DIY 3D Printed Phone Cases

by fryfoxone in Workshop > 3D Printing

2159 Views, 7 Favorites, 0 Comments

DIY 3D Printed Phone Cases

When looking online for an affordable phone case that I like, I found that there was nothing that would match the quality and design that I expected.

To solve this problem I turned to my 3d printer and started to design a phone case that would be durable, have a great design, and have good quality.

Let's take a look at what I made!

Supplies

- 3D printer (make sure your nozzle can extrude at 0.1mm)

- 20 color PLA plastic kit: PLA plastic colors (Gives you a wide variety of colors to make your design)

- 1 kg of a regular filament (used to make the actual phone case when the design is finished.)

- 1 Flush cutter

That's it!

Model a Phone

The first step to making a phone case through a 3D Printer would be to make a phone to build your phone around.

I went to grabcad.com to get a CAD model of the iPhone 10 (the phone that I currently have). If you have a different phone lookup that phone instead.

I then inserted the model into fusion 360 and started to CAD.

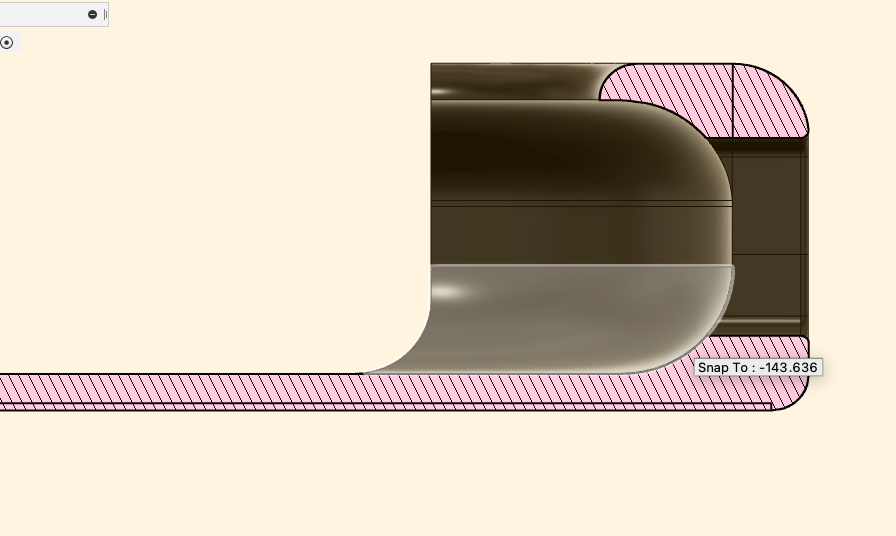

Making a Phone Case

When making a phone case we have to think about a couple of factors:

- What is the ideal thickness of a phone case? If the phone case is too thin, then we risk the phone being too flexible and breaking easily, but if the phone case is too thick, it becomes too rigid and we can not insert the phone into the phone case.

- How can we make the buttons accessible? We need to make sure that the buttons are accessible. If they are not, we would not want to use to phone case.

- What is the ideal tolerance for a phone case? If we design a phone case without any tolerance, the phone case will be too tight and will not fit. If the tolerance is too large the phone case will be too big and will not fit into the phone.

If we can answer these questions we can CAD a great phone case.

For the first question, I found that a 2mm shell around the phone was the best fit. Anything above that was too bulky and would not fit on the phone case, and anything below that was too flimsy.

To answer our second question, we can cut a 1.5mmx1mm box around each of our buttons to get the best accessibility.

To get an idea of the ideal tolerance of the case, I had to prototype three different phone cases and found that the best tolerance for a phone case was 0.2mm.

To CAD your phone case, first extrude the bottom and sides of the phone by 2mm.

Then create a drawing in Fusion 360 through a loft or sweep function to join the 5 parts together.

Lastly, add fillets to your design to make the phone case look sleek.

Making the Design

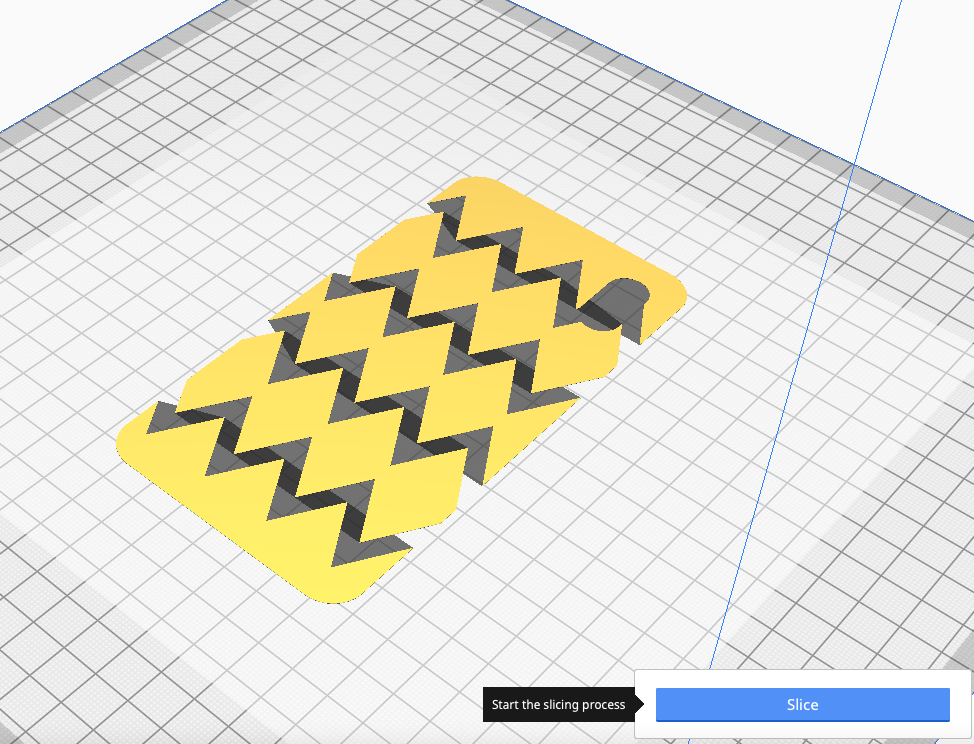

Now that we have created a phone case, we can start to create our designs.

First, extrude the back of the phone case by 0.2mm and create a new body: this will be our canvas.

Then import a DXF file or make your drawing design and extruded it through your canvas and not your phone case.

Color your design so that you can see how it will look in real life.

Import Your Designs Into a Slicer and Create G-Code

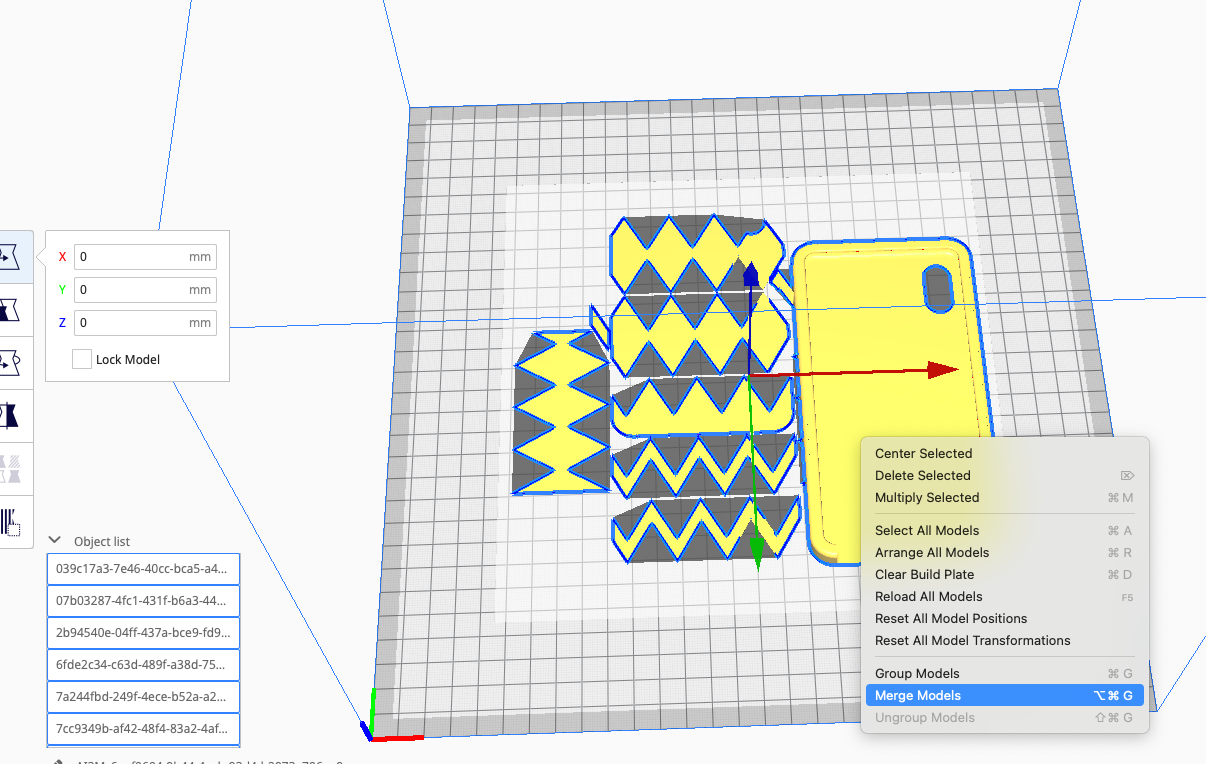

This step is important, you will first need to import your different canvas into your slicer.

Start with your background and then move on with the more detailed designs.

Then import the rest of the case.

When all of your parts of your case have been imported, hit control/command A to select all the models and center them at point (0,0,0).

Next, we have to hit merge model, and all of our models will become one object.

We will now have to recenter the object at points (0,0,0).

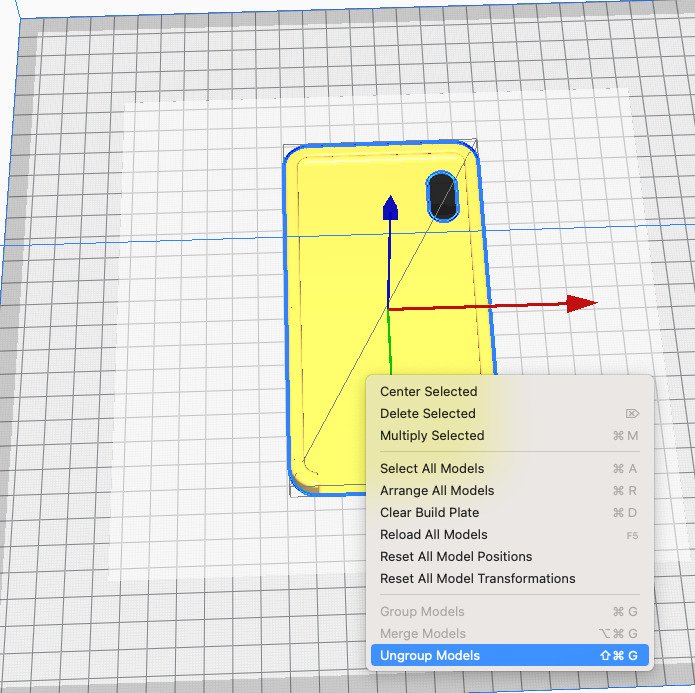

After this unmerge the models.

Now, let's go over your slicer settings:

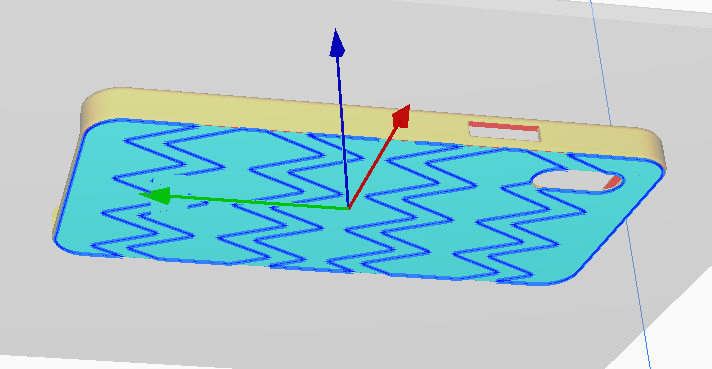

Make sure that you are set to 0.1mm nozzle size and 0.1 layer height.

Let's also set your infill to 100 percent.

We can then change our print speed to anywhere from 20mm/s to 40mm/s. Take the slower speed for more detailed prints, and the higher speed for less detailed prints.

After this, let's set our base temperature to 70 degrees Celcius to guarantee that our print will stick to the bed and set your nozzle temperature to whatever the temperature your PLA melts at.

Lastly, make sure to take off any brim, skirts, and supports because they will interfere with the other prints that we will be doing by forehand.

Once this is finally done, we can finally get to slicing/creating the g-code:

Delete all the objects that are not of the same color. Then slice the file and name it after the color name and the order that it needs to be printed.

Then hit control/command Z till you have all your parts back.

Next, repeat the process for all the other objects with different colors and save the file to your 3D printers.

Printing the Case

The final steps are to print the case,

In the order that you sliced the model, print the model.

Make sure your print bed heat stays constant while you are changing filament, to ensure that the print stays to the bed.

Ideas and Iterations

If you would like to make any of my phone cases here are the files:

I have made a special Space Case if anybody would like to make it on their own time.

The one with the spider is a symbol from a card game called Magic the Gathering.

In total, I have had to make 7- 8 different versions of the phone case to get everything that I wanted.

Testing/Summary

Testing

While creating this phone case, I did a couple of tests on the phone case.

The main test that I did was the drop test.

I dropped my phone case with the phone inside from a distance 5 feet high 62 times before the edge of the phone case cracked and broke off (Shown in the third image). My phone took none of the damage, which was very surprising.

I also tested whether the phone case would work outside and not melt in the heat, which it did not.

Summary

In summary, this is a great idea if you want to get a custom phone case that is strong and usable on a daily basis. All it needs are are some different color filaments and a creative design from yourself to get a great phone case.

Thank you so much for reading this Instructable