Lasercut Lamp

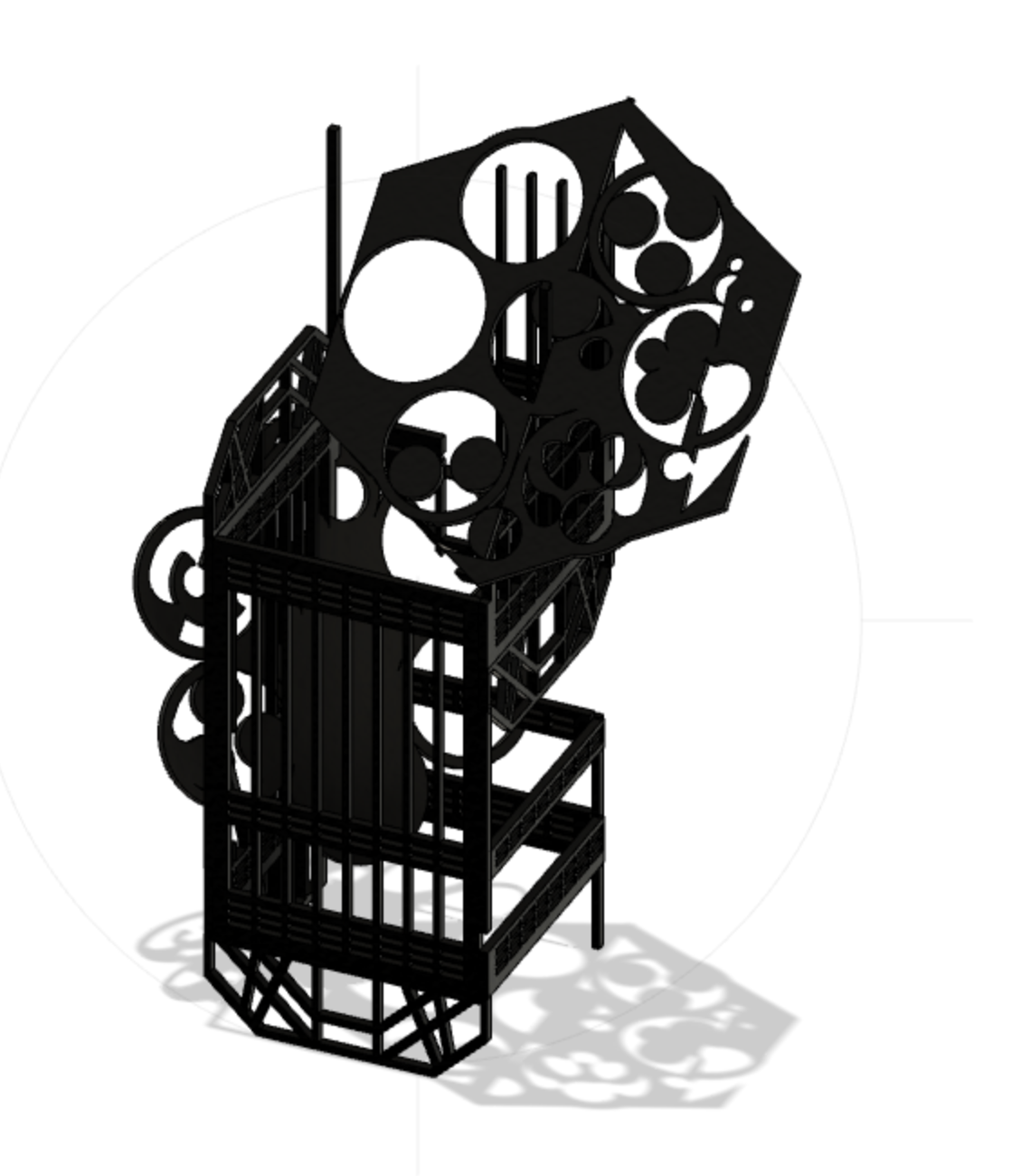

This lamp can be easily modified from a simple Fusion 360 template, and exported to be cut laser cut out of any material. As an industrial design student at the Rochester Institute of Technology, this project helped me get much more comfortable in turning a digital Fusion360 design into a laser cut reality. I developed my skills in model making, especially focusing on joints between components. I'd never used Fusion360's "arrange" feature before, but it was perfect for this project. I plan to use arrange, as well as the other skills I learned in sketching and assembly, to create many more projects in the future, and develop my skills in modeling overall!

Supplies

-access to Fusion 360

-MDF or similar material with ability to be laser cut (i.e. plywood, acrylic)

-tea light

-paint, tracing paper, glue, x-acto knife (all optional)

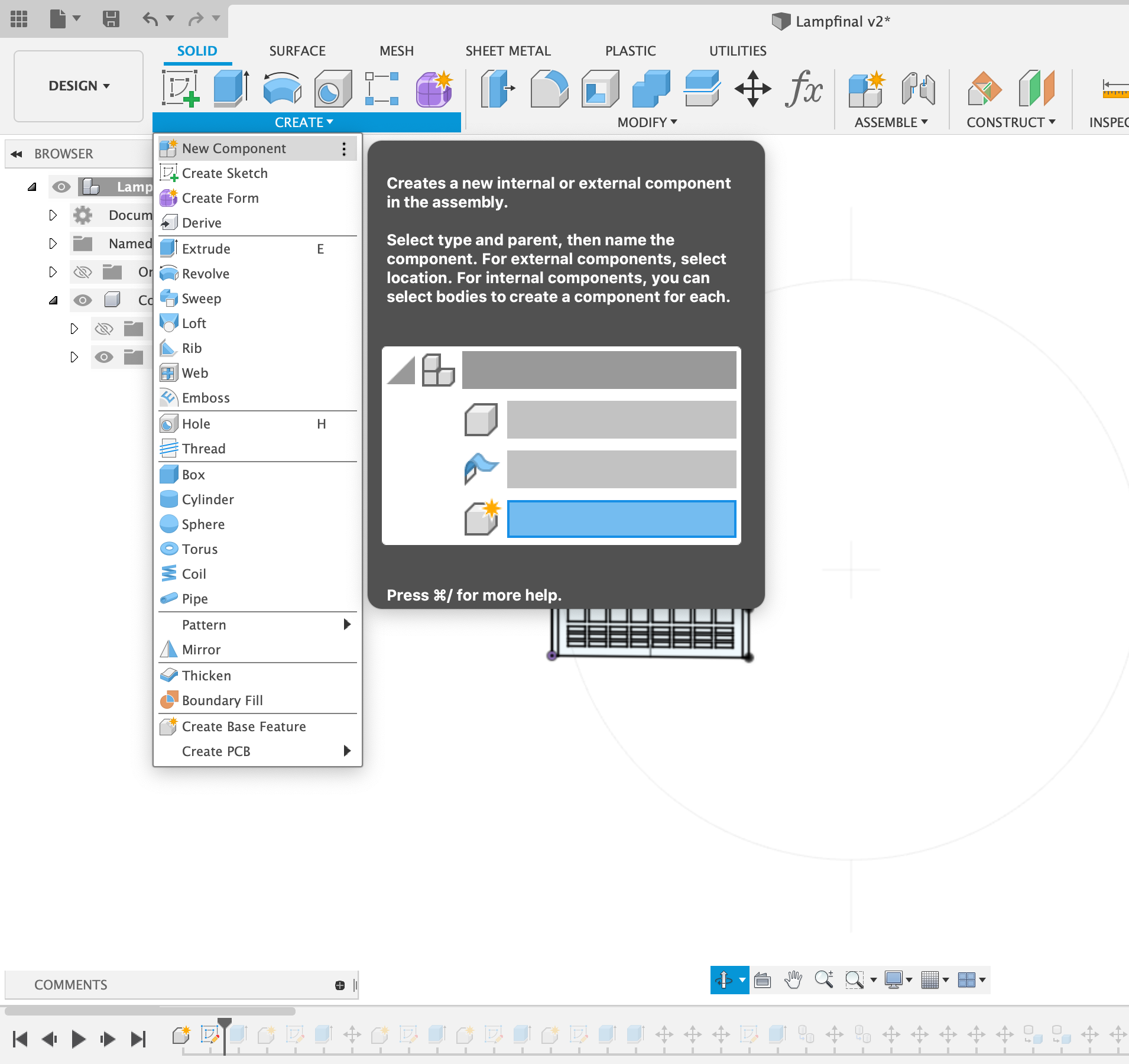

Set Up Your Fusion360 File

In a new design, create a new component. This will allow you to start designing the faces of your lamp.

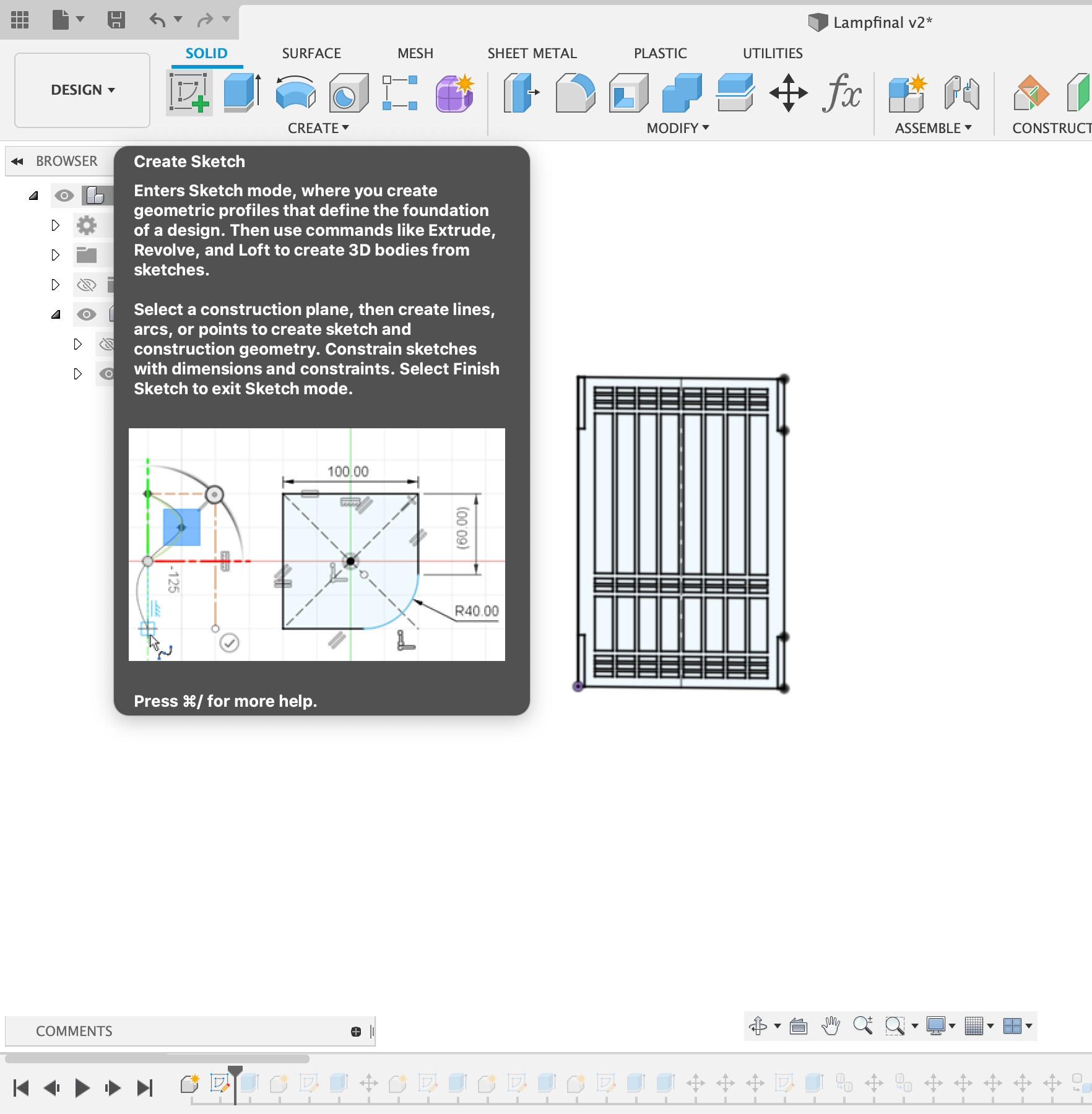

Create Sketch 1

Under the create tab, click create sketch, and choose the vertical y plane. This will orient your sketch vertically in Fusion360's grid. Now you can use all the drawing tools under the create tab to outline the design of one face of your lamp. Make sure the dimensions are appropriate for your intended material.

Also begin to plan how your faces will attach; the easiest way is to create a four-sided lamp with faces that fit together like puzzle pieces. For example, the first face of my lamp has four cut-outs for the two perpendicular faces to extend into. I made these cut-outs the width of my material so that the fit would be snug. Similar attachments are possible for lamps that follow other geometries, just make sure you are accounting for the properties of your material and including appropriate support.

When your sketch looks good, click the green check mark on the top right to finish the sketch and return to your overall design.

Extrude Your First Face

Under the create tab, click the second button labeled "Extrude". This will allow your sketch to become a 3-dimensional form. Make sure you deselect any parts of this face that you want to leave as cutouts, and extrude the rest of it to the thickness of your material.

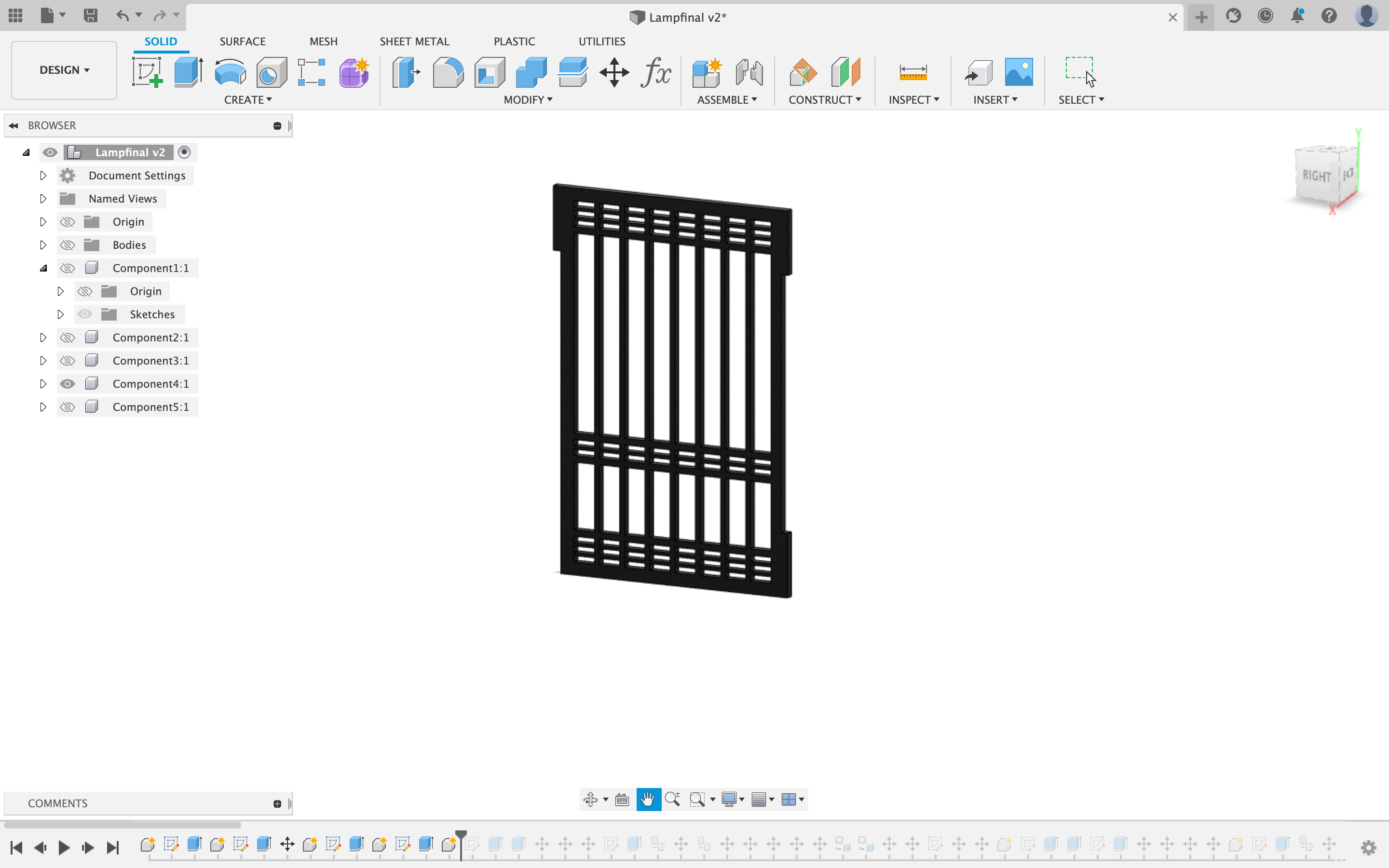

Design Other Faces and Attachments

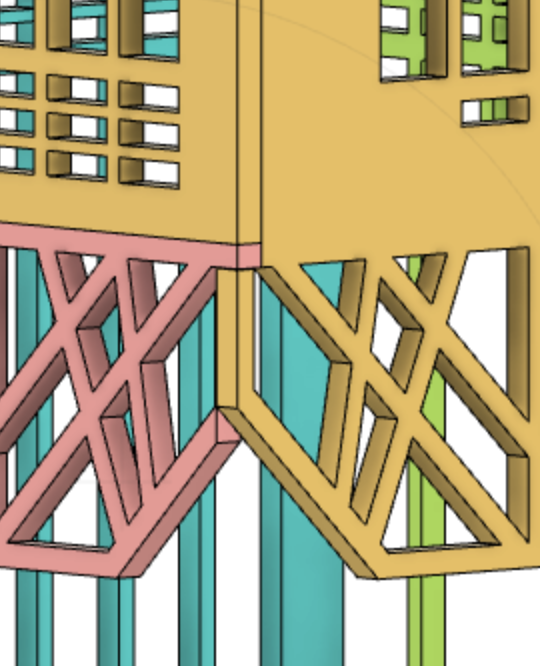

This step is where your plan of attachment becomes key, but it is also the step where you can get the most creative! The first image above shows how two out of four faces might attach in a puzzle piece style, but if you are more ambitious, you can create faces that attach at different angles and heights.

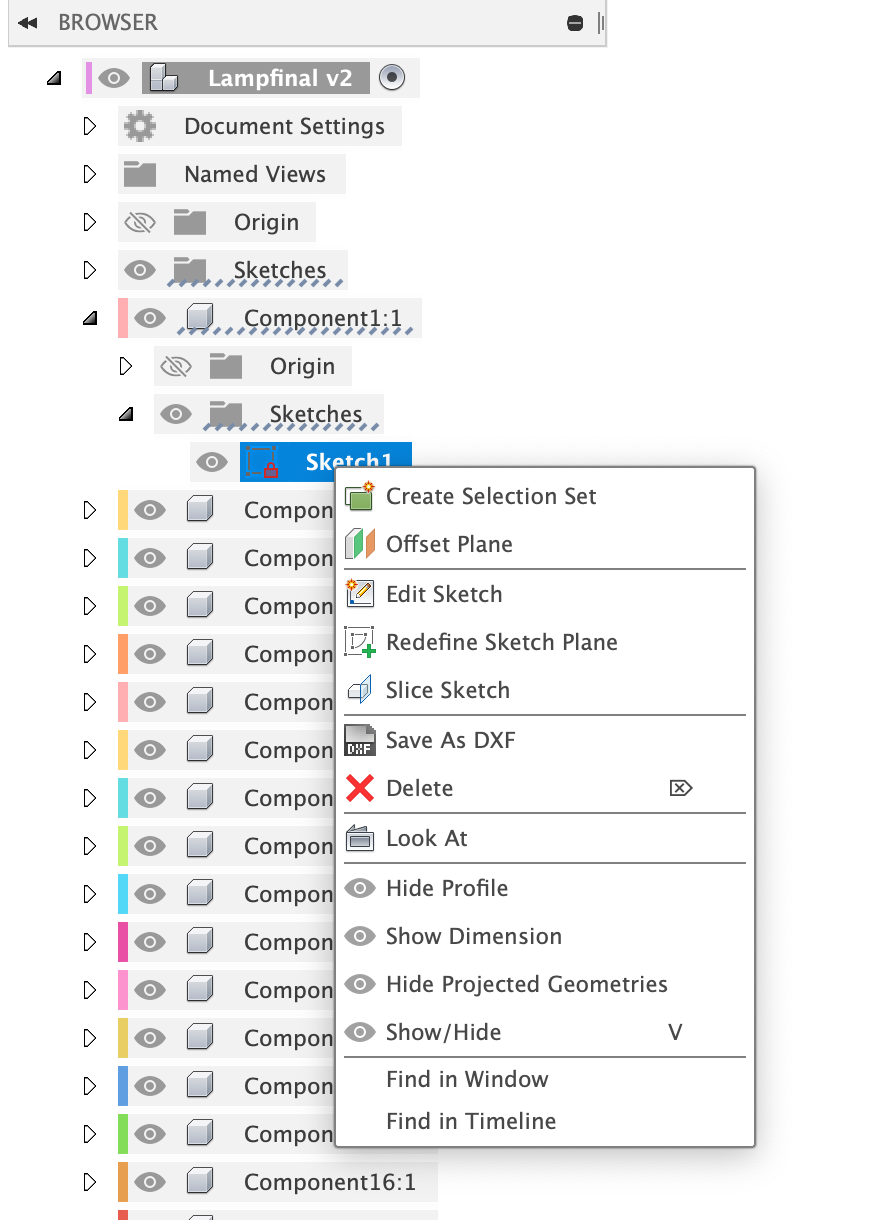

During this step, I find it helpful to use the Component Color Cycling Toggle found under the Inspect menu. This adds a different color to each separate component of your design, and can help clarify how faces might attach. To this end, make sure you are designing each face as a different component; you can see which component you are working on in the far left browser. This is important for your to easily navigate your design and make changes where necessary, without having to search through multiple bodies within components.

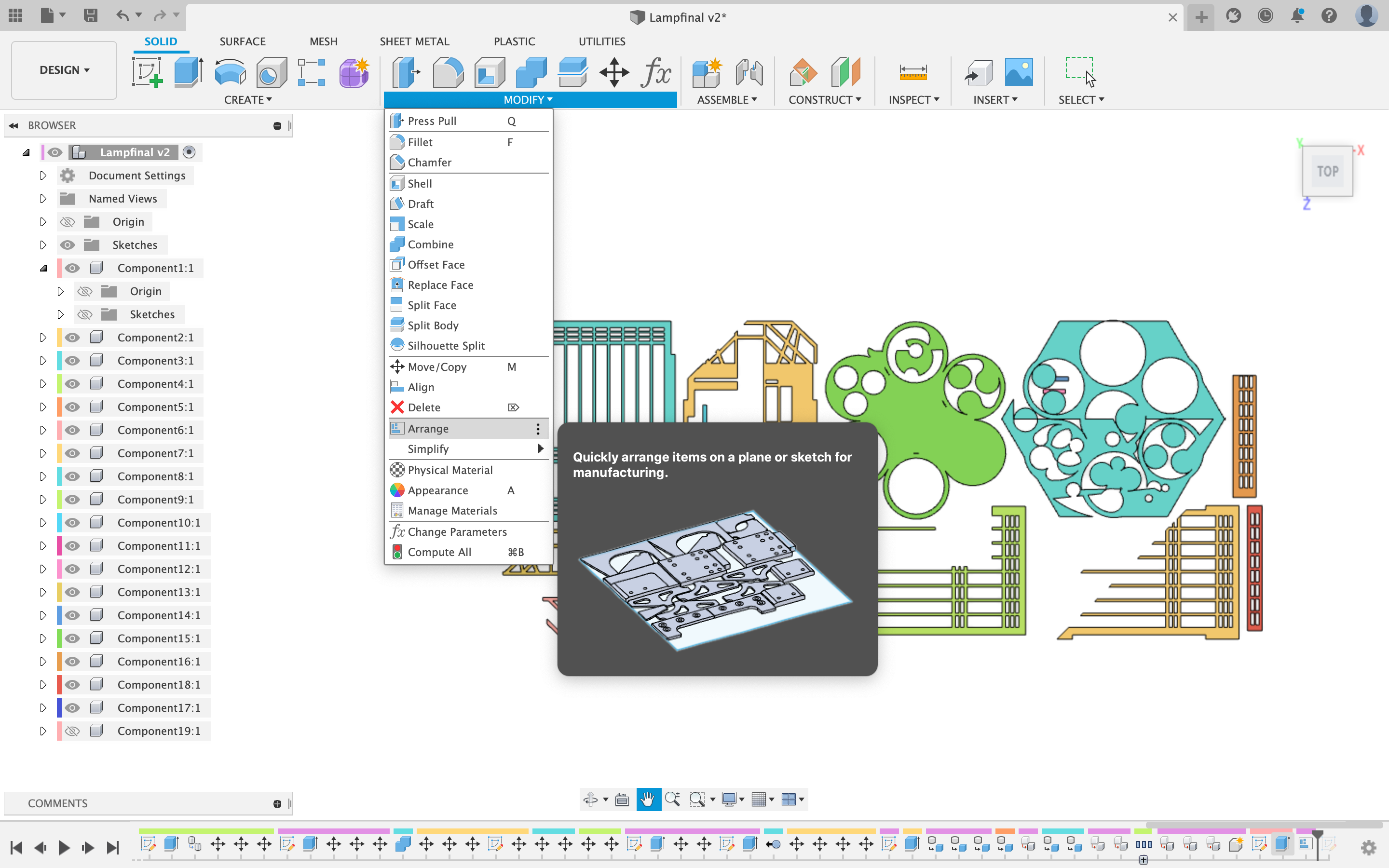

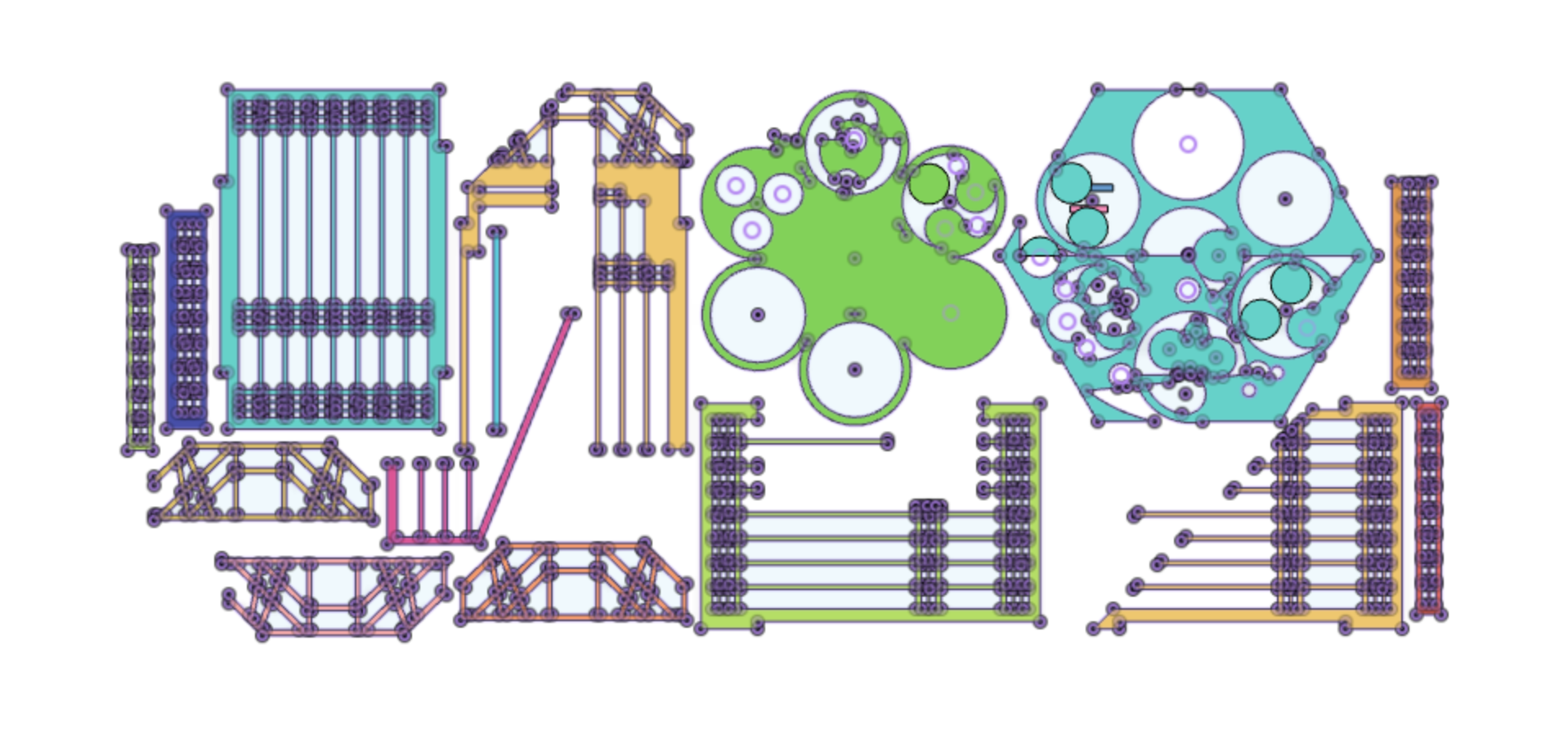

Create the Assembly

When you are happy with your design and confident in the feasibility of your attachments, it's time to make your lamp a reality. The first step to this is to arrange all the components on one plane so that they can be laser cut from a flat piece of material. Under modify, press arrange and select your entire design.

Export the Assembly Sketch

Create a new sketch on the flat plane of your assembly, and select your faces. Press "P" to project the outlines of each face onto your sketch, and hit "finish sketch". Now, find the sketch in your browser and click "save as dxf". This will allow you to take the sketch of your assembly into an outside application. I opened it in Adobe Illustrator to be laser cut, but this step will vary based on your material and access to laser cutters.

Assemble and Enjoy!

Once you have laser cut the material, assemble using glue. If it fits your design, feel free to add tracing paper to the inside of faces to diffuse the light, or add any kind of finish you like. For the final touch, turn on your tea light and place inside the lamp!