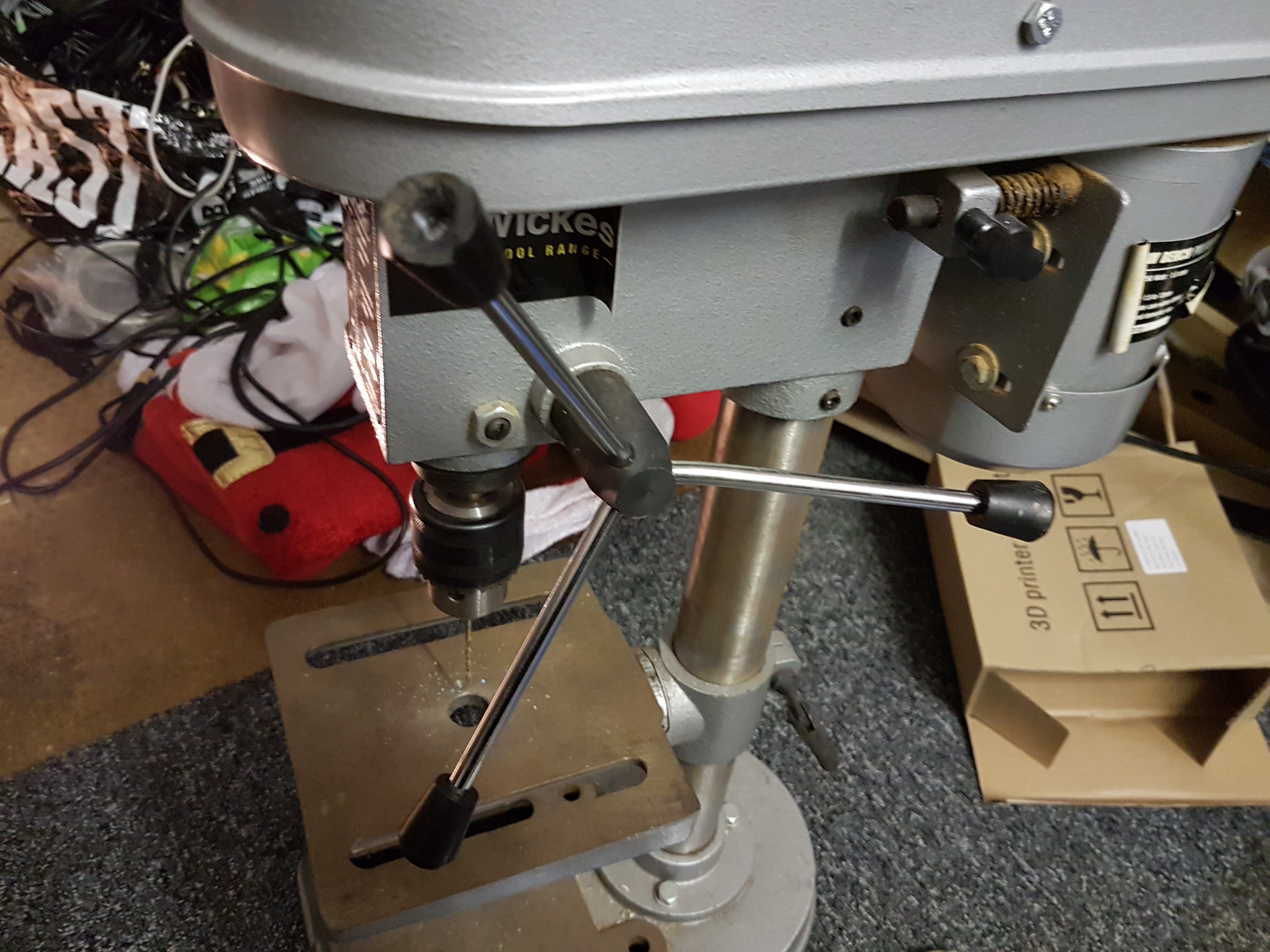

Drill Press Feed Handle Replacement

by IQsWorkshop in Workshop > Tools

3154 Views, 10 Favorites, 0 Comments

Drill Press Feed Handle Replacement

In this Instructable, my 9yr old son fixes my drill press by modelling a replacement handle in Fusion 360 and prints it out on our 3D printer.

The final part can be found here on Thingiverse

Feel free to vote for us be clicking the "Vote" link in the top right corner

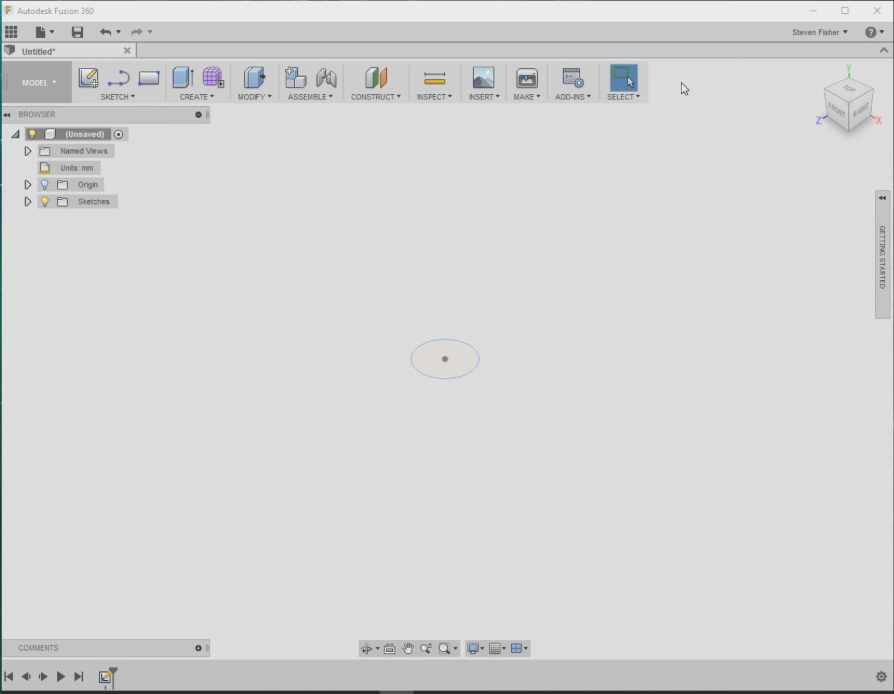

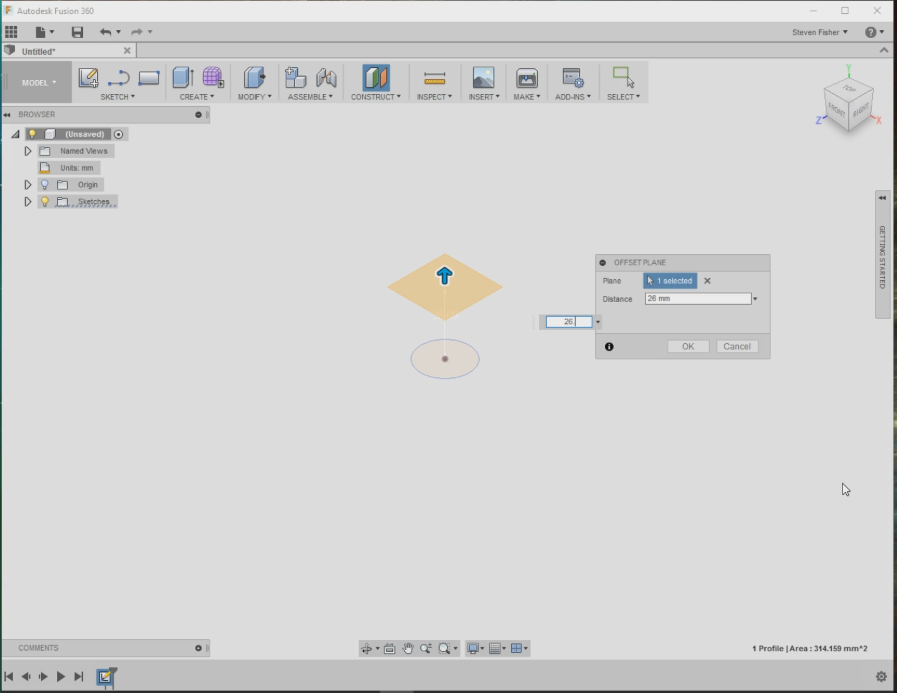

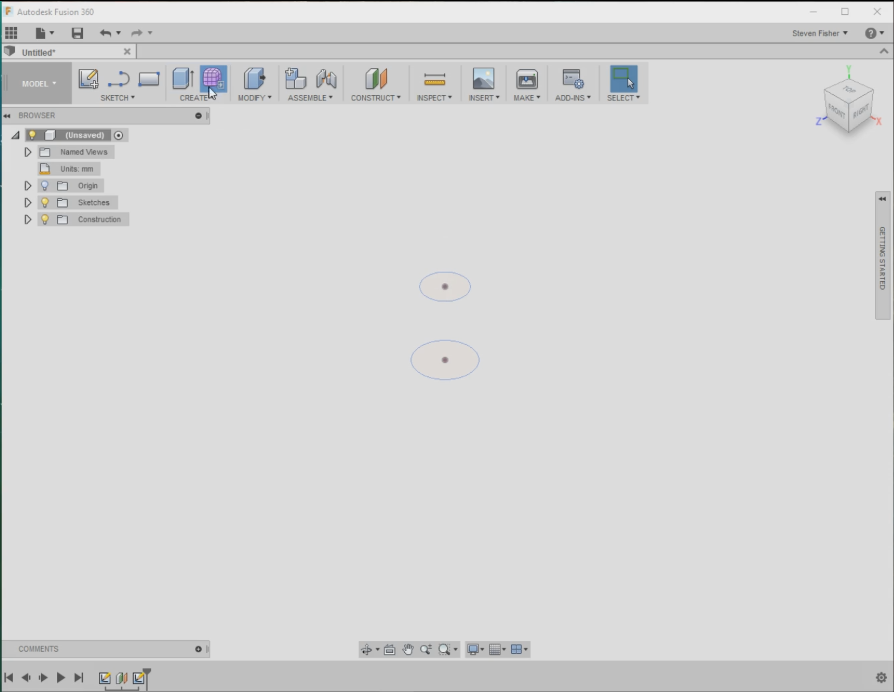

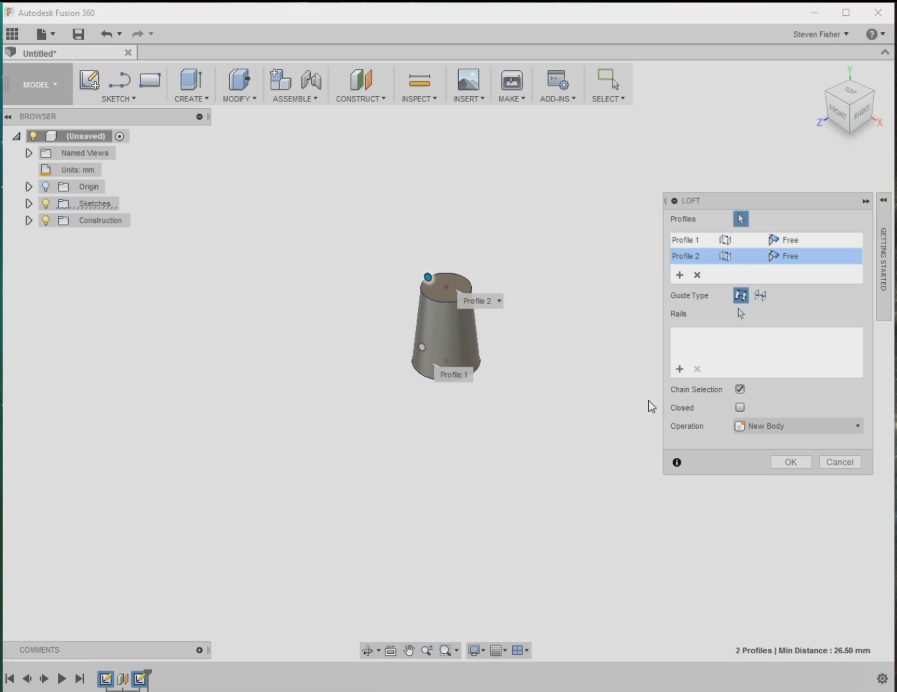

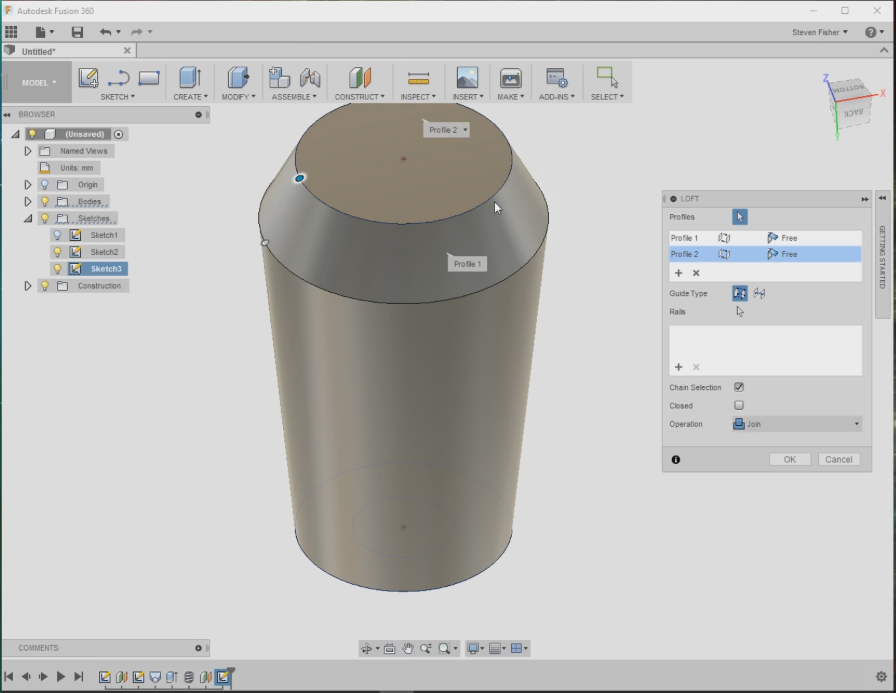

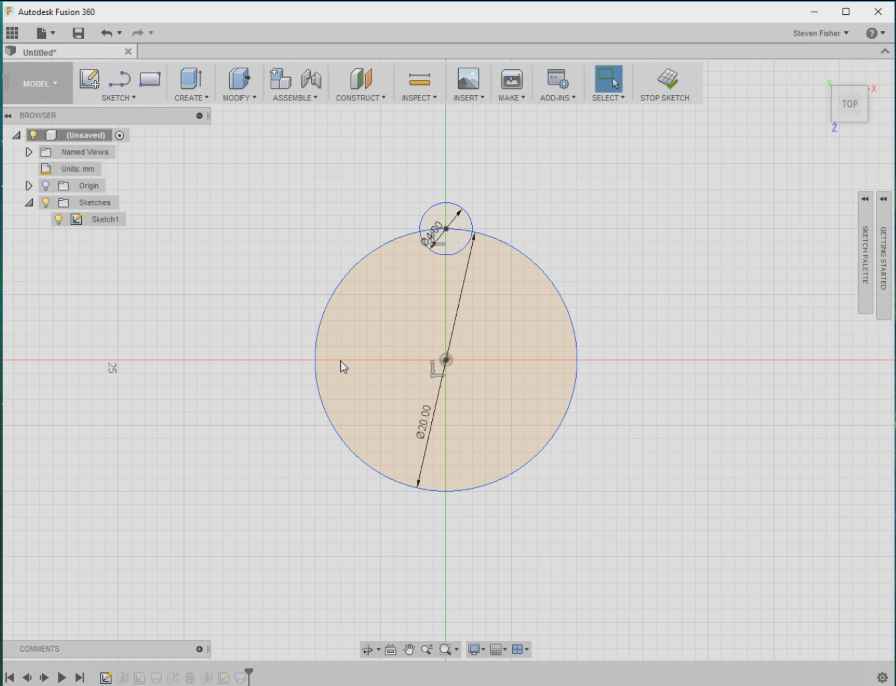

Shaping the Main Body

We started by creating a sketch looking down on the X/Y plane and created a circle. Next we created an offset plane and created a new sketch of a smaller circle on that. Using the loft tool, we connected the 2 circles to create a solid body.

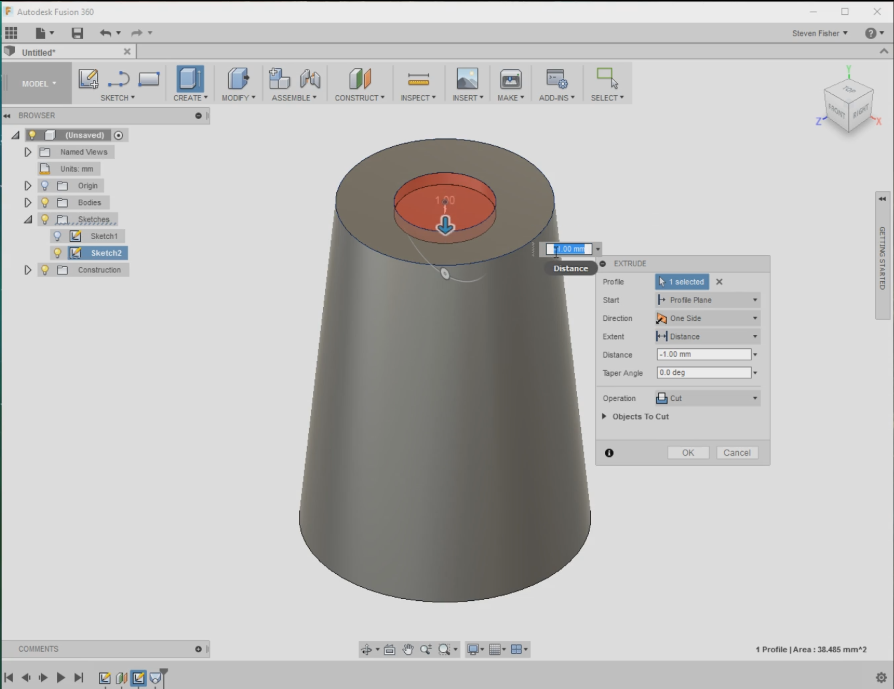

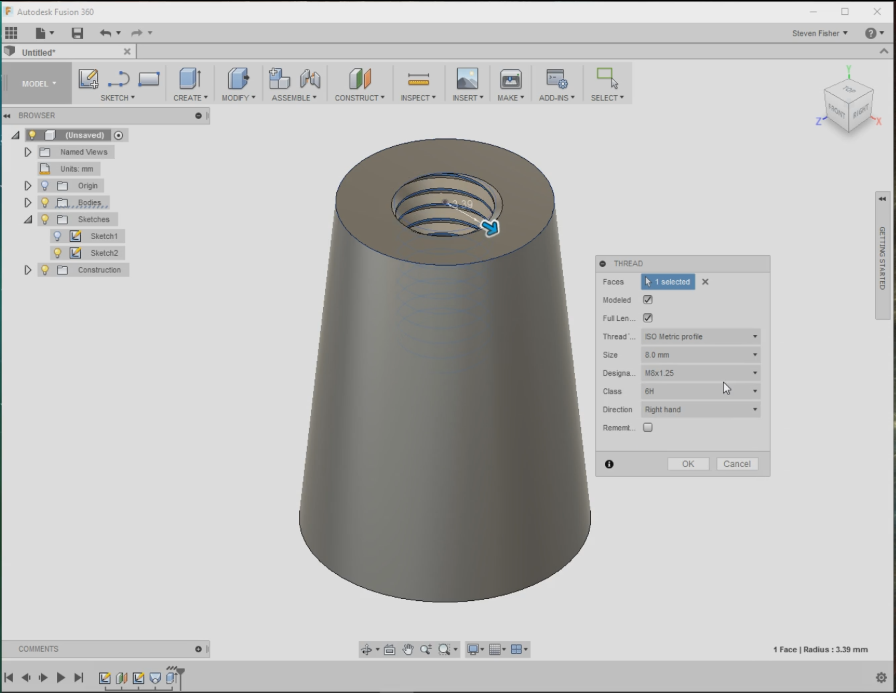

Creating the Threads

Next we drew on the top face of the body to make the hole to attach the handle to the drill press. Using the extrude tool, we put a negative number (-12) to cut into the body.We then used the thread tool to model the M8 threads we needed, but we only allowed them to go 8.5mm down the hole. This was to address an issue with the original which caused it to fail in the first place.

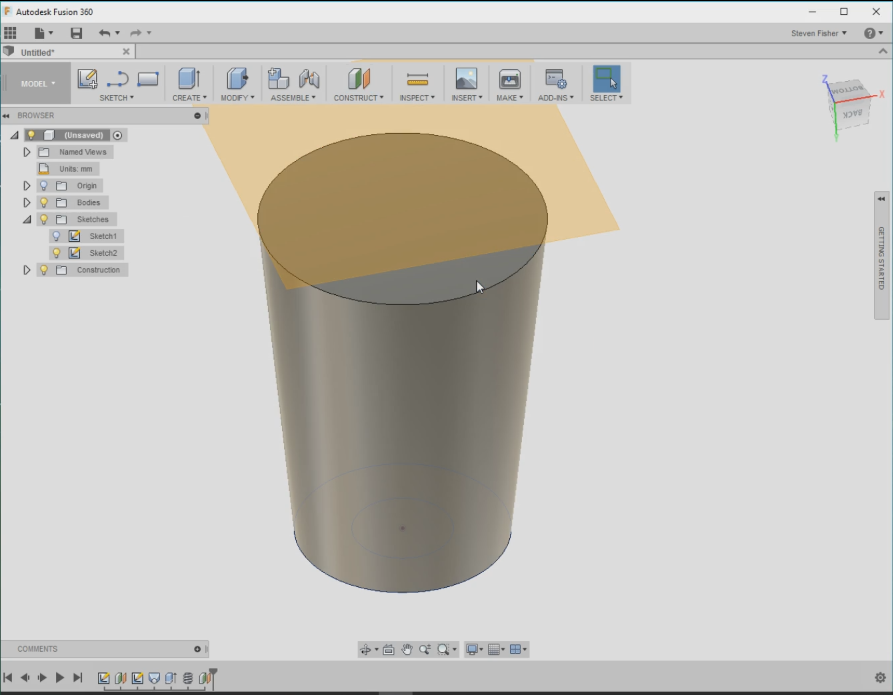

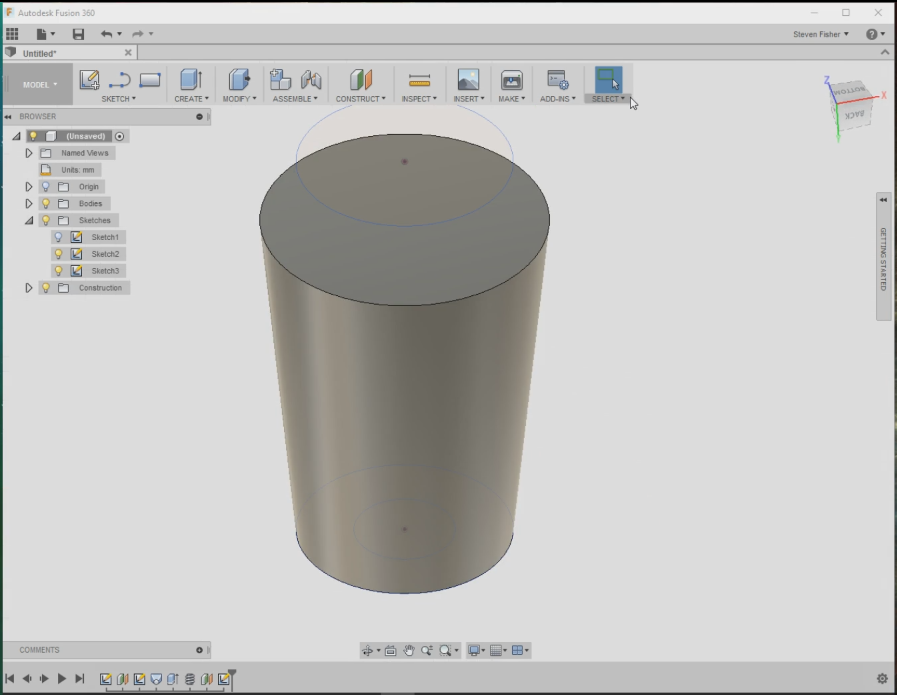

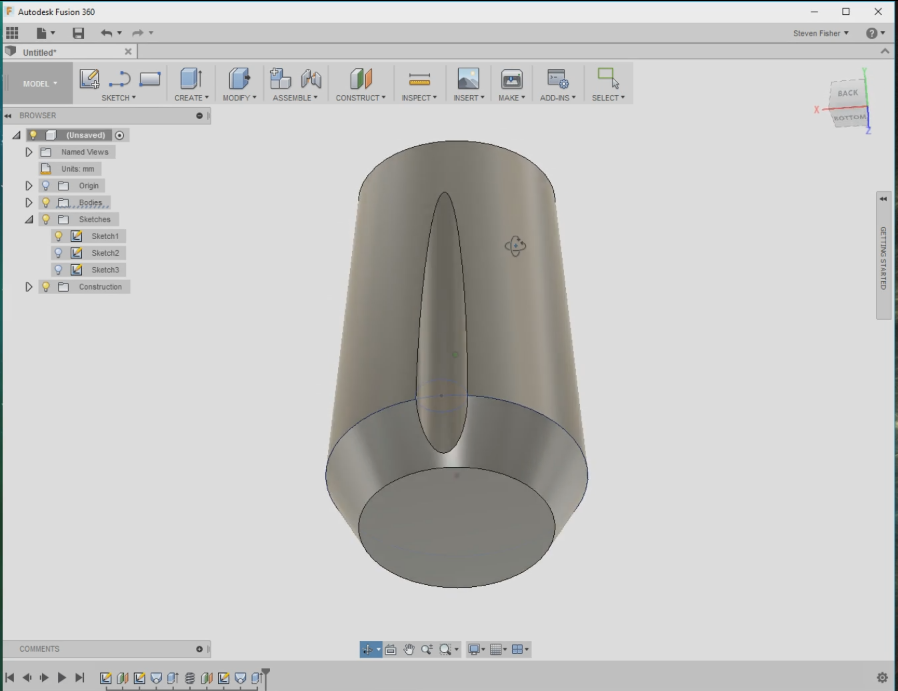

Finishing the Main Shape

To finish the main shape of the handle, we flipped the body over and created an offset plane 5mm from the face. We then drew a circle to represent the end of the handle and connected it using the loft tool again.

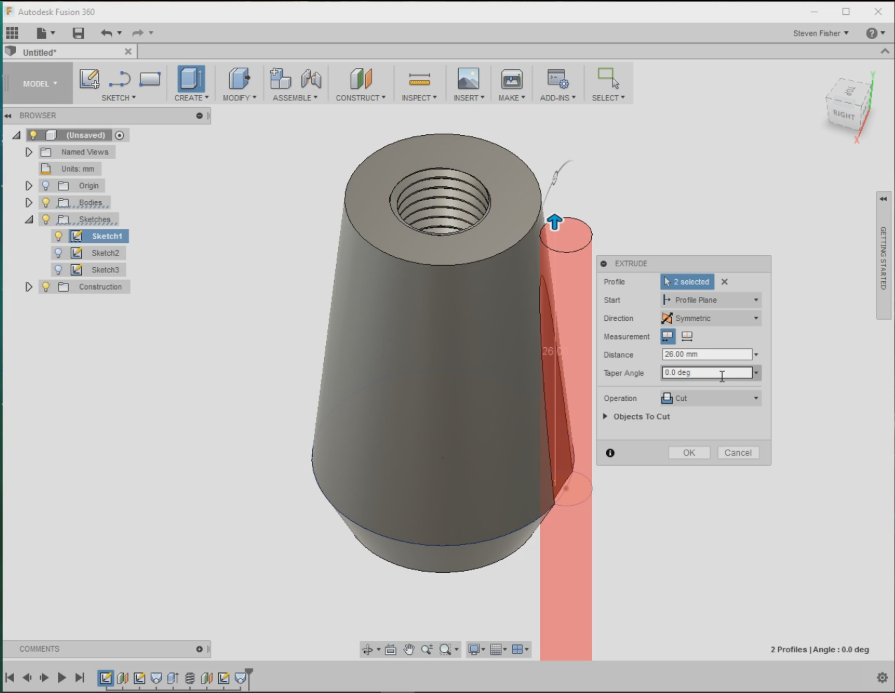

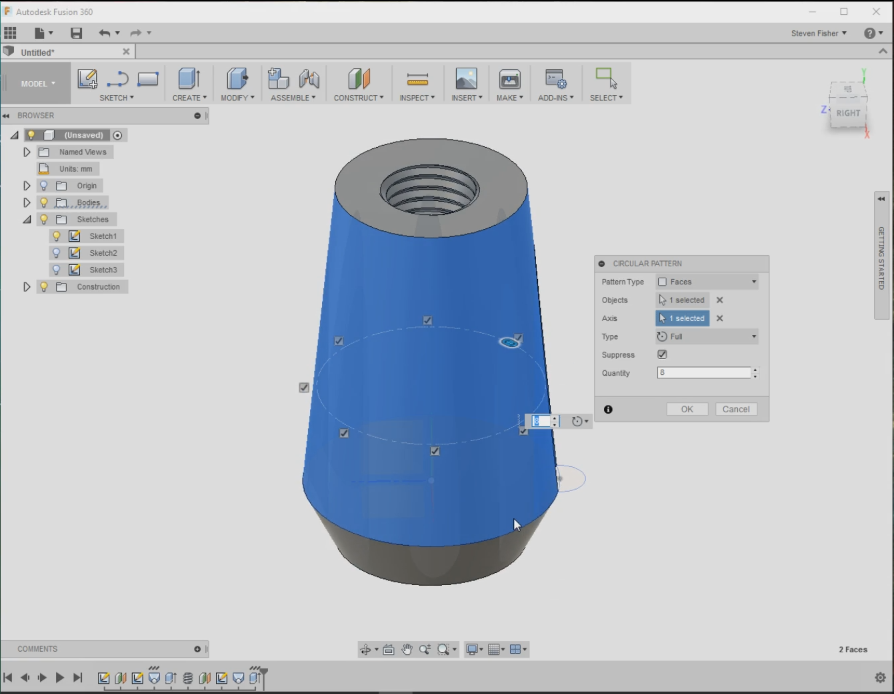

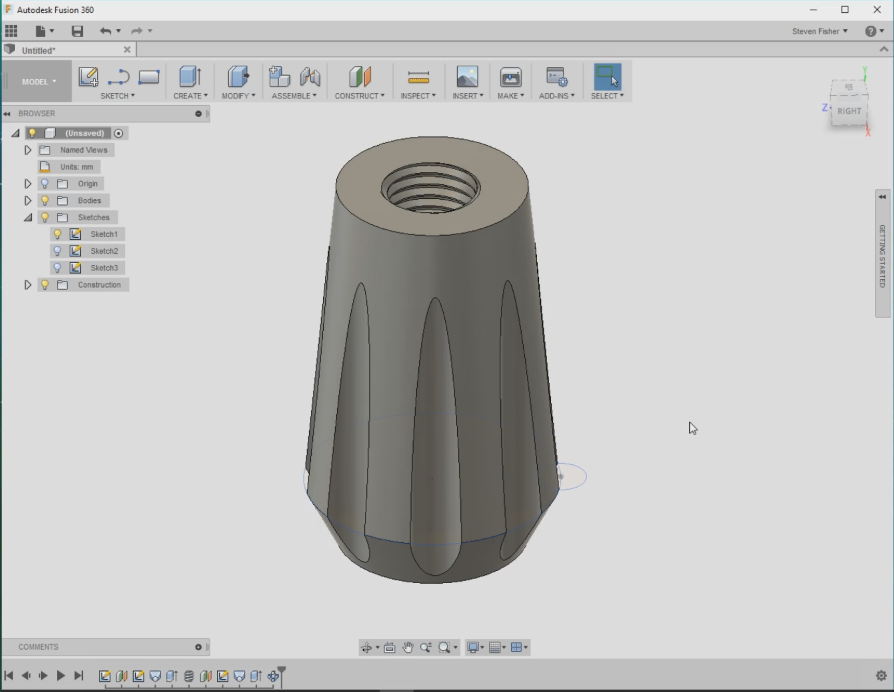

Creating the Grips

To create the grips, we went back to the first sketch and added a circle at the outer edge of the first one. using the extrude tool we cut the shape into the body, making sure this was done in both directions.

Once this was completed we used the circular pattern tool to copy the cut around the handle finishing the model

Finishing Up

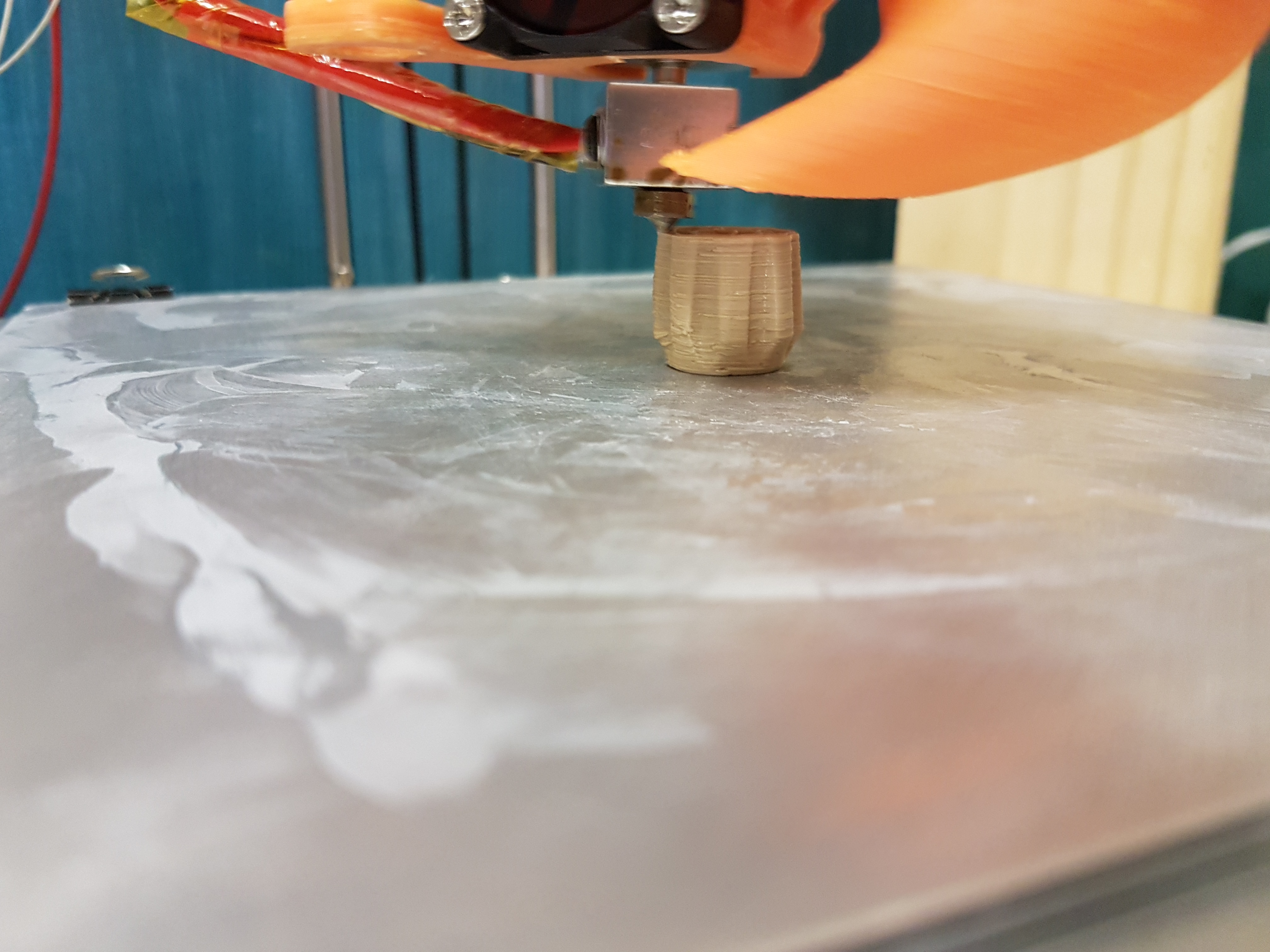

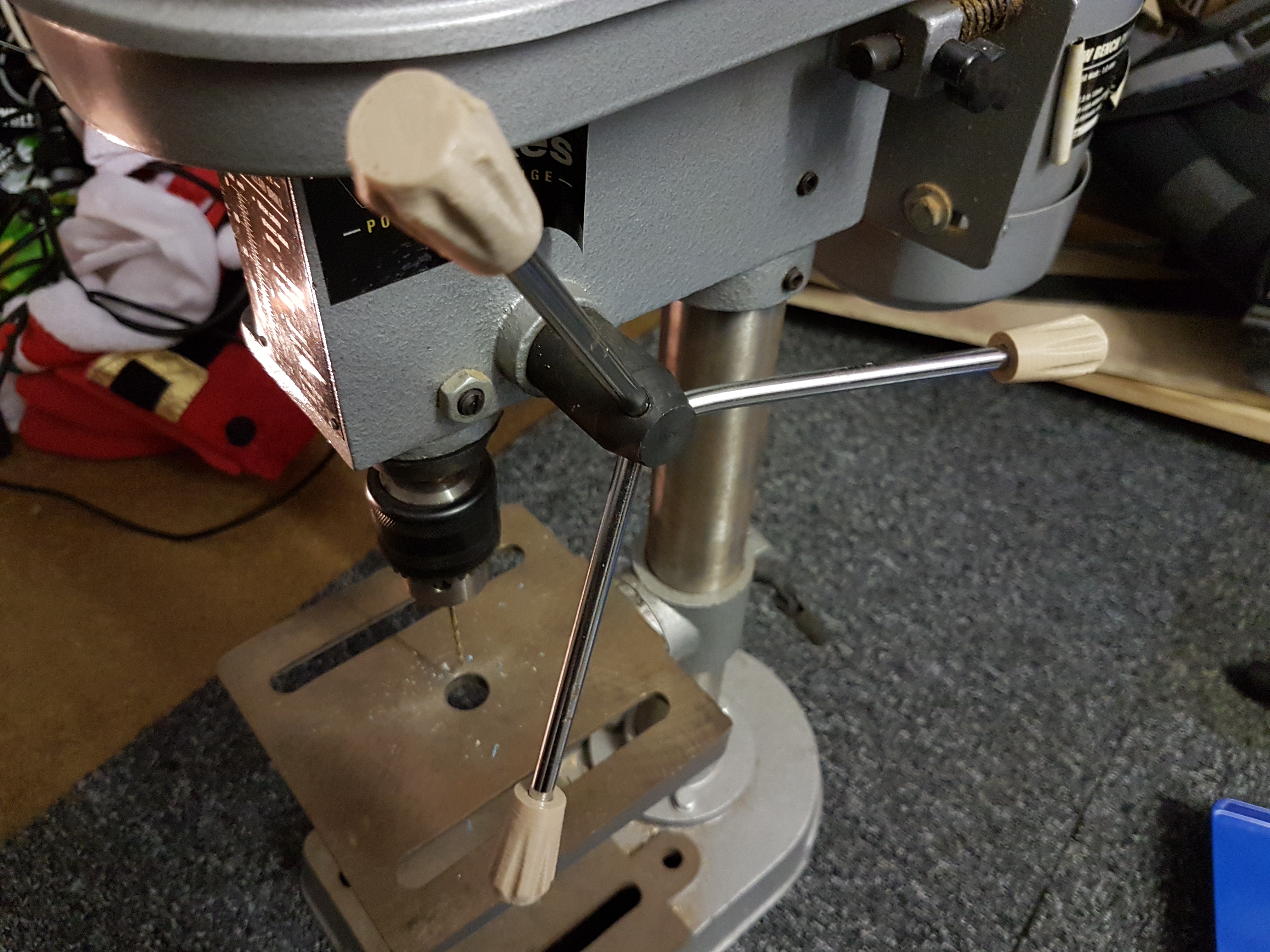

The model was then exported to our slicing software and printed in wood PLA.

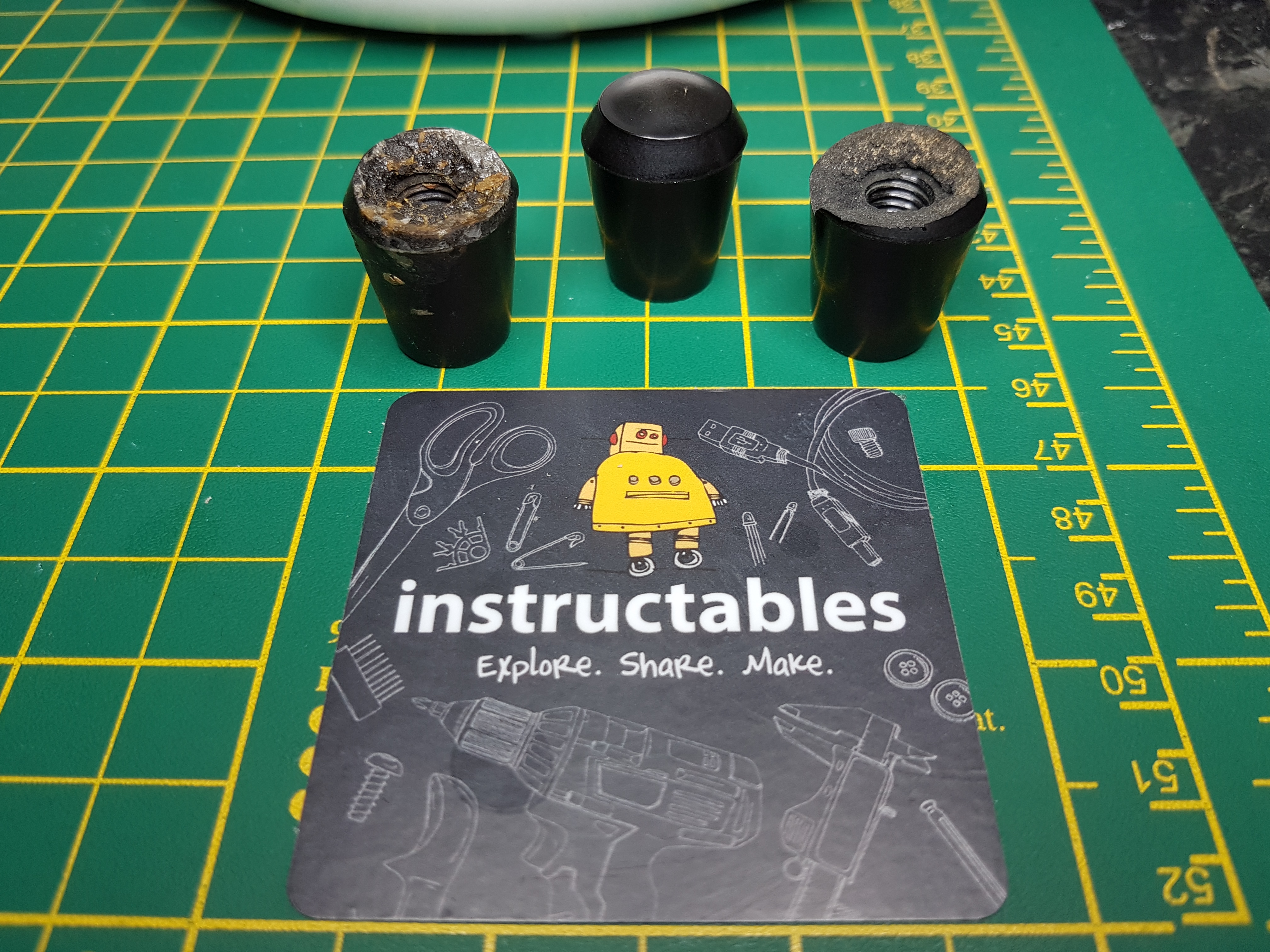

The threads turned out great, but they were a little stiff, so we ran a tap in them to make them perfect.

All in all this was a great project and my son has learnt so much from the experience.

I'm sure you'll agree that the finished item looks amazing on my drill press.

#ProudDad