Modular Desk Organizer

We created this modular desk organizer to give hobbyists a way to use their 3D printer to better organize their tools on their desks.

Supplies

- 3D printer

- Heat press

- Tweezers

- Scraper

- Scissors

- Utility knife

- Blue painter’s tape

- 1 roll of TPU barrier film

- 1 roll of PETG filament

- 1 yard of polyester fabric

Base

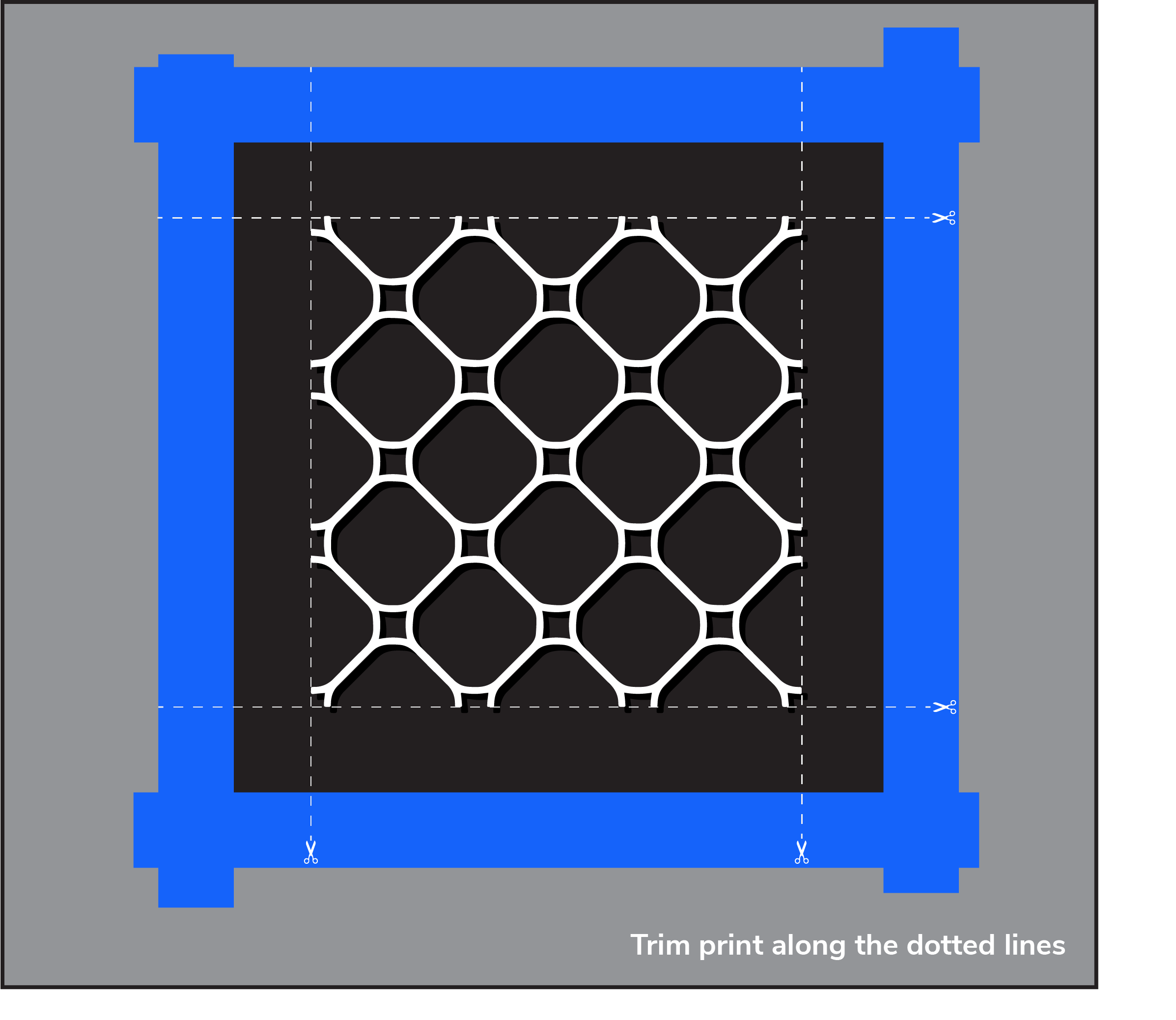

Prep

- Cut a 20x20 cm square of fabric.

- Cut a 20x20 cm square of TPU barrier film.

- Heat press fabric and TPU barrier film together at 135C/275F for 20 seconds.

- Center fabric square on the bed.

- Tape all four sides of the square to the bed.

(Note: Make sure exposed fabric is at least 16x16 cm)

(Note: For the best result, tape fabric to the bed with a bit of tension, with no creases or sagging.)

Printing

- Import (base.stl) into your slicer of choice. (We used Ultimaker Cura.)

- Settings

- Make sure that the nozzle and bed temperatures are set to filament manufacturer’s suggested settings. (Note: You might have to experiment to find the optimal settings for your setup.) Make sure there is no skirt, brim, or raft.

- Make sure that the model is centered on the bed.

- Slice and Print

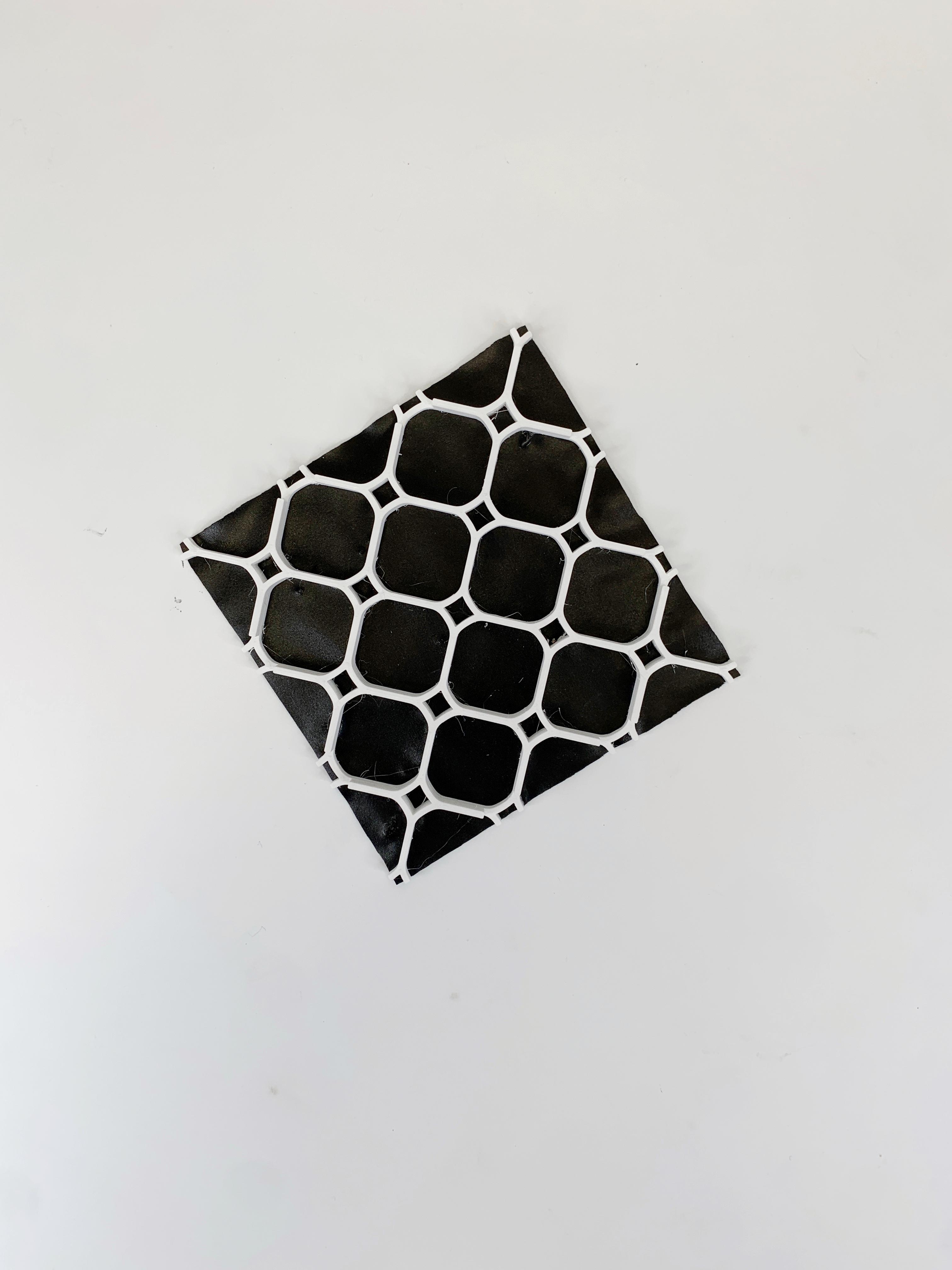

Post-processing

- Trim excess fabric

- Clean up the print if necessary

Container

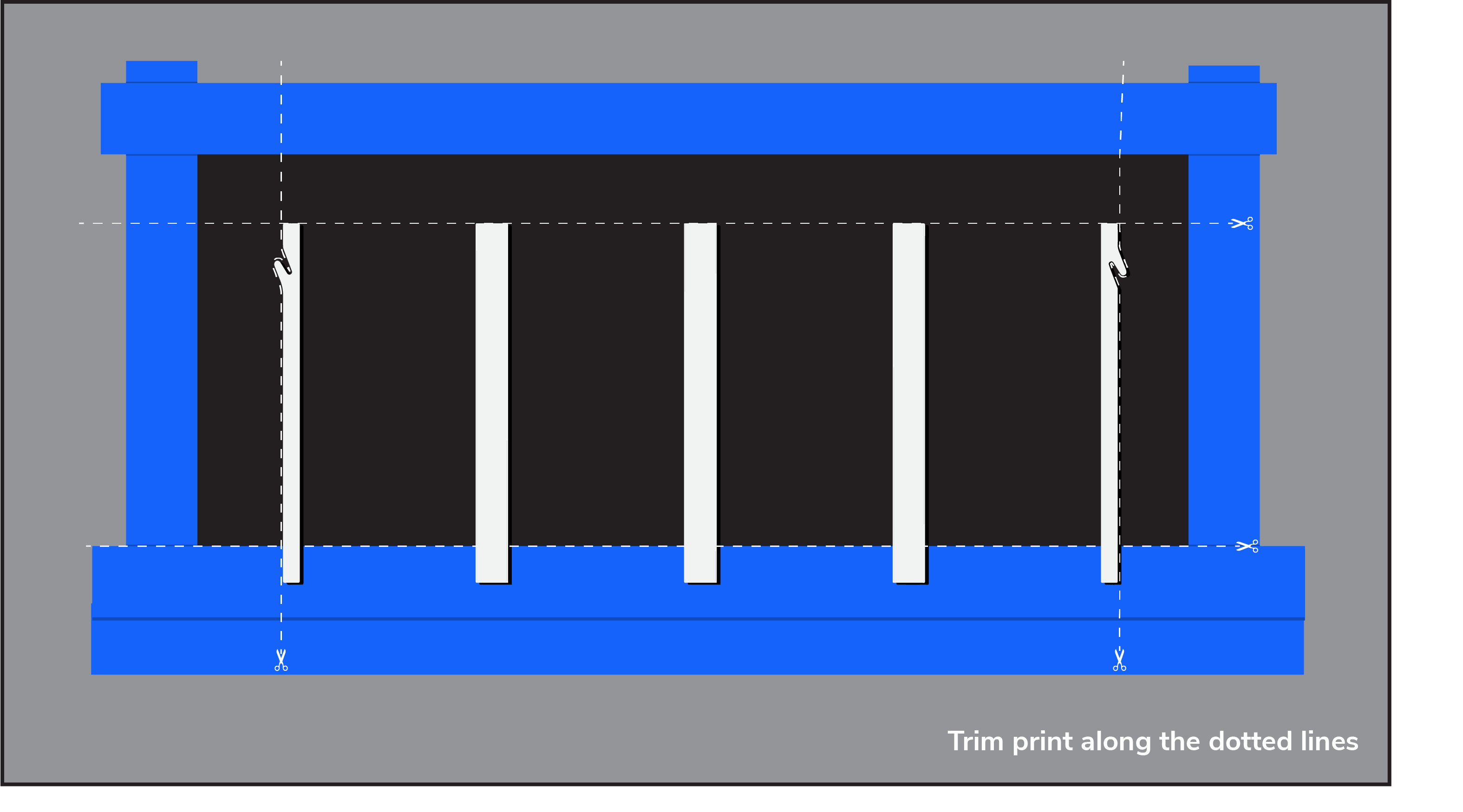

Prep

- Adjust model parameters

- Open (container.f3d) in Fusion 360

- Modify

- Change parameters

- Height - changes container height

- Post quantity - changes container size

- Export as 3mf file and import into the slicer

- Center the model on bed and make sure there is no skirt, brim, or raft.

- Cut fabric and TPU barrier film to be wider than the model, and the height to be slightly taller than the post height

- Heat press fabric and TPU barrier film together at 135C/275F for 20 seconds.

- Center the fabric on the bed and tape all 4 sides to the bed with a little bit of tension. Top of the bottom tape should sit at (((bed length-post height)/2)+1)cm from the bottom of the bed. (Refer to diagram)

Slice and Print

Post-processing

- Trim edges

- Trim top of the excess fabric to be flush with the top of the post

- Trim the bottom edge along the top of the tape

- Trim the sides flush with the end rails

- Clean up the print as necessary

Downloads

Joints

Prep

- Import (joints.3mf) and slice (Note: Use a brim if you are having adhesion issues)

Slice and Print

Post-processing

- Clean up as necessary.