How to Design and 3D Print a Custom Armchair Caddy

by Fekry in Workshop > 3D Printing

518 Views, 9 Favorites, 0 Comments

How to Design and 3D Print a Custom Armchair Caddy

Do you often find yourself juggling remotes, beverages, or gadgets while relaxing on your armchair? An armchair caddy can be a game-changer, keeping all your essentials within arm's reach. In this Instructable, I'll walk you through designing a personalized armchair caddy using Onshape—a free, cloud-based CAD software—and 3D printing it. This project combines digital design with practical functionality, resulting in a custom accessory tailored to your specific armchair dimensions. Feel free to go through the steps to design it or download the file and skip to step 7.

Supplies

Materials:

- Computer with internet access

- Onshape Account (free at Onshape) or any 3D printing software

- 3D Printer (e.g., Bambu Lab X1 Carbon or any other model)

- 3D Printing Filament (PLA, ABS, or preferred material)

- MicroSD Card or USB drive for file transfer

Tools:

- Measuring Tape or ruler

- Slicing Software (e.g., Bambu Studio, Cura, PrusaSlicer)

- Cleaning Tools for the 3D printer (scraper, brush, etc.)

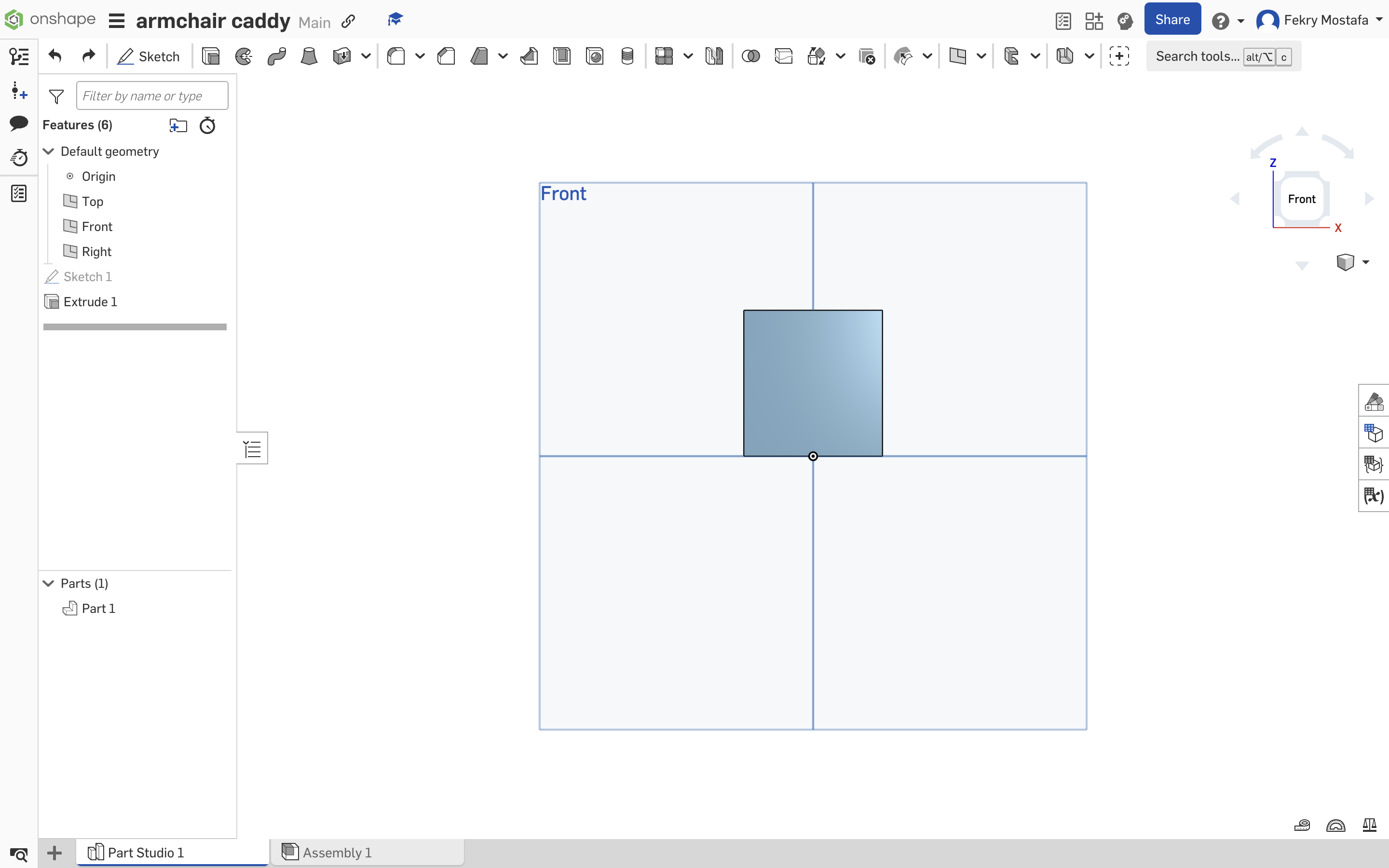

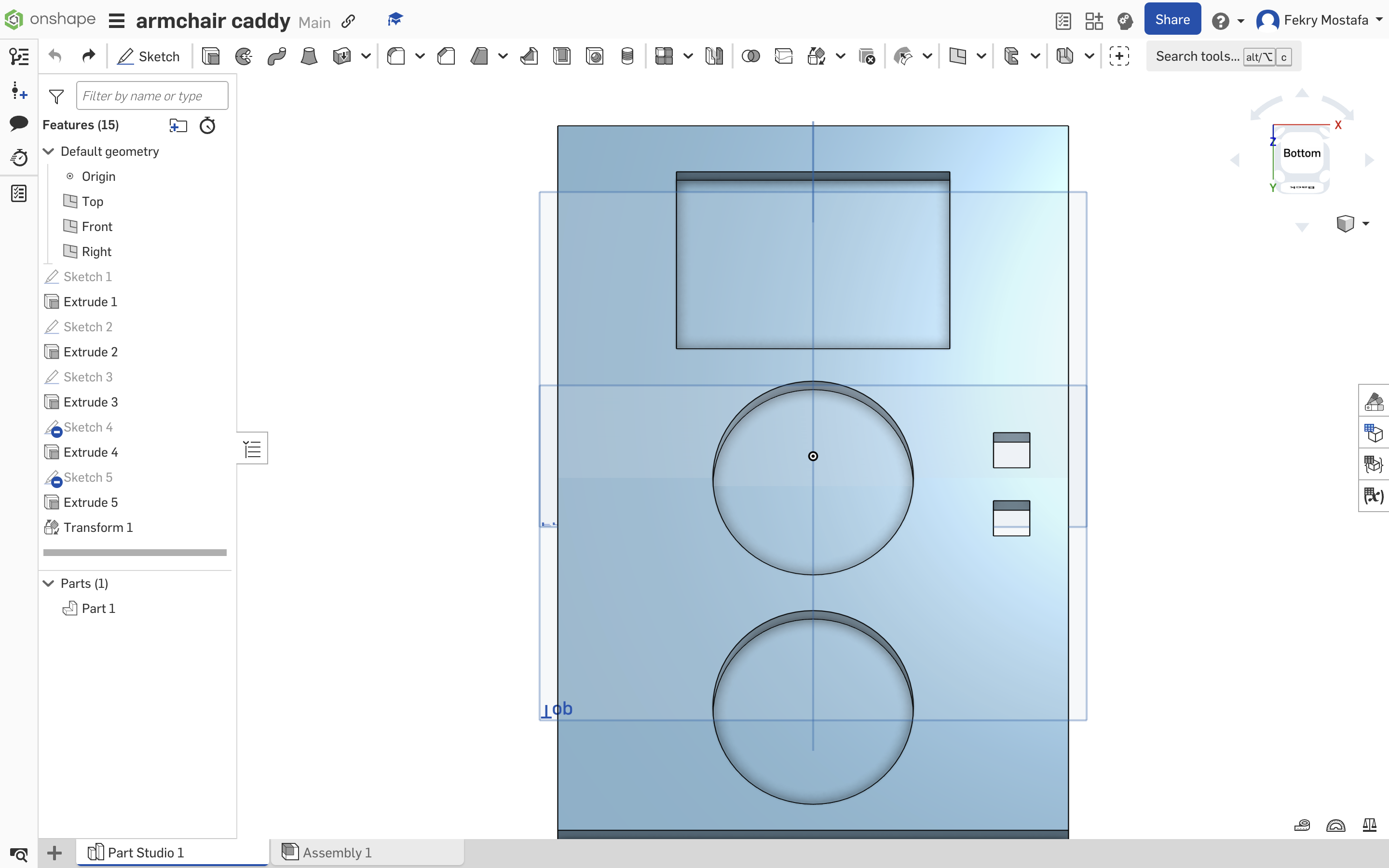

Create the Base in Onshape

- Open Onshape:

- Log in to your Onshape account and create a new document.

- Start a New Sketch:

- Select the Top Plane and click on Sketch.

- Draw a Center Point Rectangle:

- Choose the Center Point Rectangle tool.

- Click on the origin to start.

- Set Dimensions:

- Length: I chose to do 200 mm.

- Width: Enter your Armrest Width + 10 mm (to account for the walls).

- Extrude the Rectangle:

- Click Extrude and select your rectangle sketch.

- Depth: Enter 40 mm.

- Operation: Ensure Solid and New are selected.

- Click OK.

This forms the main body that will hang over the armrest.

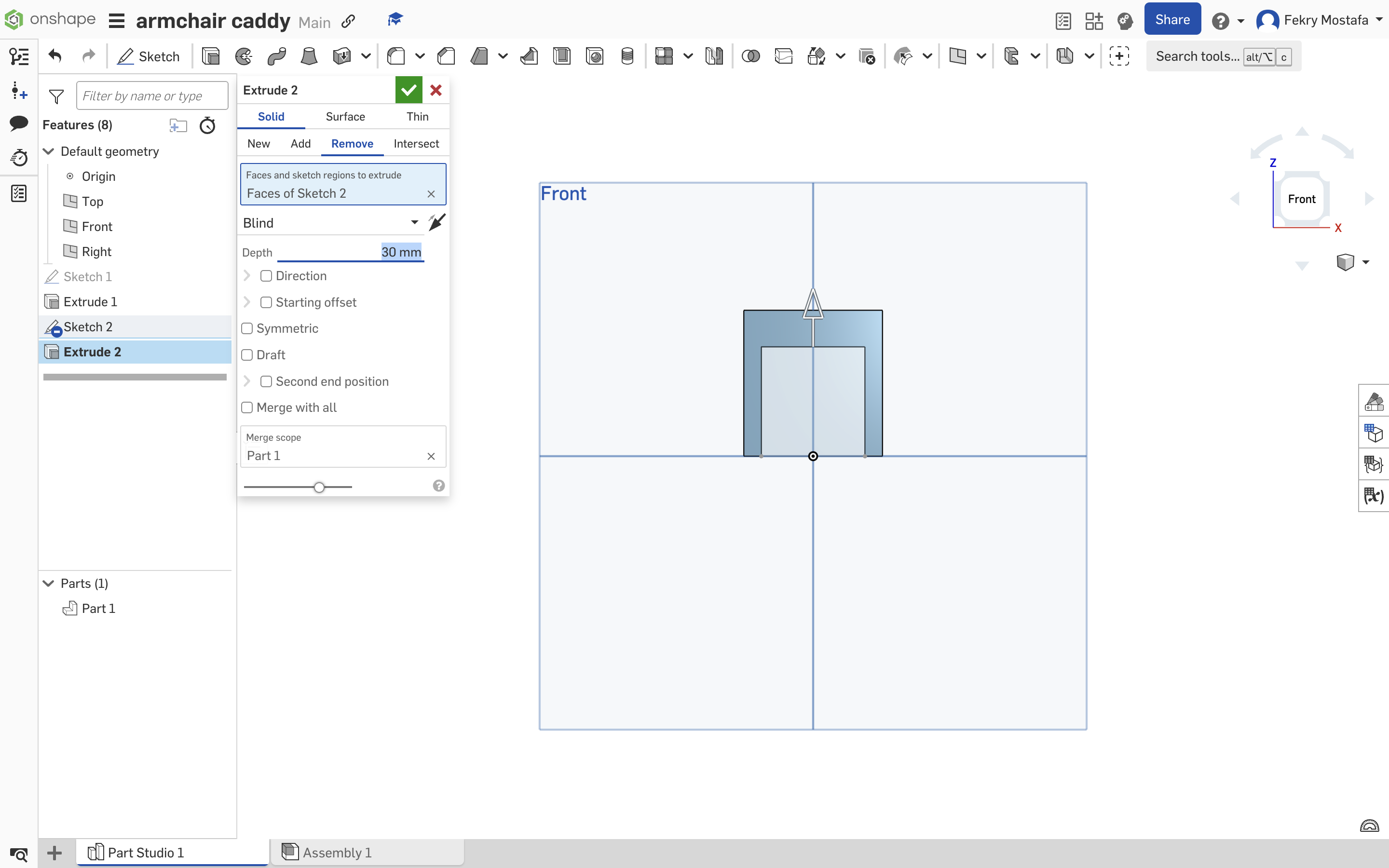

Cut Out the Armrest Slot

- New Sketch for Armrest Slot:

- Select the Top Face of the extruded base.

- Click on Sketch.

- Draw Another Rectangle:

- Use the Center Point Rectangle tool.

- Length: Enter 200 mm.

- Width: Enter Armrest Width.

- Extrude Remove:

- Click Extrude and select the new rectangle sketch.

- Depth: Enter 30 mm.

- Direction: Ensure it's set to Remove.

- Click OK.

This creates a recessed area that fits snugly over your armrest.

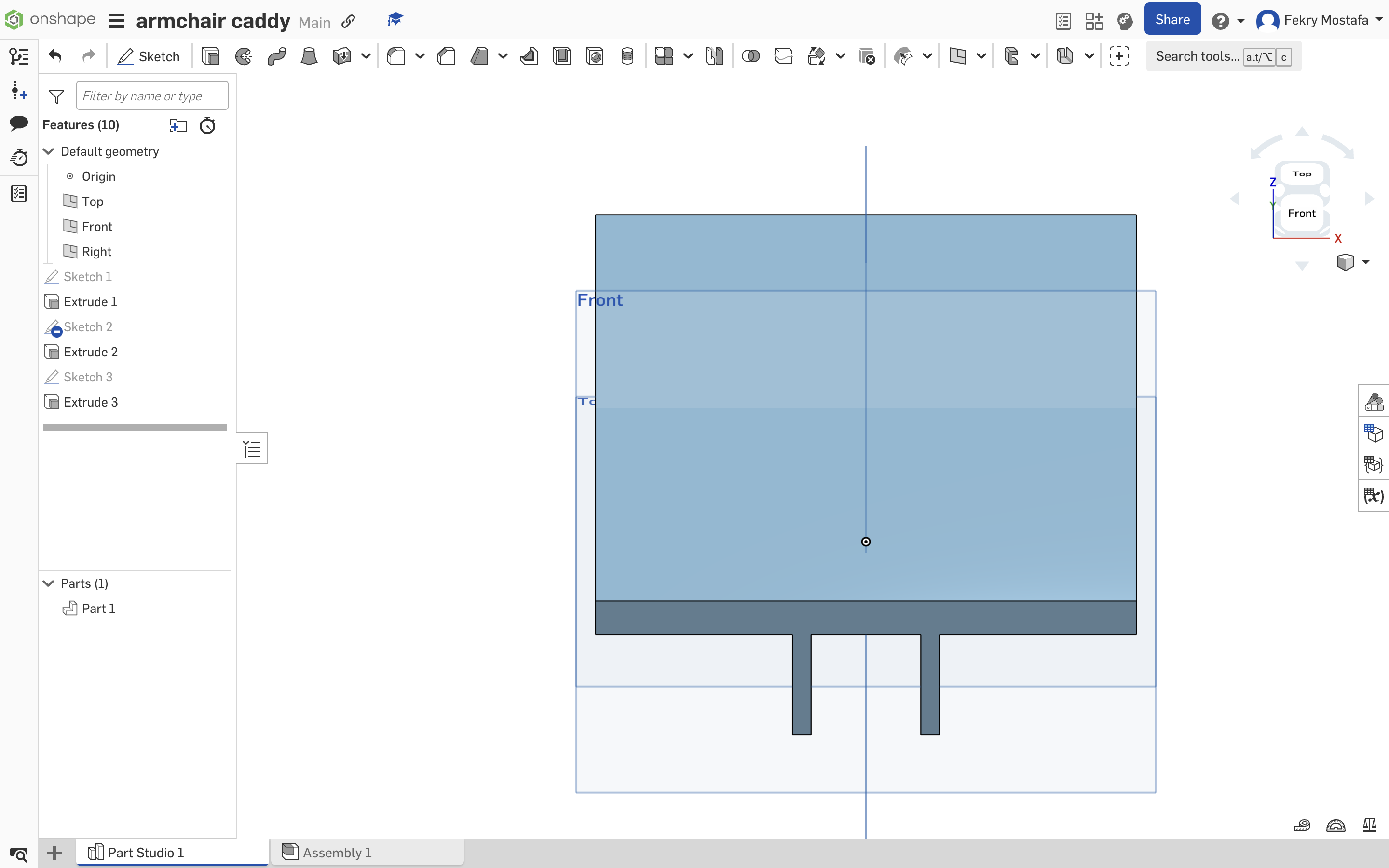

Add the Top Surface

- Sketch the Top Platform:

- Select the Top Face of the base again.

- Click on Sketch.

- Draw the Top Rectangle:

- Use the Rectangle tool.

- Dimensions: Enter 140 mm x 200 mm.

- Extrude the Top Surface:

- Click Extrude and select the new rectangle.

- Depth: Enter 10 mm.

- Offset: Set an Offset Distance of 30 mm (so it starts above the base).

- Click OK.

This creates a flat surface for holding items.

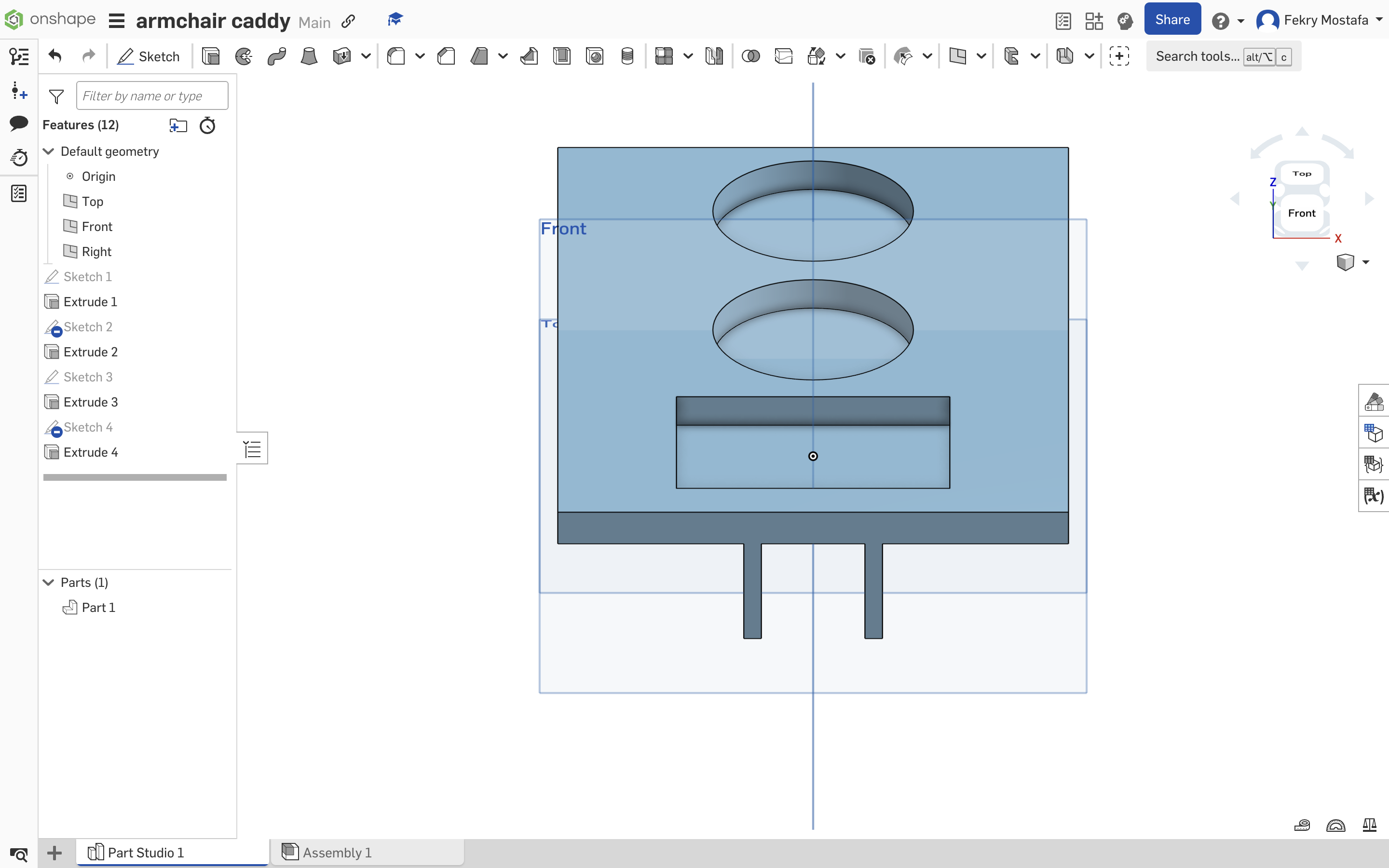

Create Holders and Indentations

- Sketch the Holders:

- Select the Top Face of the platform.

- Click on Sketch.

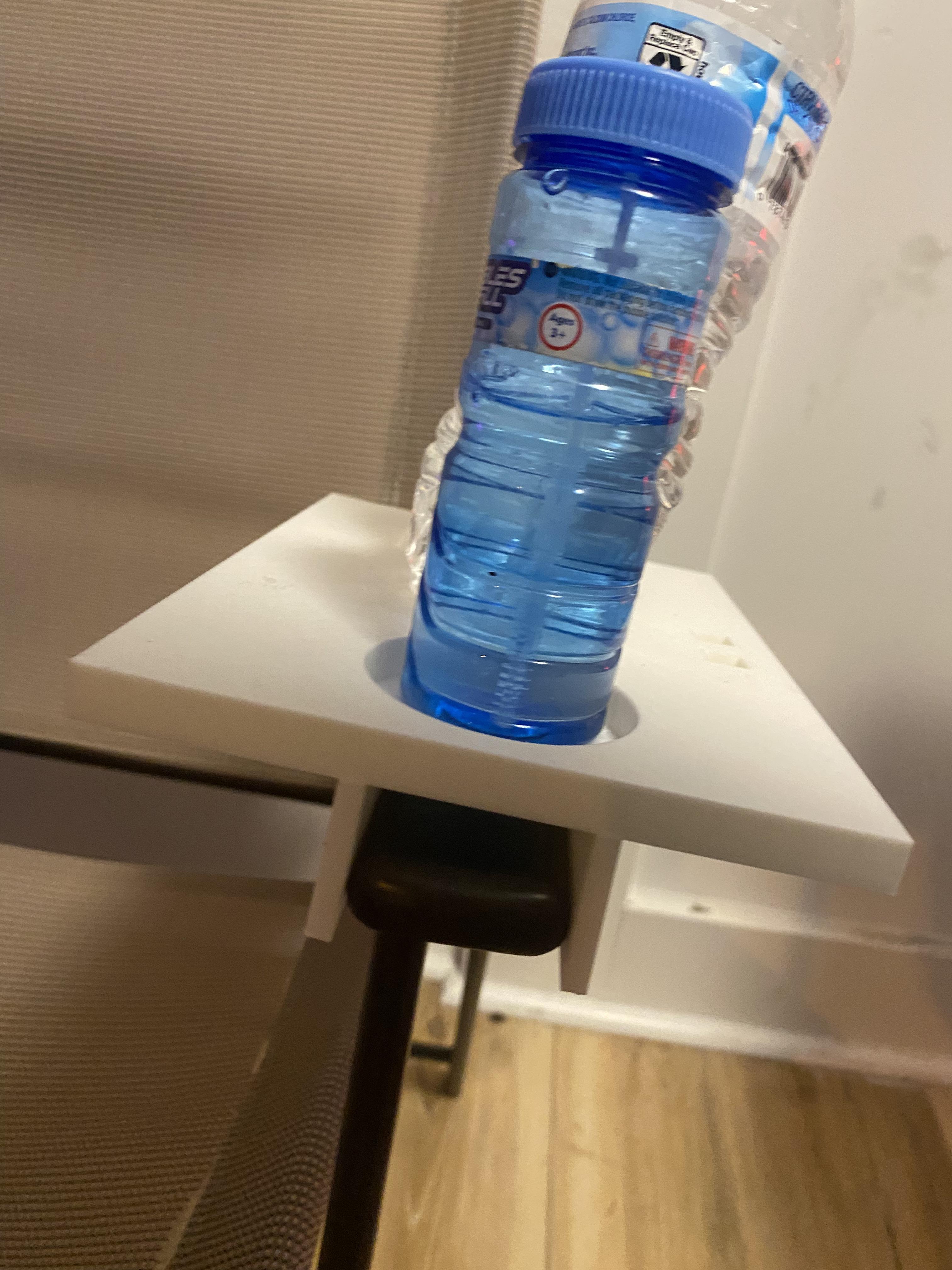

- Add Cup Holders (Circles):

- Use the Circle tool.

- Draw two circles with a diameter of 55 mm.

- Position them appropriately on the platform.

- Add Rectangular Holder:

- Use the Rectangle tool.

- Draw a rectangle with 75 mm length and 50 mm width.

- This can serve as a key holder, ashtray, or storage for small items.

- Extrude the Indentations:

- Click Extrude and select the circles and rectangle.

- Depth: Enter 8 mm.

- Direction: Set to Remove.

- This leaves a 2 mm base (since the platform is 10 mm thick).

- Click OK.

These indentations will hold items securely without cutting through the platform.

Add Cable Pass-throughs

- Sketch Cable Holes:

- On the same top surface, click on Sketch.

- Draw Squares for Cables:

- Use the Rectangle tool.

- Draw two squares measuring 10 mm x 10 mm.

- Position them where you'd like cables to pass through.

- Extrude Through Holes:

- Click Extrude and select the squares.

- Depth: Enter 10 mm.

- Direction: Set to Remove.

- This cuts holes entirely through the platform.

- Click OK.

These holes allow USB cables or chargers to pass through neatly.

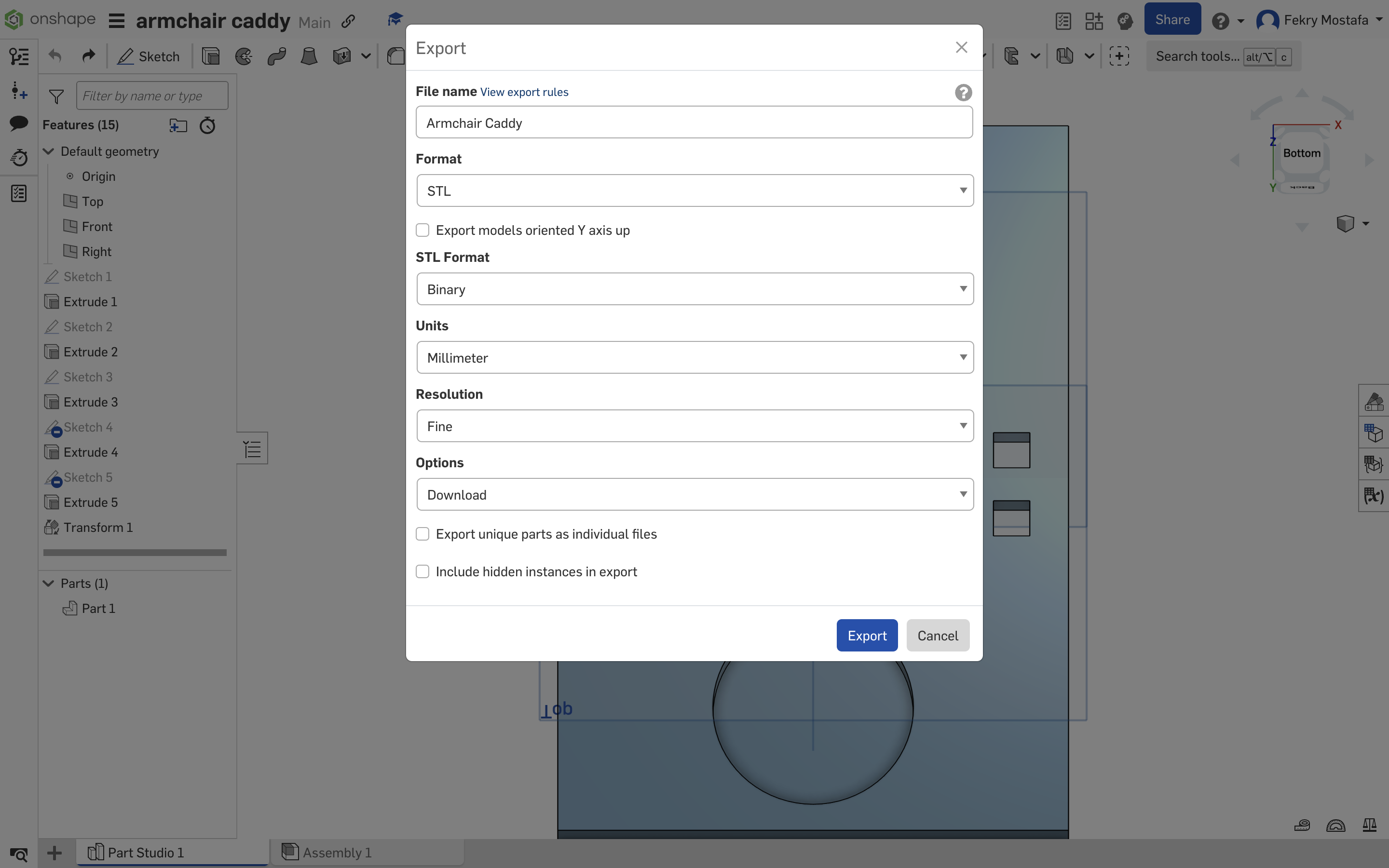

Export the STL File

- Transform the Model (optional):

- Click on Transform in the toolbar.

- Select the entire model.

- Rotate it 180 degrees.

- This positions the widest part at the bottom, improving stability during printing.

- Export the Model:

- Right-click on the part name in the Parts list.

- Select Export.

- Set Export Options:

- Format: Choose STL.

- Units: Ensure it's set to Millimeters.

- Resolution: Set to Fine or Custom for better quality.

- Click Export to save the file to your computer.

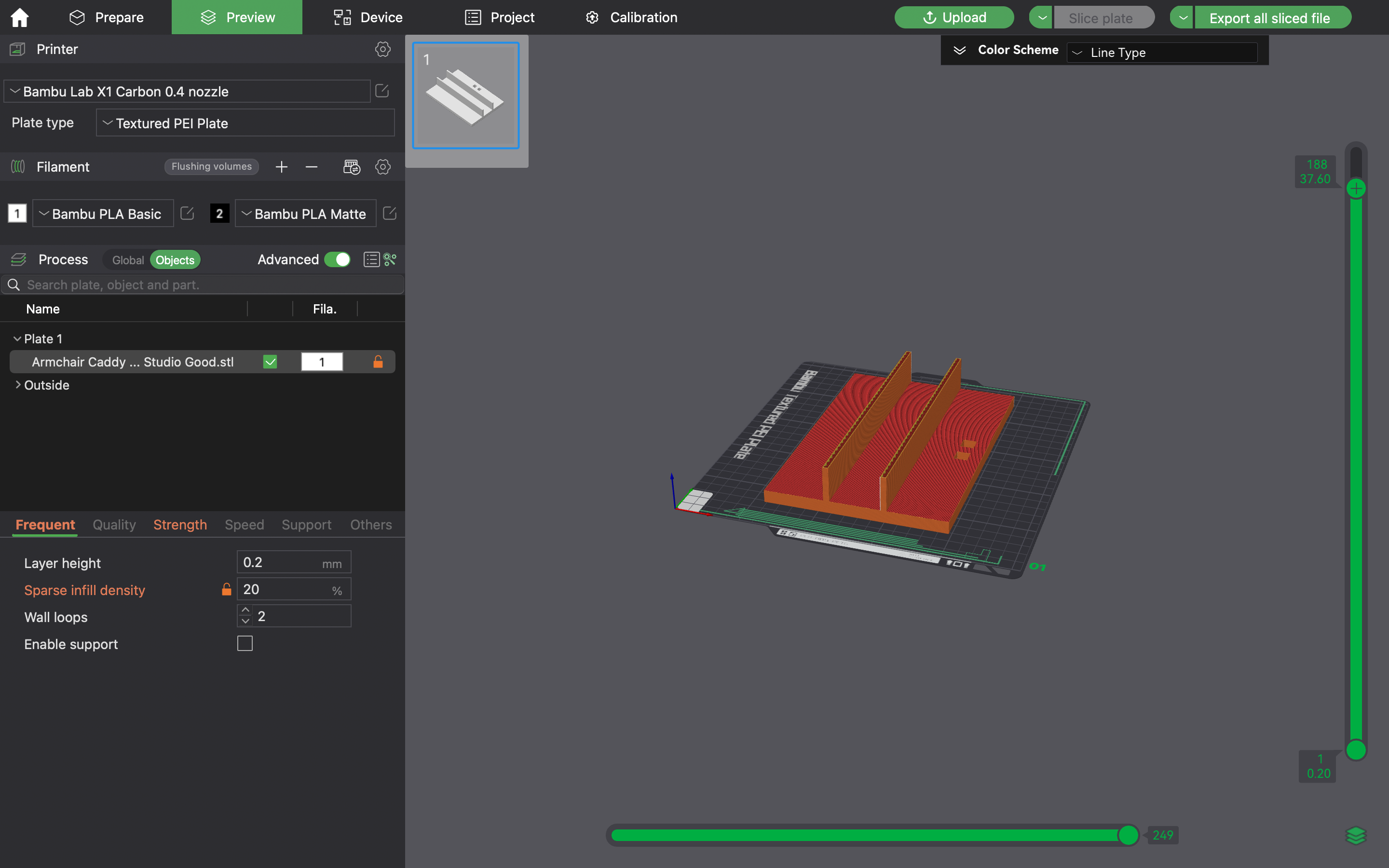

Slice the Model for 3D Printing

- Open Slicing Software:

- Launch Bambu Studio or your preferred slicer.

- Import the STL File:

- Import your STL file to the software

- Adjust Print Settings:

- Material: Select the filament type you're using.

- Layer Height: Standard is 0.2 mm, but adjust as desired.

- Infill Density: Recommend 20% for strength but feel free to adjust it as desired.

- Slice the Model:

- Click Slice Plate to generate the sliced file.

- Preview the Layers:

- Review the sliced model to ensure there are no issues.

- Export sliced file:

- Click Export and save the file to your microSD card or USB drive.

Downloads

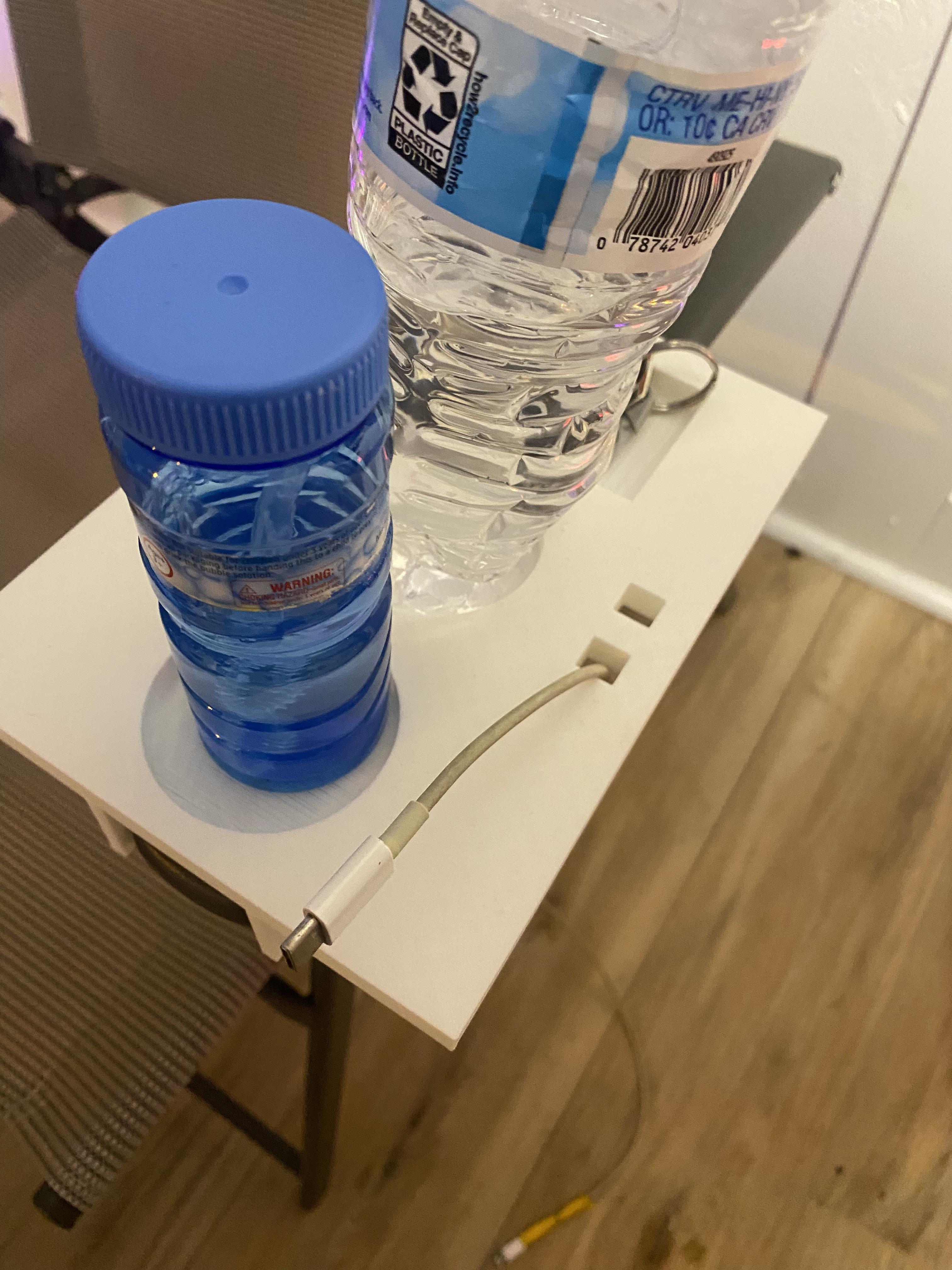

3D Print the Armchair Caddy

- Prepare the 3D Printer:

- Load the filament.

- Ensure the build plate is clean and leveled.

- Transfer the G-code:

- Insert the microSD card or USB drive into the printer.

- Start the Print:

- Navigate to the file and begin printing.

- Monitor the Print:

- Keep an eye on the first few layers for adhesion.

- Periodically check the print's progress.

- Remove the Print:

- Once completed, carefully remove the caddy from the build plate.

- Clean Up:

- Remove any support material if used.

- Sand any rough edges or surfaces if desired.

- Test Fit:

- Place the caddy on your armchair to ensure it fits snugly.

- Check that all holders and pass-throughs function as intended.

Note: Printing may take several hours depending on your settings. It took 2.5 hours for me.

Reflections on the Project

Creating this custom armchair caddy was both a practical and educational experience. Here's what I learned:

- Design Precision: Accurate measurements are crucial for a perfect fit, emphasizing the importance of planning before designing.

- CAD Skills: Using Onshape improved my proficiency in 3D modeling, from basic sketches to complex extrusions.

- Functionality: Incorporating features like cup holders and cable pass-throughs tailored the caddy to my personal needs.

- 3D Printing Considerations: Adjusting the model's orientation for stability during printing highlighted the relationship between design and manufacturing.

- Problem-Solving: Overcoming challenges, such as ensuring the indentations didn't compromise the structural integrity, enhanced my critical thinking.

Overall, this project bridged the gap between digital design and tangible utility, resulting in a personalized accessory that enhances daily comfort.