How to Make a Laser-Cut Flip-Lid Tool Box | DIY Wooden Storage Box Tutorial

by thunderlaser-nolan in Workshop > Laser Cutting

14 Views, 0 Favorites, 0 Comments

How to Make a Laser-Cut Flip-Lid Tool Box | DIY Wooden Storage Box Tutorial

A well-organized workspace starts with smart storage—and there’s no better way to keep your tools in order than with a custom flip-lid tool box. With a laser cutter, you can design and build your own sturdy storage box that fits your needs perfectly. Whether you’re crafting it for your workshop, garage, or as a DIY gift, this project combines practicality with creative design. Let’s get started and make your own laser-cut tool box that looks great and works even better!

Supplies

Machine Used

Thunder Bolt 30W

Material Needed

3mm Plywood

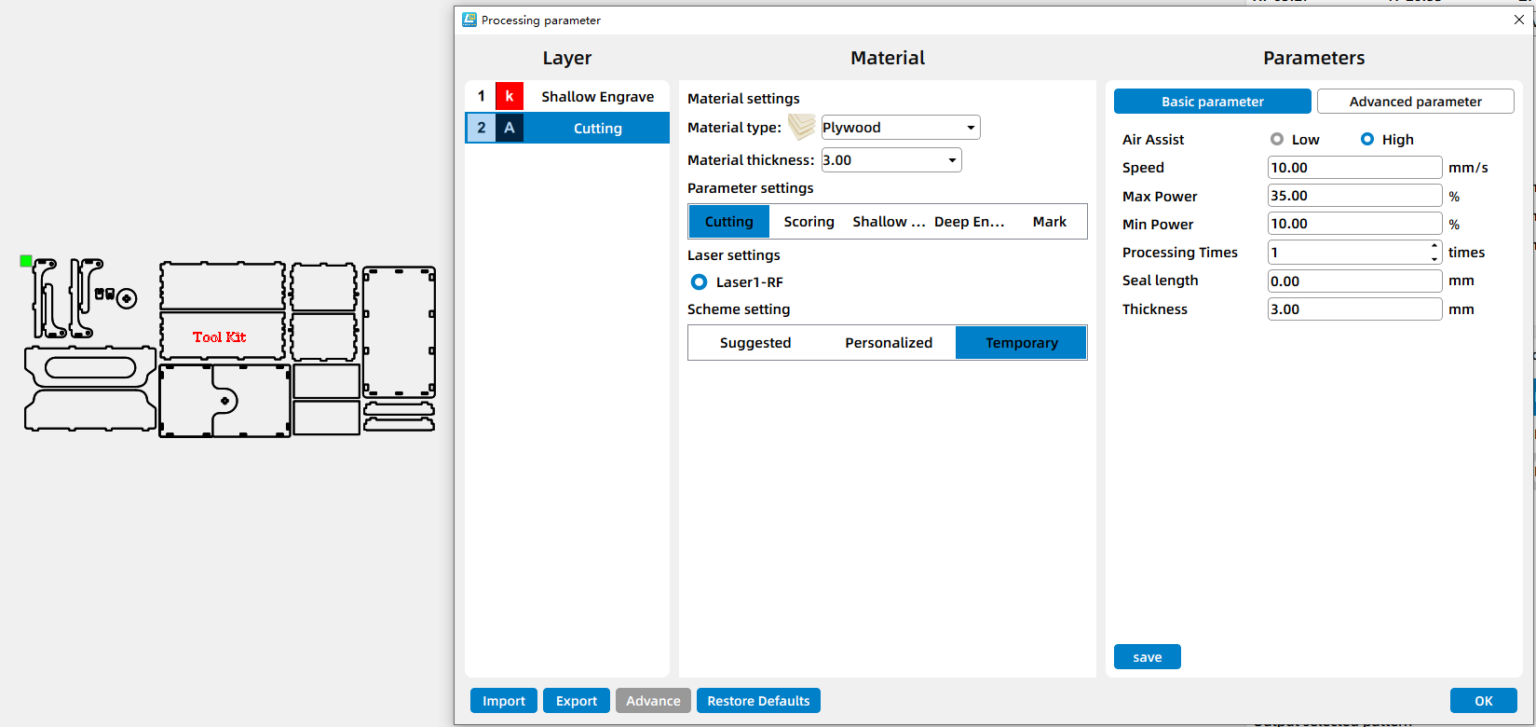

Settings

Cutting

- Speed:10mm/s

- Max Power:35%

- Min Power:10%

- Number of Passes:1

Engraving

- Speed:500mm/s

- Power:25%

- DPI:300

Downloads

Place the Wood

Lay your wooden sheet flat on the honeycomb worktable. Ensure it’s well-aligned and firmly secured to prevent any movement during cutting.

Open the File and Check the Settings

Open your design in LightBurn, LaserMaker, or your controller. Assign colors/layers for engraving vs cutting. Scale the design to the final physical dimensions. Double-check everything, and decide if you want to add or subtract elements according to your preferences. For the laser cutting layers, pay extra attention to the power setting.

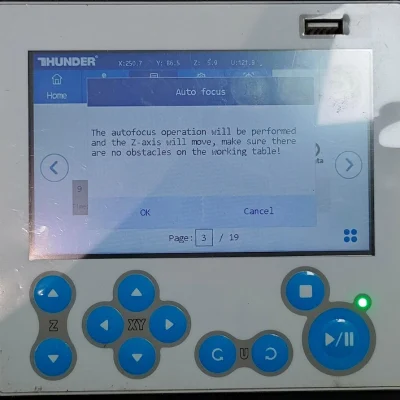

Focus Your Laser Machine

Proper focusing ensures neat, polished edges. If your machine has auto focus, use it for quick setup. For manual focusing, lower the laser head with the focus stick until it touches the wood surface at a perfect angle. Always double-check before cutting.

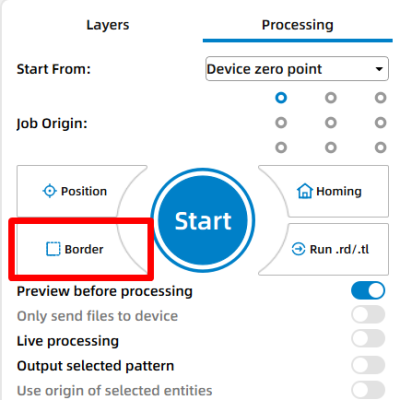

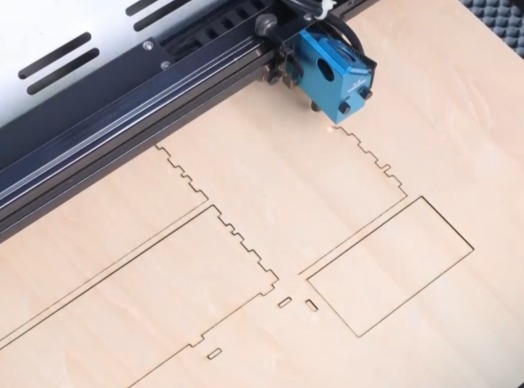

Frame the Design and Start Laser Cutting

Then click “Frame” or “Border” to preview your cutting area and make sure the design fits nicely on your board. This confirms your material placement and avoids wasting wood. Adjust as necessary. Once everything is set, start the laser job.

Monitor the Laser Cutting Process

Stay close to the machine while it’s running and watch the cutting and engraving progress. Keep an eye out for excessive smoke, small flame-ups, or any movement of the material that could affect the outcome. Make sure your workspace is well-ventilated, and rely on air assist if available to achieve cleaner edges on the wood.

Assemble the Box

When the cutting is done, remove all pieces carefully and start assembling. Each part should fit snugly into its slot — no glue needed! The interlocking design ensures a solid and durable build.

Come and Try!

And that’s it! Try designing and laser-cutting your own flip-lid tool box today. It’s a fun and rewarding way to keep your workspace organized and your creativity flowing!