Parametric Storage System

by Glebanatik in Workshop > Organizing

2271 Views, 22 Favorites, 0 Comments

Parametric Storage System

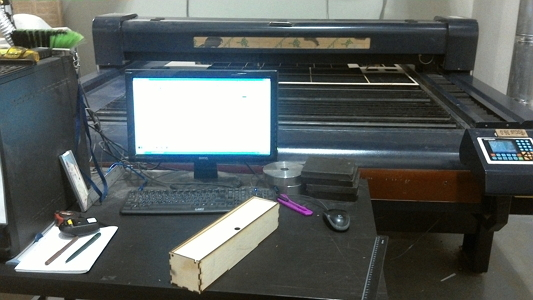

This is what I made for a "computer-controlled cutting" assignment of FabAcademy 2016. Made in FabLab Polytech

Requirements:

SolidWorks2014 or later, laser cutter, PVA glue.

Downloads

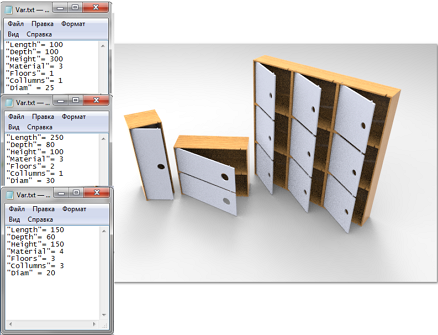

Adjusting Parameters

Edit file Var.txt. Parameters represent inner size of each cell, don't get confused.

Axis/paremeter relation: Z - "Depth", X - "Length", Y - "Height";

If you'd like to make an array of boxes, change "Columns" and "Rows" parameters.

Check thickness of your material and change "Material" parameter.

"Diam" stands for diameter of hole in the door.

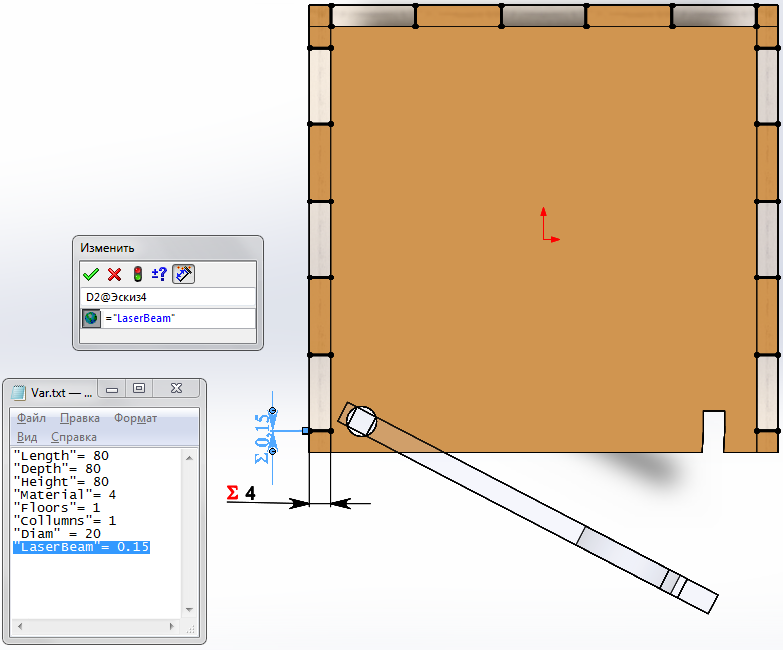

If you would like your system to be held just on interference fit, you'd probably like to test your cutter and material with two parts and different values of "LaserBeam" parameter and then cut the whole thing.

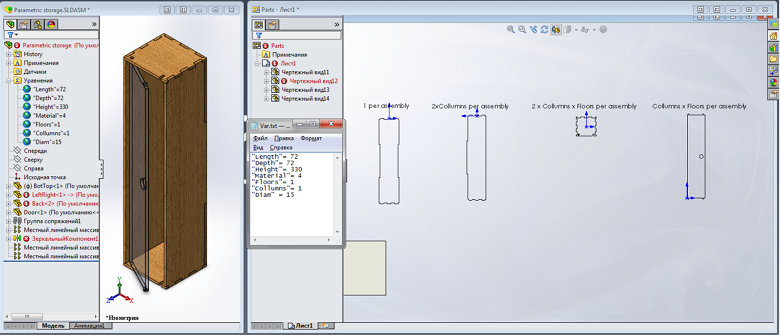

Making Layouts

Open "Patametric storage.SLDASM" and rebuilt the assembly (traffic light icon) twice because the first time side parts will probably go upper or lower. It doesn't influence layout file but you'd like to see an assembled construction rather than chaotic flying parts.

NOTE: If "Columns" or "Rows" parameter equals 1, SW would probably show you an error caused by making an array of 1 element. Ignore it.

Then go to drawing file "Parts.SLDDRW" and agree to rebuild it as well. Then save the file in any format your laser cutter reads (in my case, .dxf) and you are ready to go!

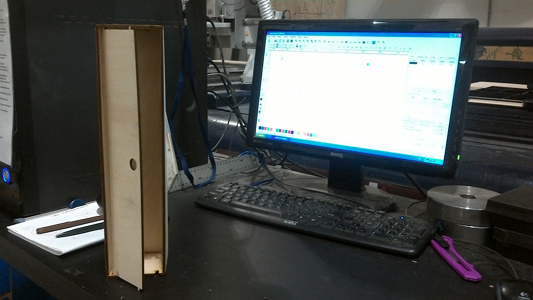

Cutting and Assembling

Now you are able to cut and assemble the system. You could try make it using interference fit only but I'd recommend using PVA glue instead or in addition to it.

Enjoy!

Sincerely yours, Gleb