Getting Started With Ender 3v3 Se and First Impressions

by Amit_Jain in Workshop > 3D Printing

13288 Views, 1 Favorites, 0 Comments

Getting Started With Ender 3v3 Se and First Impressions

Hi All,

Creality has launched a new Ender 3 v3 se 3d printer

In this instructable, I will share how to get started, with it.. and How different it is from Ender 3 (original). It is a huge upgrade in the price range of an entry-level 3D printer. But it has a few issues that I will share

Supplies

Unbox

- Open the box and place its contents on a table

- You do not need to buy any tools, all are included in the package

Assembly

- Assembly is simple, follow the instructions from Creality or the official video here

- The printer comes 90% pre-assembled

- We need to put the gantry and base together

- Fix the screen and some wires

- Remember to set 110V or 230V based on your location

- Assembly took me 15 to 25 minutes unlike few hours on my ender 3

Bed Leveling

- The first thing one needs to do is to auto-level the bed

- The process is simple and the printer does it all

- As you can see in the picture, my bed is wrapped

- The printer should be able to adjust automatically*

- I am quite used to manual bed leveling and I miss the adjustment knobs

Firmware Upgrade

- This step is optional

- Go to Creality website https://www.creality.com/pages/download-ender-3-v3-se?spm=..page_1934481.products_display_1.1&spm_prev=..index.header_1.1

- Download the firmware and follow the steps as per the release notes

- This is extremely simple compared to what I had to do on my Ender 3

Printing

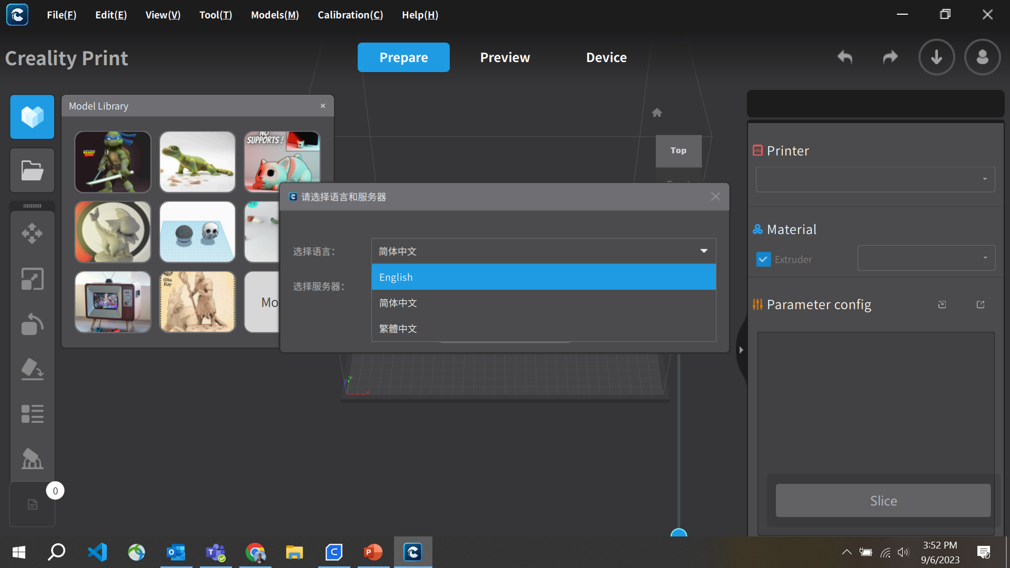

- Since the printer is new, we do not have it in the Cura 5.4 slicer

- The only option is to use Creality Print 4.3 or higher

- If you have been using Cura for a long time, then will find creality slicer a bit hard to use

- It has a marketplace for models, settings for printers, and profiles are mixed

- issues with software

- Limited profiles ( only 0.1 and 0.2 mm layer height)

- No jerk control, even after enabling

- Overlap between skin and top layer is not enough

- Retraction settings needs to adjusted to lower value

Print Quality

- Over the weekend I printed a few different objects

- my observations

- Positives

- Easy Installations

- Quiter than Ender 3

- 32 bit MB

- Print at higher speeds

- Direct drive

- Can print big objects faster

- Negatives

- The creality slicer needs improvements

- Jerk control needed for X and Y

- Compensation for auto-leveling is not good

- The flexible bed has a plastic layer, that easily melts

- Many plastic parts are used, which could lead to unknown issues

- Build volume dues to cable is reduced to 210mm on Z axis

- Smaller objects need to be printed at lower speeds

Cura

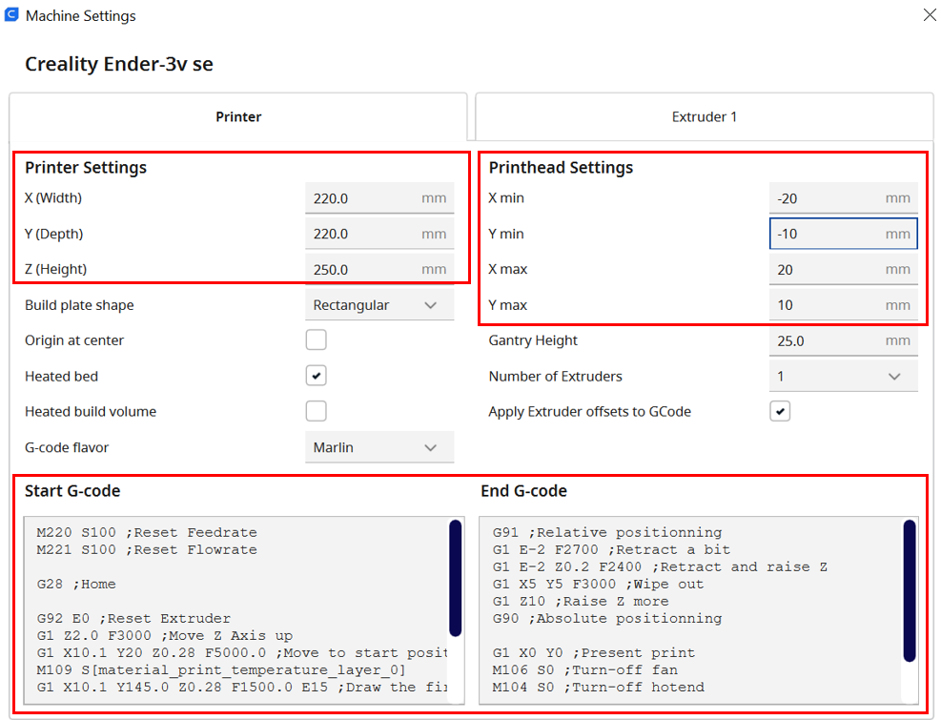

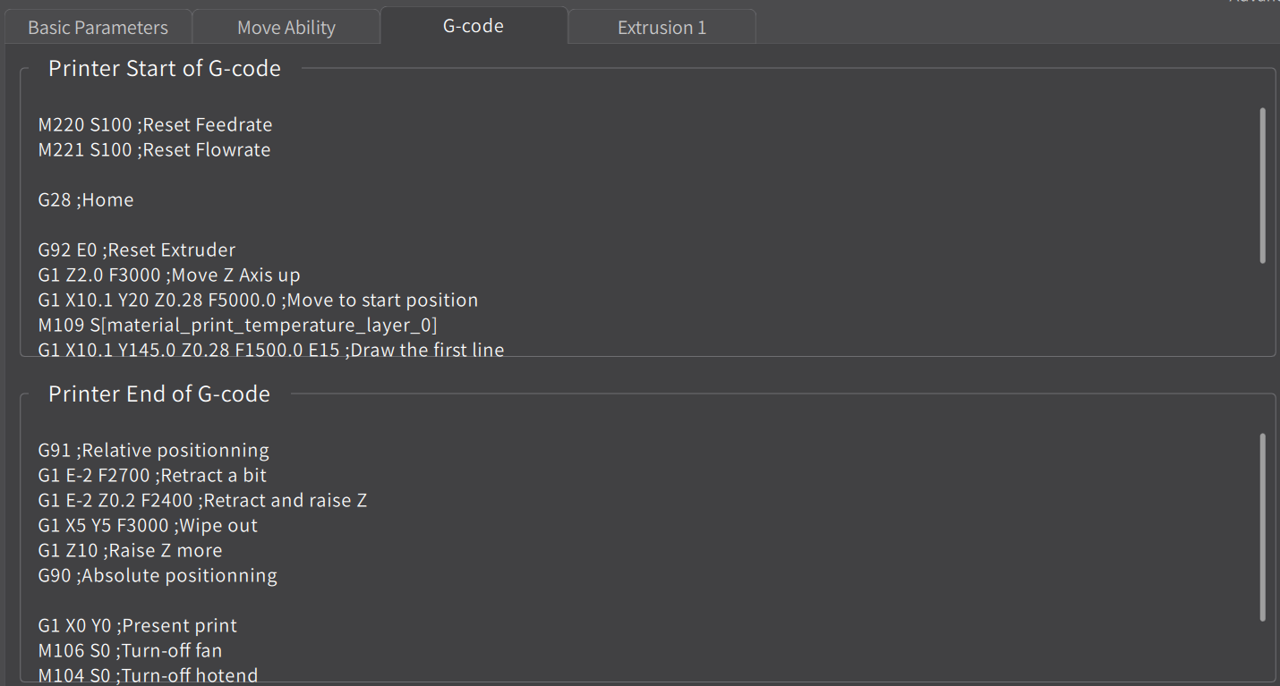

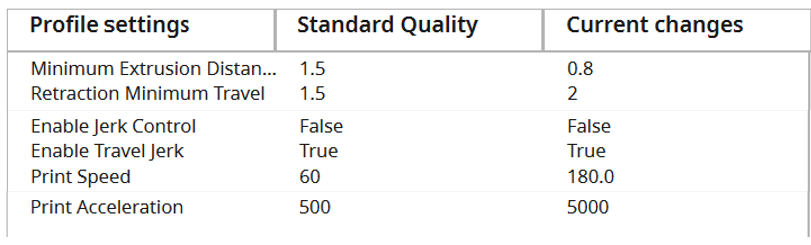

- This step is optional: I tried to create a machine and profile that matches Creality's slicer

- Machine definition cannot be exported or imported in Cura, so all steps are manual

- In Cura add a new printer select Ender 3 s1 or higher

- Then copy the setting from Creality Slicer to Cura

- Then edit a standard 0.2 mm layer height as in the picture

- I was able to print faster, without jerks, but was not able to get the same speeds as the Creality slicer

- Needs more work

Suggested Upgrades

- Bed

- Converting to an adjustable spring-screw mechanism is possible

- Glass bed

- Or PEI plate

- Printer

- Firmwave is still not open source, maybe later, we will be able to use Marlin and fix a few issues

- The cooling fan is 3D-printed and needs to be changed with a better one

- Cura slicer

I am happy with the printer, just that I miss a few tinkering options on it. Perfect for any beginner