Transportable Unfolding Modular Home

by jeanyoo039 in Design > 3D Design

708 Views, 4 Favorites, 0 Comments

Transportable Unfolding Modular Home

Today, there is a huge housing crisis, especially in America. In 2024, the USA hit record high in homelessness, with over 770,000 people in shelters, temporary housing, or without shelter at all (Department of Housing & Urban Development). Especially in heavily gentrified areas, the prices of housing and rent is far surpassing what people are able to afford. With such difficulty finding places to live, there is a huge need for the quick and efficient creation of new homes.

Recently, the development of modular homes, or pre-fabricated homes, have become a potential solution to this issue. It is built on the idea of creating a home in factories, compacting them for transport, and quickly being able to construct them on-site. While there is variation to the amount of time this process could take, a modular home often takes only around 3-4 months to build, while a traditional home can take 9 months to up to a year (Next Modular). Once the site is prepared, many homes take less than a day to set up. Companies like Boxabl claim to set up homes in just an hour, and the uBox created by Ten Fold Engineering can be "unfolded" in under 10 minutes.

Because these homes are also made in factories, the cost to produce one is often 15-20% less expensive than a traditional home. With supervision from a factory, these homes require less resources and produce less waste than traditional homes made on-site, and are ensured to adhere to high levels of quality.

For this challenge, I decided to design my own unfolding, modular home with 720 square feet, able to house an average family of four or more.

Supplies

Fusion 360

Optional (To Build the Model):

3D Printer

Filament

String

Research & Design

The main goal of this project was to design a modular home that could be produced to help people requiring rapid housing. Therefore, I established the following criteria:

- Must follow major regulations of modular homes and shipping sizes

- Less than 16' wide, no more than 64'-76' long

- While in transport, must be less than 16'-20' wide, less than 60' long, less than 18' tall (Built Prefab)

- Must be a relatively small space to fit an average family (4 people)

- Each room be an efficient use of space, and each room should be well designed

For my home, I decided to attempt to design it with 2 bedrooms, 2 bathrooms, a kitchen, and with comfortable living room space so people can play, study, or work. I wanted the interior space to be under 1000 square feet so it remains reasonably priced, and primarily designed for two adults and two children.

Designing the Modular Home

Making the folding design maximize its expansion while keeping parts relatively simple was key to making a realistic design. Each wall and floor panel is six inches in width, and must be accounted for while folding.

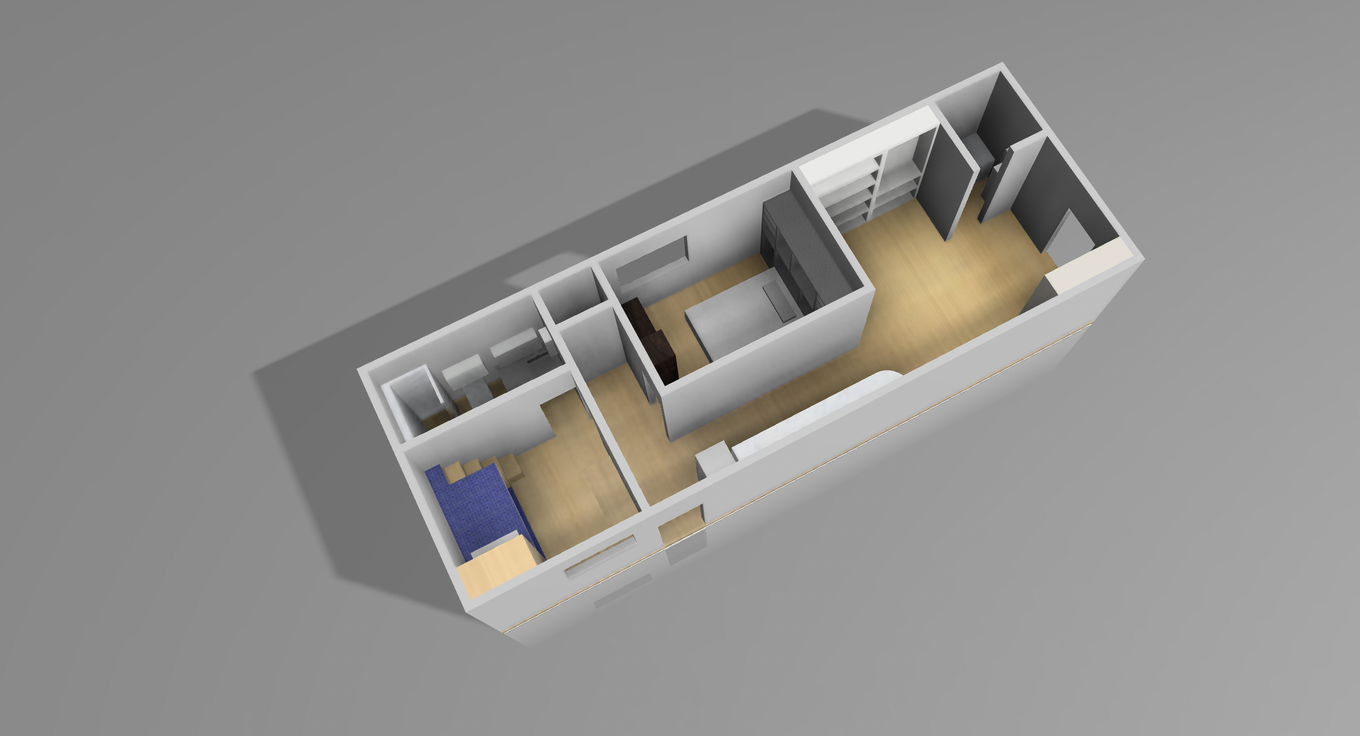

I decided to go with a tri-fold design for its large expansion ratio and relatively simple folding process. When unfolded, the house is 720 square feet. While folded, it is 15' wide, 17' long, and 17' tall.

Similarly, as the house is to be folded into three sections, I fit the parts of the house to fit within these divisions. With a total length of 45 feet, each "section" of the home is around 15'x16', or 240 square feet.

The sizes of each room are as follows:

- Living room & Bathroom: 240 square feet

- Kitchen: 90 square feet

- Adult's Bedroom: 150 square feet

- Kid's Bedroom: 110 square feet

- Bathroom + Shower: 66 square feet

- The rest of the space is a hallway between the rooms and kitchen, and holds the washer/dryer.

Modeling the Floors & Walls

To CAD the design, the scale factor is very important. I scaled my dimensions down directly from feet to inches, therefore my floor is 45"x16"x.5" and the walls are all 6" thick.

- Doors are standard 80" tall (estimated 6.5" in the CAD file)

- Exterior doors are 36" wide (3" in CAD)

- Interior walls are 28" wide (estimated 2.5" in CAD)

This portion of the design can be done with the rectangle, line, and extrusion tool to add doors and windows.

- Note: At this step, make sure to keep the exterior walls, interior walls, and floor separate bodies, especially to build the model later!

Modeling the Living Room & Kitchen

The furniture for this section includes:

- Kitchen cabinets, oven, washing machine, fridge

- Main pantry

- Sub-storage & TV Stand

Kitchen:

- Sketch & extrude rectangles for the base, fridge, and rectangular cabinets (recommended bottom cabinets around 3.5' tall, top cabinets around 6' above the ground)

- Revolve a thin rectangle to create circular cabinets

- Extrude an upper layer for the countertop

- Extrude details for the oven and dishwasher

- Optional: create a small base (~.2" smaller, .5" tall) for the kitchen to slots into the floor

Main Pantry:

- Sketch a large rectangle and the cabinet space, then extrude. Don't be afraid to make it too big––the more storage, the better.

- Tip: use the rectangular pattern for multiple same-size spots

- Optional: create a small base for the pantry to slots into the floor

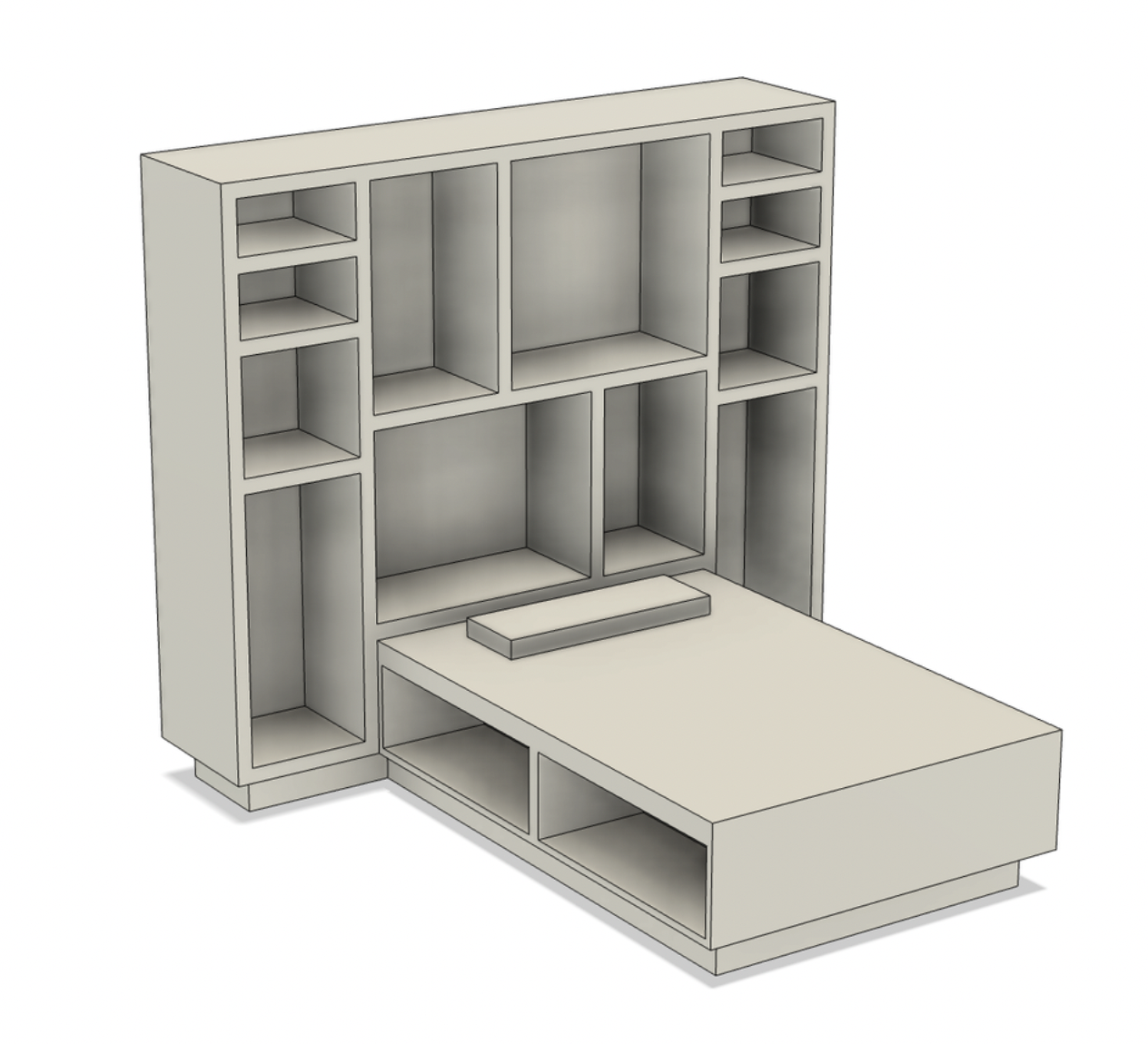

Sub-Storage & TV Stand

- Extrude a large rectangle for the sub-storage and a shorter rectangle for the TV stand (TV stand recommended 2.5' - 3' tall)

- Optional: create a small base to slot into floor

- Note: Some of the parts featured have a small base (all bases are ~.2" smaller than the parent shape, and .5" tall). This is added to help the part fit into the printed floors.

Modeling the Bedrooms & Bathrooms

The furniture for this section includes:

- Queen bed, desk & storage

- Child's bunk bed, desk

- Shower

- Sinks (x2)

- Toilets (x2)

- Cabinets & Mirrors (x4)

Bedroom 1 (Adults):

- Sketch two perpendicular surfaces, first for the cabinets and storage that act as a headboard, then for the bed.

- Try designing the bed to be a standardized size, like a Queen (60"x80").

- Tip: use the Mirror tool to reflect the storage from the left to right side across the center of the headboard

- Sketch the desk and extrude cabinet space

- Tip: use a Rectangular Pattern for the repeating cabinet sizes

- Optional: add base

Bedroom 2 (Children):

- Sketch the base of the entire bed surface, dividing it for enough space for a pull-out wardrobe and stairs

- Remember this design is for children! The beds can be smaller than an adult bed, but should not be much smaller than 6 feet

- Extrude the pull-out wardrobe and upper bunk storage, and bottom bunk

- Tip: consider how far this design will be scaled down, especially because this design has a lot of empty spaces

- Sketch the upper bunk and extrude surfaces

- Remember to add enough space for both children to sit up and avoid feeling cramped

- Create supporting pole between the upper and bottom bunk

- Design the steps from the floor to upper bunk

- Tip: this bed is for children, so try to make the steps a size that is easy for children to climb up. In this design, I added an extra step past the bed to decrease the overall height of these steps and make them more accessible.

- Extrude all storage segments

- Pull-out wardrobe on the bottom bunk

- Under the bottom bunk

- First two steps of the staircase

- Inside the upper three steps (facing the bed)

- Behind the upper bunk's headboard

- Tip: for all pull-out storages, consider how far the storage can move within the room. For example, the pull-out wardrobe should not hit the desk, the steps should not cross the doorway, etc.

- Sketch & extrude desk

- Optional: add base

Bathrooms:

- Sketch and extrude the sink, toilet, and cabinets

- Sinks should be around 36" tall, and toilets should be 28"-30" long, 20" wide, and 27"-32" tall.

- Tip: remember that floating cabinets should not hit each other, or be too low/high for people to access

- Optional: add base

Note: Some of the parts featured have a small base (all bases are ~.2" smaller than the parent shape, and .5" tall). This is added to help the part fit into the printed floors.

(Optional) Print the Model

Printing the model takes a little extra preparation for the model itself, mainly cutting it apart into separate pieces.

Furniture:

- To create cuts in the floor, extrude the bases of the furniture -0.5"

- To make assembly easier, shrink (by around .2" on each side) and extrude the bottom face of the furniture to create a base.

Walls & Floor:

- Move the internal walls (these will still be printed, but are not folded)

- In Construct, make Construction Planes separating the walls and floors into three sections, each 15" (or your unique the scaled-down value) in length.

- In Modify, use Split Body to split the floor or walls into pieces along the constructed plane.

- On the leftmost and rightmost floor/wall pair, cut the edge at a 45 degree angle so the wall and floor can meet perpendicular. This should cut the following components:

- Left & Right floor panel

- Left & Right wall panel

- Side wall panels on either side of the left and right floor panels

- Cut holes into each plane that meets and needs to fold along another.

- I did two along every edge that folded with another component, with a diameter of 0.75" (my model is scaled down another 4 times in print).

Extra tips:

- I highly recommend tree supports for most of the furniture, which were easier to remove and left less residue

- Rotate & position furniture to be easier to print––most likely, only the adult bed and child bed need major structural supports, most others will be for the smaller base

- When printing the external walls & floor (which are flat, likely thin surfaces), consider using a raft so the edges don't curl up and warp while printing

- If slicing with Ultimaker Cura, consider downloading the mesh tool extension to easily split and move around the parts for a more-efficient print

(Optional) Build the Model

Once all parts are printed, you can use string to tie the walls that should fold together.

To compact for transport, fold the walls into the middle and fold the floor and walls up to create a box. The roof can similarly be folded to compact in the middle.

Furniture can be slotted into the "holes" to be more stable, and the center walls can be glued perpendicular for further support. The inner walls and furniture should be enough to support the other walls, but they can be glued down as well––just remember that you won't be able to fold the house once it is all glued together. Similarly, the center plane of the roof can be glued down, but it greatly restricts visibility into the model.

Conclusion

Making this project has demonstrated the importance of juggling between cost and space efficiency and practicality, while designing a small house that could comfortably house families in need. This challenge has definitely been a lesson of minimalism, and creatively maximizing space as much as possible.

Overall, this challenge has taught me a lot about the process of designing spaces and how challenging it can be to create something truly efficient in all aspects. However, really delving into this topic has also demonstrated that there are solutions that can be created to help people all over the globe, if we only take the time to think outside of the box.