Mini Trailer Shelter - Make It Small, But Serviceable.

by jiaxuanl in Design > Architecture

11219 Views, 56 Favorites, 0 Comments

Mini Trailer Shelter - Make It Small, But Serviceable.

Hello! My name is Jiaxuan and I am a junior at the time of this contest. As an immigrant, I came to America in 2011, and here I am now, in New York City. I took a mandatory CAD class in my sophomore year of high school, and I found a love I never knew I had. I am now in the advanced CAD class as a junior, hoping to hone my technical skills as well as develop other soft skills through my projects.

After producing an entry I was nowhere near happy with for an Instructables contest in the previous year, I felt it was necessary to try again. When I first saw this contest, I felt a wave of nostalgia. In my mind, the concept of this contest is extremely similar to something that I believe heavily contributes to who I am today.

Minecraft.

The cover, the idea, the description, all reminded me of the old trend on YouTube surrounding the remarkable video game. There are videos and posts from content creators and other ordinary players from a decade ago, and even up until now, attempting to make the smallest but functional base in Minecraft. This really struck me. As a long-time fan, I grew up on the game Minecraft... I would even say it raised me. I enjoyed designing structures, building contraptions, struggling with redstone, and also making my own attempt at these trends. The seemingly goalless sandbox game allowed me to express my creativity freely; I truthfully believe that this game has sparked interest in me regarding engineering. I also vividly remember the Department of Education granting free Minecraft: Education Edition accounts during quarantine, where I would take time out of my day to do the embedded educational STEM lessons and activities. Hours were spent on the game, whether if it was alone or playing survival with my friends. Anyway, enough about me and my inspirations.

My goal for this project is to present a solution to an issue. Recently, in my junior year of high school, I have explored sustainability in engineering by researching CAD, CAM, and sustainability to compile a literature review. In the midst of the presidential election season, I also newly discovered my interests in politics... something I never knew I had. As someone who always claimed to not care about politics, I have never ever in my life thought I would be genuinely interested in researching policies surrounding the issues in our system and society. Looking at trends, statistics, facts, and claims from these politicians, it is obvious that our economy has been a hot topic for debates. As someone living in New York City, I see homeless people everywhere I go; it's inevitable.

Supplies

Microsoft paint, to brainstorm and draw the plans.

AutoCAD, to sketch the plans and set up laser cutting.

Revit (optional), to create the very basic foundations.

Inventor, to model the plans and add details.

Laser Cutter, to bring it to life.

Wood & wood glue.

Brainstorming

Like I stated previously, the goal of my project was to present a possible solution to an issue that I witness daily in society: homelessness. I was also further inspired to work on this topic after I participated in the falls Girls Who Code Self Paced Program (GWC SSP). For one of my web development courses, my final project consisted of research and the construction of a website that aims to advocate for the homelessness. I always knew that homelessness was a big issue, but only after GWC SSP, I have realized that it is actually a crisis.

I want to engineer a solution that would help the homeless in any way, shape, or form, with the goal of easing some of the burdens that they already face.

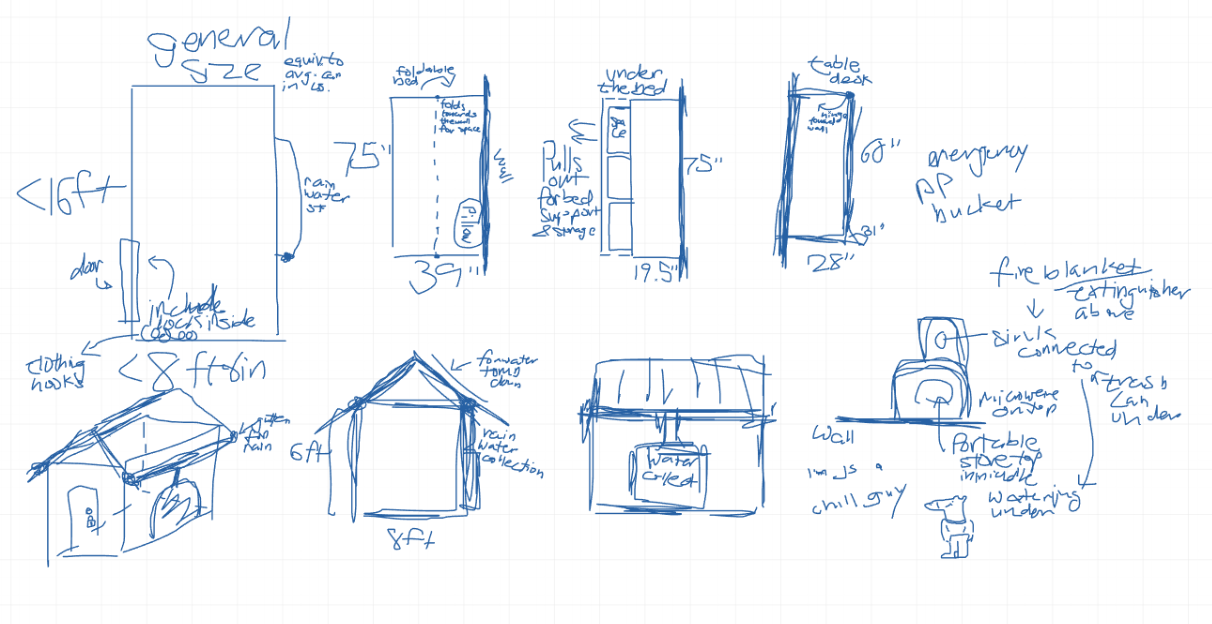

Attached above is an image of what I was possibly planning on doing for my project. It was a really rough sketch, but I created this during a free period of my APUSH class so... My first idea was to have a mini home the size of a car, which could be "parked" in major parking lots that allowed overnight stays (my idea to make it possible was to negotiate and work alongside government agencies). I would design everything based on the average size of the car and make sure to incorporate basic necessities, foldable beds, and space efficient tables in order to save the minimize the size. I also wanted it to be easily transportable, but I wasn't sure how I was going to do that at first. After all, this was only my immediate solution; there would be tweaks, but in the end, it should result in something similar.

The Problem

Why is this important? First, some history.

The Great Depression was a cruel and egregious decade that continues to impact modern-day United States. From 1929 to 1939, the nation of America witnessed severe economic issues. Homelessness was at an all-time high. It has been an ongoing issue that always comes up as a hot topic of debate throughout the American politics. From late-2007 to mid-2009, America and other developed countries at the time underwent a period known as the Great Recession. The gross domestic product, or GDP, declined by 4.3%, and unemployment doubled from 5% to 10%. This meant there was lower real income and ultimately, millions of Americans lost their jobs, homes, savings, etc, causing the poverty and homelessness rates to skyrocket.

When President Barrack Obama came into office in January 2009, his administration aimed to fix the damages left behind by the George W. Bush administration. After passing many economic policies, the United States witnessed one of the most significant recoveries in their economy changes to homelessness. However, the issue has been steadily increasing again as Obama left his second term. Despite the recovery of the US economy, many individuals were still left unable to afford stable housing, and many today continue to fall into the struggle with homelessness. Homelessness has been a topic that most influential policymakers have failed to address, and the effects are very prominent in many urban cities in the United States (img 3.).

To make matters worse, during the COVID-19 pandemic in 2020, once again, there were severe economic challenges for everybody in the working class or lower. The pandemic disproportionately affected the most vulnerable, posing a higher risk of homelessness for many. This situation was even worse for those who were already homeless, forcing them further down the rabbit hole. With businesses closing down, skyrocketing unemployment rates, and also the lockdowns, many people faced financial instability, even with government-issued stipends.

Homelessness is no longer only a social issue or a political issue, it is a humanitarian crisis that requires urgent attention. The main reason for why homelessness is such a significant problem is that it denies many innocent people the rights to access to basic needs. This includes stable housing, healthy food, good hygiene, clean water, and more. In the long run, the lack of access to these resources may lead to physical health, further complicating their lives and perpetuating the cycle of poverty.

Because of how difficult it is to cope with homelessness, it is often linked with mental health struggles, substance abuse, trauma, etc. This can contribute to higher crime rates, public safety concerns, and the endless cycle of homelessness. On the other hand, this trend does not represent everyone who struggles with homelessness. The homeless also consist of innocent and unfortunate elders, war veterans, and teens; they wished for their lives to turn around for the better, but they lack the opportunities to do so. On top of all their personal struggles, they are also subject to discrimination, dehumanization, and negative stereotypes from the public and media, further harming the homeless population.

How is it fair that they don't get a chance? How is it fair that people in the world have to worry about food, water, and shelter?

Here are some statistics about homelessness in the United States recently:

A record-high 653,104 people (Over 12.1% increase from previous year) experienced homelessness in January 2023.

From 2019 to 2023, the number of people who entered emergency shelter for the first time increased by over 23 percent.

In New Hampshire, from 2022 to 2023, there was a recorded 52% increase in homeless populations.

Img 1. (Data for the graph I made): Statista

Img 2.: World Population Review

Img 3.: USA Facts

Statistics: National Alliance To End Homelessness

Factors and Limitations

Regulatory and Legal Factors

Many local laws and regulations, especially in urban cities, prohibit the use of public space for overnight shelter. Many vacant parking lots of even large retail stores do not allow cars, let alone trailers, to park overnight. Typically, parking non-driven property, such as boats and trailers, on the side of the streets are also prohibited.

Sustainability Factors

With the growing environmental concerns like global warming, sustainability is a key factor when it comes to any newly designed or engineered product. It is important to try to keep the product as sustainable, eco-friendly, and less wasteful. It should also be long lasting.

Mobility and Portability Efficiency

For the structure to be portable by car, it must fit trailer regulations. To maximize its efficiency, the size should not require a permit, as not everyone can easily obtain it, and it should also be towable by a standard car. But I believe that shouldn't be an issue because I plan on making it the smallest it can be.

Typical max size in the US: 16x8x13.5 LWH in feet

Standard car tow strength: 5,000 lbs

Accessibility to Utilities

The temporary shelter must provide access to clean water, working electricity, other basic necessities, and overall be a pleasant place to stay. Even if its intended use is to only house an individual overnight, it must still have aspects of a home.

Safety and Security

The temporary shelter should provide a feeling of security and stability to the vulnerable homeless population. Despite being temporary and intended for only overnight use, it should still be durable, withstand weather conditions, and have safety mechanisms to bring a sense of comfort to the individual.

Cost Efficiency

Because the shelter is meant to be small and for the poor, it should be cost effective. If it is efficiently priced, it would be more affordable to deploy as well as give to others. Using affordable materials should not take away from the overall functionality and safety of the shelter.

My Plan

My proposed solution is a mini shelter that would consist of aspects of both a RV trailer and a camping tent. It would be portable and would be able to be placed in designated places/communities---hopefully with the help of others like homeless advocacy organizations or the state/government participation. It would also be able to be towed by car, meaning it should be relatively small. The intended use of the shelter would be an overnight stay; however, it still should still be comfortable to hang out in during the day.

Here is my plan:

Basic Needs Access

Water: Rainfall that is filtered and pumped into the sink. Greywater container under the sink. Space for gallon jugs in case of emergencies. Rainwater collection is a sustainable method of collecting water.

Food: Small microwave and/or a portable gas stove.

Energy: Solar panels with battery storage for cloudy or rainy days. Solar panels are extremely sustainable as it is very energy efficient and it is also a renewable source.

Other Features

Foamboard insulated double-layer walls for temperature and noise regulation. Insulated walls reduce the need for artificial heating or cooling. The exterior walls are made of steel or aluminum, which are highly recyclable materials. It also has long lifespans and are resistant to extreme weather.

Lockable doors and windows.

Ventilation system for portable stove. Propane tank compartment on the exterior.

Fire blanket and extinguisher for emergencies.

Security camera on the outside.

CO2 and smoke detectors.

Wheels and hitch so it is easily transportable by car.

Drop down stabilizers to keep still, without the need of a car.

Foldable bed to save space.

Drawing the Plan

One of the biggest challenges was getting the dimensions right. Initially, I rushed and tried to build my idea in Inventor without proper planning. After not being happy with my results halfway through, I tried again; still wasn't unsatisfied. This was when I realized the importance of planning and taking my time.

I took another route and turned to AutoCAD to draw out the actual plans for my project. Drawing it out in AutoCAD beforehand allowed me to have a 2D visual, providing a comprehensive breakdown of each element and an overall visualization of how each item would look in the space.

Although the dimensions I chose to use were not all concrete from start to end, the drawings were still extremely helpful references for when I was modeling and editing my 3D models. The 2D drawings ultimately served as the blueprint of my project.

Bottom Left Drawing, Floor Plan:

I started with the floor plan as it was the easiest one for me to draw. After my first two failed attempts with Inventor, I had a good idea of the general dimensions I wanted to use. The floor space was chosen to be 6 ft x 8 ft with double layered foam-insulated walls. I added a 3 ft wide door in the center so it would be symmetrical. A symmetrical door would be beneficial for both balance and aesthetics. Alongside the door was a doorframe because, believe it or not, a door frame is not only for decorative purposes. A door frame is necessary in most cases as it supports the functions of a door as well as the overall structure integrity of the construction. Without a frame, the door may become unstable.

Bottom Right Drawing, Interior Plan:

Next, I focused on the interior furnishing plans. After my planning and brainstorming, I had a general idea of what I wanted to include in the limited space. I knew the size of the bed I wanted to include so I needed some other measurements. I measured my counters at home and found it to be 24 inches by 21 inches. With that, I decided to trim off 2 inches to save space without compromising on functionality. I then included the portable stove and sink because they were a part of the list of necessities. I also wanted a counter and some sort of storage. My initial idea was to make a wall shelf above the counters, but I felt like it might've not provide sufficient storage space.

Top Left Drawing, Bottom View:

My brainstorm sketch initially intended for the water tank to be on the side of the trailer. However, I realized that the idea would not be feasible as the center of mass would be very off, dangerous even, if it were to be filled with water. To address this, I moved the tank to underneath the trailer. Despite that solving one issue, there were more concerns raised. Because it was on the bottom, the size of the water tank would be limited by the other parts underneath the structure as well as the height of the tires. The tank underneath is designed to hold 35 gallons of water (originally intended to be 50 gallons on the side). This capacity may be sufficient as there is no shower or toilet. My estimation is around 6-10 gallons a day without a toilet or a shower:

Cooking and dishwashing (assuming they're making small/one-pot meals) = 3-4 gallons

Toothbrushing = 1 gallon

Handwashing = 2 gallons

The average rainfall in America has consistently been 30 inches, which would be a problem if we solely relied on rainwater to be the main water source.

30 in = 2.5 ft. Average annual rainfall in feet

6 ft * 8 ft = 48 ft^2. Area of roof that will collect rain.

48 ft^2 * 2.5 ft = 120 ft^3. Annual rainwater collected.

120 ft^3 = 897.67 gal. Annual rainwater collected in gallons.

897.67 gal / 52 wks = 17.26 gal/wk of water. Average gallons of water collected per week.

17.26 gallons is not even half of 35 gallon tank. However, there are campsites and RV sites scattered throughout America that offer free or extremely low-cost refills for water.

Near the water tank is the water pump. The water pump would push the water through multiple filters like mesh, carbon, UV, and polishing, before reaching the sink. It is recommended to boil the water before being consumed or used in cooking. Waste water from the sink would go down the drain and enter the greywater compartment underneath the sink. In most cases, the greywater can be directly dumped into municipal sewers, but in the case of local regulations that prohibit doing so, the greywater tank can be emptied at places like RV parks or truck stops.

Another feature is the four stabilizers. There is one in each corner, designed to keep the home stable by leveling it flat. The stabilizers are both strong and adjustable, allowing adaptability to different terrains through minor leveling adjustments. Lastly, there is a dedicated exterior compartment in the back for the gas tanks needed to run the portable stove. It can also be used as extra storage for other items if needed.

Top Right Drawing: Side View

Finally, the side view drawing offered another perspective. The side view allowed me to note the proper height dimensions as I was able to see it from another plane rather than just top-down. I also wanted to visualize how the gutters and pipe would look, as well as how far the water tank would be from the ground with the tire size I chose.

Design comments:

The wheels are positioned on the outside of the structure to maximize stability and interior space. If the wheels were to be placed where they typically are, it would cause conflicts with the interior layout, especially since there is already extremely limited space on the inside.

The twin sized bed would be both comfortable and reliable for any person under 6 feet tall, or approximately ~85% of the world's population. The mattress on it is also multi-functional. It is foldable, meaning it can double up as couch cushions and a bed. The ability to fold and position the mattress as needed allows for more living space when not in use, but also provides extra space for sleeping when needed. This flexibility is ideal for a place with limited space like this.

There is no dedicated bathroom (toilet and shower) in this project due to the water usage and overall size of the home. As a possible compromise, a portable camping toilet could be added. Other options include a cheap gym membership, beach bathhouse, public pool bathhouse, or public restrooms. I would have loved to include a bathroom and shower for maximum comfort, but the limited space could not accommodate it.

Building the Foundations

I used the dimensions I noted for the walls, floor, and roof to create a model in Revit. Since this was my first experience with Revit, I asked my friend for some help on this step. This process was surprisingly quick, allowing me to easily see what I was working with and confirm if the foundations looked right. The structure was then exported and imported into Inventor, where I would add the other details like the furniture, the wheels, etc.

Modeling the Details

List of things I added with Inventor:

Window

Gutter caps and pipes

Solar panels

Drawers and mattress

Counters, sink, and shelf

Wheels and axle

Hitch and stabilizers

Compartments underneath (for water tank, water pump, & extra storage)

The thing I enjoy most about Inventor is modeling. To model the components above, I searched up references to understand what each piece should look like. For dimensions, I measured the objects that I had access to at my home; otherwise, for items I did not have, I went on amazon or shopping sites for its dimensions from the product description or images.

Every single model begins as a sketch, whether it is based on the origin plane or a part from the Revit model. Constraint, copy, move, trim, offset, and rectangle were my most-used sketch tools in this project. After drawing my desired shapes, I used 3D modeling tools like extrude and sweep on the sketches to shape and structure my component. Some parts may also use multiple sketches or shared sketches for additional extrusions in order to perfect their shape, often to cut out sections from the previously extruded parts. A helpful tool for sketching is slice graphics. It is found under view and makes seeing the sketch so much easier than having to use half section views every time.

To add more details and make the part cleaner, the fillet, chamfer, and delete face tools are very reliable. In my opinion, rounded edges look better as it makes the models look more polished and less blocky. To give the part material and color, the view tab also has the material and appearance buttons. I chose textures for my components based on both aesthetics and what actual project may use. I also adjusted the appearance and colors of certain textures by lightening or darkening it as needed with the tint tool.

When creating each part, it is important to make every part in a separate file. This makes the project easier to manage and easier to assemble in the end. Not only that, it also makes the project easier to export and share to others.

After I constructed and edited all the parts I needed, it was time to assemble. In assembly, I placed two or three parts at a time. For example, I imported the drawers and the mattresses so I could constraint them as a group. Using assembly constraints like mate, flush, and angle, I was able to put together most of the project, including the bed so that the arrangement of the mattress and drawers can be changed through editing the constraint values. For some parts, I used the joint assembly because it was more straightforward and intuitive, such as for connecting the wheel and axle. I did have to go back and add a few more planes, points, and axis in my parts to more easily constrain my parts, but it wasn't difficult. Quarter section view and half section view helped me get a better view of the parts I was putting in the limited space. It let me see the little gaps and various angles of my project.

For rendering, I used Inventor Studio. With render image, I experimented with the lighting styles, camera angles, and orthographic vs perspective views. When I found a setup I liked, I rendered the image on render until satisfactory, high mode, and 3 wide gaussian blur.

List of things I want to include but did not model:

Deadbolt lock on doors

Security camera

Smoke and CO2 detectors

Proper ventilation system (only a window)

Battery for solar panel (I did not model it, but I ended up laser cutting it... but I think I lost the pieces in the laser cutter)

Fire blanket and extinguisher

Laser Cutting

Back to AutoCAD.

This was my first time laser cutting as I have only worked with the 3D printer in the past. I asked my CAD teacher to help me with this step. He assisted me by teaching me and helping me set up the AutoCAD file to laser cut.

Thank you Mr. Buro !!

When I requested to use his 3D printer for this project, he suggested that laser cutting would be a better approach instead. I was a little hesitant because the process was unfamiliar to me, but I trusted him and it turned out much better than 3D printing would have.

We used 11.5 x 11.5 x 0.125 inch wood boards. Using my original AutoCAD design document and the annotate tool in Inventor for the parts that were altered/not on the original document, I was able to get the dimensions I needed to draw my laser cut parts. It was a little confusing to draw at first, but after the first few parts, it made a lot more sense and the process became easier. The concept is basically to lay everything out flat and then glue them together to make it 3D again. It's like how I imagine folding a cube: drawing all the faces out, cutting it out, then folding it up.

Laser cutting the gutters wasn't working though, so my teacher helped me recreate it to 3D print it. We then decided to use dowels for the pipes.

This was my first time working with wood and, yet not surprisingly, I found it very fun and entertaining. I would love to do more hands-on laser cutting projects in the future. I would have loved to paint it if I had more time in class that day.

Downloads

Final Assembly

My CAD teacher also helped me assemble the project. He helped me put the hinges on the door and the mattress so that it was functional and could move. When it came to the gutters and the pipes, the dowels we used for the pipes were not long enough. It presented a challenge, but he helped me exacto-knife the dowels to close off the gap, as well as 45 degree slits to fit into one another at the corners. (Thank you Mr. Buro!) It was very satisfying, however, when everything else fit together nicely.

All there was left after putting everything together was to take pictures of my final product.

I took a few photos of my project against a black background with some lights, but then I noticed the sun was shining through the windows---I had to take my chance. I love it when the sunlight hits perfectly, and it just so happened to cast a beautiful, warm orange color. I grabbed a chair and a flat reflective surface to set my project on. I positioned my project so that the sunlight hit where I wanted it to hit, and I really liked how it turned out.

I am also really please with how the counters and shelves came together. Very cute, in my opinion. One of my favorite features is how a part of the roof can be taken off and put back on. This simple feature made it so much easier to move things around on the inside and provided another angle to display my project.

Reflection

(For size reference, the wooden guy would be 6 ft tall relative to the home.)

This project taught me a lot. Rather than giving up after the first two failed attempts, I decided to try again, just with a different approach. This project helped me realize the importance of planning ahead your next steps rather than diving in blind and head first.

Thinking back, a lot of my previous projects have taken unnecessarily long or even abandoned due to lack of planning and my bad habit of jumping straight into Inventor. There have been several projects where I realized I made a huge mistake in the middle of the project, but it would have been preventable if I had just spent some time thinking about the project beforehand.

My submission for last year’s contest also had evidence of a lack of planning. I ended up extremely unsatisfied and did not even want to submit it because so many things went wrong. Although extremely embarrassing and frustrating, I have also learned a lot from the failure of that project as well.

This project also introduced me to different form of CAM (Computer Aided Manufacturing): subtractive manufacturing. After working with 3D printers, I never really considered working with laser cutters for my projects before; but now that I did it once, I would love to incorporate it more into my future projects.

Additionally, I also learned the basics of Revit from this project. As an Inventor user, I have never planned to learn or use Revit; but, now I am open to exploring more about the software and possibly using it more in future designs as well.

The Instructables contests have given me with a project goal, guidelines, and direction. More importantly, participating in these contests ultimately motivates me to explore beyond what I am comfortable with, teaching me how to deal with unfamiliar situations and challenges. I am grateful for being able to participate in the contest and the chance I was given to grow during this project.

Lastly, I want to thank everyone who has supported me through this project, especially Mr Buro.