How to Make a Windmill House Model

by thunderlaser-nolan in Workshop > Laser Cutting

87 Views, 0 Favorites, 0 Comments

How to Make a Windmill House Model

Let’s make a laser cutting windmill house model as inspiring and innovative as you are! Laser cutting transforms plywood into an intricate masterpiece, ensuring your model stands out in maker spaces and classrooms while sparking creativity and learning.

Ready to give your projects the creative edge they deserve? Follow the steps below and cut your way to success with the windmill house model!

Supplies

Machine Used

Thunder Bolt 30W

Material Needed

3mm plywood

Settings

Engraving

- Speed:1000mm/s

- Power:45%

- DPI:254

Cutting

- Speed:5mm/s

- Max Power:80%

- Min Power:10%

Downloads

Place Your Plywood for Laser Cutting

Before your work begins

- Verify the lens is clean or there's no problem in the laser.

- Make sure the exhaust fan is working well.

- Ensure the air assist is on.

Choose a flat plywood board on the laser honeycomb bed.

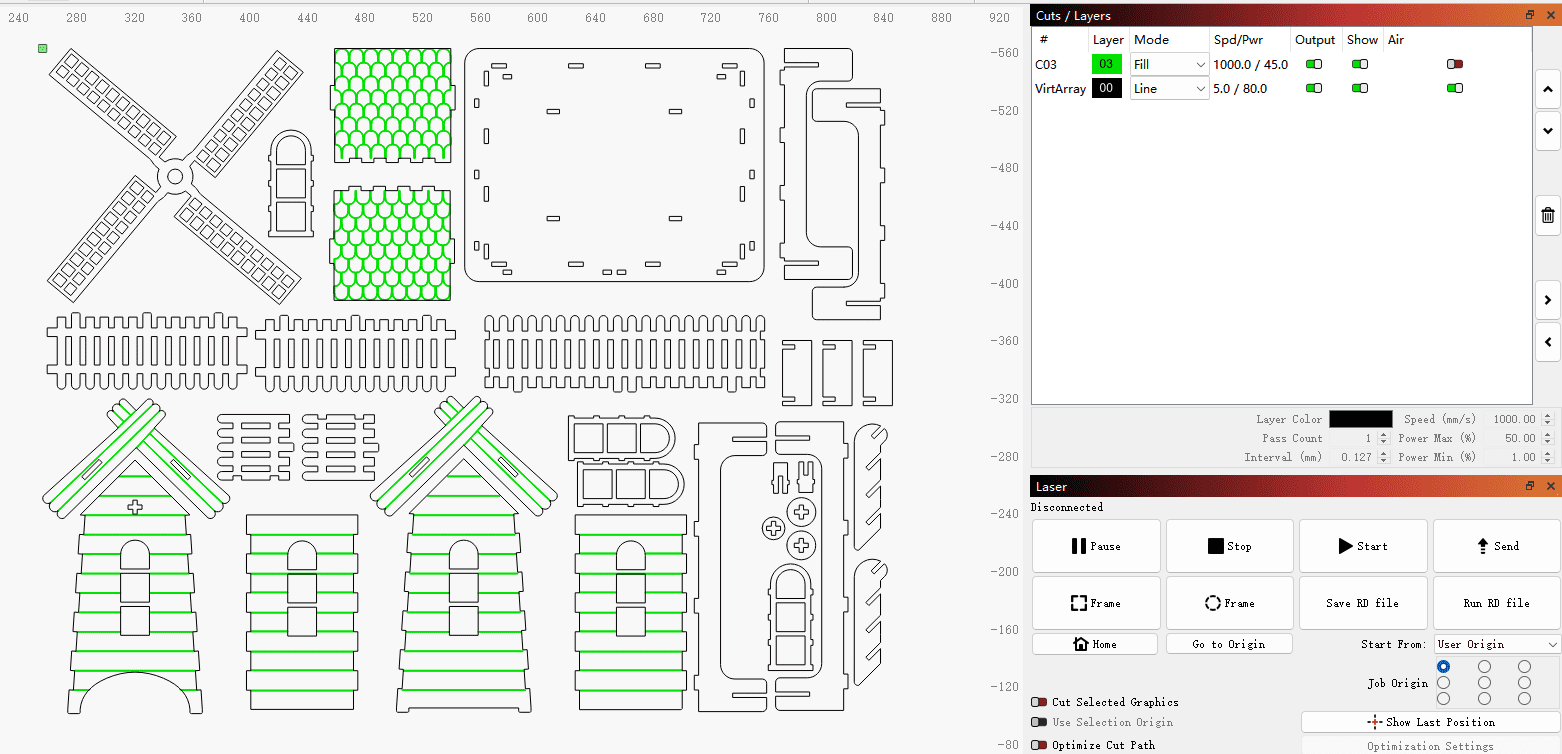

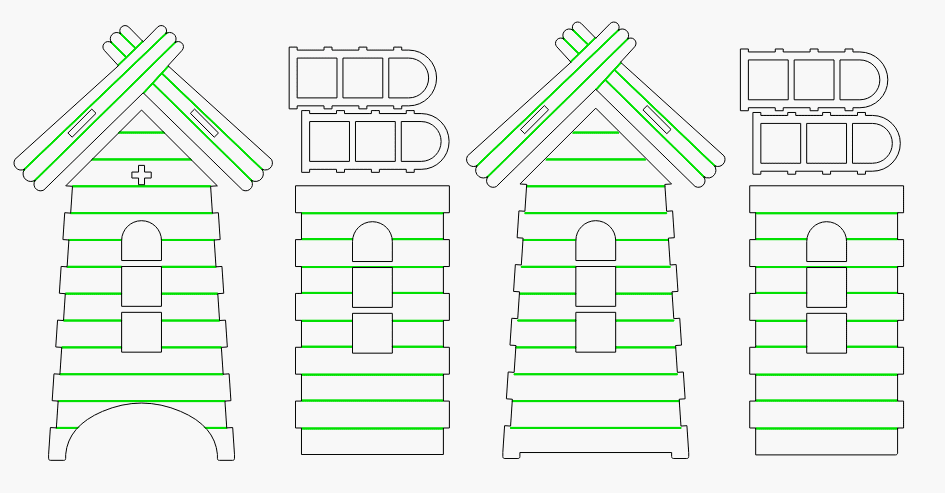

Open the Model File and Check the Laser Plywood Settings

Check out the design is important. Since there are a lot of parts, don’t miss anyone! And ensure that the parameters are set correctly to achieve the ideal laser cutting windmill house model. In addition, laser compensation is to be set.

If the min power is too low, it will cause the stroking corners will be too shallow and the cutting corners will not cut through; if the min power is too high, it will cause the stroking to cut through the corners and the laser cutting will be bad at the corners.

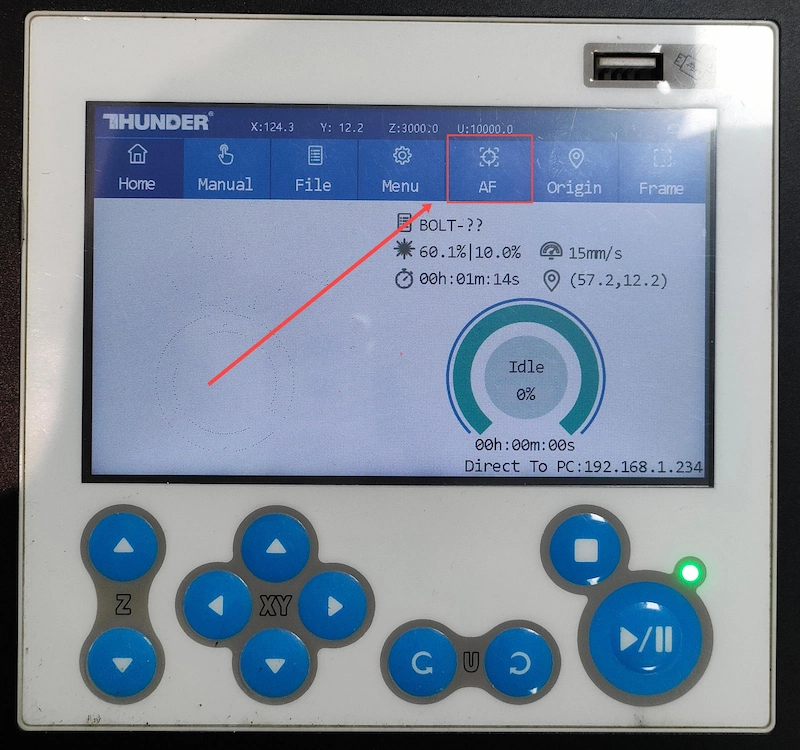

Focus on the Plywood

Without focusing, your outcomes may fall short of expectations. So before starting, make sure you’ve rightly focused.

For focusing, you have two options: Auto Focus, which is simple—just press the AF button on the Thunder Bolt screen. Then you’re ready to have a laser cutting.

Frame the Model Design and Start Laser Cutting

When you click “Frame”, the red light will display the laser cutting area. This is a safe process, and the frame will align with the plywood. Once aligned, simply press “Start” to begin the plywood laser cutting with the Thunder Bolt!

Monitor the Laser Cutting Process

To avoid any issues, carefully monitor the laser cutting, especially when unusual conditions like alarms arise.

Considering the laser cutting energy, for safety reasons, we advise against staring directly at the process, even with the laser door closed.

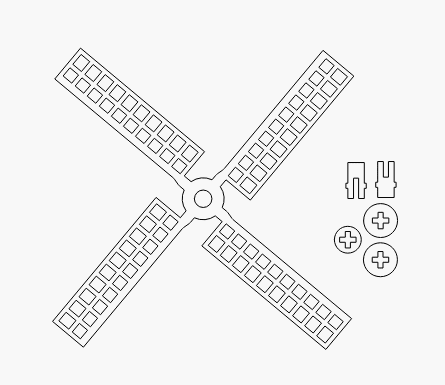

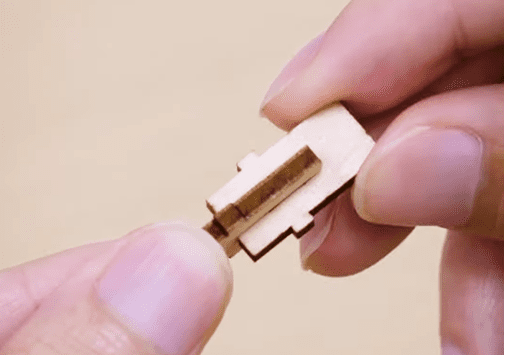

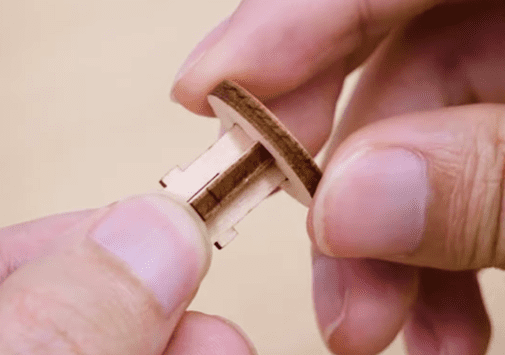

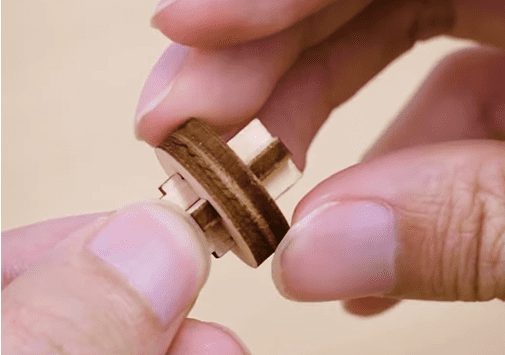

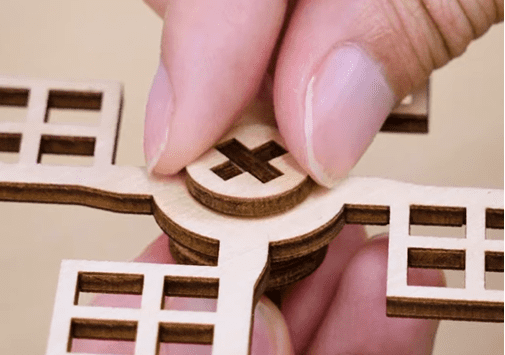

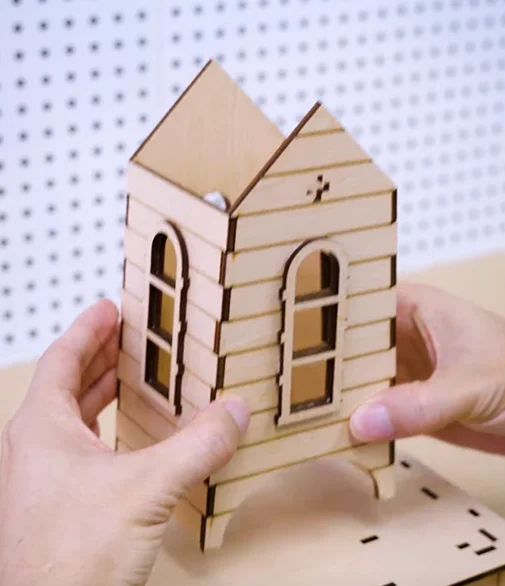

Assemble the Windmill House Model

When the laser cutting plywood is completed, it’s time to get it out. Then it’s just a fun assembly time to get the ideal windmill house model. Imagine the joy of assembling the model, as each piece clicks into place to create a beautiful, layered home decoration.

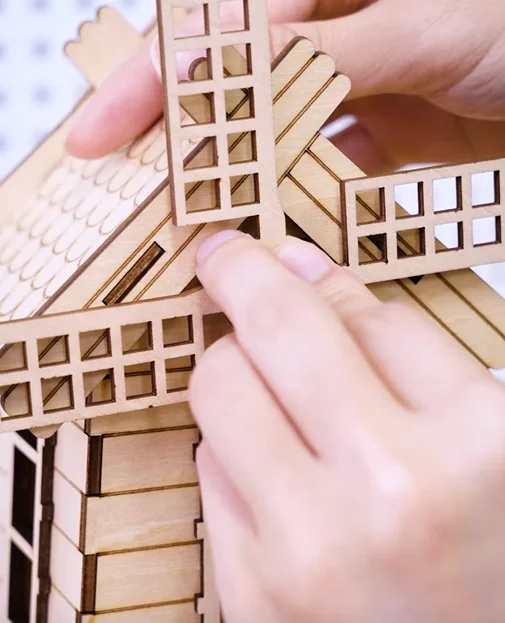

When assembling complex models, following the sequence from bottom to top and inside to outside makes it easy and quick to complete the assembly. Another tip is modular assembly. For example, we can assemble the base, windmill, house, and ladder separately, and then put them together quickly!

Assemble the Windmill

Assemble the House

Assemble the Other Parts

Come and Try!

Laser cutting windmill house model is designed to inspire hands-on learning and spark innovative ideas. Its elegant design serves as a functional educational tool, and transforms any space into a vibrant workshop of imagination.

Ideal for creative projects, collaborative learning, and engaging demonstrations, the windmill house model is more than just a model. It’s also an invitation to explore, experiment, and elevate the art of laser cutting.