Recreating Grandeur: the Metropolitan Cathedral Scale Model

by Artur784 in Workshop > Woodworking

270 Views, 2 Favorites, 0 Comments

Recreating Grandeur: the Metropolitan Cathedral Scale Model

Being a CAD and Laser cutting enthusiast, I always wanted to design and create a scale model of a structure. Upon finding out about the contest, I decided it was the perfect time to accept the challenge, put my skills to use, and design the scaled model of the Metropolitan Cathedral of Mexico City. The project took 50+ hours to complete and required three attempts to make the building look as desired. The structure is accurately scaled by a ratio of 1 inch per 200 inches.

Supplies

.png)

Software utilized: OnShape, Solidworks, Fusion360, AutoCAD, Adobe Illustrator, Xtool Software, Bambu Studio.

Machines / Tools: Laser cutter, 3D printer, hand sketch tools, dial caliper, super glue.

Resources: White PLA filament, 25+ 12"x12"x1/8" Basswood, LED lights.

Brainstorming

While learning about the "Make it Small" Contest, I was reading a book titled Built: The Hidden Stories Behind Our Structures, written by Roma Agrawal. The book discussed different structures and engineering concepts behind them. One of the structures is the Metropolitan Cathedral of Mexico City. Construction started in 1573 by architect Claudio De Arcniege, it took over 240 years to complete the building and is one of the biggest and oldest churches in the Americas. Upon seeing the incredibly beautiful architecture of the structure I fell in love with it, and despite it being a complicated structure I decided to pick that one to construct the scale model for the contest.

Designing

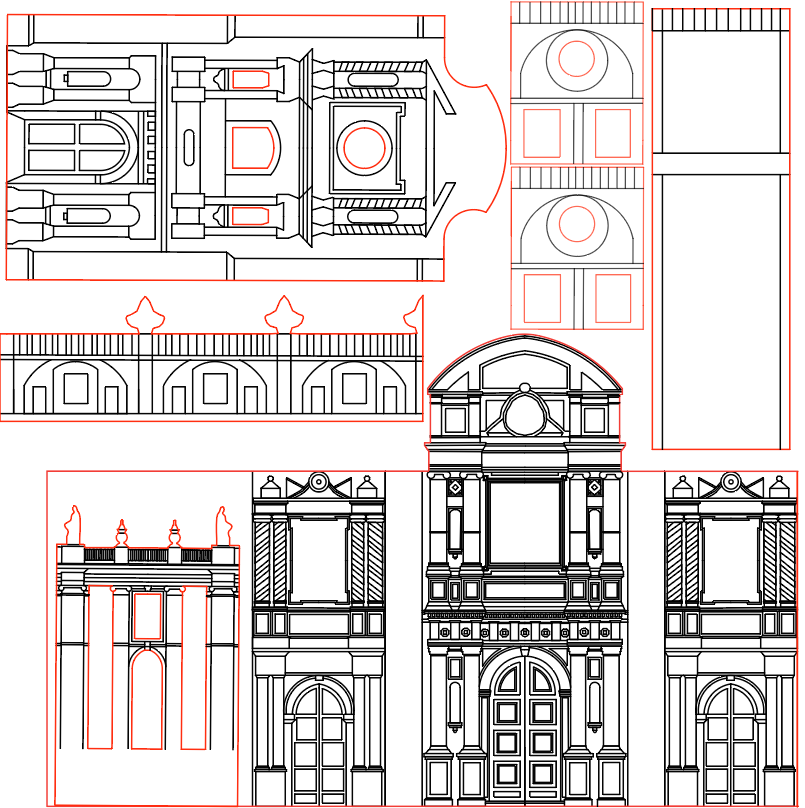

After picking the structure, the next step was to find relevant drawings, blueprints, and or images of the building. However, a big setback to this project was the fact that due to being over 450 years old, there were no drawings that would help me design all of the parts/walls. Despite making the project significantly difficult, I did not give up and utilized any image of the building that I was able to find, which helped me to design all four sides and the roof of the cathedral as accurately and as detailed as possible. Using AutoCAD and Onshape software I sketched all of the parts individually and my goal was to be as detailed as possible, since it was that design and architecture that made me fall in love and choose the Metropolita cathedral for this contest. After numerous hours of designing, I had all the unique parts drawn and ready to be laser cut, but before doing so, there was another crucial step.

The 3D Model

Before laser cutting the pieces it was crucial to make sure all of the parts would fit together perfectly. To achieve this, I had to make a 3D model of the cathedral. Using SolidWorks software I put all the pieces together, and in numerous cases, I had to make adjustments to the 2D sketches. Afterward, I also went ahead and designed the top domes of the cathedral using Fusion360. Finally, once I was confident that I had the 3D and 2D parts designed correctly, It was time to machine them.

Machining

Step four involved a straightforward and efficient process that progressed seamlessly. During this phase, I utilized advanced tools, including a laser cutter and a 3D printer, to fabricate the individual components required for assembling the scale model. With meticulous attention to detail, I carefully monitored the production process, ensuring that each piece was manufactured to the desired specifications, met the highest quality standards, and was produced in the correct quantities. I remained patient and thorough throughout, verifying that all components emerged in optimal condition, free from defects, and ready for assembly.

Assembling and Finishing

After gathering all the necessary components and tools, the final stage of the project was dedicated to assembling and constructing the miniature replica of the Metropolitan Cathedral. This phase demanded significant time, patience, precision, and a high level of hands-on craftsmanship to ensure a successful outcome. One of the most demanding aspects of this step was achieving perfect alignment for each piece, a task that required meticulous attention to detail. To aid in this process, I relied on a small lever to maintain accuracy throughout the assembly. Once all the walls were securely glued together, I proceeded to install the roof and carefully position the domes to complete the structural elements of the model. To enhance the realism of the finished piece, I integrated LED lights inside the building, mimicking the illumination of the actual cathedral at night. This final touch not only brought the miniature to life but also captured the essence of the iconic structure's grandeur.

Conclusion

In closing, this was an incredibly enjoyable project that challenged me to overcome difficulties and use my knowledge of CAD software and hands-on skills to construct the scale model of an architectural wonder, the Metropolitan Cathedral of Mexico City. I am sincerely grateful for the chance to participate in this contest and embark on such an inspiring journey with Instructables. Thank you for making this experience possible.