Laser Etch a Wine Box Lid -- I Made It at the TechShop !

by ktchrist007 in Workshop > Laser Cutting

1039 Views, 4 Favorites, 0 Comments

Laser Etch a Wine Box Lid -- I Made It at the TechShop !

How to make a laser-etched wine box lid...at the TechShop!

Remember to follow all safety rules, seriously! E.g. at my TechShop we never put the laser power over 90%.

I had not ever done anything on the laser when I approached this project, except take one class at the Tech Shop. Seriously, take the class, it was fantastic, especially with my teacher Robert at the Menlo Park (now Mid-Peninsula) location. There were all levels of folks in the class, from experienced engineers who just needed to learn these specific machines, to folks who had done stuff at other shops, to well, me.

Important things I learned in the class:

One, pick a really attractive image, it’s what it is going to look like!

Two, use beautiful materials, and your work will be more meaningful.

Three, it helps a lot to know Illustrator (I didn’t!). I had once tried to use Illustrator in the past, got frustrated, and given up.

Four, Corel Draw will do (I had even less experience with that!).

Five, if anything every catches fire, open the lid immediately and get help!

Choose High-quality Materials

I chose to work with cherry wood, it is lovely. I had this class under my belt, and was dying to MAKE SOMETHING, when two very lovely people we know decided to get married…light bulb! I had very little time, so I purchased a pre-made pine wine-box from a wine store and got a couple of pieces of cherry and cut them the same size as the lid. I planned to buy the wine in Spokane where the wedding was, so I didn’t have to carry it on the plane.

Choose a Beautiful Image

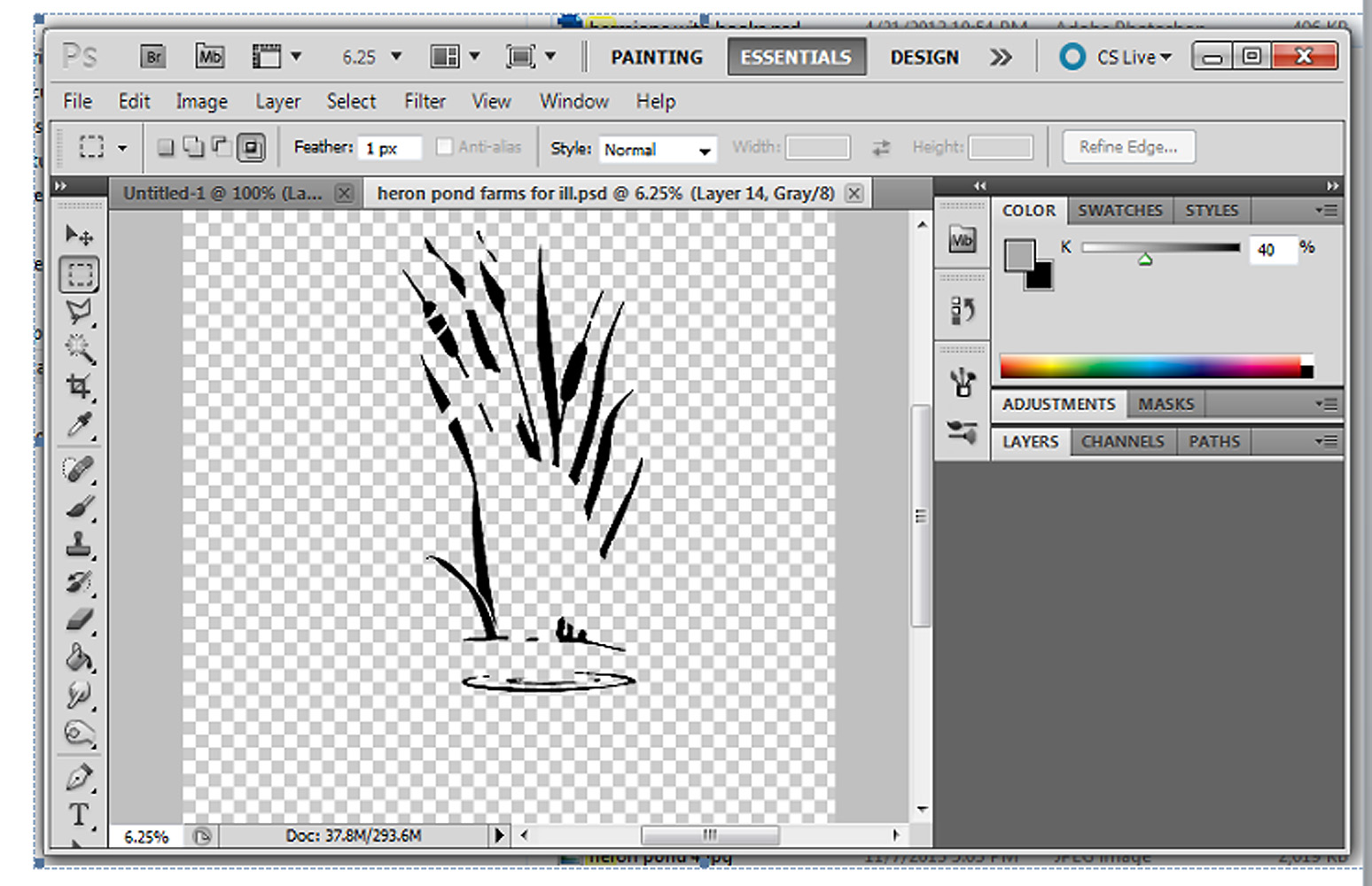

I got a bitmap of the lovely image I wanted to use (the logo for the family farm), simplified and smoothed it a bit in Photoshop, and divided it into two layers. I cannot overemphasize the value of preparing your image in Photoshop or Photoshop Elements before taking it in to your drawing program.

Preparing the File

Make sure your artboard is the right size, and your layers line up! I isolated a silhouette of each element, then made a ‘vector’ layer for lines and a ‘raster ‘ layer for shading. This way you can make sure they line up perfectly.

The Hardest Part...

I made three separate simplified image layers, and created a silhouette for each one.

Then I cut and pasted the parts into Illustrator, making

sure each was in its own layer and that they lined up.

Here it what I had in Illustrator, the gray layers are to raster and the blue is the vector outline. I used ‘live trace’ to determine all the points.

Get Ready to Laser!

Check the material in advance with an approved instructor to make sure you won’t poison, burn up, or explode anything or anyone; things with ‘vinyl chloride’ are a no-no, for instance. You can bring in a MSDS paper (downloadable from most manufacturers) if your instructor is unfamiliar with the material…

The next most important step is, learn to calibrate the lens, that is, focus the laser. This is really important!!! Follow the steps of your particular machine to the letter. I had to check out a kit from the front desk at Menlo Park, but the new Mid-Peninsula location keeps the focus gadget right on the machine.

Doublecheck that your artboard is the right size and units, (matching the material to be etched) and that your image is centered on the artboard.

Know how to set the variables in the program you use (at Tech Shop we use a special window to talk to the laser, regardless of what program you start in). Our teacher gave us a chart to use, and some specifics for our particular machines. Each type of machine and even each individual machine may have different variables…make sure you know them! These include resolution, raster and/or vector, and speed and power levels for each. Choose a dither pattern that you like for the raster.

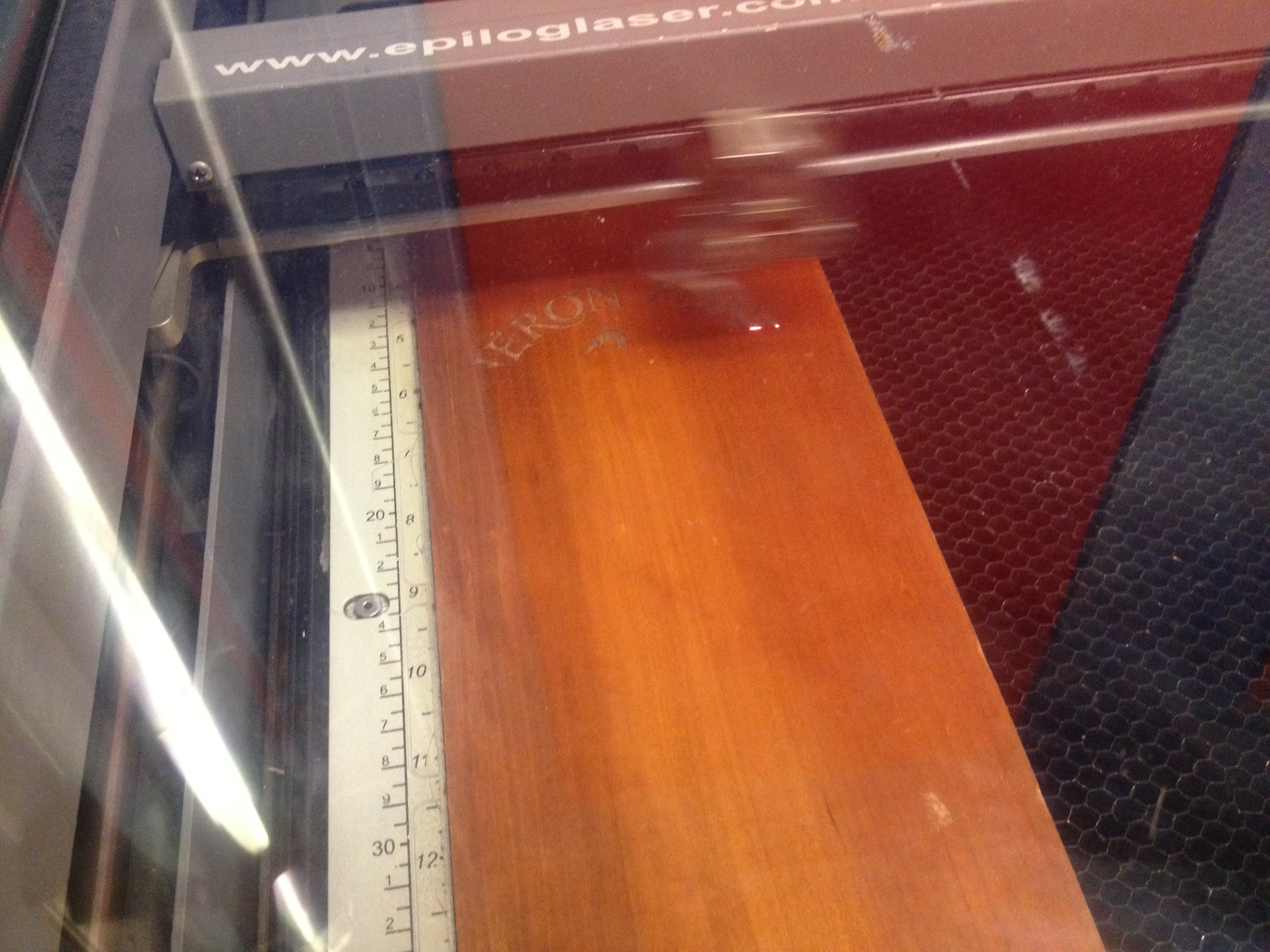

Test! One of the best things Robert taught us was to run it once with the lid open to see if it is printing in the right place.

I chose to ‘print’ on cherry, positioned the wood, ran it with the lid up, then down…it worked!

AdmireYour Handiwork!

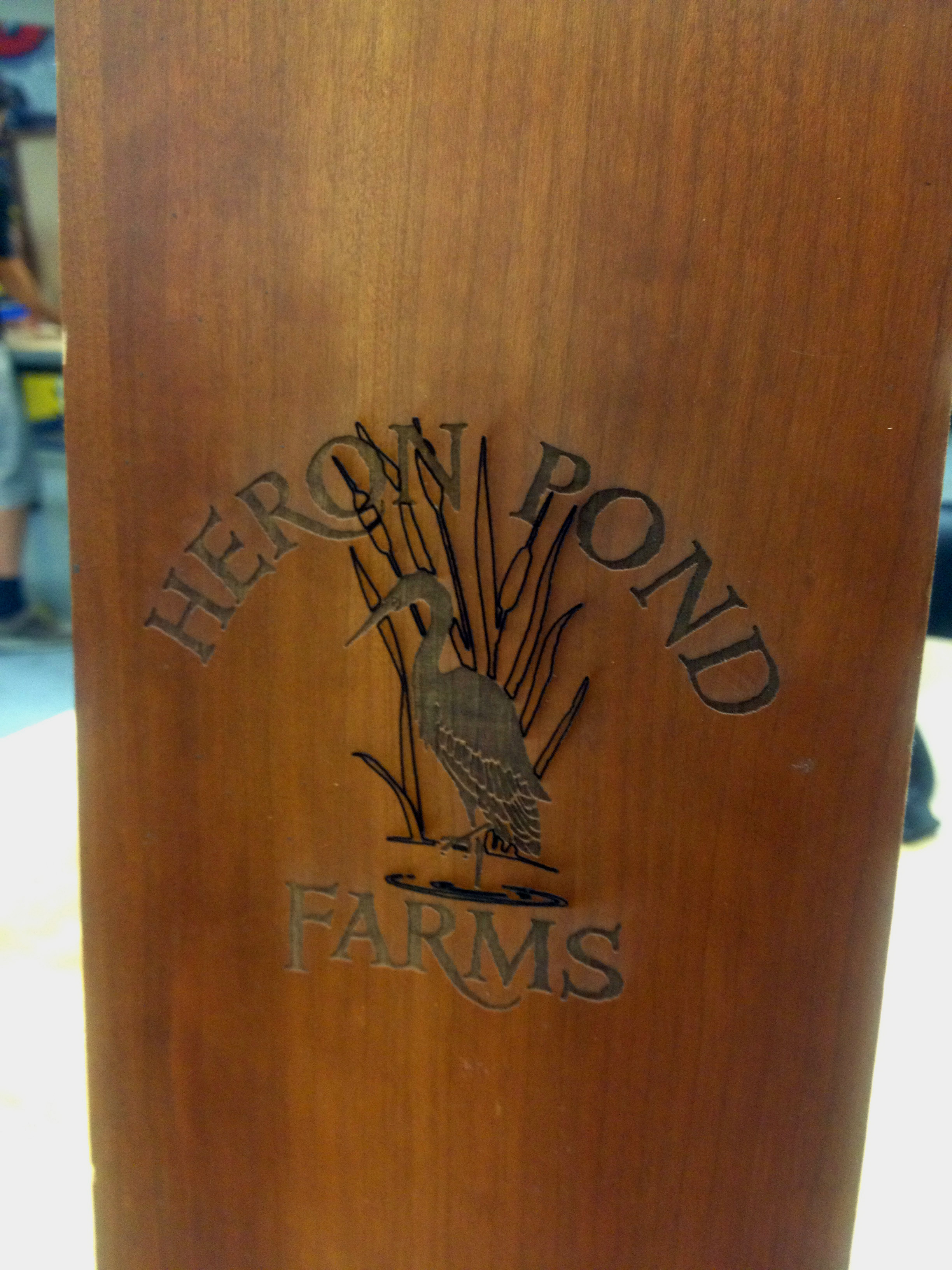

Here is the image lased onto the cherry wood…you can see how

different the ‘vectored’ and ‘rastered’ parts look! Just the right contrast.

I was really happy with this project! It looked just right, was centered, and really wowed the happy couple!

Here is the finished product slid into the wine box.

All that was left was to find the right bottle of wine...

You can do it too! Just go to http://techshop.ws/ !