Making a Project Description Plaque

by TSSJ-ryan in Workshop > Laser Cutting

7027 Views, 26 Favorites, 0 Comments

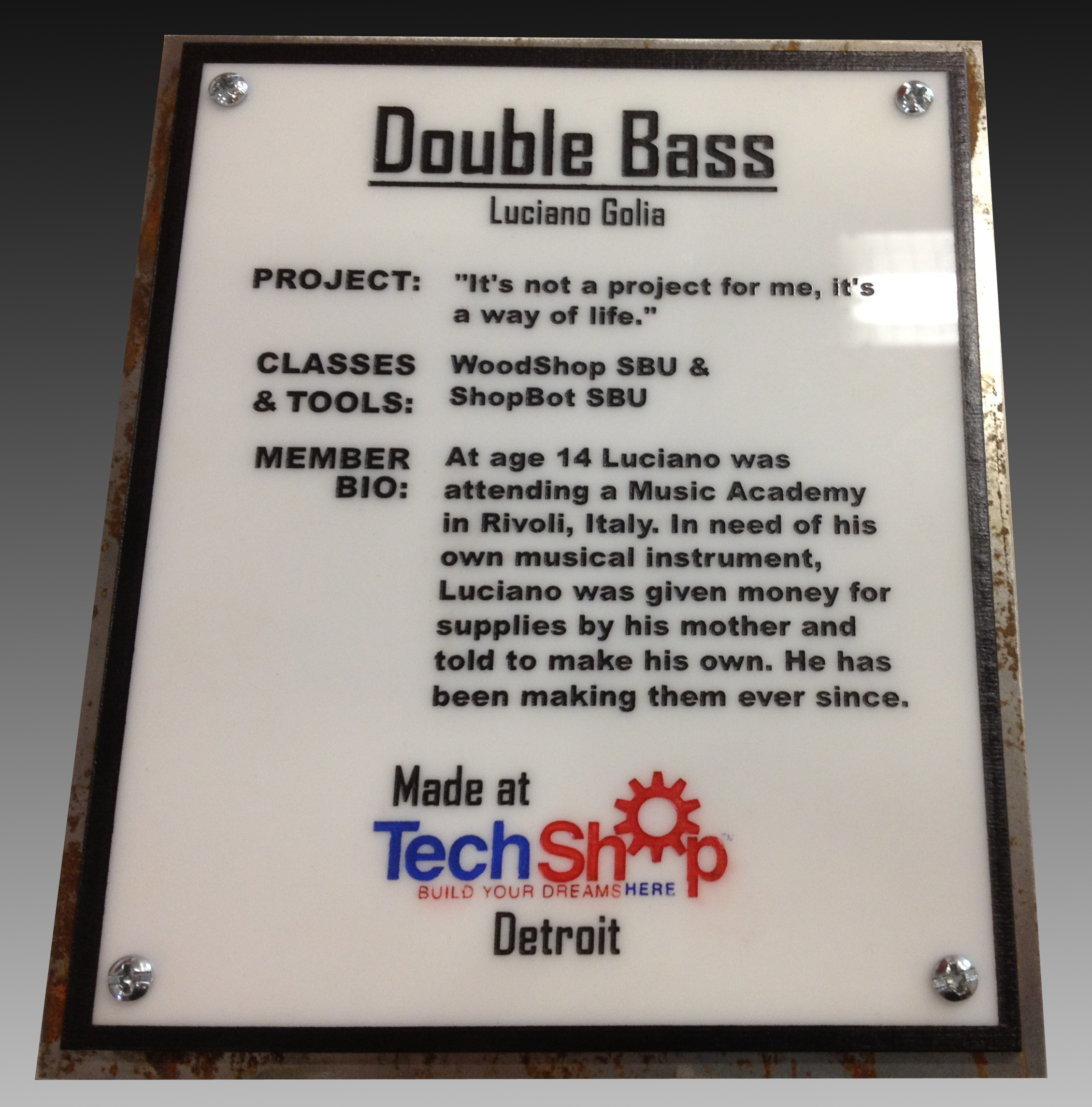

Making a Project Description Plaque

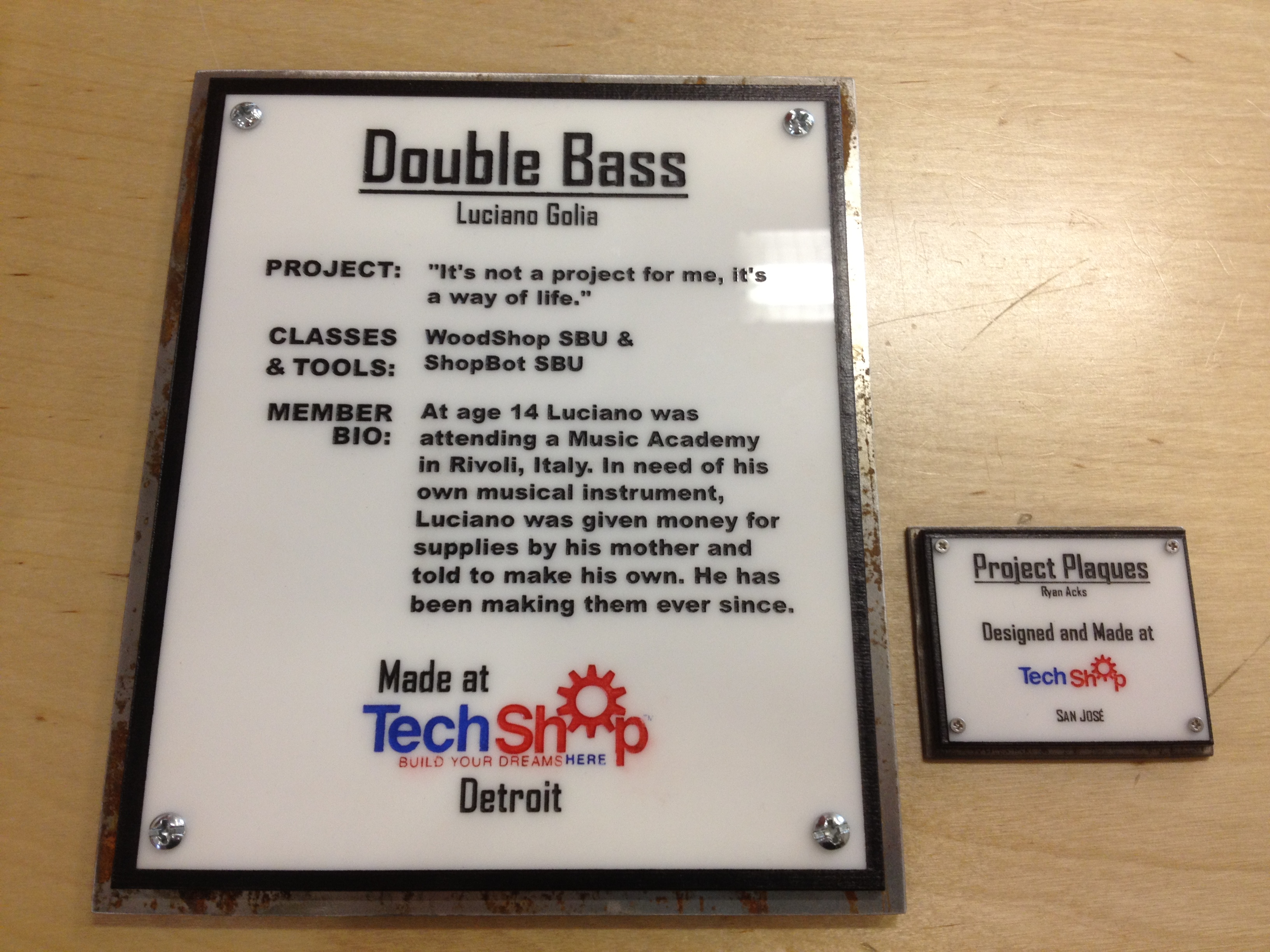

In this Instructable I will show my process in making plaques for

TechShop member's project pictures. We have MANY great members at

TechShop, who make incredible things, and we like to show them off. =)

These little plaques describe the project, a little bit about the

member, and the tools/classes they used to make their project.

Items Used:

Adobe Illustrator, VCarve Pro, FlowPath

Epilog Laser Cutter

Flowjet

1/8" acrylic sheets

1/16" mild steel

4 screws & 4 nuts

gouache artists paint (red & blue)

paint brush

black enamel spray paint

command strips

TechShop member's project pictures. We have MANY great members at

TechShop, who make incredible things, and we like to show them off. =)

These little plaques describe the project, a little bit about the

member, and the tools/classes they used to make their project.

Items Used:

Adobe Illustrator, VCarve Pro, FlowPath

Epilog Laser Cutter

Flowjet

1/8" acrylic sheets

1/16" mild steel

4 screws & 4 nuts

gouache artists paint (red & blue)

paint brush

black enamel spray paint

command strips

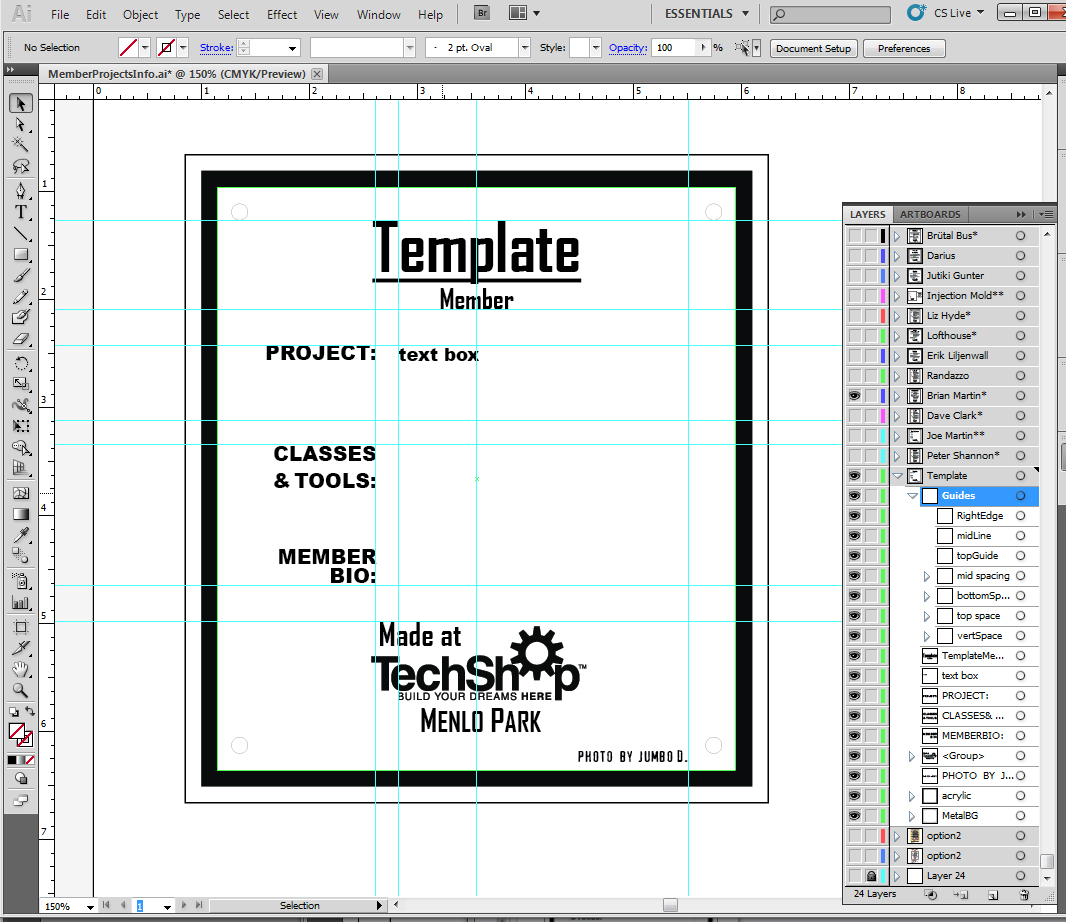

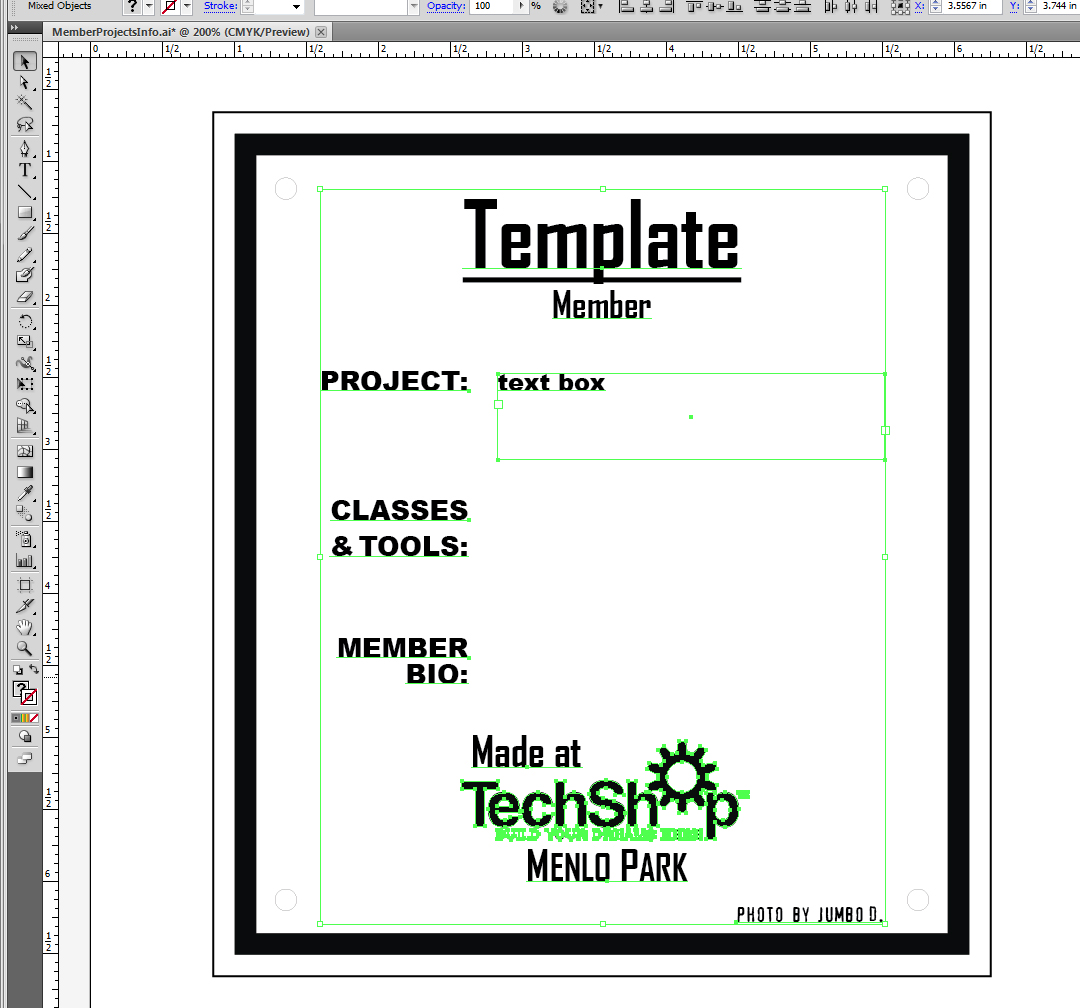

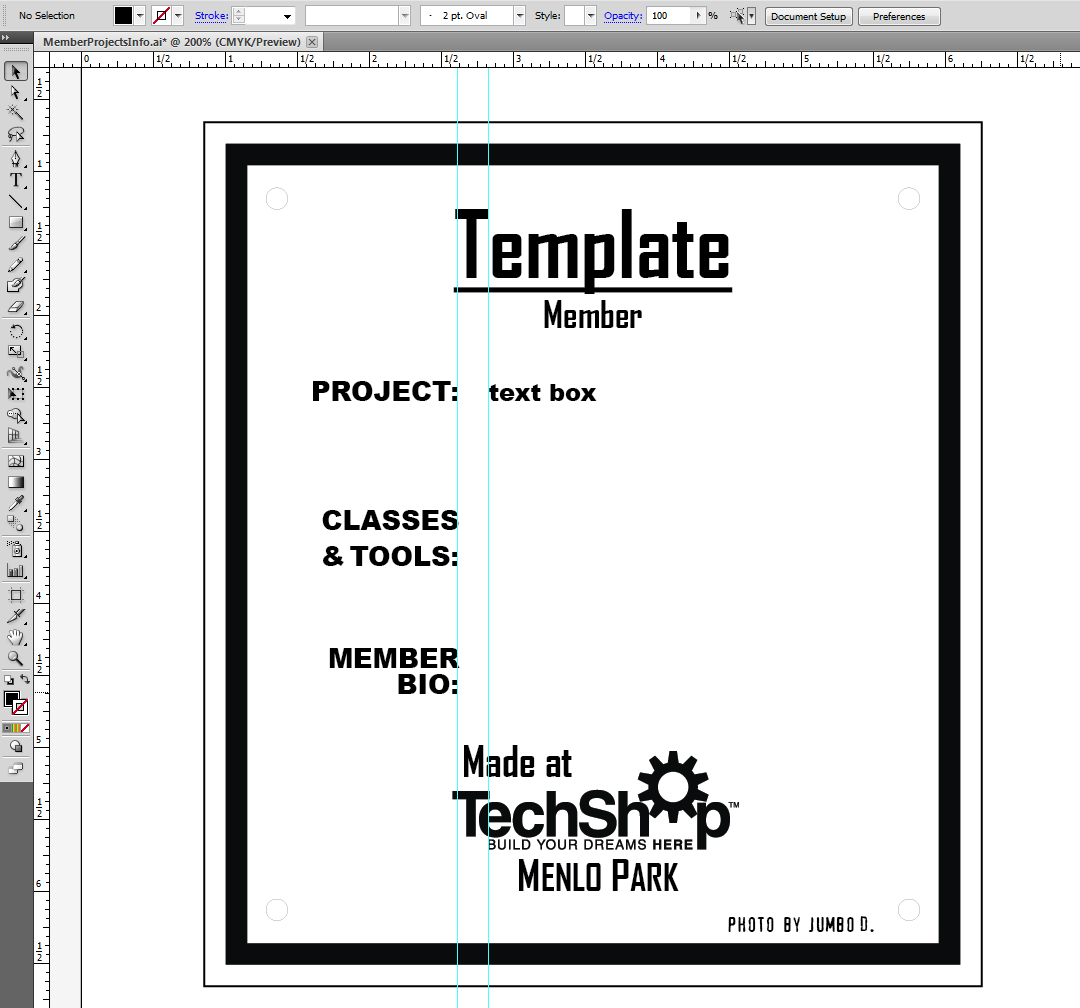

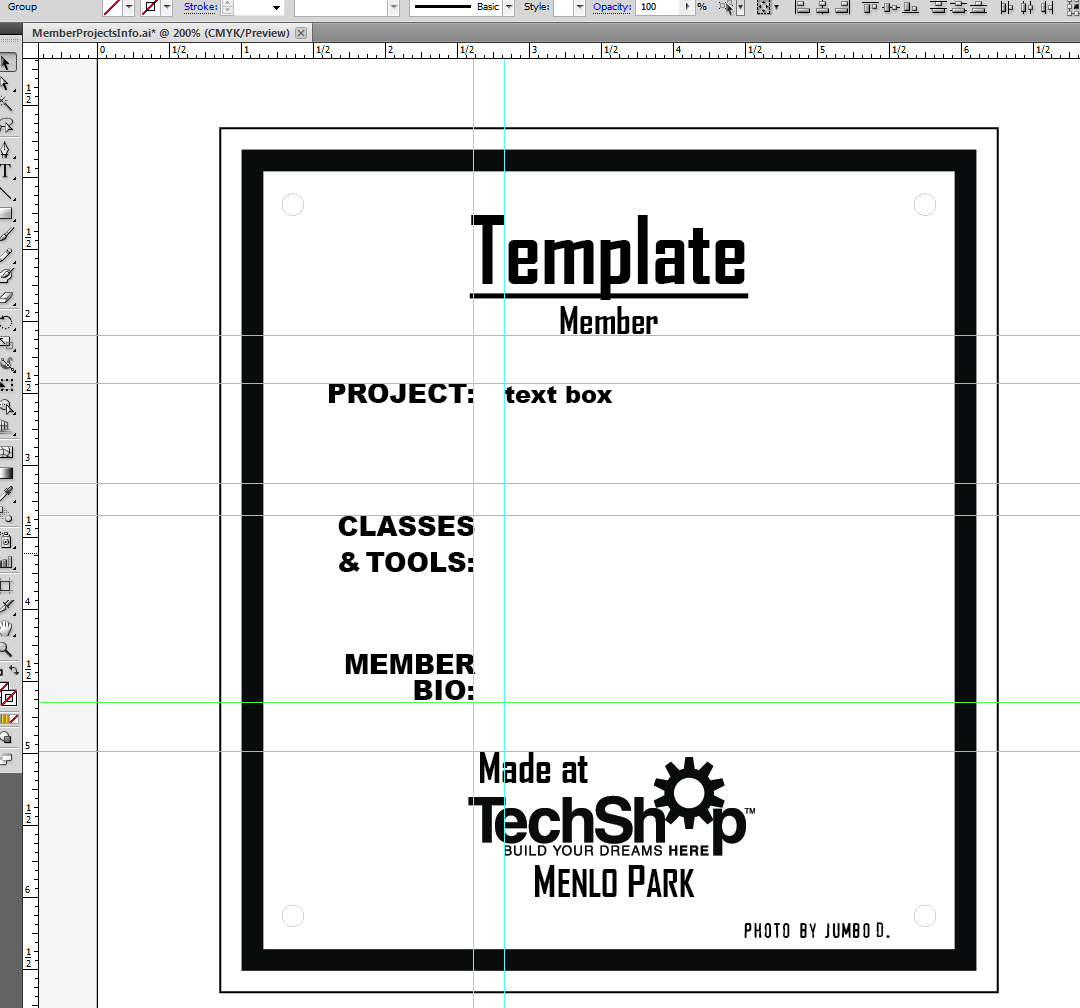

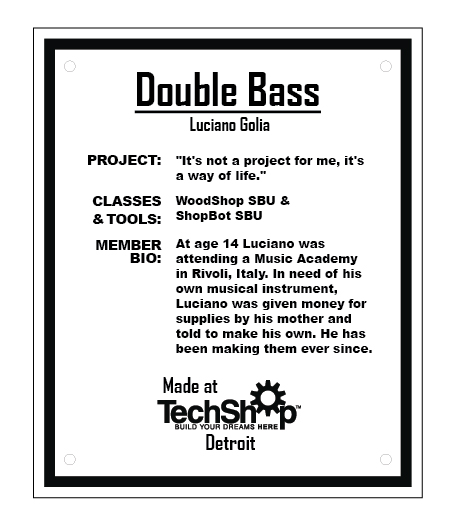

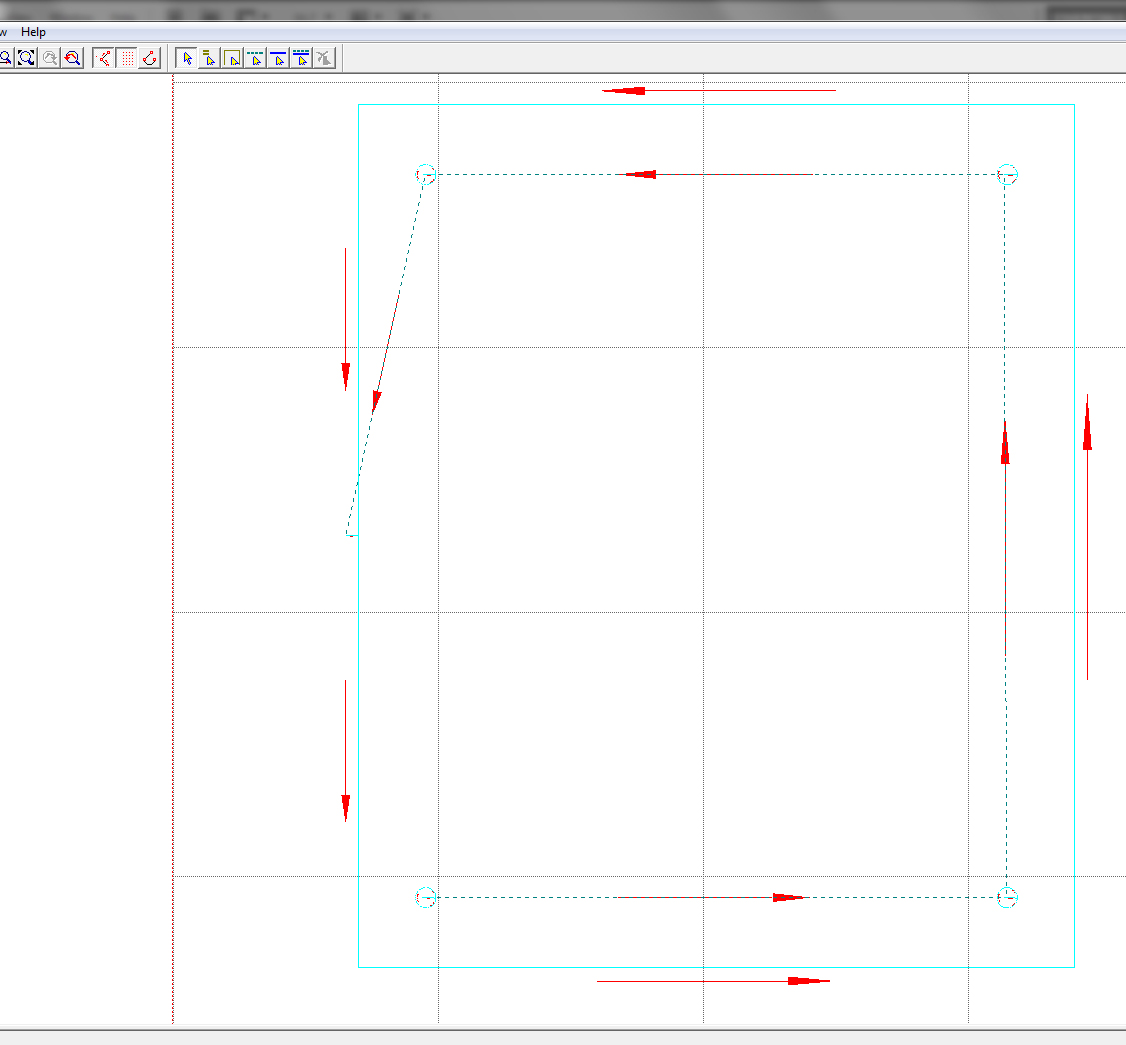

Design Template

First step in the process was to make a template file on Illustrator.

I had many plaques to make, so making a template was crucial to keep

everything consistent. Every plaque has a title, member name, project

description, classes&tools, and the TechShop logo (with location of

projection's creation). And most, but not all, have member bio and

photography credits. It's a simple design, but to keep everything

organized, I made a series of guide lines to ensure even spacing.

Each member and their project has different amount of text, so I made

the design adjustable in height. Just scale the height to fit the

text using the guides.

I had many plaques to make, so making a template was crucial to keep

everything consistent. Every plaque has a title, member name, project

description, classes&tools, and the TechShop logo (with location of

projection's creation). And most, but not all, have member bio and

photography credits. It's a simple design, but to keep everything

organized, I made a series of guide lines to ensure even spacing.

Each member and their project has different amount of text, so I made

the design adjustable in height. Just scale the height to fit the

text using the guides.

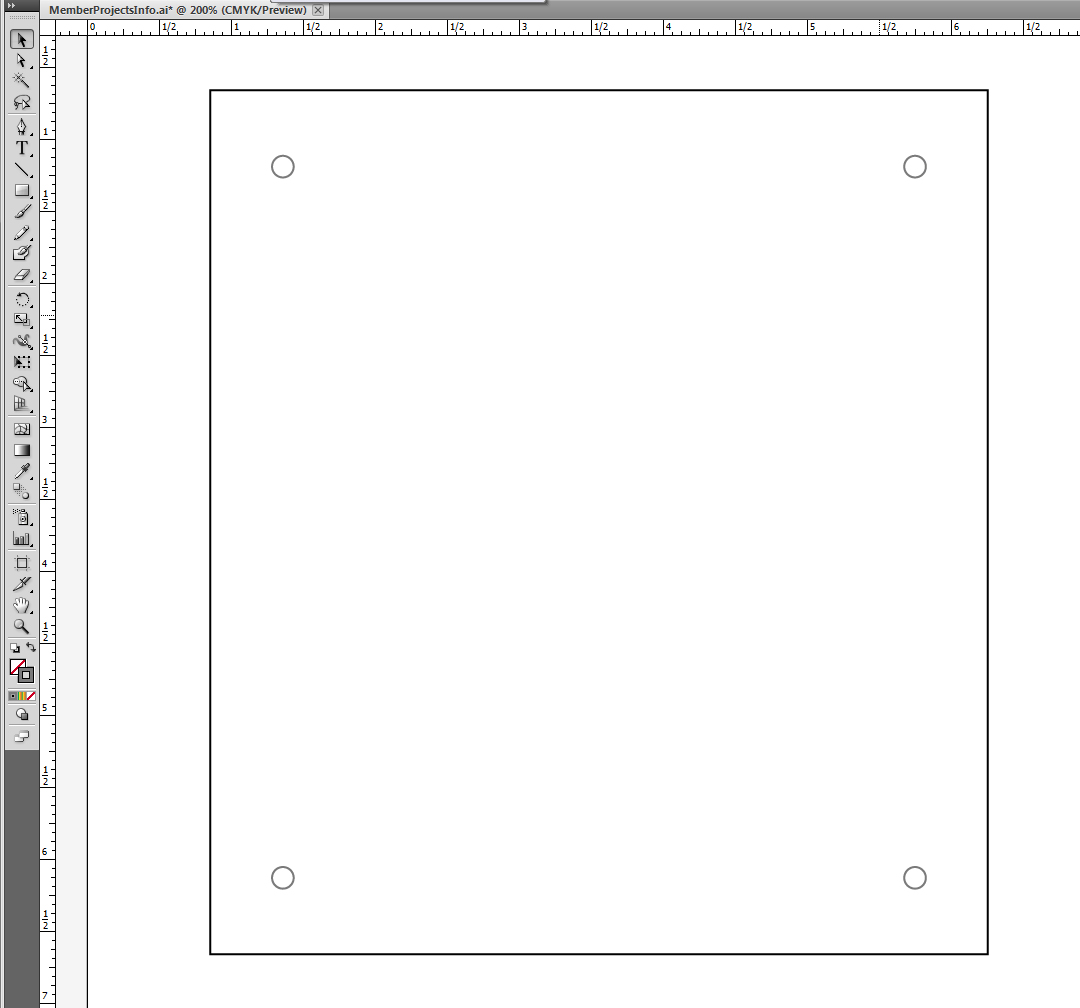

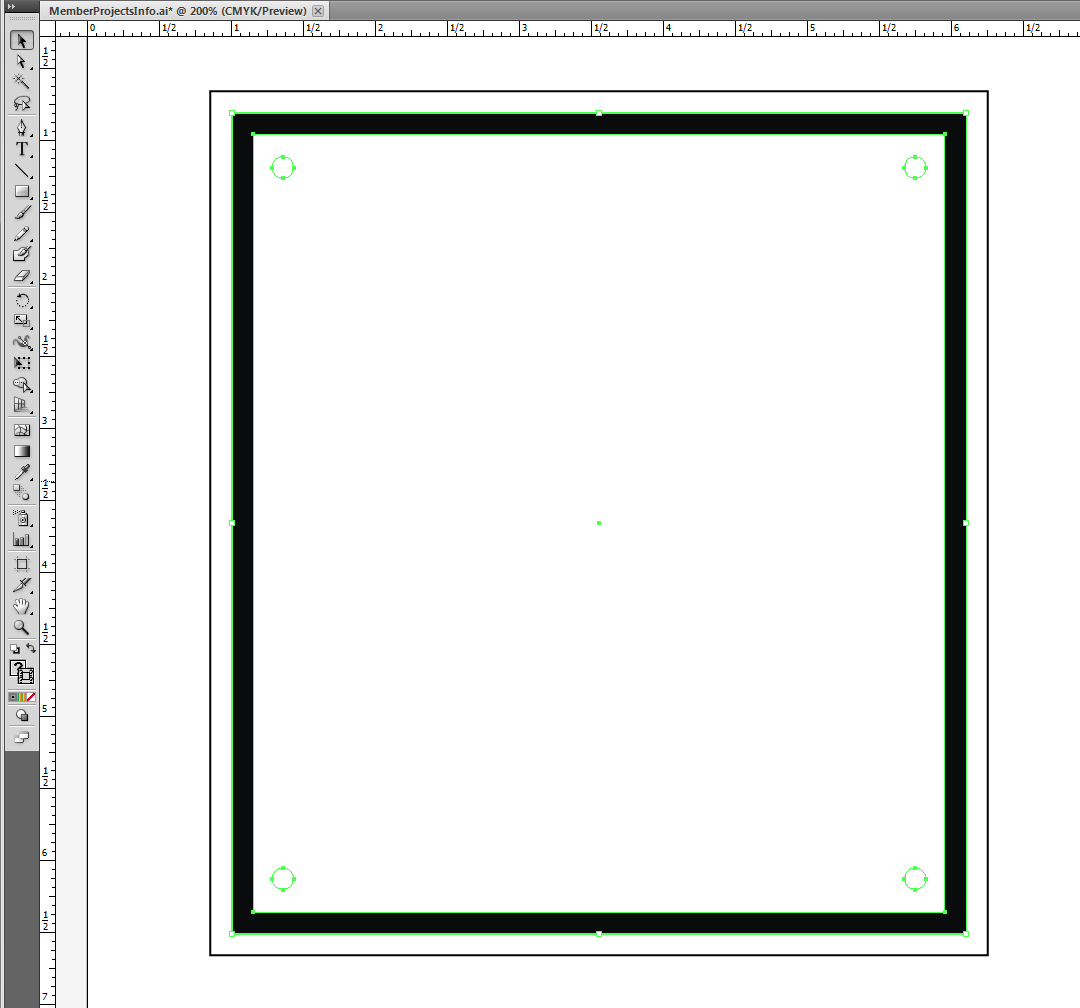

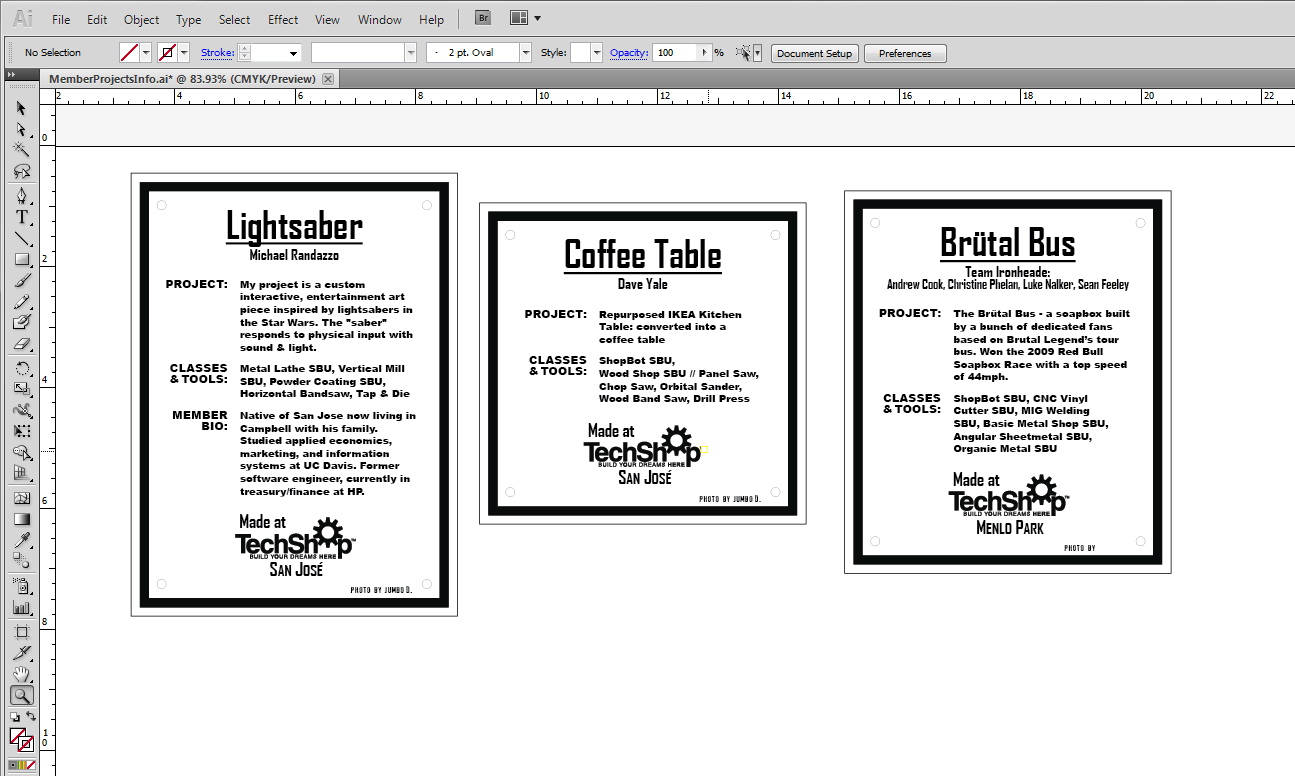

Plug-In the Data

After the template was made I simply added in all the text, did a little

adjusting on the height of the overall plaque, and then it's ready to be

laser engraved and cut. I also made a steel border for the plaques. Now

that my plaque files are completed, I need to use my vectors to create

an .ord file to use on the waterjet.

adjusting on the height of the overall plaque, and then it's ready to be

laser engraved and cut. I also made a steel border for the plaques. Now

that my plaque files are completed, I need to use my vectors to create

an .ord file to use on the waterjet.

FlowPath the Steel Border

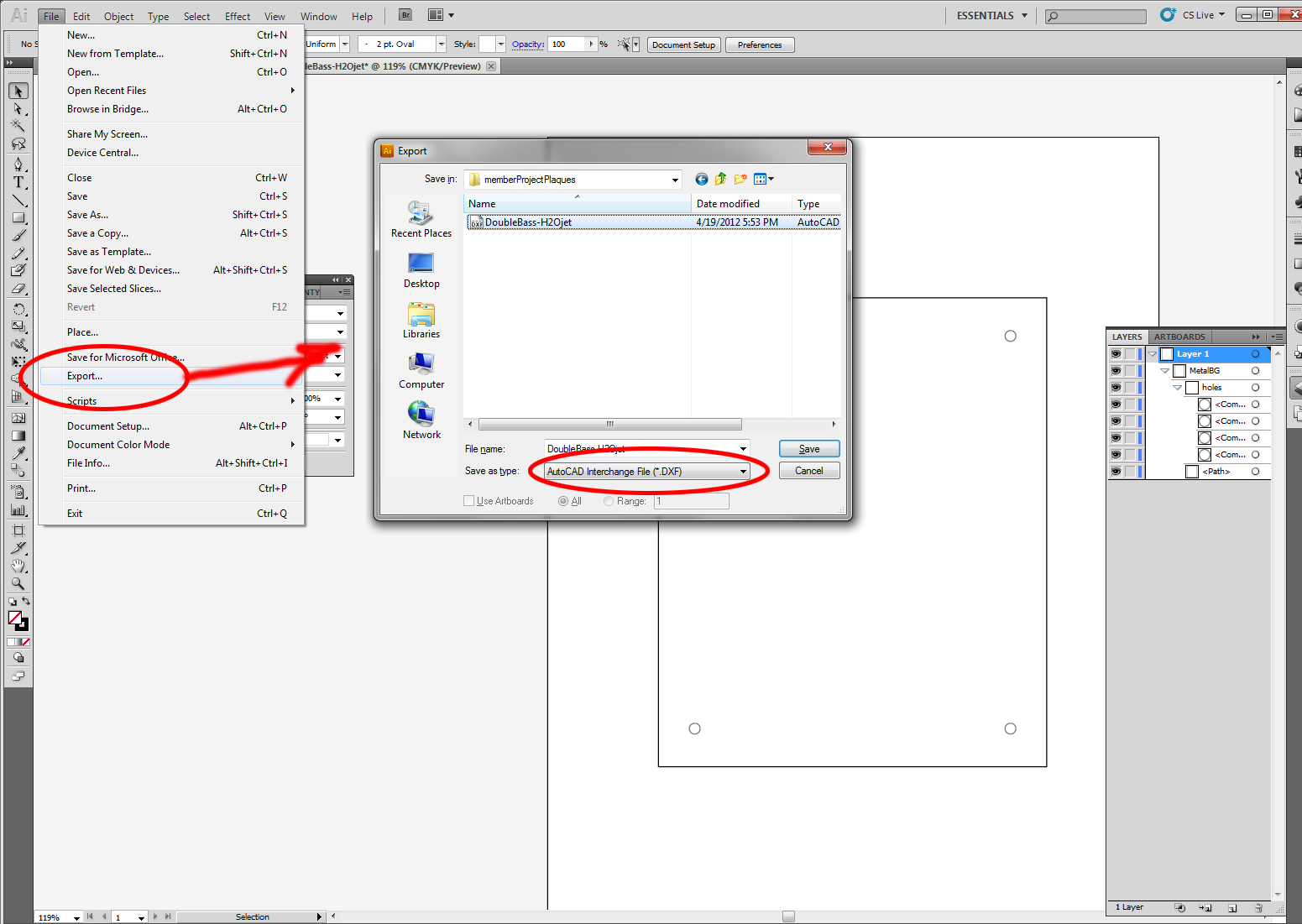

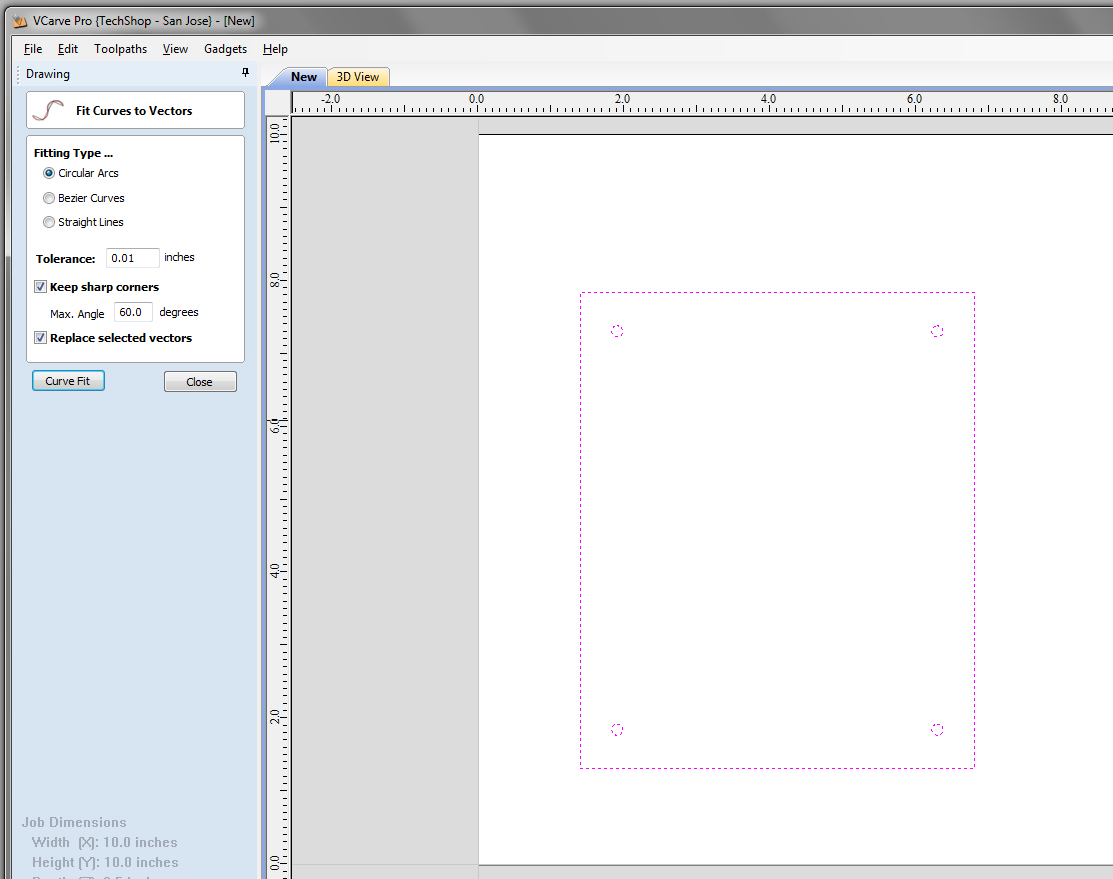

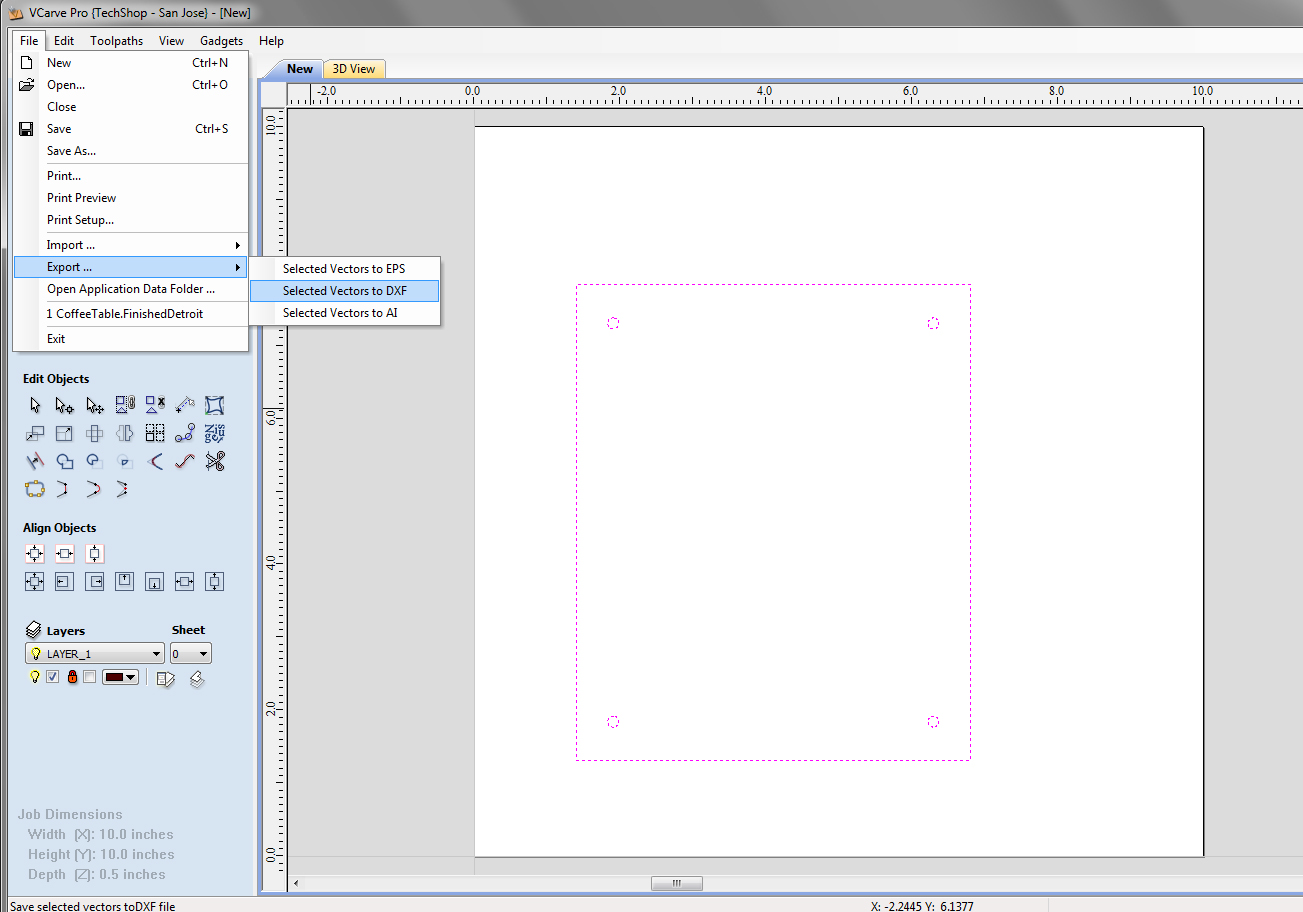

Now to get the vectors from Illustrator into FlowPath, you need to export

the outlines for the steel border (with the holes) as a .dxf file.

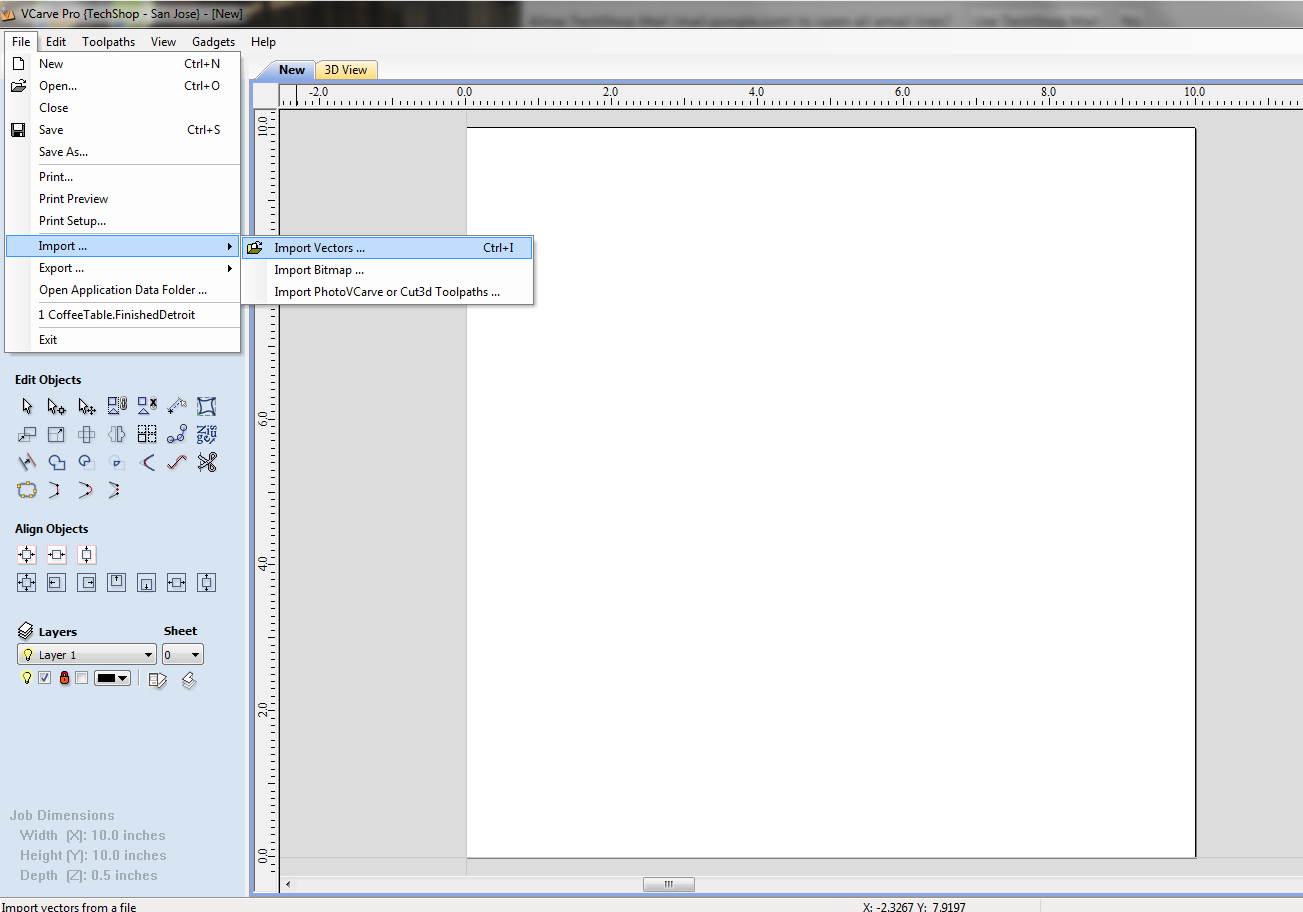

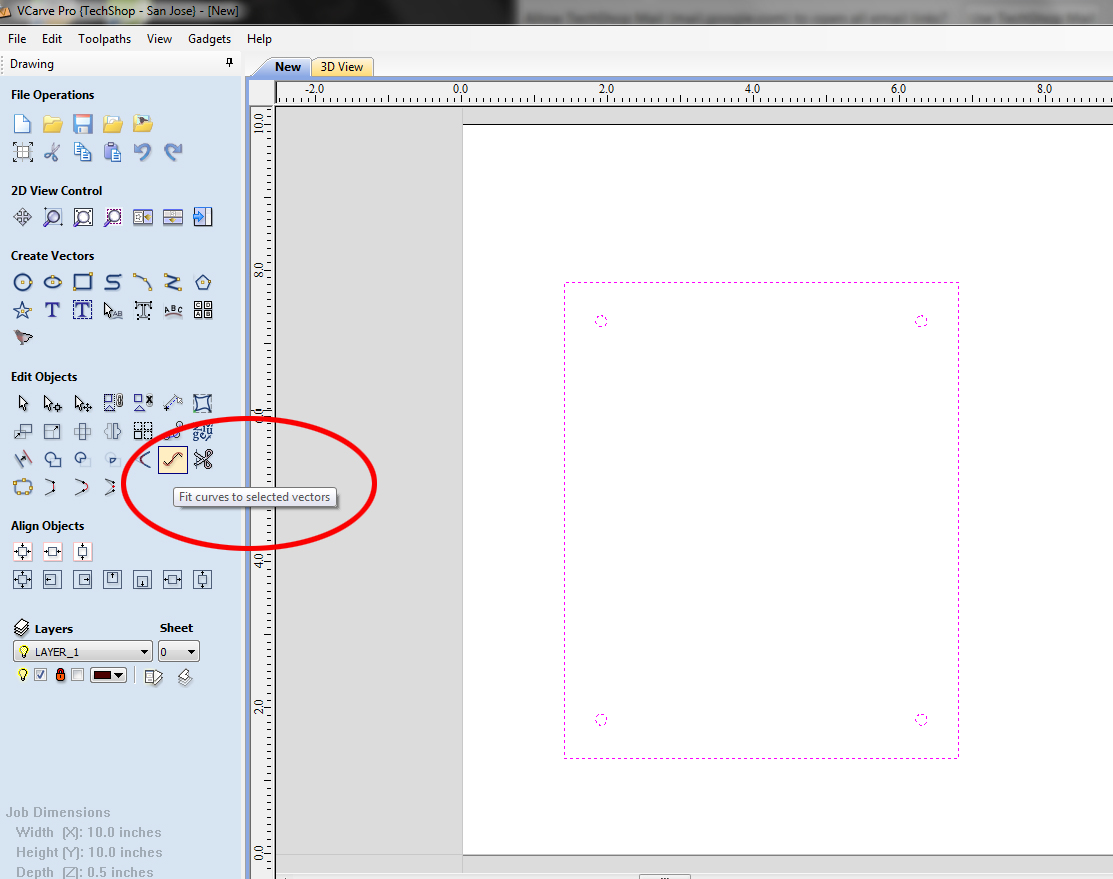

Note: Illustrator does not usually save very good .dxf files. You can get

around this by importing your vectors into VCarve Pro, use the Fit curves

to selected vectors tool (to clean up the curves) and then export .dxf file.

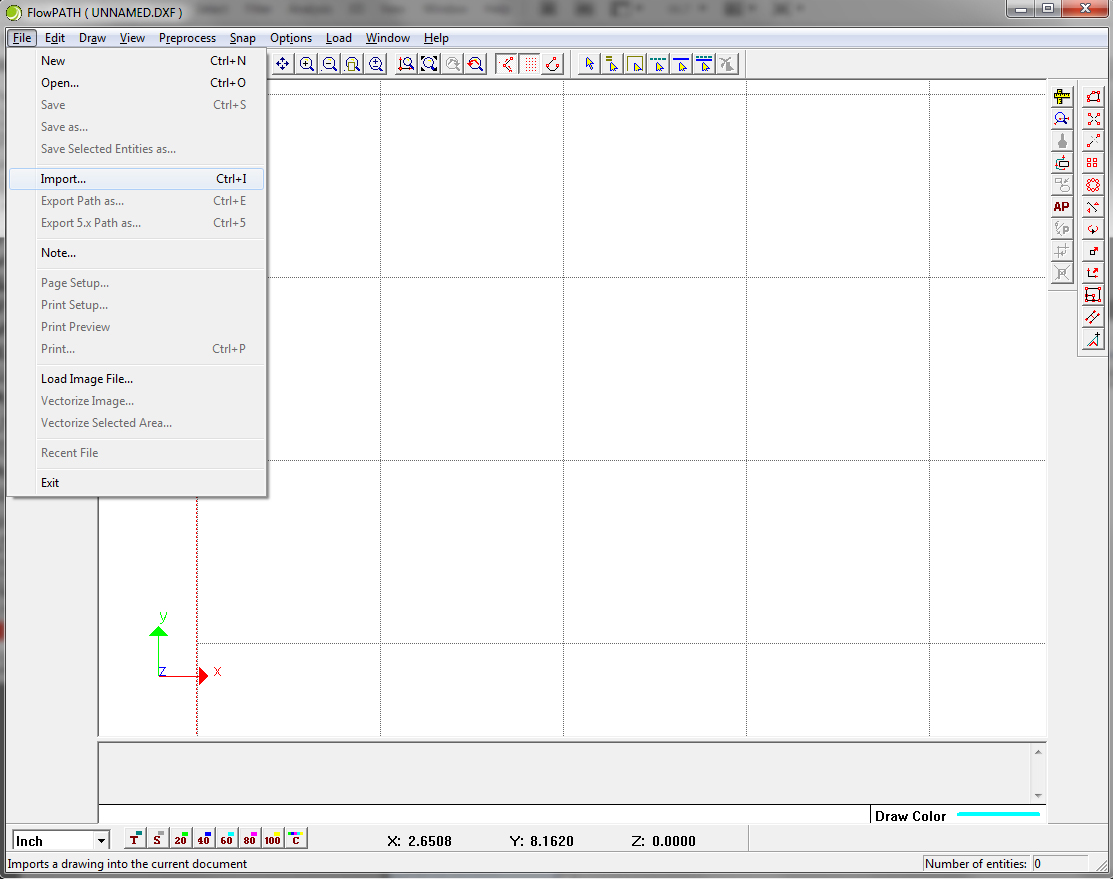

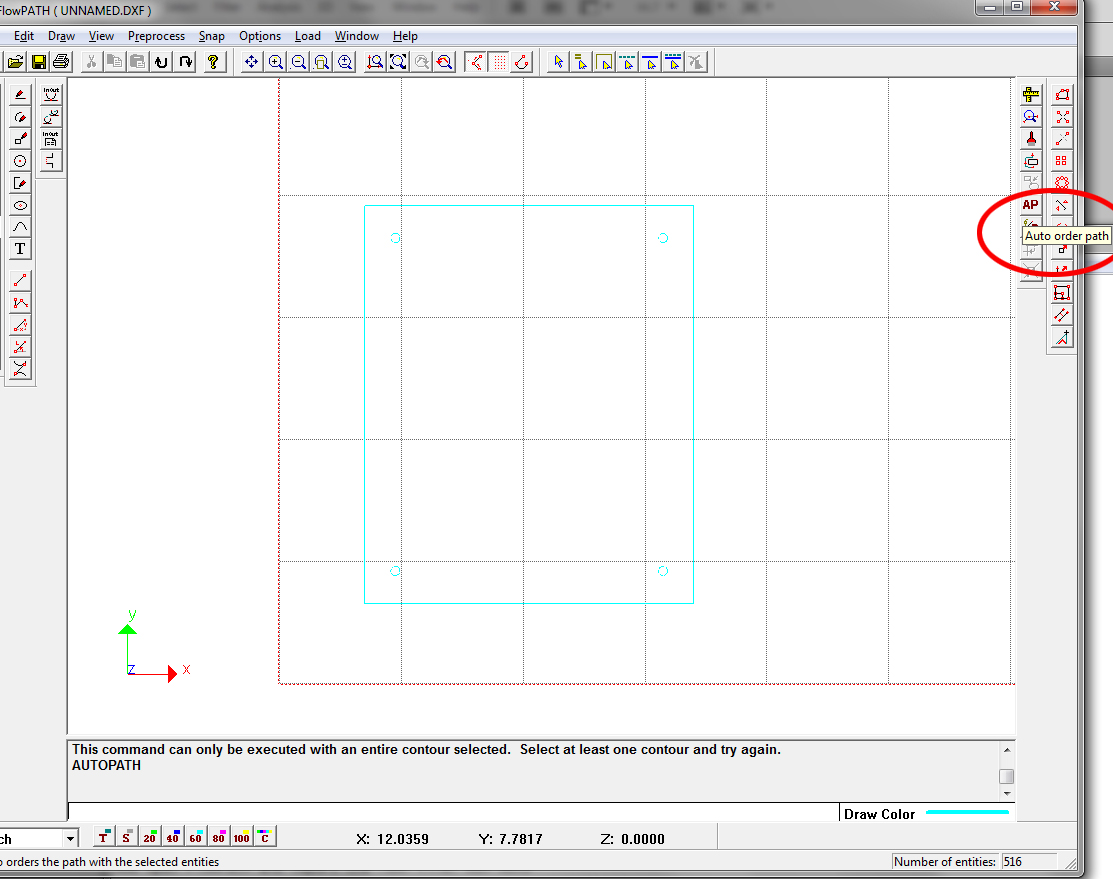

Now open FlowPath and import the .dxf file. Run Auto Path order, select all

vectors and hit Enter. Do a quick inspection to make sure everything will

be cutting on the correct side of the vector. Then Export Path as a

.ord file, and it is ready to be cut on the waterjet!

the outlines for the steel border (with the holes) as a .dxf file.

Note: Illustrator does not usually save very good .dxf files. You can get

around this by importing your vectors into VCarve Pro, use the Fit curves

to selected vectors tool (to clean up the curves) and then export .dxf file.

Now open FlowPath and import the .dxf file. Run Auto Path order, select all

vectors and hit Enter. Do a quick inspection to make sure everything will

be cutting on the correct side of the vector. Then Export Path as a

.ord file, and it is ready to be cut on the waterjet!

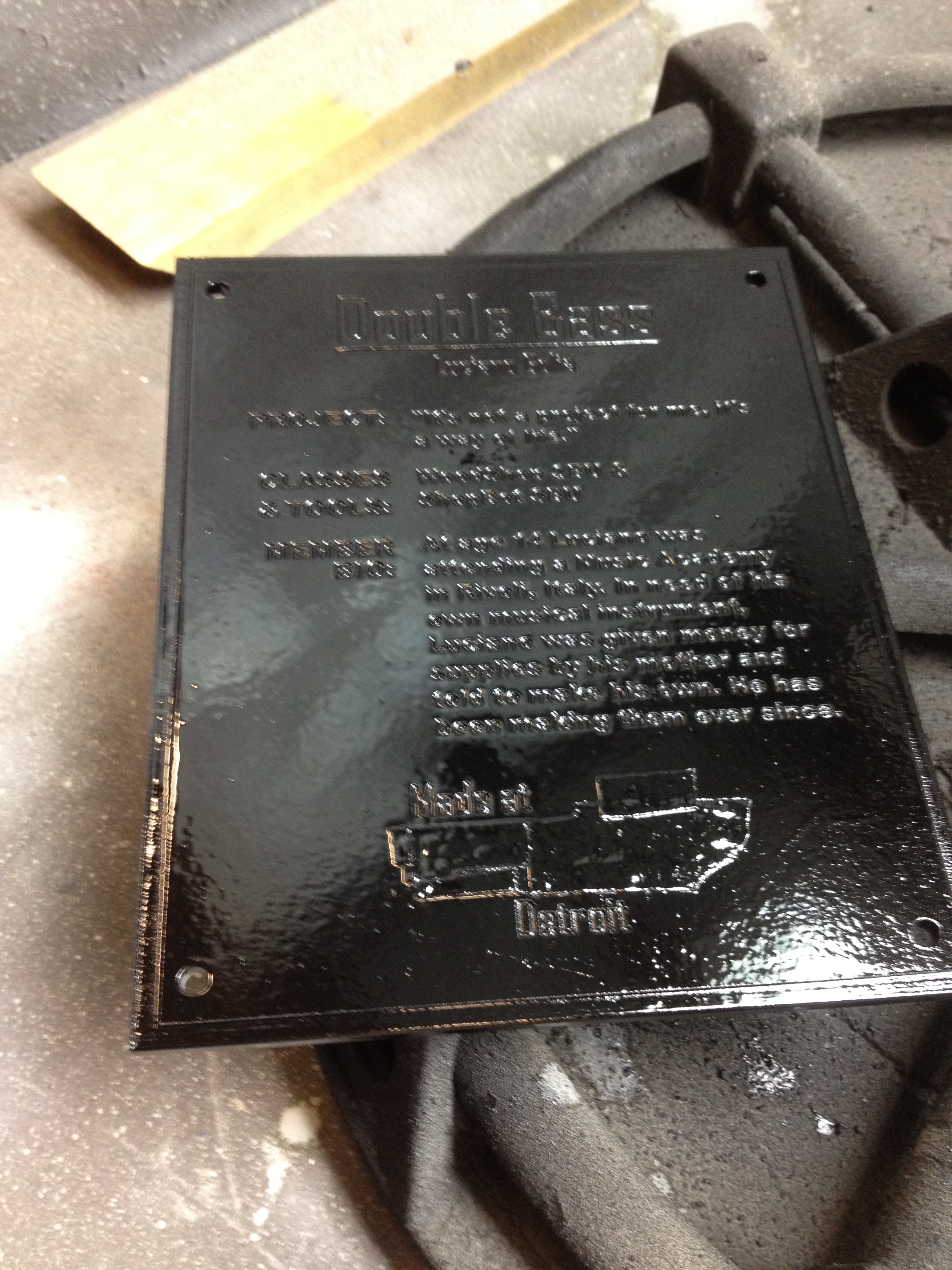

Cut Out the Steel Border

Open the .ord file with FlowCut, setup your material, and watch as the

amazing FlowJet cuts out the steel border for the plaque.

amazing FlowJet cuts out the steel border for the plaque.

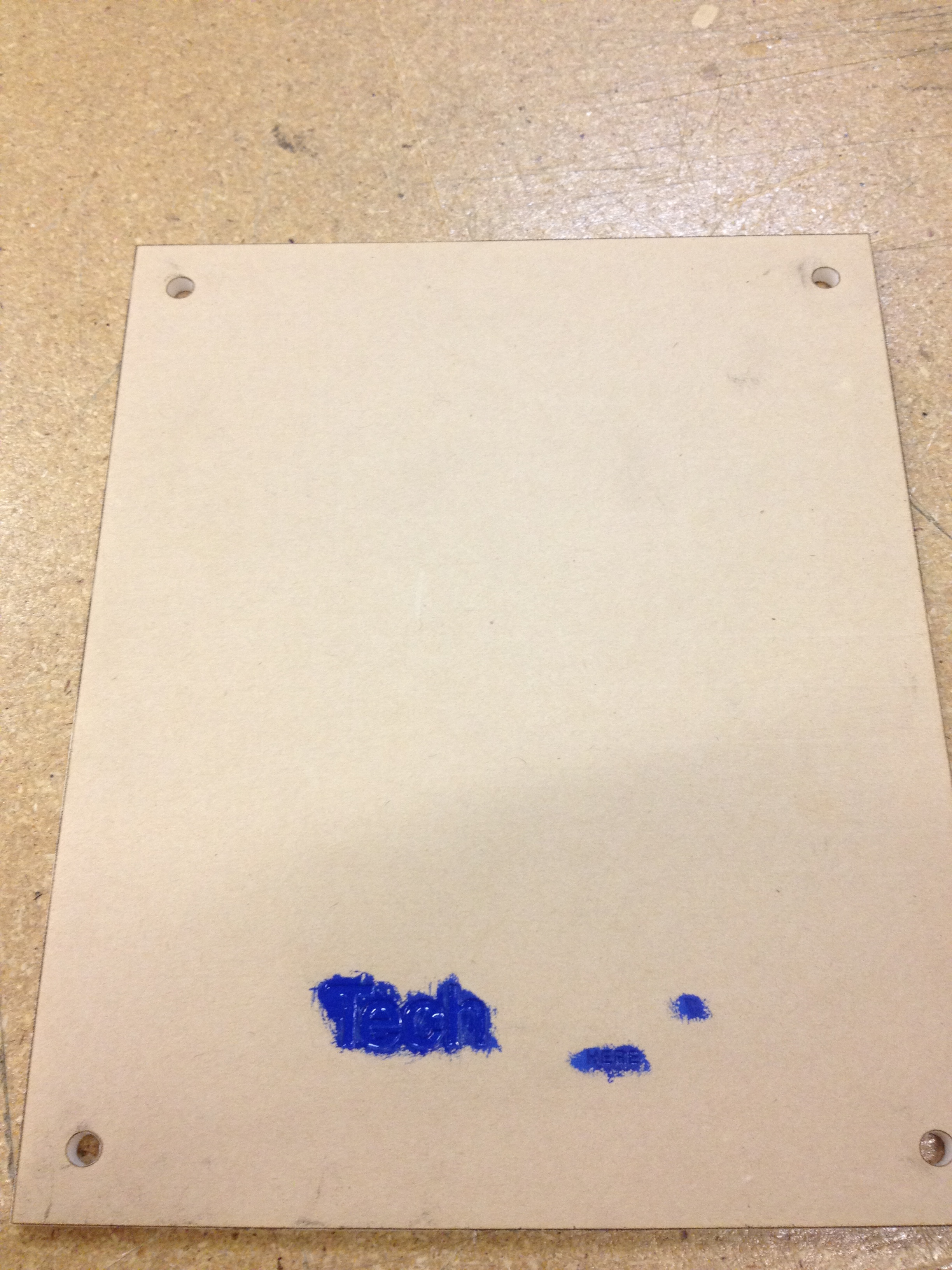

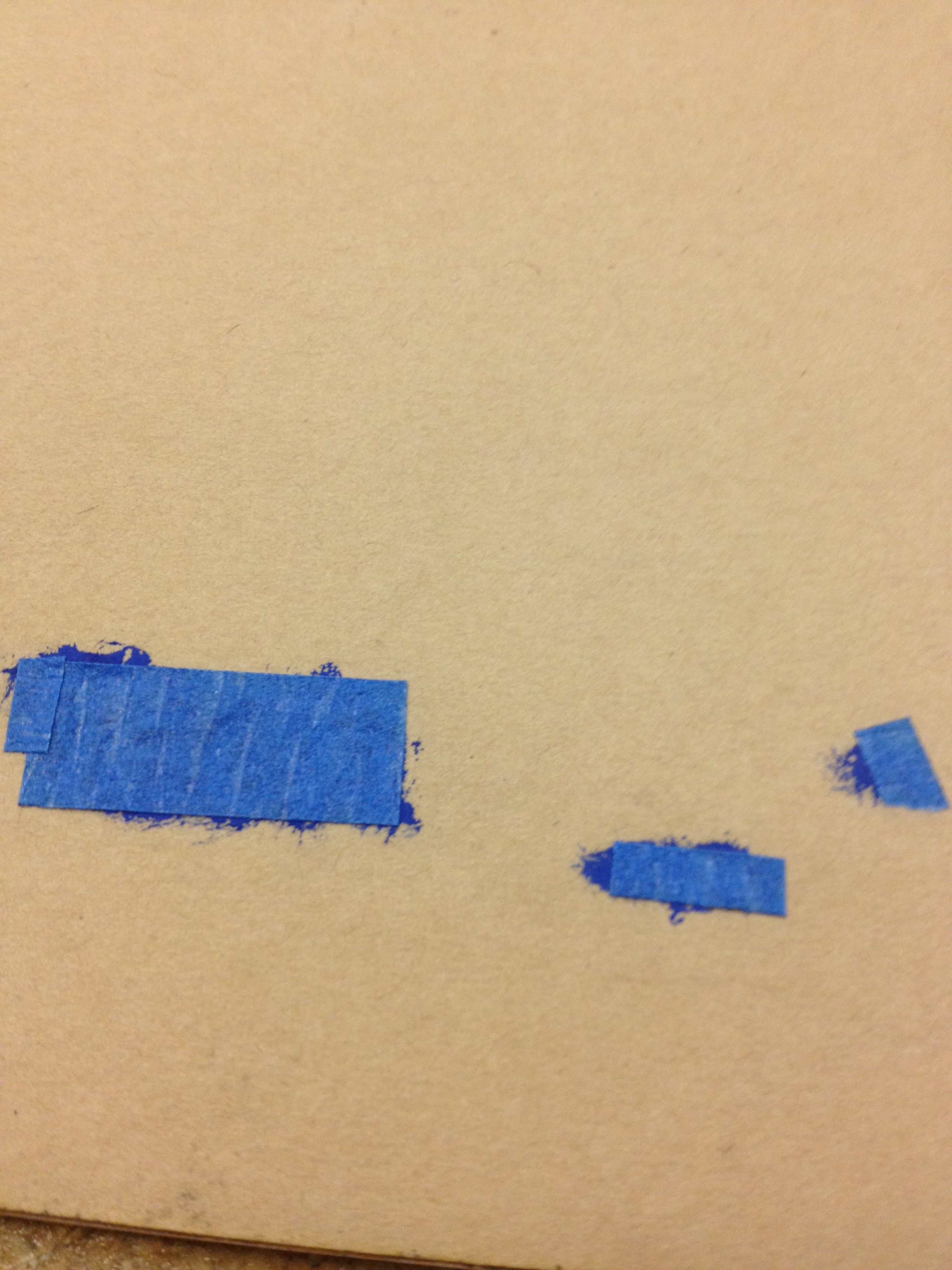

Acrylic, Paint, and Lasers

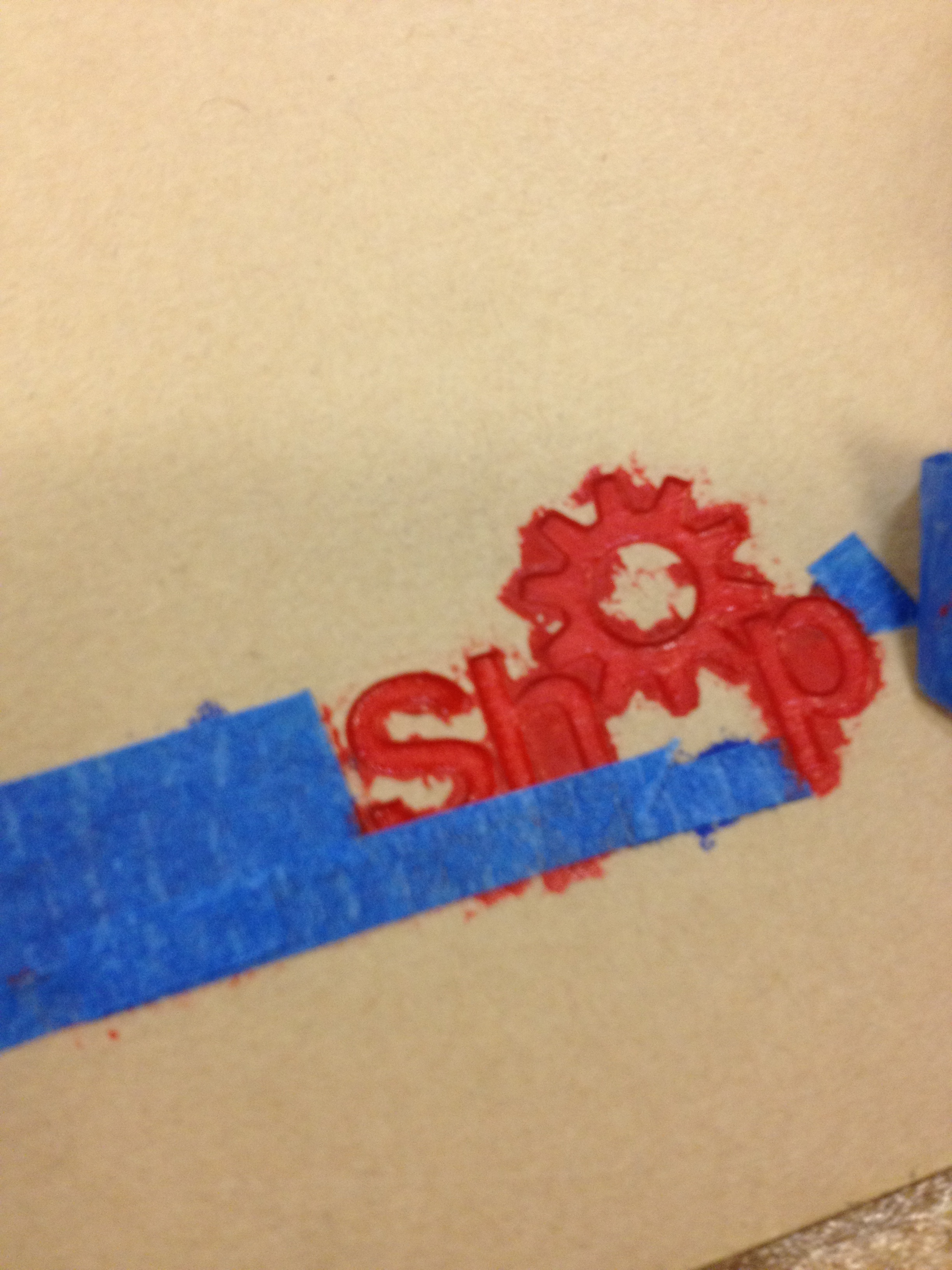

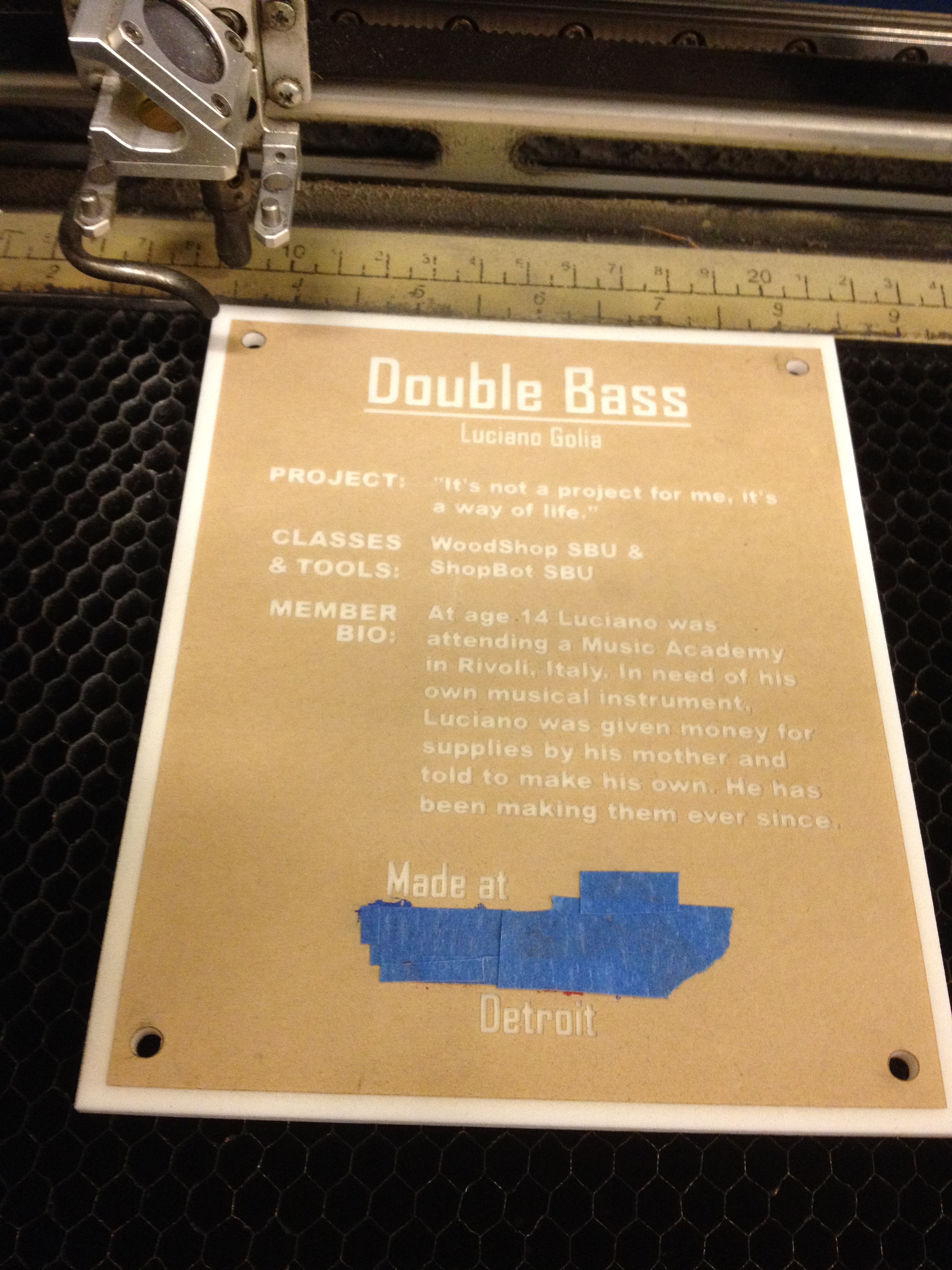

Now to make the actual acrylic plaque, I take my project plaque file and

my acrylic (with the protective paper covering still on the surface) to the

laser cutter machine. First, I cut out the plaque shape as well as the

mounting holes, and etch the blue parts of the TechShop logo. When that is

done I paint the etched parts using guache paint. I chose gouache for its

fast drying time and uniform opaque color. Once the paint dries, I use some

painter's tape to mask off the painted area. Then I put the plaque back on the

laser and etch the red parts of the TechShop logo. Again, paint and mask. Once

the logo has been fully painted, and masked, I again put it back into the laser

to etch the remaining black letters and border. Once the etching is completed

I use a black enamel spray paint to fill in the rest of the plaque. When the

paint has dried, peel off the protective paper cover and reveal all the painted

lettering.

my acrylic (with the protective paper covering still on the surface) to the

laser cutter machine. First, I cut out the plaque shape as well as the

mounting holes, and etch the blue parts of the TechShop logo. When that is

done I paint the etched parts using guache paint. I chose gouache for its

fast drying time and uniform opaque color. Once the paint dries, I use some

painter's tape to mask off the painted area. Then I put the plaque back on the

laser and etch the red parts of the TechShop logo. Again, paint and mask. Once

the logo has been fully painted, and masked, I again put it back into the laser

to etch the remaining black letters and border. Once the etching is completed

I use a black enamel spray paint to fill in the rest of the plaque. When the

paint has dried, peel off the protective paper cover and reveal all the painted

lettering.

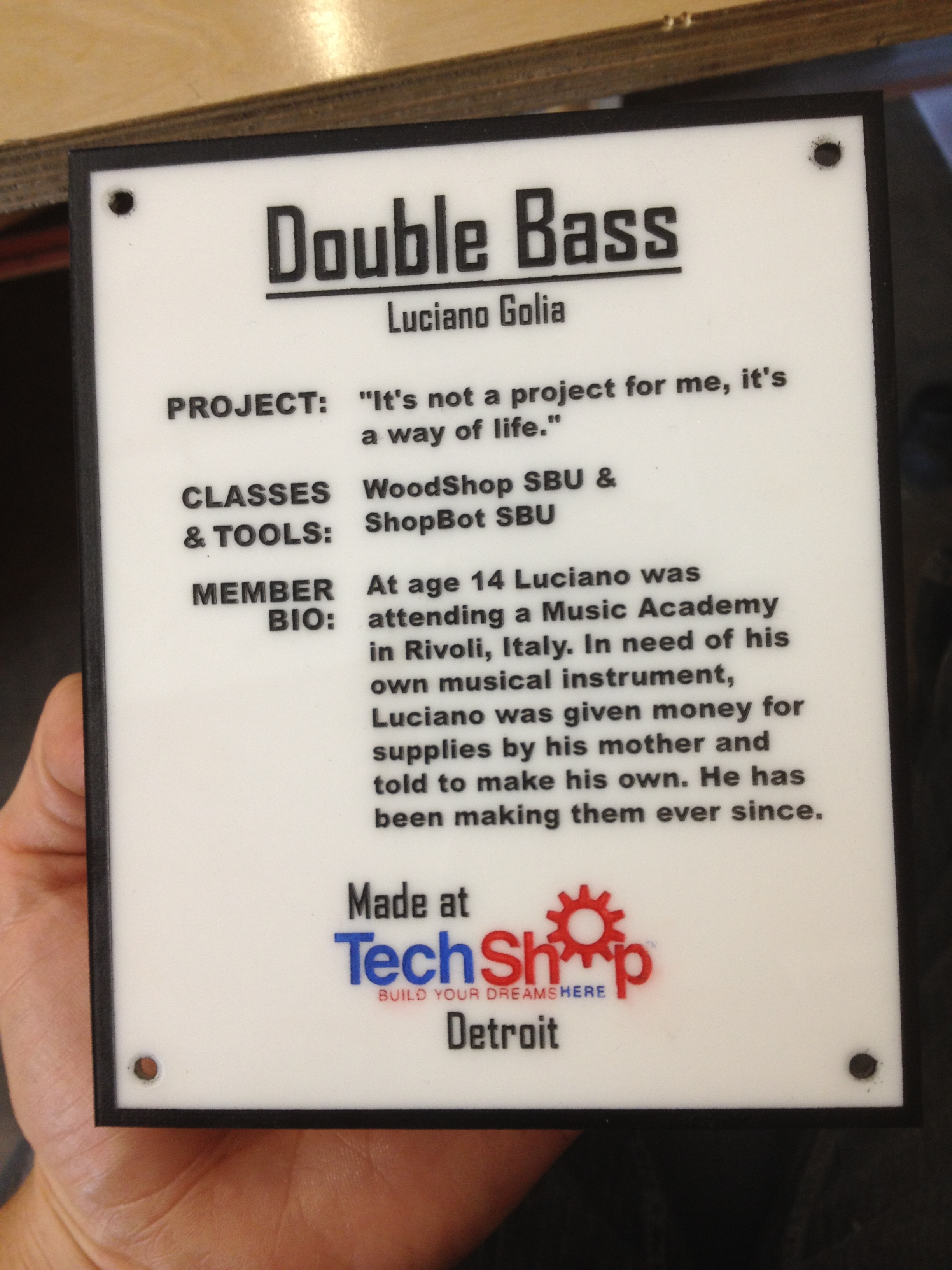

Assembly

The painted plaque is finished and so is the steel border, the only thing left

to do is assemble. Take your nuts and bolts and screw the plaque onto the border.

To mount flush to the wall you may have to grind down the back of the screws,

depending on whether they stick out past the nuts or not. Place a command strip

on the back of the plaque and on the wall to be hung, and project completed.

to do is assemble. Take your nuts and bolts and screw the plaque onto the border.

To mount flush to the wall you may have to grind down the back of the screws,

depending on whether they stick out past the nuts or not. Place a command strip

on the back of the plaque and on the wall to be hung, and project completed.