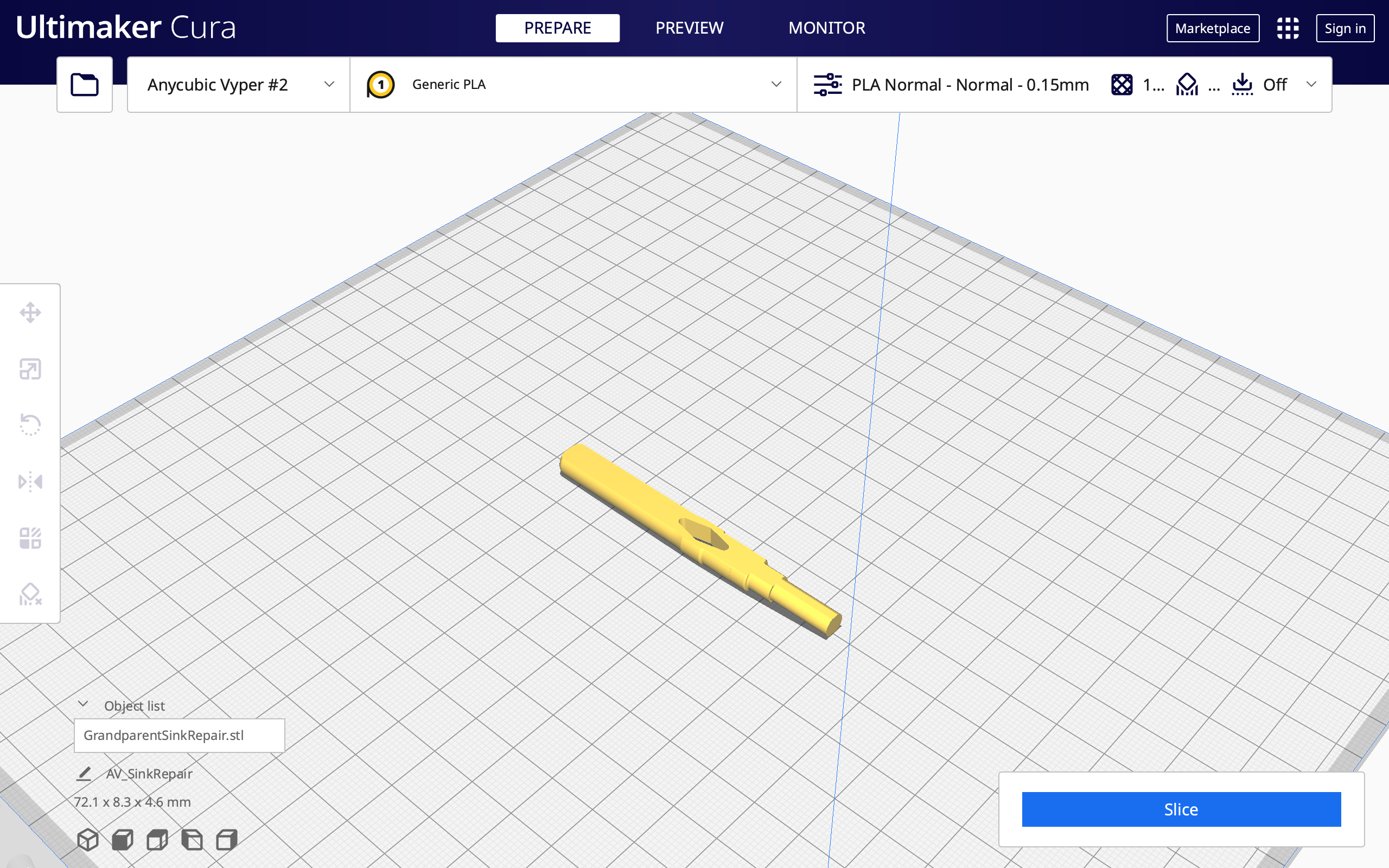

Slicing and Printing

- In your slicer, place the part on its side

- Enable supports (not needed if you did the optional step in Step 4)

- Slice and print

Making Changes

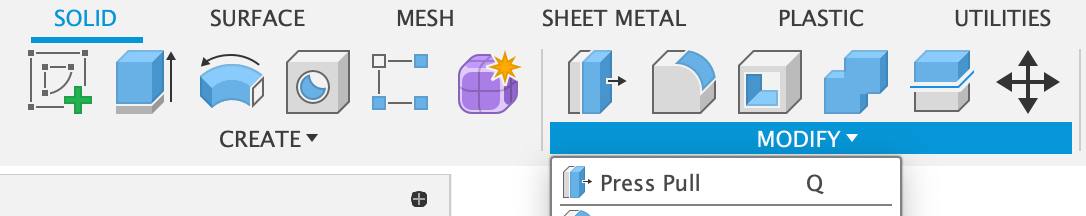

If the part doesn’t fit make some changes using the "Press Pull" feature in Fusion 360.

(Optional) Sand the part smooth

Done

You're done!