Model Rockets

With the basics of rocketry under your belt we can now tackle the most exciting form of rocketry, making rockets with real model engines to blast off!

Model rockets are great, as it's just as entertaining to watch as it is to launch and everyone loves running after the rocket as it safely parachutes down to a safe landing. This lesson will cover the supplies you'll need, and how to setup your first model rocket for a safe and easily recoverable flight every time.

Here's what you'll need to get started:

|

Rocket Parts

|

Tools + Supplies

|

Before we go through assembly, let's take a closer look at the most complicated part of model rockets, engine selection.

About Engines

Model rockets use a solid-propellant engine. These solid pucks of fuel are great as there's no worry of spilling anything, and they are very reliable. There's many types of model rocket engines for different size rockets, and for desired performance. It's not all about going as high as possible, some engines are designed to have multiple stages, or a larger payload. Solid-propellant engines also have a unique feature which allows for a small secondary charge that will jettison the parachute after a certain time.

Rocket engines are governed by the National Association of Rocketry (NAR), and almost all rocket engines follow the same alphanumeric coding format on their engines, along with a color, to help you identify which engine is right for your rocket.

The code for rocket engines are as follows:

Letter: Impulse Power (Newton-Seconds)

Each successive letter has twice as much power of the previous letter, starting at 'A'. For example: 'B' class rocket engines have 5.0 Newton-Seconds of impulse power, and "C" class have 10.0 Newton-seconds of impulse power.

1st Number: Average Thrust (Newtons)

Measured on how slowly or quickly the engine delivers its total energy and pushes the rocket. Low numbers have weak thrust over a long duration, high numbers have high thrust over a short duration. High numbers are a good choice for heavier rockets, or rockets with lots of drag (like a large diameter).

2nd Number: Delay (in seconds)

Time between end of thrust and ejection charge. A zero number here means there is no secondary charge. These are for booster stages or special rockets only.

Color Codes:

- Green: single stage engine

- Purple: high-performance single stage / final stage multi-stage engine

- Red: booster stage engine

- Blue: special use engine

All rocket engines have their 3-part code (letter-number-number) clearly printed in a colored ink, and be visible on both the rocket engine and packaging. You can lookup more data on every type of rocket on the NAR website. For this introductory lesson, we're using low-powered 'A' class rockets.

Before choosing an engine, let's start building our rocket! Then, we can determine which engine best suits our needs.

Getting Started

While your brain digests all the science behind which engine to choose, let's get into building the rocket.

If you bought a kit, take everything out of the packaging. If you're making your own rocket from scratch, then follow along and find supplies that closely match the parts shown. You'll notice a few basic components:

- Fuselage

- Nose cone

- Stabilizing fins

- Engine mount

- Parachute

- Shock cord

- launch platform + guide

There are countless alternatives to what is supplied in a kit. As long as the materials are lightweight and sturdy, you can make a rocket with almost anything. The most critical part will be the engine housing and how that attaches to the fuselage. If you're making your own, follow along with the engine mount step a little later on in the lesson to see some tips on what a mount should look like.

Remove Fins

Most model rockets have stiff fins that help guide them straight when in flight. Some fins are made from wood, while others are made from cardstock – either way they are typically die cut from a large piece to the correct shape. Before removing the fins from the sheet they are cut from, lightly sand their surfaces (both sides) while they are in the parent material. This makes their edges easier to sand once removed.

If you look closely you can see small tabs where the fin pieces are attached to the parent material,. These will need to be cut free in order to remove the fins.

A sharp and thin hobby knife makes quick work of freeing all the fin pieces. Most rockets have different shaped fins, and some are made from more than one piece. Make sure you get all the fin pieces from your parent material.

After removing the fins you may find a few tags left over, these can be cleaned up with the hobby knife.

You can sand the edges if there are any uneven parts, or sand the faces if you find they need it. Set the fins aside for now, we'll come back to them after we finish assembling the rest of the rocket.

Engine Mount Assembly

To keep the rocket engine in the right place – and securely in the fuselage – there's a mount that needs to be assembled which will nest inside the rocket body. Engine mount assemblies will be different for some rockets, depending on their size and the engine power they are rated for. However most will have a similar setup.

In the picture above we have:

- Engine holder - brown tube

- Engine block ring - small green ring

- Centering rings - two large green rings

- Depth spacer tool - yellow tube

Measuring

To make sure the components go together correctly with the proper spacing we'll need a measuring tool. I find digital calipers a great choice for this.

For the small increments we'll be working in, it's easiest to use metric millimeters, as counting in whole numbers is much easier than imperial fractions. All digital calipers have a units button that will switch between imperial and metric. To do this, turn your calipers on, push them completely closed, hit the 'zero' button, and switch to metric. You're good to go!

Engine mounts can differ depending on the manufacturer, but most aim to isolate the engine from the fuselage (rocket body). What we'll do here is measure out where the spacing rings will be placed on our engine mount before inserting the assembly into the fuselage. Your numbers may differ (and that's okay), but the concept is the same.

Start by taking the engine holder and choosing an end to measure from. Measure out 3mm from your chosen end and make a mark. This mark will indicate how far the engine mount will be inserted into the fuselage once assembled.

From the same chosen end, measure 16mm and make another mark. This mark is for where a spacer will be placed.

Continuing from the same end, measure 57mm and make a mark. This mark will be the incision we make in the next step to place our engine hook.

Lastly, measure 67mm from the same end. This will be the second spacer ring location.

From left to right, the markings are: insertion depth mark, spacer ring location, engine hook incision mark, spacer ring location.

Spacer Tool

The yellow spacer tool is the exact size of the rocket engines we'll be using and slides perfectly inside the engine mount tube. We'll make a mark at 13mm from one end,. This mark will help us accurately place a spacer inside the engine mount.

Here's what my engine mount and spacer tool look like with all the markings made.

Engine Block (Small Green Ring)

To install the small green ring inside the engine mount, we'll use the yellow spacer tool. This ring will stop the engine from sliding too far inside when being inserted.

The green ring will be placed inside the engine mount and pushed with the yellow tool down the engine mount tube until the marked line on the yellow tool meets up with your selected end of the tube.

Place the small green ring inside the selected end of the engine mount.

Gently push the small spacer ring down the brown tube until you reach the mark on the yellow tool. From the other open end of the brown tube, use a think craft or bamboo stick to add a small dab of glue to hold the spacer ring in place. Make sure to remove the yellow tube quickly after applying the glue to ensure you don't accidentally glue the yellow tube inside.

Engine Hook + Centering Rings (Large Green Rings)

Before adding on the centering rings we'll install the engine hook. This hook's job is to push against the rocket engine bottom and keep it locked in place. To remove the rocket engine, we can just push the hook aside and pull the engine out to replace it after it's spent.

The yellow spacer tool pushed the engine block ring to just past the third marking on our engine mount tube. Using a sharp hobby knife, carefully cut a small 4mm incision at the 3rd marking (57mm from our reference end).

The 90° bend end of the engine hook can be placed inside this incision until fully seated.

With the hook in place, put a small dab of glue just above the 2nd marking (16mm from our reference end).

From the opposite end of the tube, slide on one of the green centering rings. Push the ring down the engine mount tube, over the engine hook, until it reaches the 2nd marking and the dab of glue. The glued ring will secure the engine hook in place.

next, add a small dab of glue to just above the 4th marking (67mm from our reference end).

Slide the second centering ring onto the engine mount tube until it reaches the marking.

Once the centering rings are installed, add a few extra dabs of glue around the centering rings to ensure a good bond.

Locate + Install Engine Mount

Adding a center line to the fuselage will give a reference point to where to place out launch guide, and allow us to measure up from the bottom of the fuselage and make a mark on how far inside the engine mount will be placed.

Using a pencil and a straight edge, draw a line down the length of the fuselage as straight as you can. This line will act as a reference which we'll use to mark measurements on the fuselage.

In order to allow the future pieces to be installed on this rocket the engine mount needs to be placed precisely inside the fuselage. Using the calipers, measure back 83mm from the bottom of the fuselage and make a mark on the previously drawn center line.

If you line up the engine mount assembly next to the fuselage, you can see that the mark you just made on the fuselage lines up with the top of the engine mount, and the bottom of the fuselage matches the first marking on the engine assembly. This means that we measured everything correctly and that the engine mount assembly, when inserted into the fuselage, will be at the correct depth.

Start inserting the engine mount into the fuselage from the bottom, ensuring the engine hook is is pointing away from the fuselage.

Gently push the engine mount into the fuselage until the last marking on the engine mount lines up with the bottom of the fuselage.

Carefully turn the fuselage so that the hook is pointing straight up to the sky and drop a very small amount of glue inside the fuselage tube, onto the centering ring that's closest to the end. This will help secure the engine mount assembly in place.

Nose Cone + Engine Nozzle

As mentioned earlier, each rocket set is different. My rocket came with the nose cone and the engine nozzle as one piece of plastic that need to be separated.

Though the plastic isn't thick, it can sometimes be difficult to separate the nose cone and engine nozzle. To separate mine, I used a sharp hobby knife to pierce the plastic connection and carefully work the blade around the circumference of the narrowest part of the back end of the nose cone.

There is a fluted section between the nose cone and the engine nozzle that needs to be trimmed away. Then, another fluted section at the end of the engine nozzle which also needs to be removed using a hobby knife.

Once the plastic pieces have been cut at the appropriate sections, the ends of the nose cone and engine nozzle must be sanded to remove any burs, making them smooth.

Install Engine Nozzle

The engine nozzle is meant to slip into the bottom of the rocket fuselage, in the gap between the engine mount assembly and the fuselage tube. The engine hook needs to have a little room in order to be pulled back so a small notch needs to be cut into the engine nozzle.

Add a small dab of glue to outside edge of the engine nozzle and then push it into the bottom of the rocket fuselage until fully seated.

Engine nozzle installed (high five!)

Rocket Fins

With most of the rocket assembled, the rocket fins can be installed.

Start by dry fitting the fins into the slots at the bottom of the rocket fuselage. It may be that the tabs on the fins need to be sanded slightly to take the hard edge off and allow them to slide into the slots a little easier.

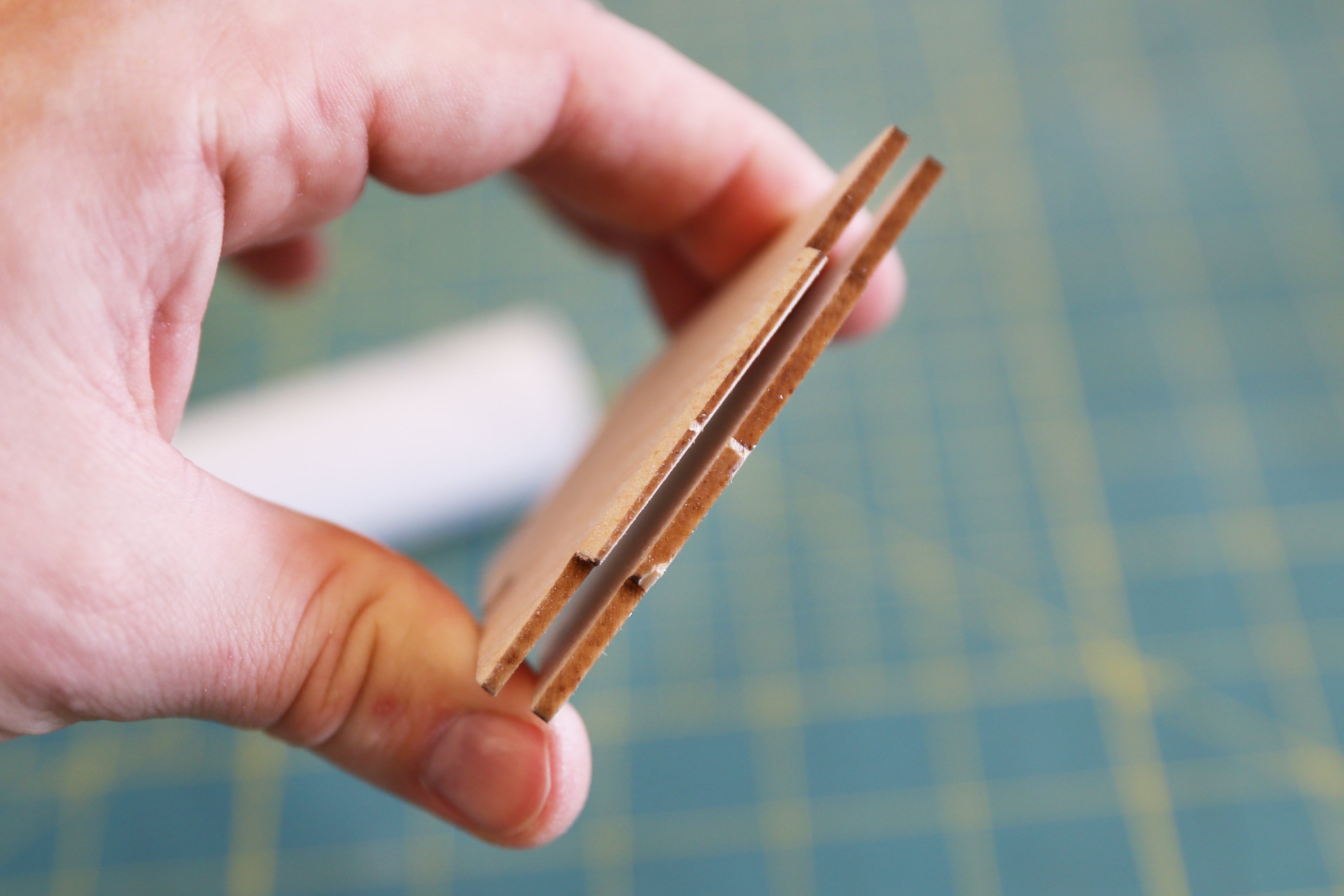

The picture above compares two fin tabs, one sanded and one with a square edge. The sanded tabs will slide easier into the slots on the rocket fuselage.

Apply a small dab of glue onto each fin and install them one at a time into each slot on the fuselage.

To get the best stability from the rocket in flight, it's important to make sure the fins are equidistant from each other. Looking from the bottom, down the rocket fuselage, align the fins so there is equal spacing (120°) between them.

This model has stabilizing stakes that are attached to the bottom of each fin, allowing it to rest on the fins. These stakes have slots that fit neatly onto the existing fins and are glued in place.

Launch Guide

With the fins installed we can glue the launch guide along the centerline we drew earlier to complete the fuselage.

The launch guide gets installed at the mark we made earlier on the centerline, right where the top of the engine mount is located.

Shock Cord Mount

Model rockets rely on a parachute to slow their descent after they have reached the apex of their flight. This parachute is attached to the nose cone which is tethered to the fuselage by a rubber shock cord (like a large rubber band). Here we will be making the mount that attaches the shock cord to the rocket fuselage.

A standard piece of printer paper is all that's needed to make the shock cord mount. The basic shape of the mount will be an elongated triangle.

Using a pencil and a ruler draw the letter 'T' on the paper, with the leg of the letter about four times longer than the bar. Draw diagonal lines connecting the bar of the T to the leg terminal to create the elongated triangle shape.

The dimensions aren't critical as we're only going for a general shape. Roughly, the dimensions I used for my T-shape were 1" (25mm) for the top bar, and 4" (100mm) for the leg. Once you have a triangle shape cut it out with scissors Then clip off the sharp point of the triangle, about 1" up from the point.

With our truncated triangle shape finished, fold it into thirds.

Shock Cord

The shock cord gets glued into the triangle mount with white glue.

Place one end of the shock cord in the middle section of the paper mount. Then apply a dab of glue and fold down the thinner top section of the mount to seal in the end of the cord. Press firmly to secure the end of the cord in a paper sandwich.

Once you've done this, apply another dab of glue to the larger section of the triangle mount and fold the previously glued section downwards.

Press firmly to ensure good adhesion. The shock cord is now secured inside the shock cord mount.

Set the freshly glued shock cord mount aside to dry. While it's busy doing that, we can move on to painting the rocket body.

Painting

Painting is optional, but it's been scientifically proven that decorated rockets outperform plain ones. Spray paint is the best choice to paint a rocket, as it's easy and provides even coverage.

Using a fine grit sandpaper (about 220 grit), gently sand the entire rocket to make a nice smooth surface finish. This is important as once paint it applied a rough surface will be very noticeable. When your rocket is smooth carefully wipe off any dust with a rag.

Before applying the paint color I wanted, I first sprayed a thin coat of primer. Primer works as a base coat for paint, applying an underlying white color to the piece and giving the paint better adhesion.

I protected areas that I didn't want painted, like the neck of the nose cone, with painters tape.

Here's the rocket after painting.

Attach Shock Cord to Fuselage

After painting, the shock cord mount can be attached to the fuselage.

Using more PVA glue, attach the shock cord mount from the top of the fuselage on the inside.

Firmly press in place to ensure a good bond. Set aside for the glue to dry completely.

Nose Cone

The parachute gets attached to the nose cone with a simple knot. The nose cone should have an obvious attachment point where the parachute cord can be threaded through and securely attached.

Make sure that your parachute cords are all approximately the same length, ensuring your chute will distribute the weight evenly when deployed.

Lastly, attach the loose end of the shock cord to the nose cone, tying a secure double not at the same attachment point as the parachute cord. The assembly of the rocket is complete!

Stuff Parachute

Before stuffing the parachute into the fuselage, we need to add some wadding. Wadding will helps control the blast that will push the nose cone outwards, ejecting the parachute. Without wadding, the blast can melt the parachute and prevent any controlled descent.

Stuff 2-3 bunched up pieces of wadding into the neck of the fuselage. The aim is to stuff the fuselage with enough wadding to make the ejection blast knock the cone off, but not so much wadding that it jams the fuselage and inhibits the blast.

Lay the parachute flat, fold over lengthwise, then wrap the edges inwards to make a tube shape. Insert the folded parachute into the fuselage and close the rocket up with the nose cone.

Decals

Just like paint, decals make your rocket fly higher. I named my rocket Waldo, since I knew I'd be excited every time I found it after a launch.

Engine Install

Model rocket engines require an igniter to operate. These igniters take an electrical current and convert it to heat through a thin metal wire. This wire, when glowing red hot, will ignite the rocket and allow your rocket to blast off.

Cut or tear off one rocket igniter and insert it into the bottom of the rocket engine until it touches the bottom of the cavity. Then, bend the igniter wires away from the cavity and install the plug. The plug will keep the the ignition wires in contact with the rocket engine for when you're ready to launch.

After the rocket engine has been prepared, it can be slid into the rocket fuselage until it's fully seated and locked in place by the engine hook.

You're ready to setup and launch your rocket!

Launch Area + Setup

Choosing the right area to launch is critical. You'll want to launch your rocket in a wide open space, away from buildings, people, power lines, or any other obstructions.

It's important to know that many areas classify solid-fuel model rockets as a type of firework, and as such will require a permit for launching. Check with your local fire department before blasting off.

When you're cleared for take off, set up the launch pad and connect the ignition leads to the rocket igniter. Make sure to stand well back before counting down to launch.

Launch

When you're ready to go, perform one last visual check of your surroundings to make sure the launch area is safe.

Now, here comes the best part, in a loud and clear voice shout the countdown sequence:

The countdown is an audible reminder to everyone that you're about to send your rocket skyward and they should be aware. Press the ignition and watch your rocket fly!

Take into consideration the wind when you're launching. Depending on the conditions and the size of engine your rocket has, your rocket can travel very far laterally - you might be going for quite a hike to retrieve it.

Recovery

If all goes according to plan, your rocket will launch, reach its zenith, then deploy the parachute and gently return to earth.

Launching rockets with friends is best, since there's a few pairs of eyeballs tracking the rocket as it descends.

Post Mortem

Model rockets are designed to be reusable, but that doesn't mean that every launch will return a pristine rocket.

Damage, either from flight, descent, or mishandling, is part of being a model rocket engineer. Inspect your rocket after every use, and if something went wrong with your launch take a moment to analyze the outcome and see where the failure occured.

Seasoned rocket scientists will tell you to take extras of everything when you launch, along with plenty of tools, to perform field repairs.

{

"id": "quiz-1",

"question": "Why add wadding to your rocket?",

"answers": [

{

"title": "To protect the parachute from the ejection blast",

"correct": true

},

{

"title": "Ballast weight",

"correct": false

}

],

"correctNotice": "Yes! Without wadding the ejection blast can melt the parachute.",

"incorrectNotice": "Wadding is not ballast for solid-fuel rockets."

}

{

"id": "quiz-2",

"question": "Launching in a crowded or populated area is fine if there's no wind.",

"answers": [

{

"title": "Never launch anywhere that there's a chance the rocket could hit any obstruction, in either takeoff or landing. Always launch in a wide open area free of any obstructions.",

"correct": true

},

{

"title": "It's okay as long as no one is watching.",

"correct": false

}

],

"correctNotice": "Yes! Just because there's no wind at ground level, doesn't mean there's no wind higher up that can carry your rocket very far away from you.",

"incorrectNotice": "That's incorrect."

}

Next Stop...SPACE!!

Great job, Cadet!

You've only seen the beginning of what's possible with homemade rockets, but you've got a solid foundation with an understanding on how they work and ways to make your own. With a little experimentation you can come up with all kinds of rockets.

If you made a rocket from this class I'd love to see it. Better yet, post an Instructable of your creation for all to see.

To infinity, and beyond!