RMS - Injection Molding Demonstration Via TechShop

by ResilientModularSystems in Circuits > Tools

6628 Views, 76 Favorites, 0 Comments

RMS - Injection Molding Demonstration Via TechShop

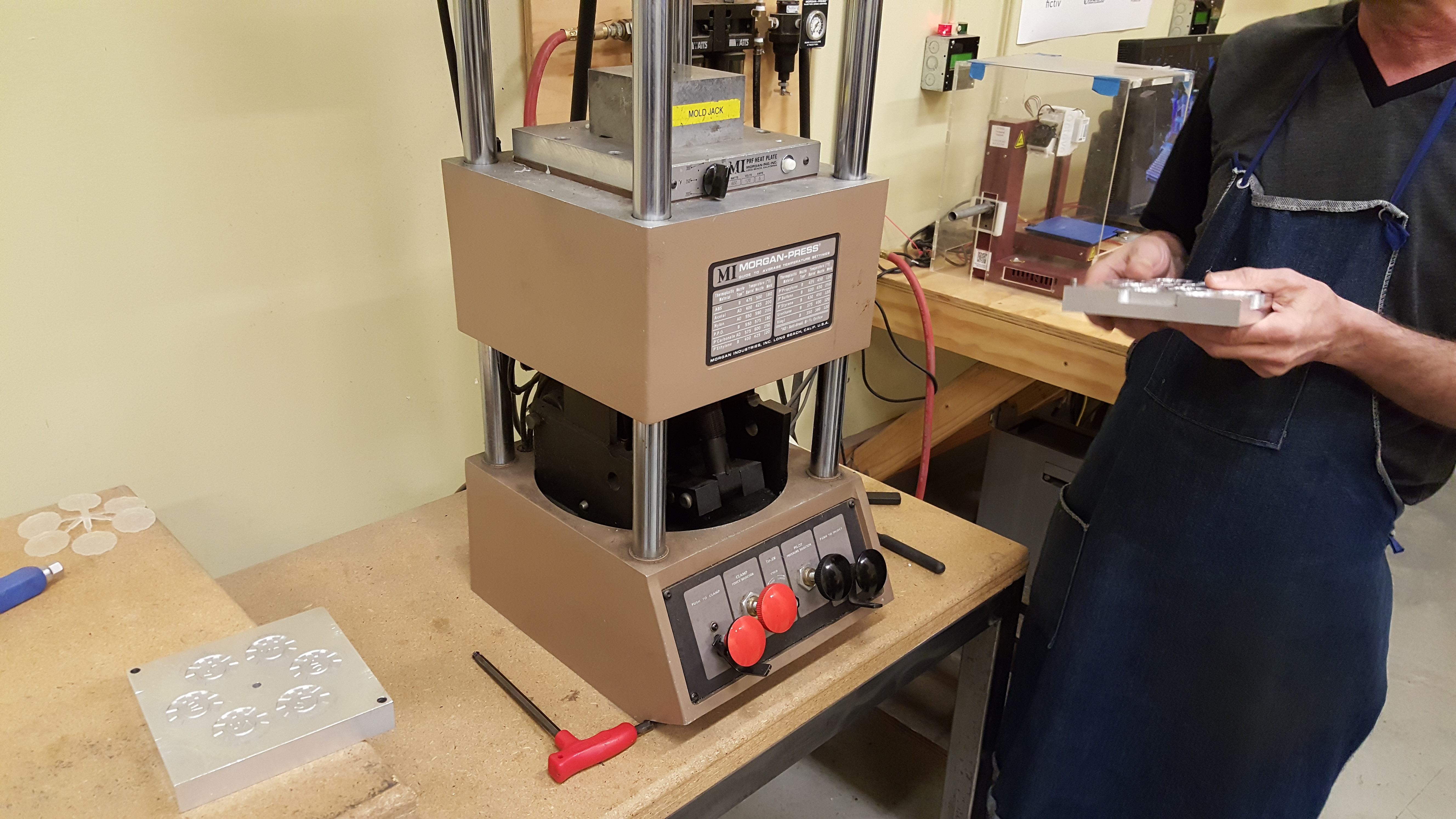

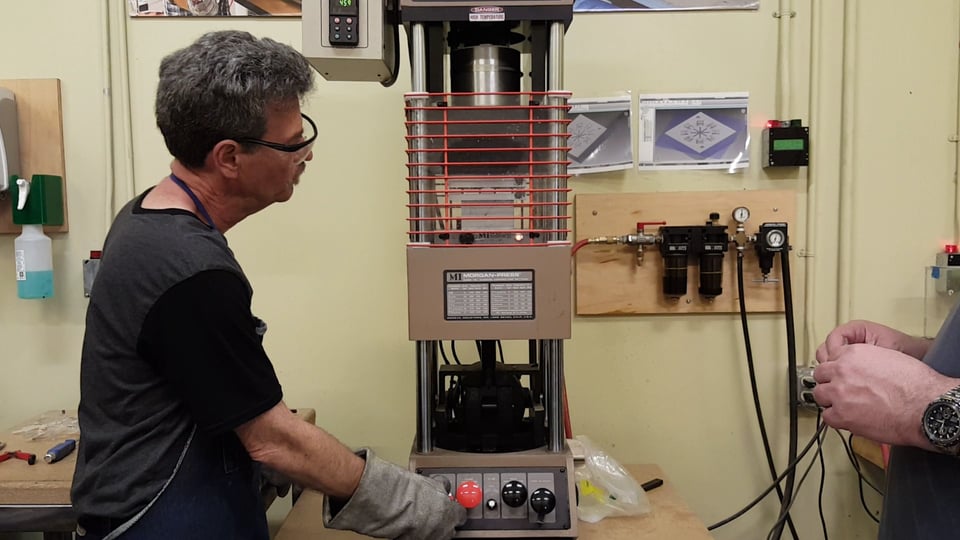

This instructional video is to demonstrate the Injection Molding Machine at the TechShop San Jose location. This machine is similar to the one that is located in the San Francisco TechShop. The video demonstrates the cycle process to work with the basic Injection Molder, made by Morgan Industries G-100T machine.

This demonstration and workshop, instructed by Nik, was for the research and development of the Resilient Modular Systems is a Public Benefits Corp, and leader in innovative sustainable modular components for the building industry in emerging markets.

Facebook - http://facebook.com/ResilientModularSystems

Twitter - http://twitter.com/RModularsystems

Website - http://resilientmodularsystems.com

Safety and Settings

Time required for the workshop at TechShop is usually recommended for 3 hours.

The Tools required to make sure the machine runs smoothly is as follows -

- 3/8" hex wrench for adjusting bottom platen height

- 5/16" hex wrench for adjusting upper platen height

- long needle-nose pliers for clearing "drool" (left-over plastic after clearing)

- heat-resistant gloves, preferably leather

- screwdrivers or other de-molding pry bars

- nippers for removing any extra plastic

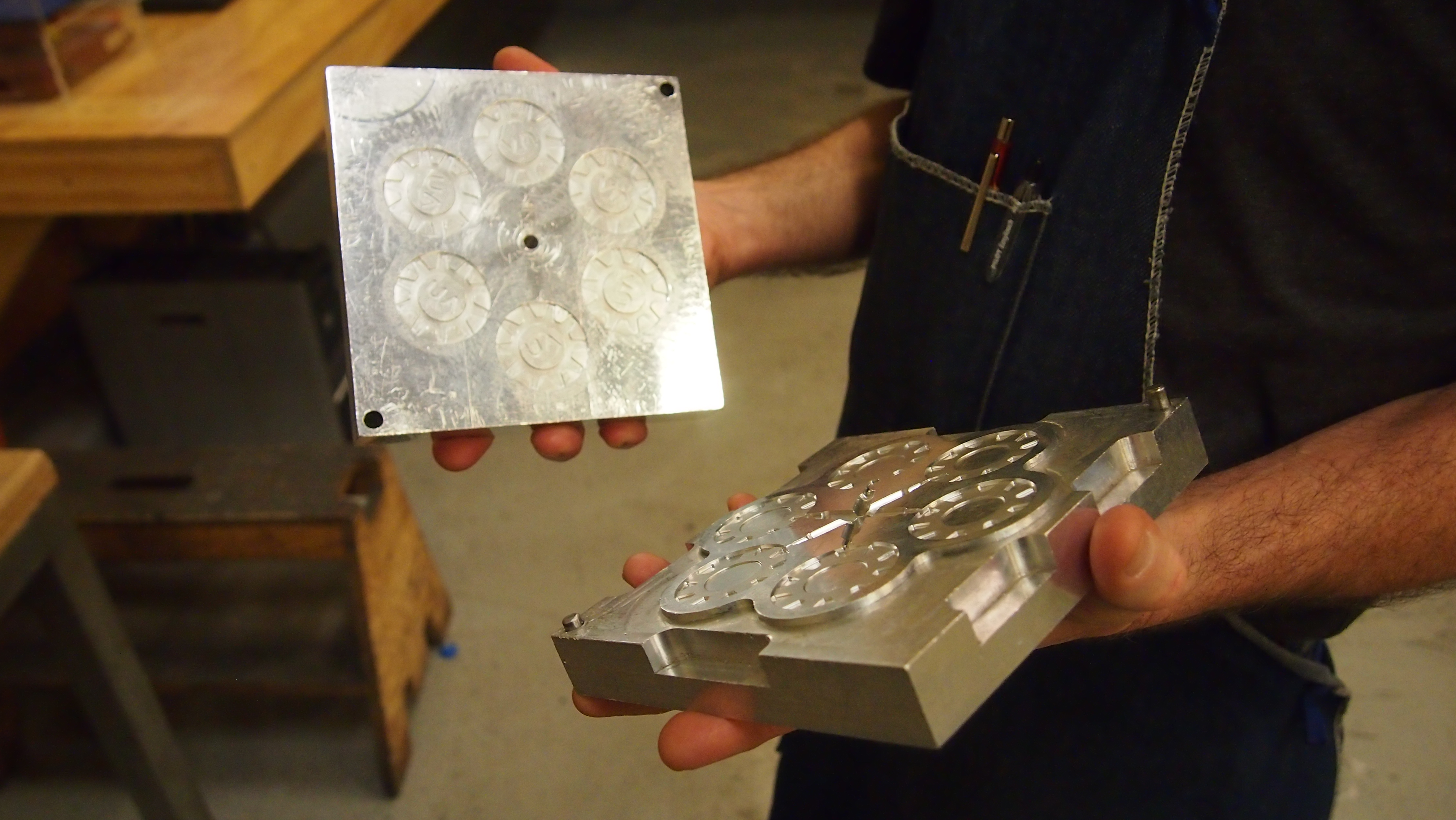

- mold (CNC milled from Aluminium material, preferred)

- mold rise

- sprue bushing

- plastic pellets for molding the pieces

Adjustments

Before using the machine, make sure that the machine is well-adjusted and prepared. *A more extensive instruction manual is available at the respective TechShop locations with the G-100T Morgan Industries machine.

Make sure that the top plate of the molds has a 1" diameter ball with a 3/16" orifice. The mold we used for learning how to use the machine was designed to use a sprue bushing (not shown) between the nozzle and the mold. The sprue carries the melt from the nozzle to the gate.

In addition to adjusting the mold on the top platen and bottom platen to fit accurately between the molding area within the machine, make sure that one also removes all the left over plastic within the fill hopper.

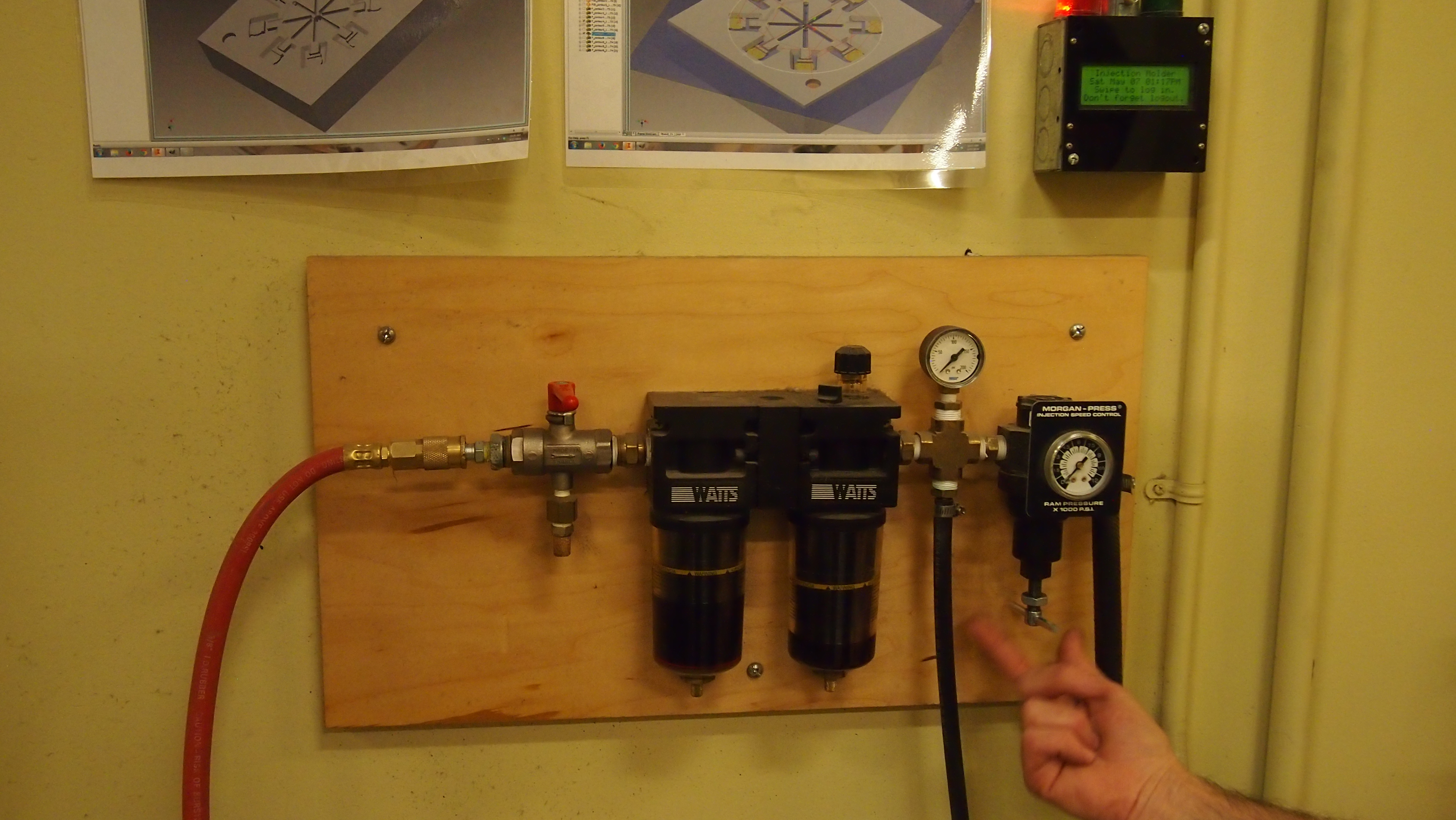

To head the injection molder -

1) turn on the machine by flipping the switch on the side of the temperature control housing

2) adjust the temperature according to the materials you're trying to mold with

3) heat the platen to the material you milled the mold from

4) make sure the pressure PSI on the various areas are set to the correct 200 PSI settings.

Setting Up the Mold

Insert the locating bolt into the heater block on the bottom platen. The locating bolt keeps the bottom plate centered and secured under the injection nozzle.

After fitting the mold onto the bottom plate, and setting the heat to the material your mold is made of. Adjust the clamp force to 10 tonnes, by turning the clam force knob. 10 tonnes is the maximum clamping force that may be placed onto the injection nozzle, without damaging the nozzle. Meanwhile, adjust the Pilot Pressure to 6.

Make sure to adjust the cage, and that when using the safety cage, that you pull the cage on the middle section. Pulling or pushing on the top or bottom risks hurting yourself and your fingers, if the cage shuts itself onto you.

Cleaning Out the Nozzle

Before making the pieces, make sure to clean out the hopper.

This would allow your parts to be injected with the correct material and temperature setting according to the plastics that you have chosen. These are examples of the types of the waste or drool materials that could come out of the machine from the previous prints. Our material is a milk-white color, meanwhile, the last used material was black.

Preparing the Plates and Making Molds

To make parts, make sure that the mold is well prepared.

1) release the safety on the inject knob and push it in, for about five seconds. It should take at least 5 to 30 seconds, depending on the design of the mold for the plastic to fill out the mold.

2) Release the knob and wait for another five seconds. This keeps pressure on the plastic in the mold and allows the plastic to fully solidify.

3) Pull the clamp knob out to release the bottom platen and raise the safety cage. Carefully remove the mold using leather gloves, twist the sprue bushing several times to sever the plastic holding it to the mold and place it back on the heater block to ensure that the platen is heated for the next injection.

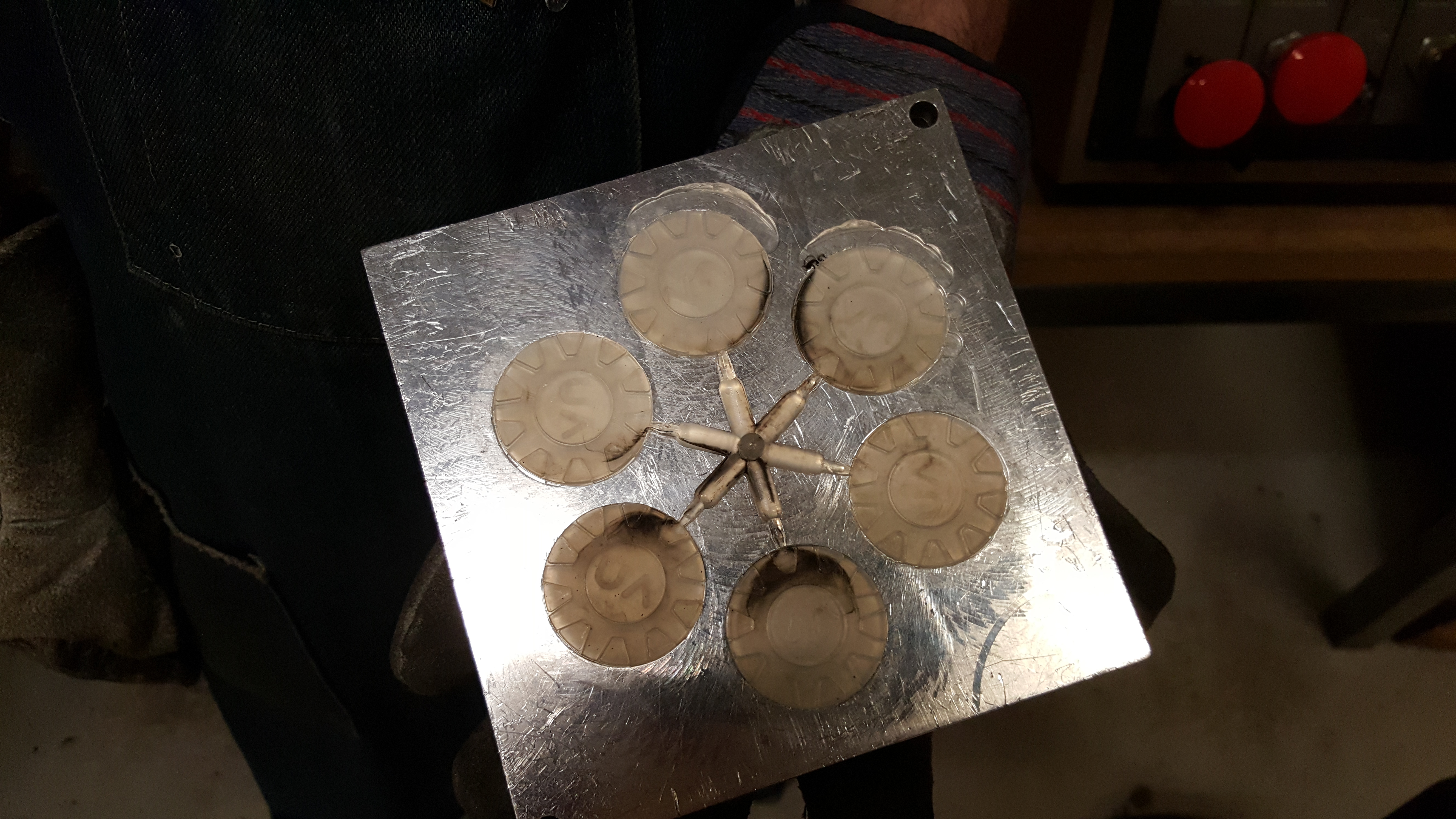

4) Carefully split the mold in half, and reveal the parts.

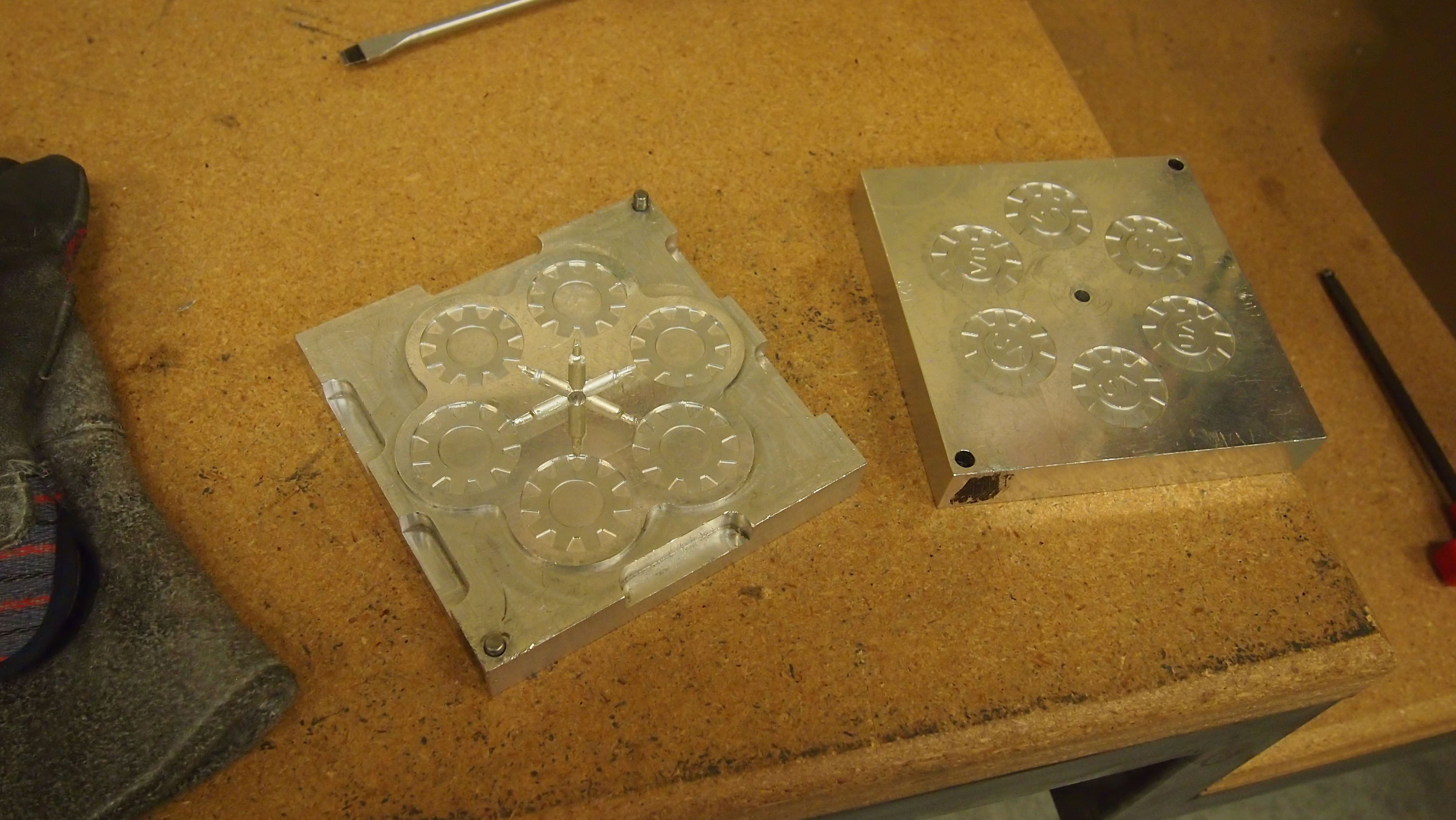

Mold Demonstration

This video shows the cycle of making the injection, with instructor Nik from the TechShop in San Jose. The two images show the various types of short injection or long injection. These types of mistakes usually occur when one doesn't wait long enough for the plastic to fill the mold, or overfills the mold. To ensure the greatest result, make a few tests, and also use a stopwatch to time the injection periods.

Finished Product

Making the mold takes many tries, and perhaps a few trial runs of mistakes before one would know what is the best timing to allow the injected plastic to fill the mold. It would be suggested to also clean out the hopper entirely before making the molds, this way, you would have one pure color injection. However, these test examples also show the smokey effect of how the plastic enters the molds.

Again, this instructional instructable is to demonstrate the Injection Molding Machine at the TechShop San Jose location. This machine is similar to the one that is located in the San Francisco TechShop location. The video demonstrates the cycle process to work with the basic Injection Molder, made by Morgan Industries G-100T machine. Thank you for reading.

This demonstration and workshop was for the research and development of the Resilient Modular Systems is a Public Benefits Corp, and leader in innovative sustainable modular components for the building industry in emerging markets.

Facebook - https://www.facebook.com/ResilientModularSystems

Twitter - https://twitter.com/RModularsystems

Website - https://twitter.com/RModularsystems