Convert a 3D PRINTER to LASER ENGRAVER | Under 40$

by Jakes workshop in Workshop > 3D Printing

138351 Views, 614 Favorites, 0 Comments

Convert a 3D PRINTER to LASER ENGRAVER | Under 40$

What is up everybody, in this Instructable I am going to show you, how you can convert your 3D printer to a fully functional laser engraver for less that 40$

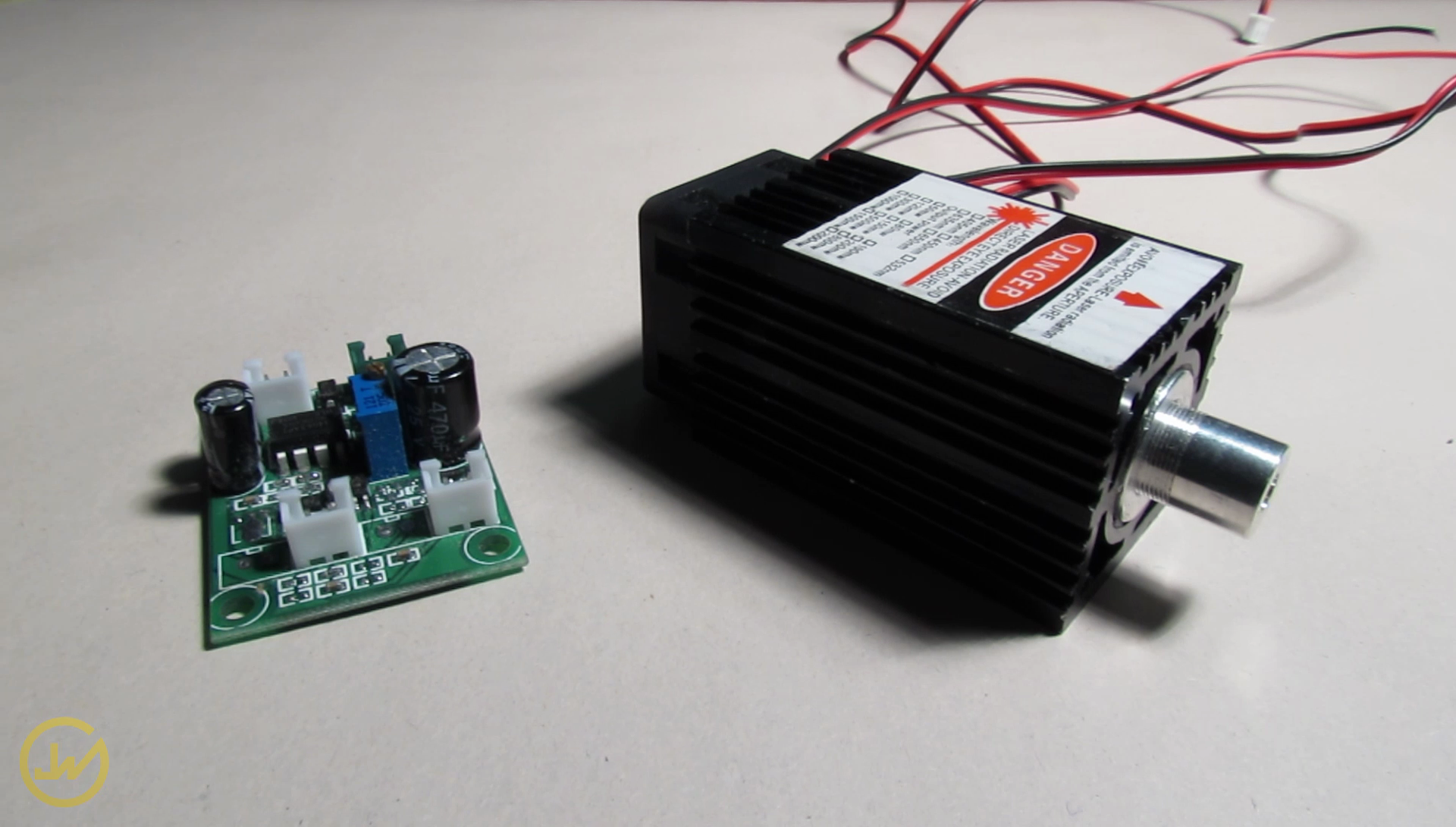

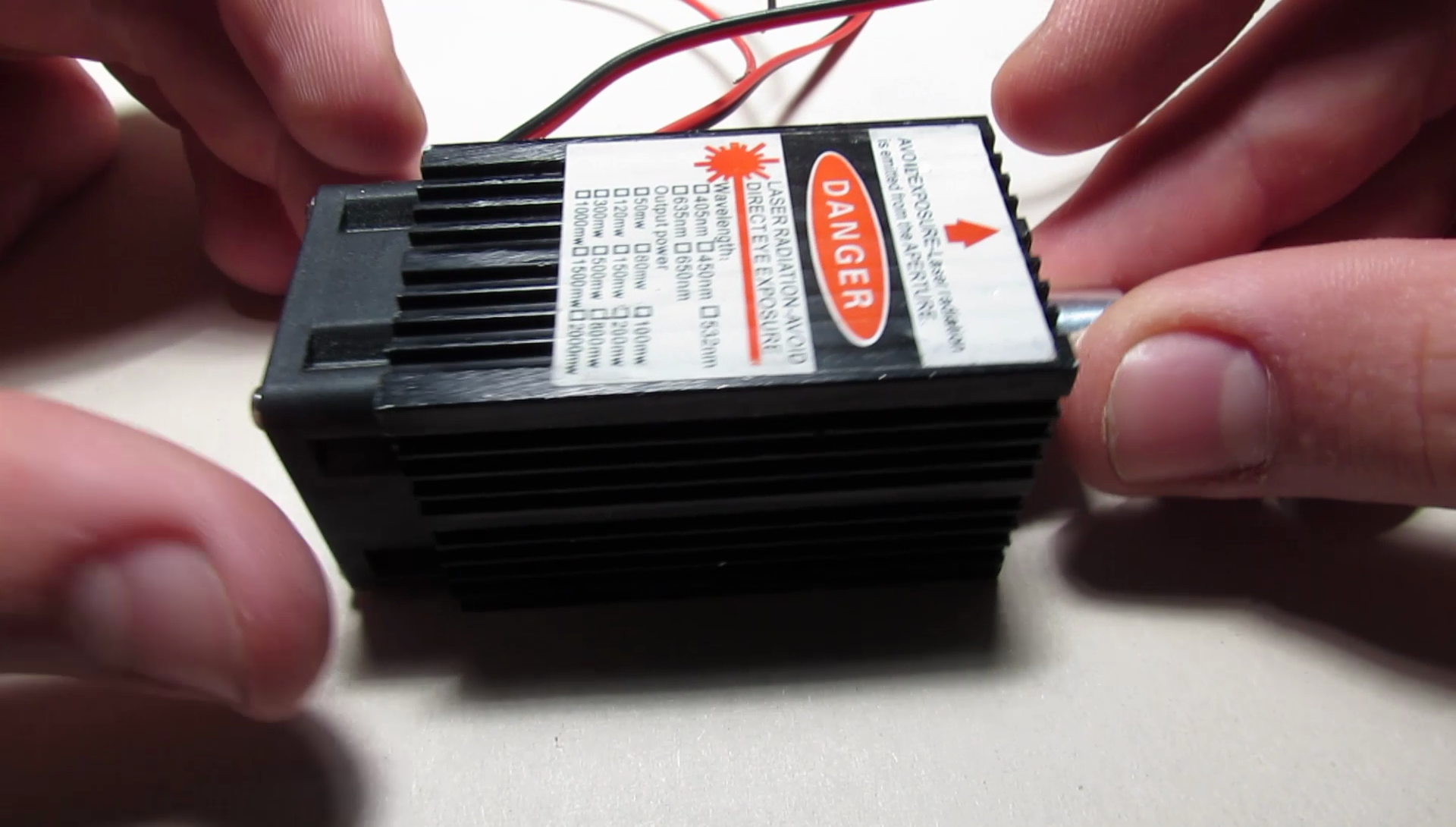

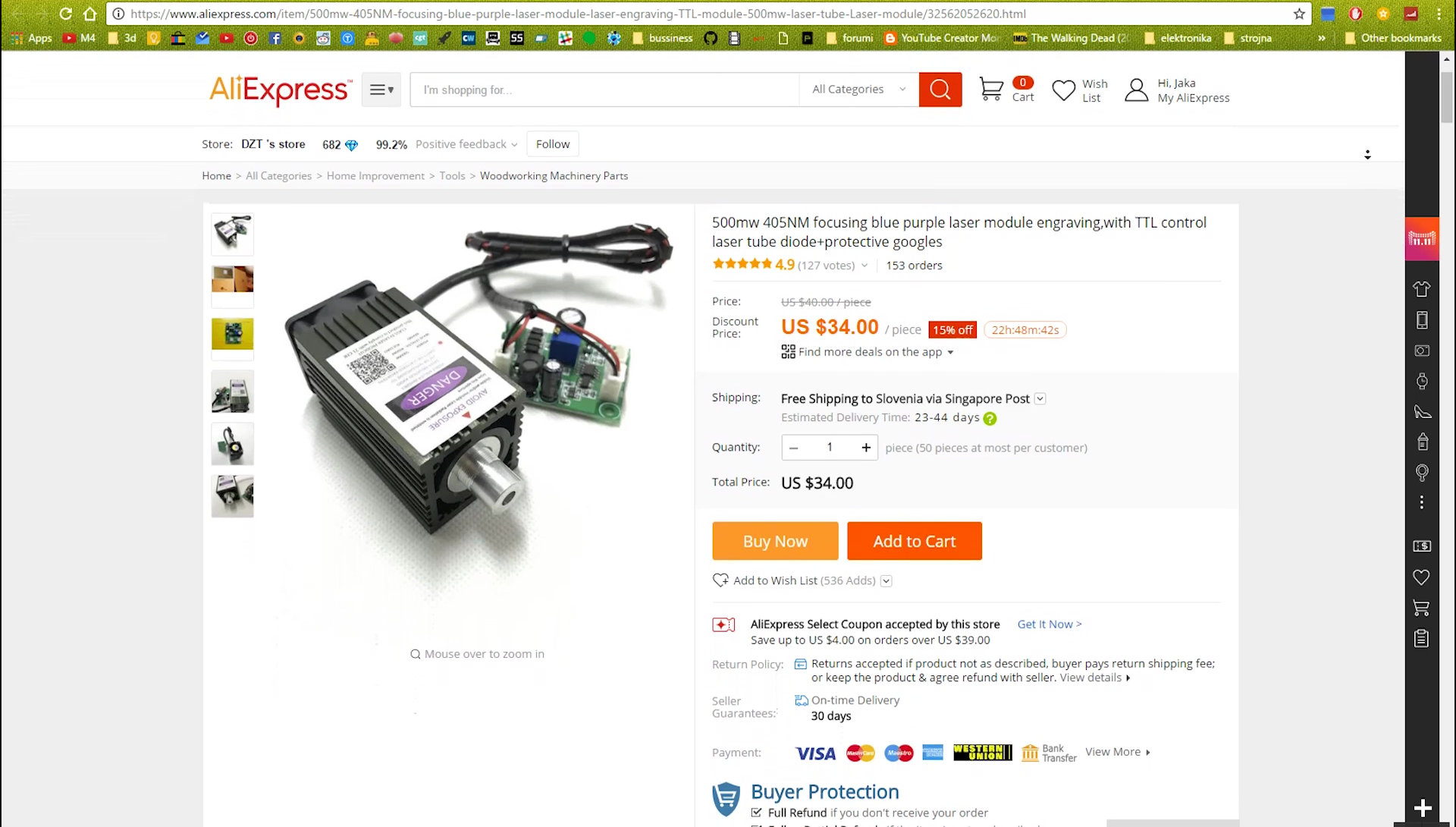

Buying a Suitable Laser

- To start this project we are gonna need a laser that is strong enough to burn into most of the household materials. I found that 500 mw laser is just right for this project due to its low price and capability of engraving in almost every material with exception of metals and glass.

-I bought my laser on Aliexpress for a small price. Here is the link: https://goo.gl/obFmFD

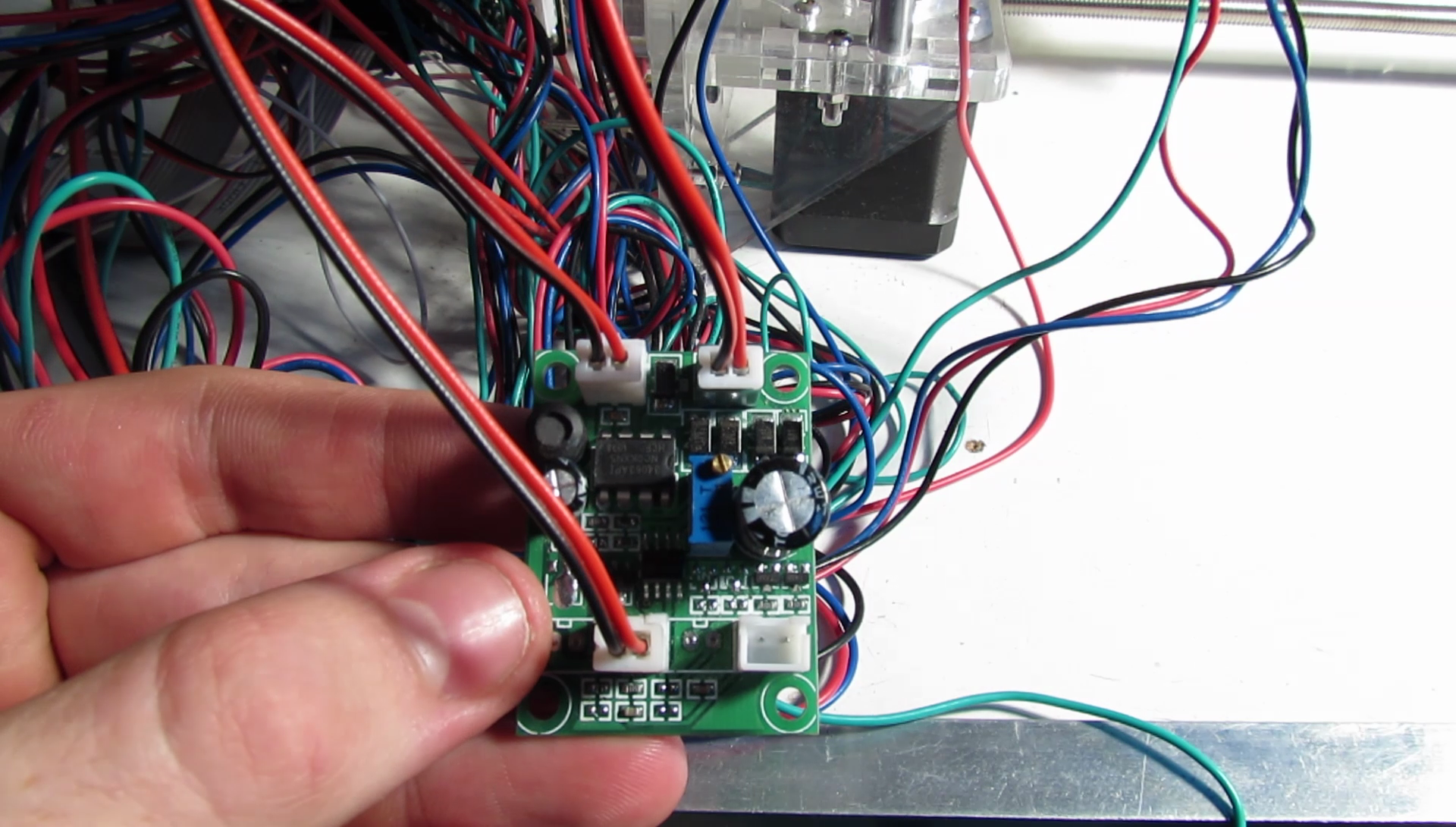

-With laser you will also get a laser driver circuit and a safety glasses which are necessarry when operating with lasers.

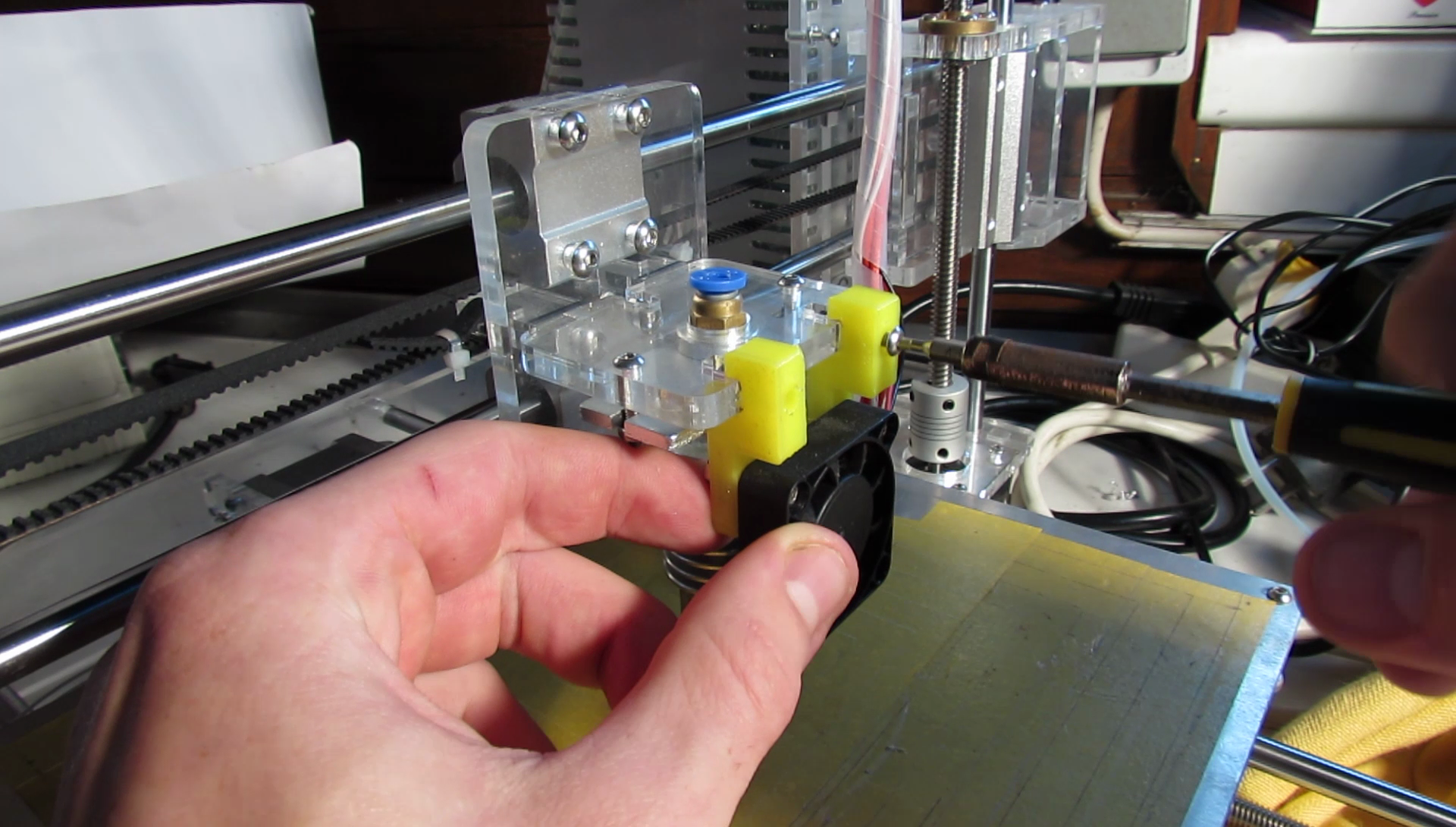

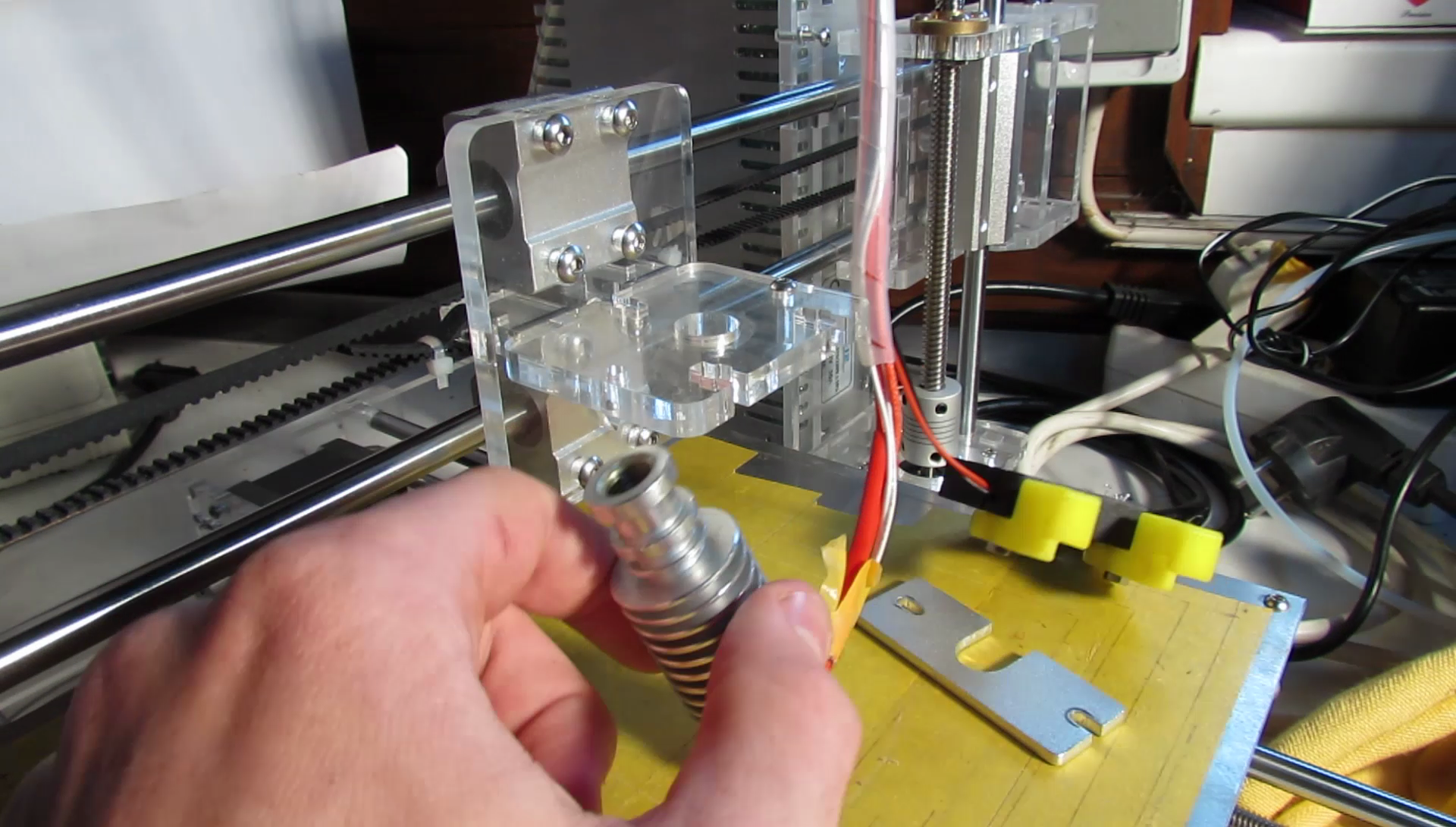

Mounting the Laser

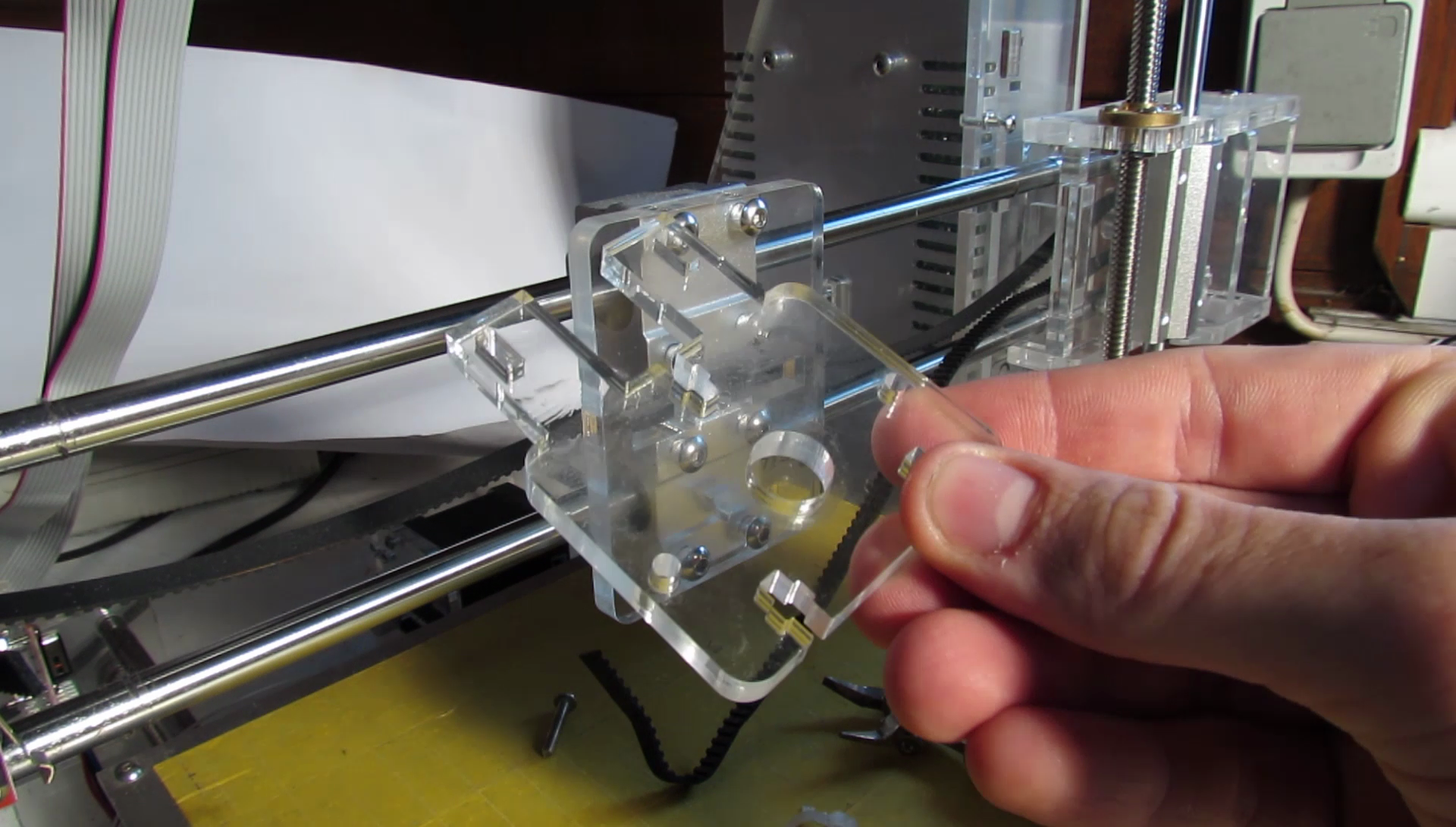

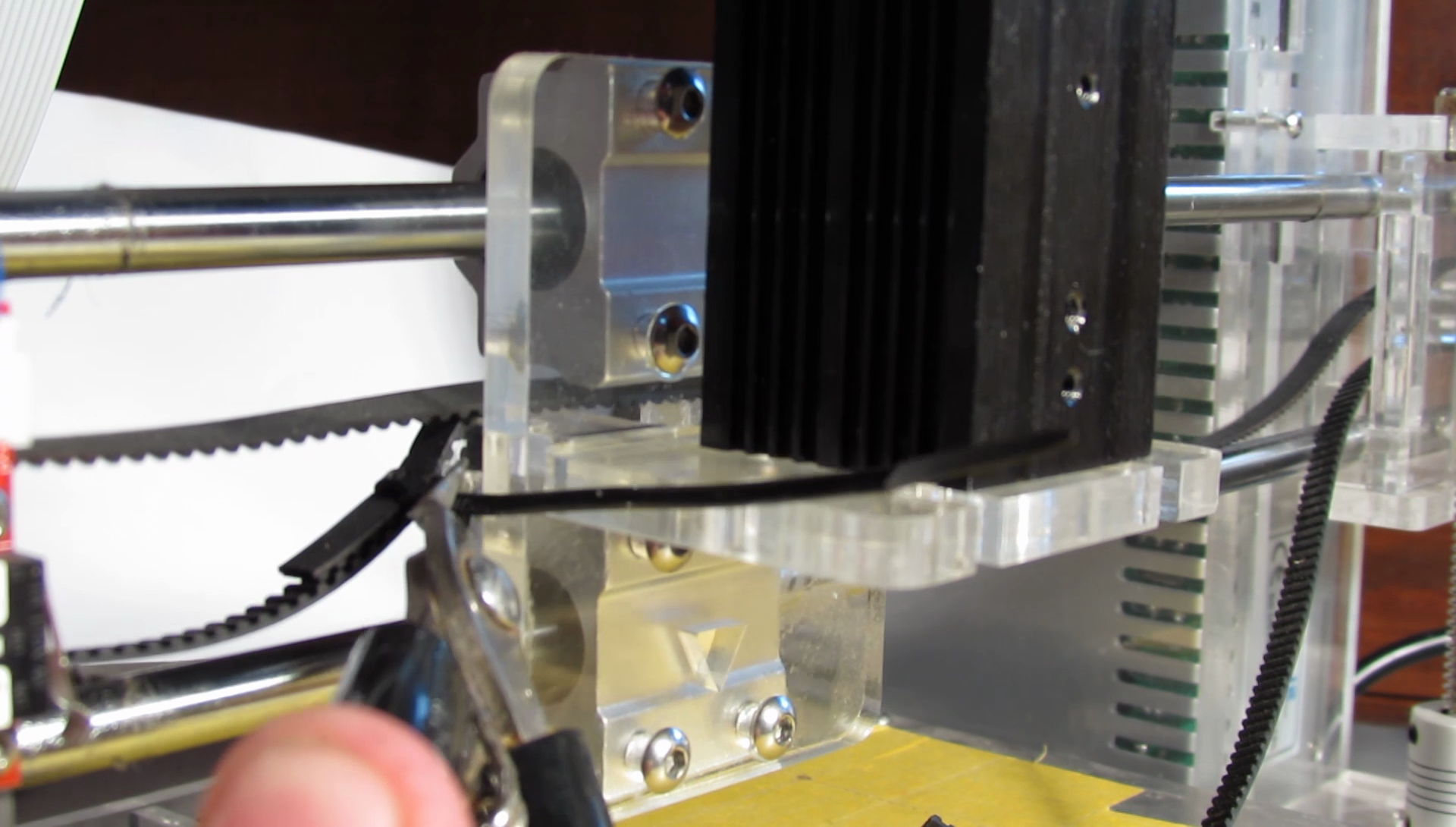

- So I firstly removed a small fan which was attached to the plastic mount and I unscrew a 3d printer hot-end from the same acrilic mount.

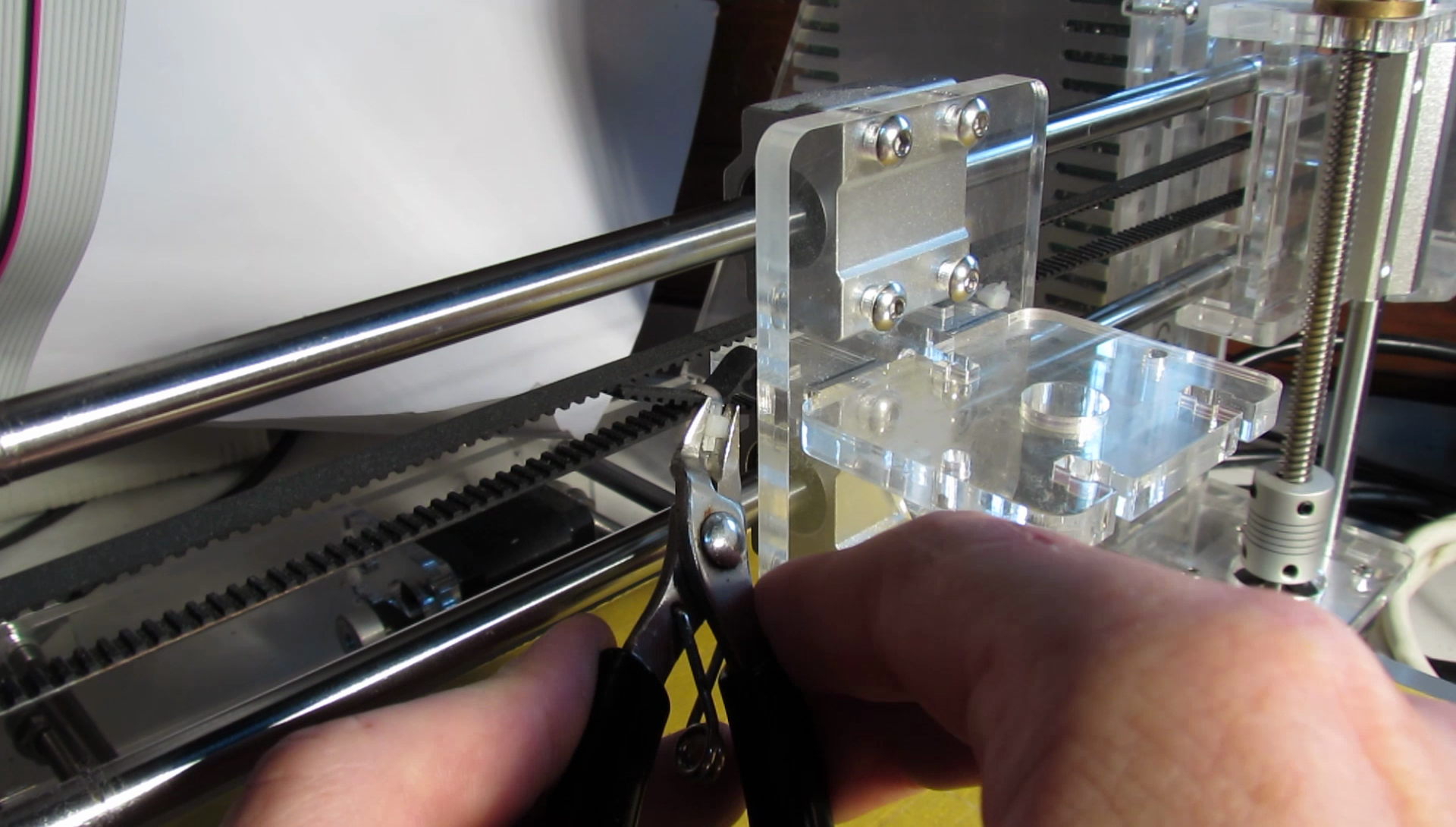

- Then I cut 2 zip ties that were holding a 3d printing belt in place and remove the last screw so we can finally drill 2 holes in the plastic mount.

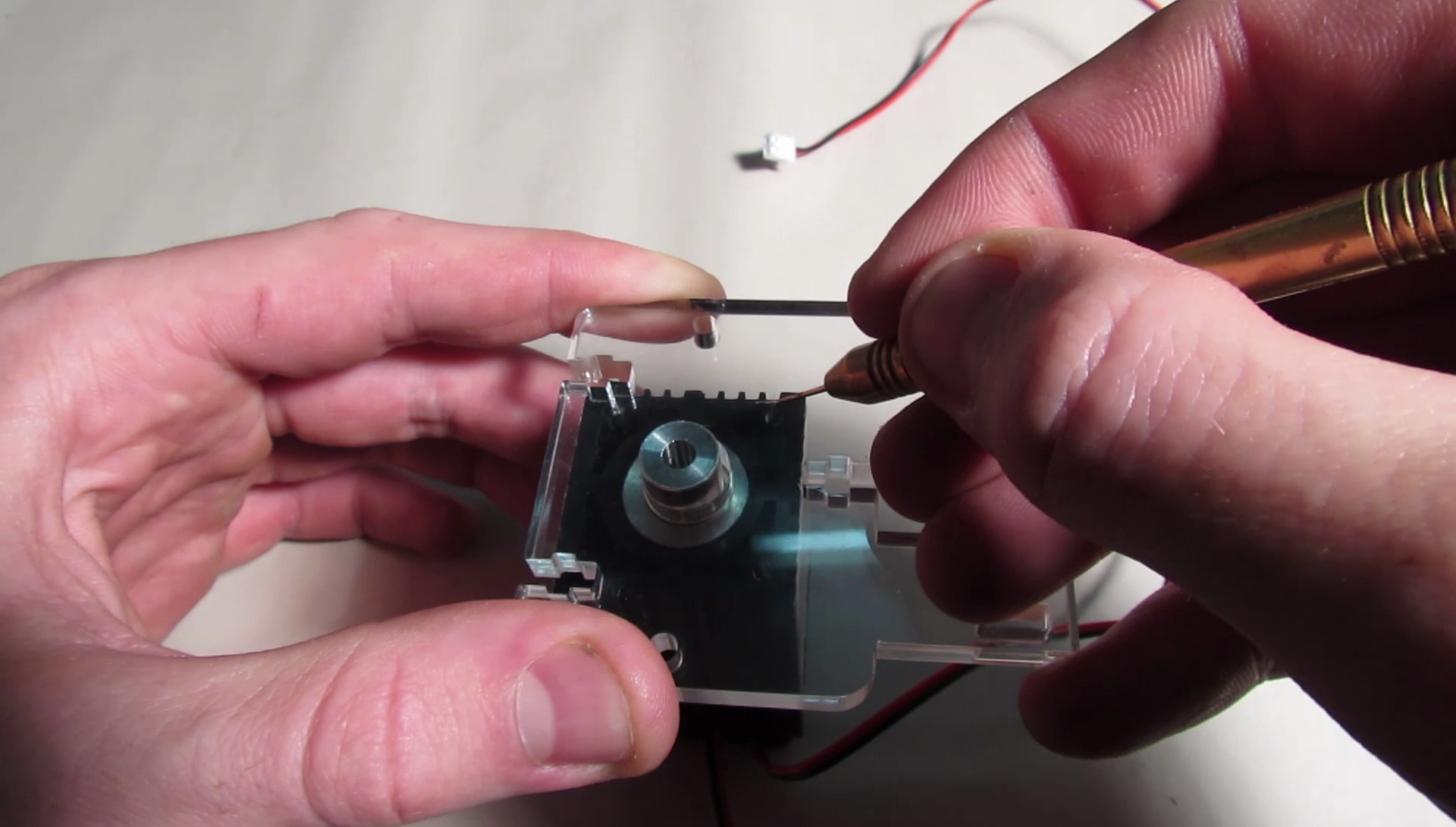

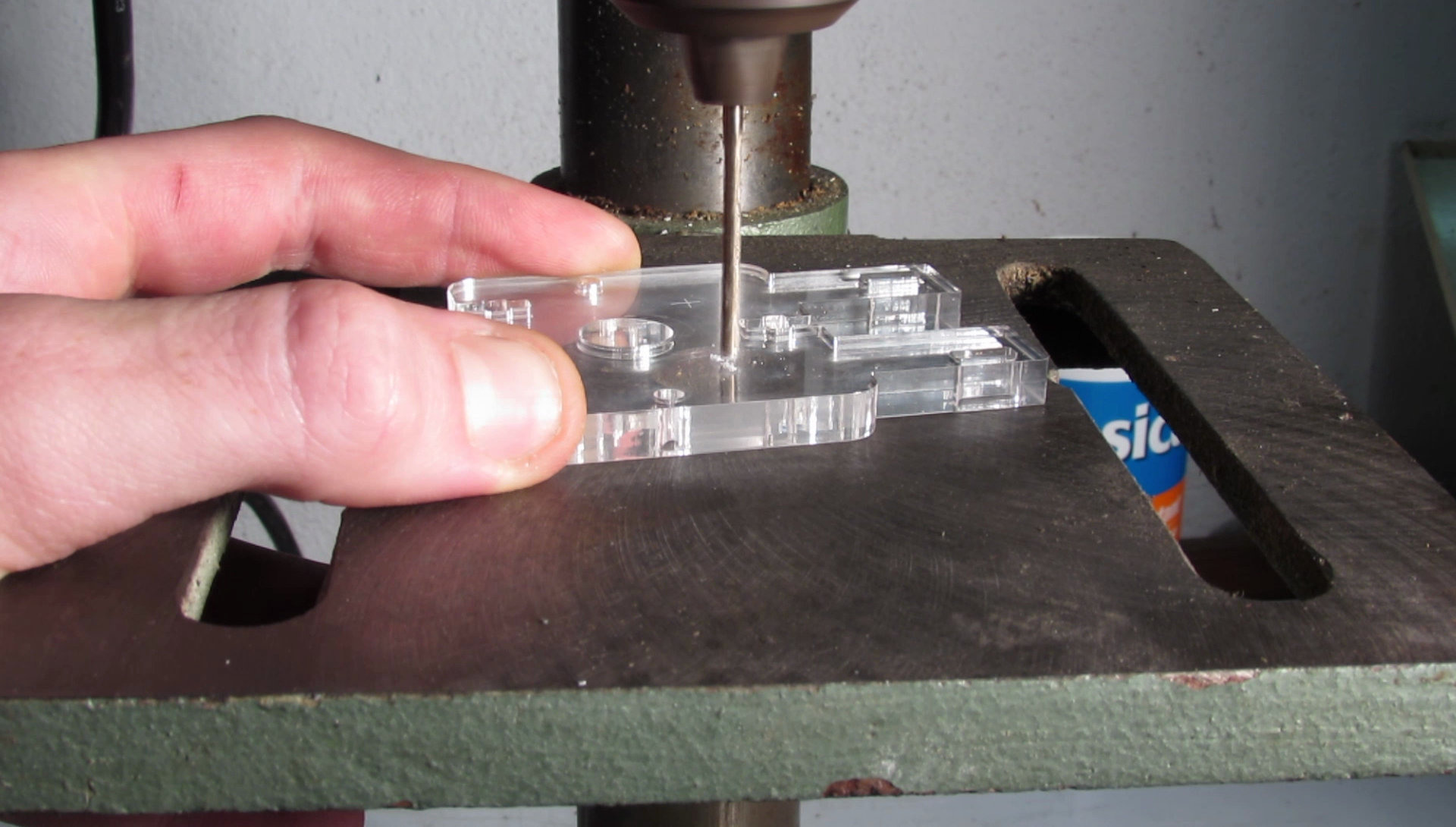

- Laser module had 4 holes pre-drilled so I just needed to mark down the spots where I drilled two 3mm holes on my drill press.

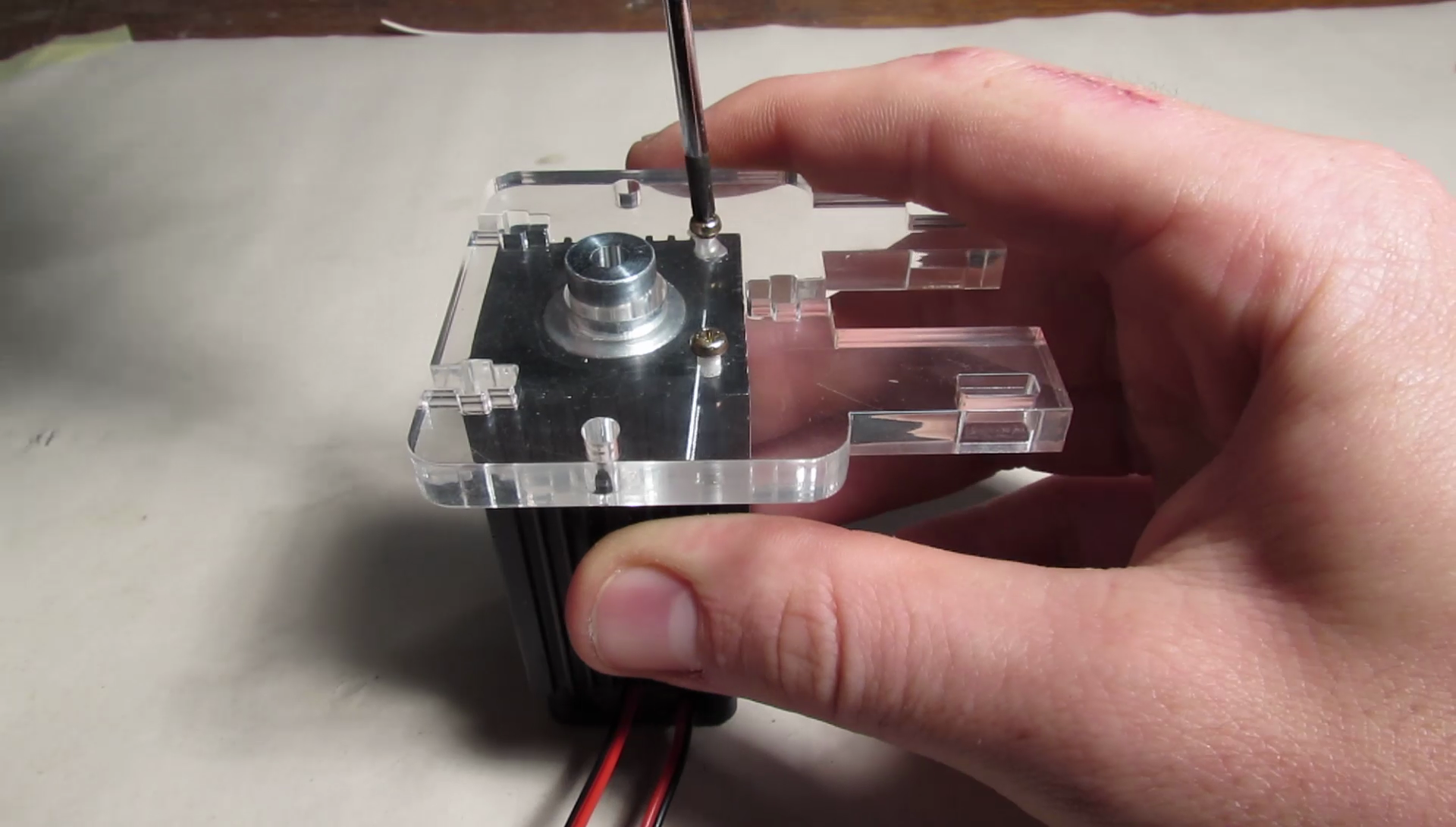

-I used 2 small screw which I found in my screw collection box but you can also use 2 screws from the fan that is attached in the back of the laser module.

- Now I put everything back together and secure the belt with a new pair of zip ties.

Calibration and Starting Point

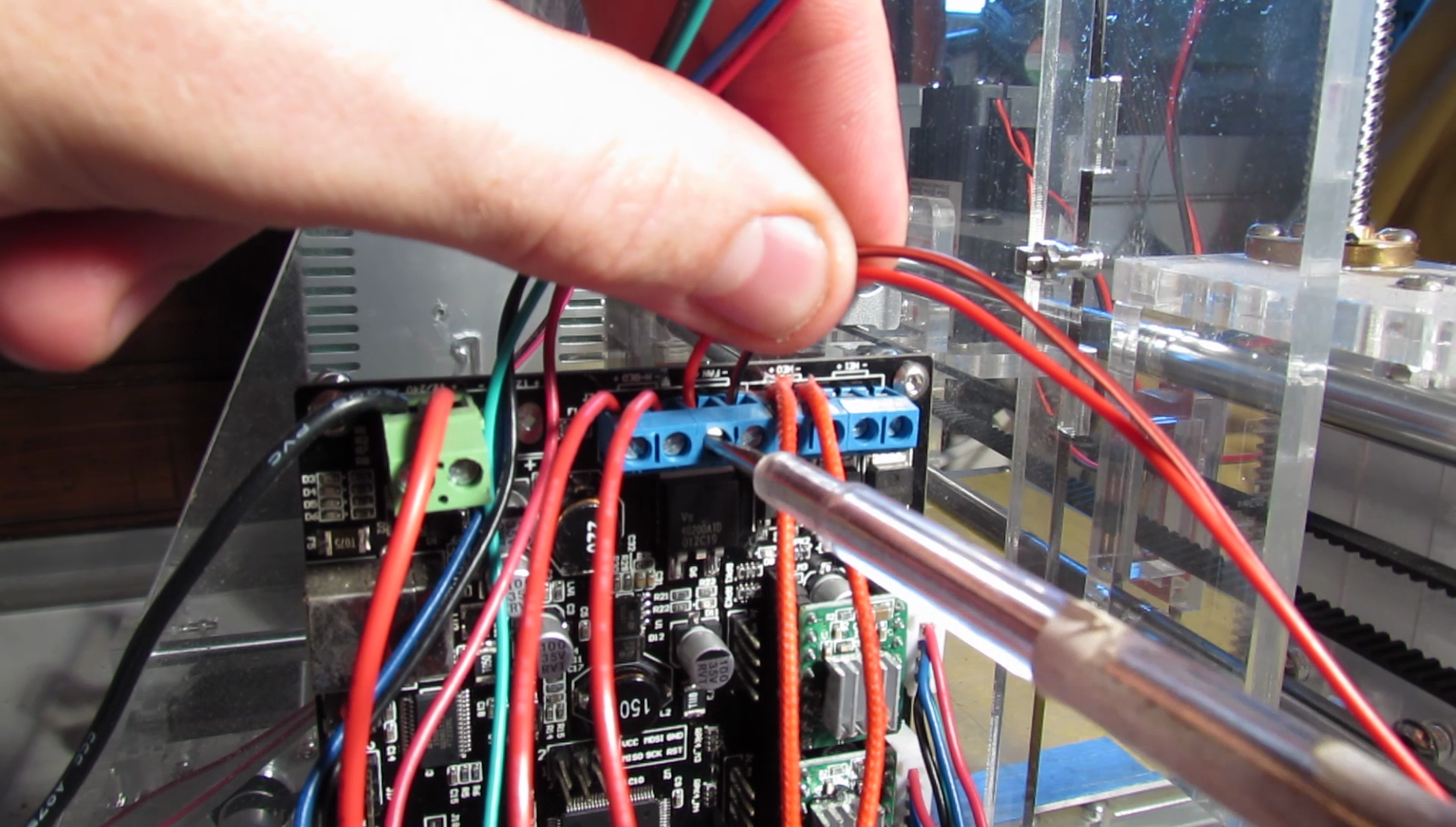

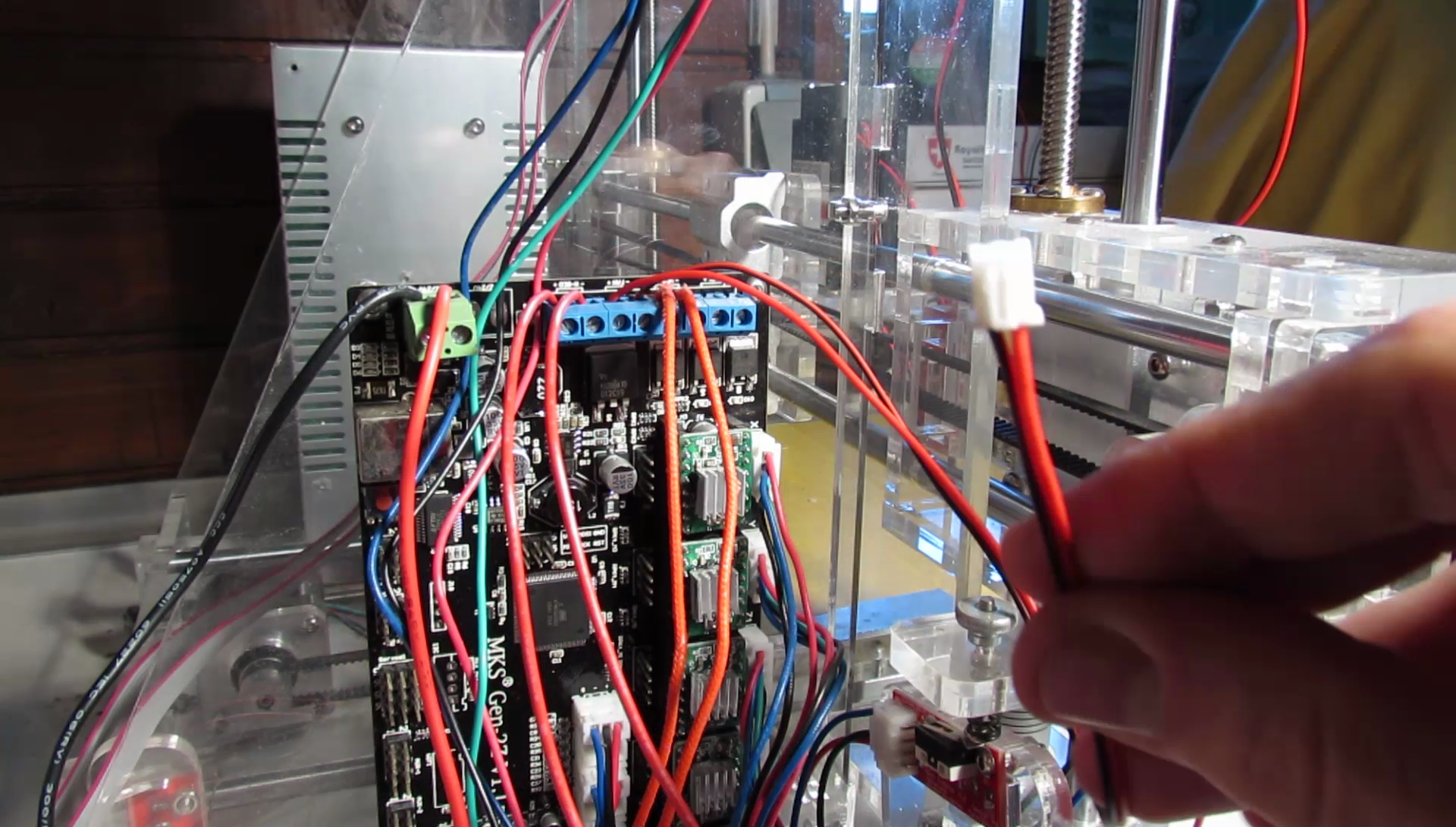

- After installing everything back, connect the laser input voltage to the 3d printer motherboard's fan port. I will explain why we did this step later in the video.

- This is the scheme of the laser driver that we received with the laser. Connect the fan on the laser to the cooling fan port, laser to the laser port and those 2 wires from the 3d printer motherboard to the 12v power port. Leave the TTL port unplugged because we won't need it.

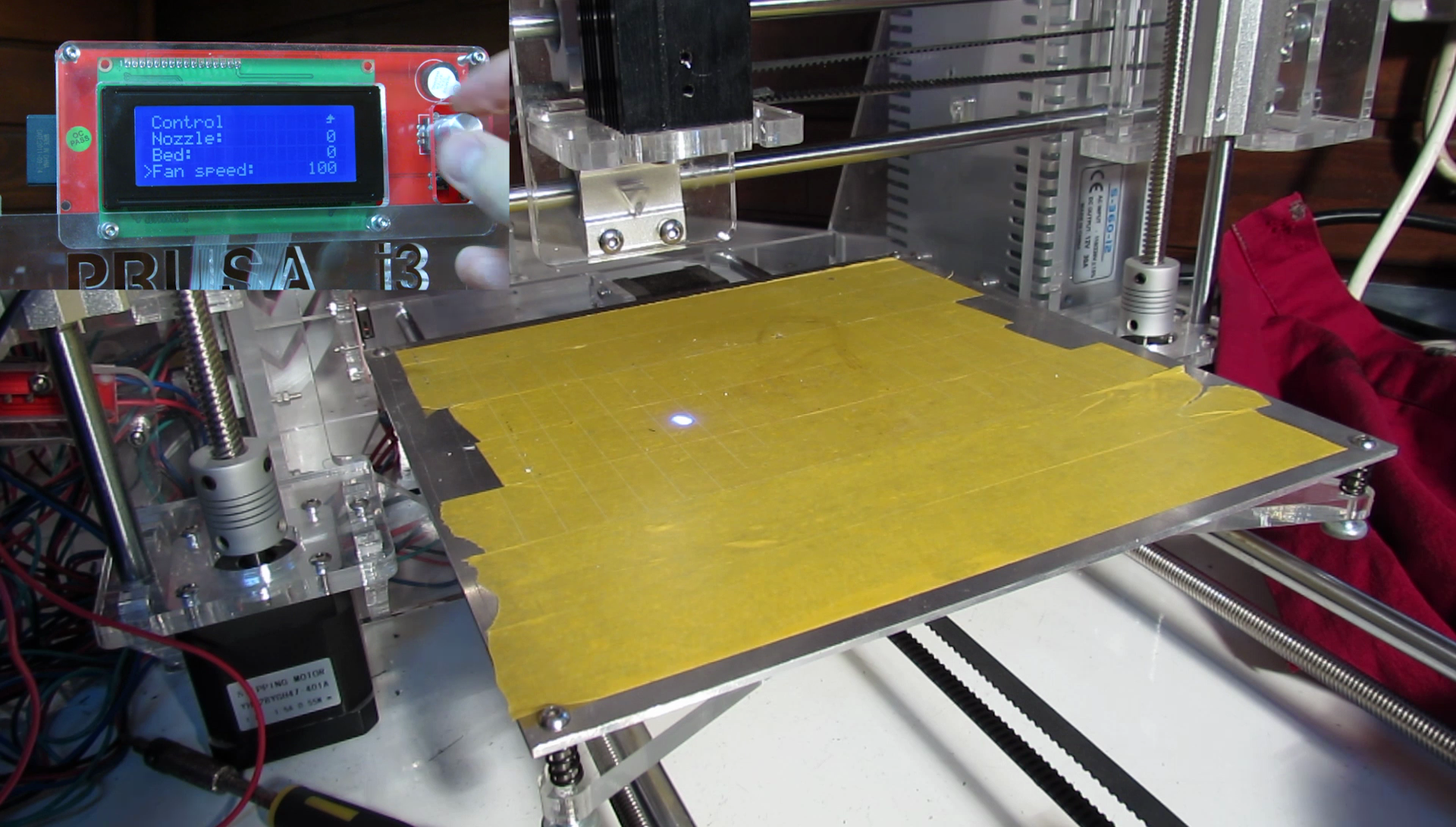

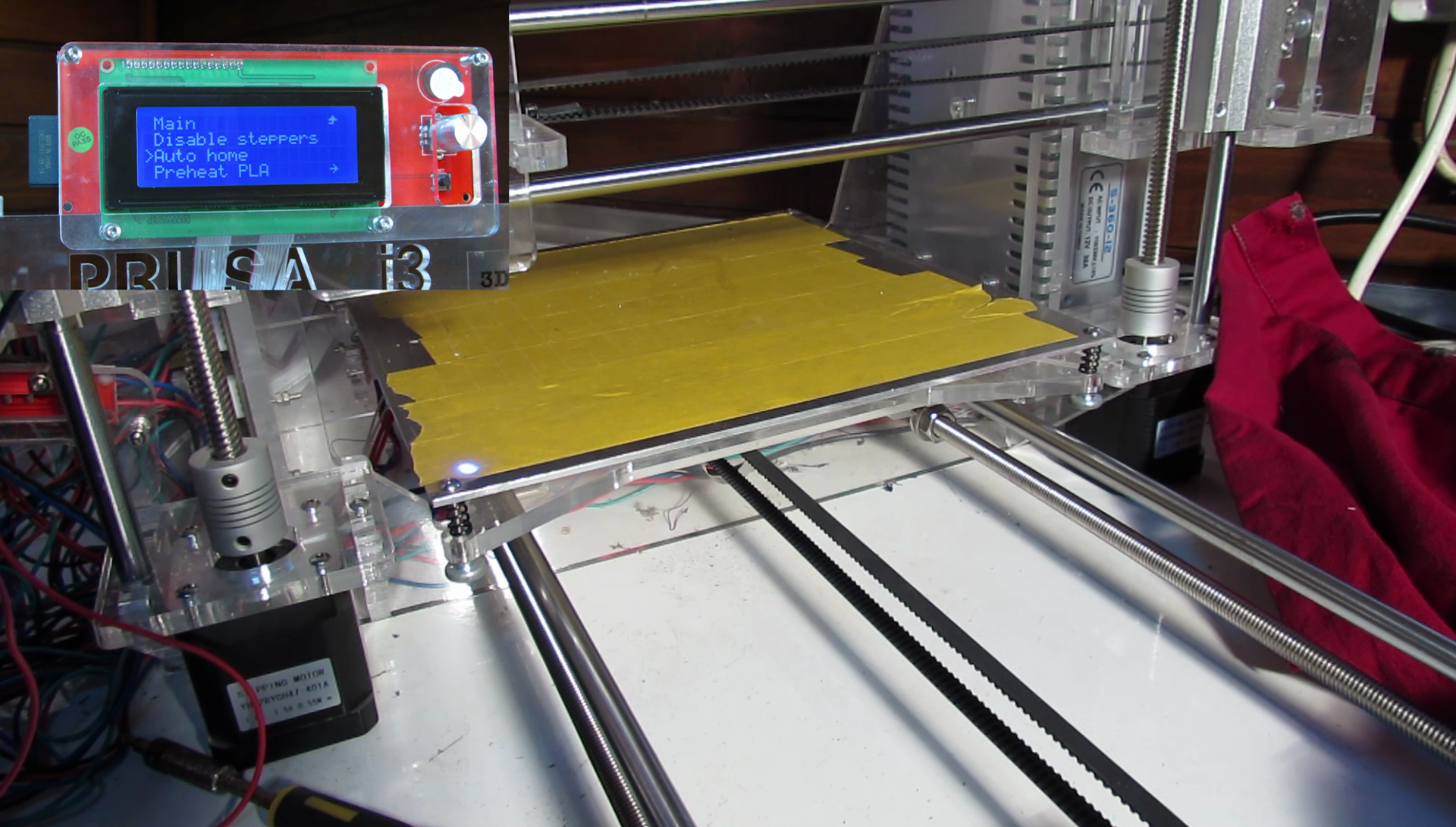

- Now simply turn on the fan in 3d printer settings and autohome all axes

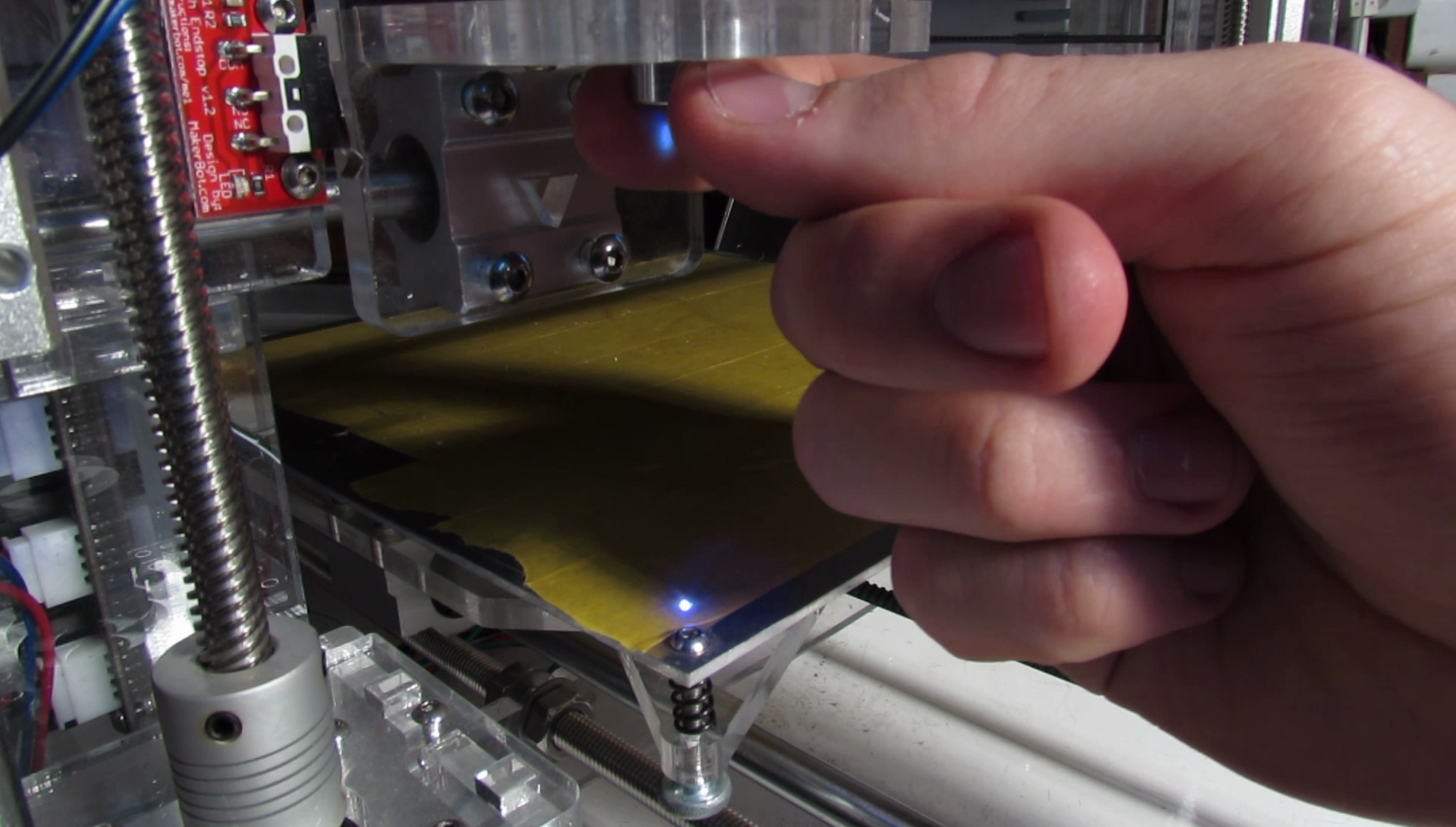

- Remember that you will need to adjust the focal length to the height of the engraved subject.

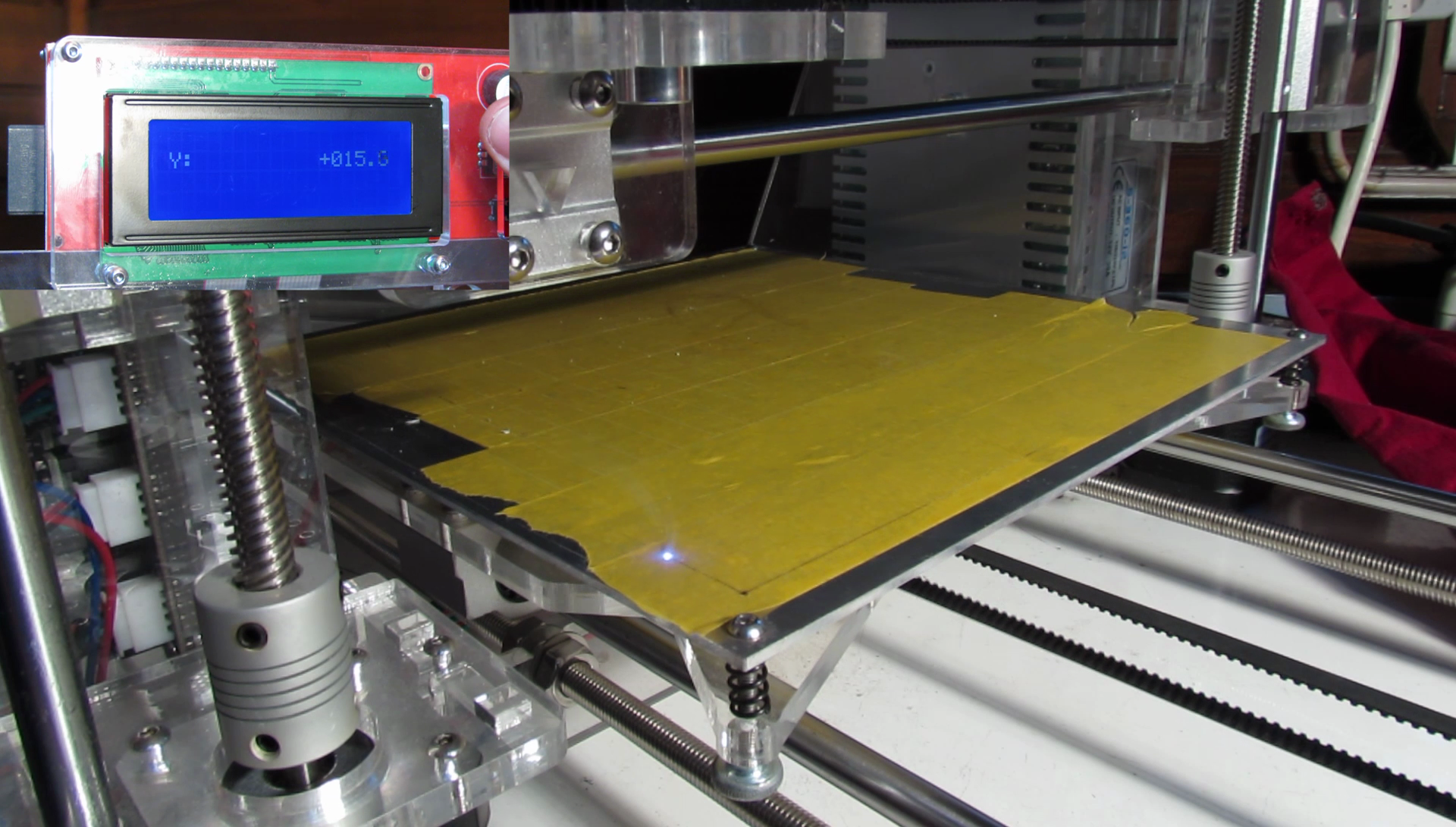

- The final step is to engrave a small starting origin in the painters tape so we could know where is the zero of x and y axes.

- Engraving software that I am using is called Inkscape and you can download it through the link: https://inkscape.org/en/

- You will also need a plugin for Inkscape called inkscape laser tool plug-in which is also linked here: https://jtechphotonics.com/?page_id=2012

- Download both files, install the inkscape and copy the files of inkscape plugin tool to the extensions folder of the inkscape program.

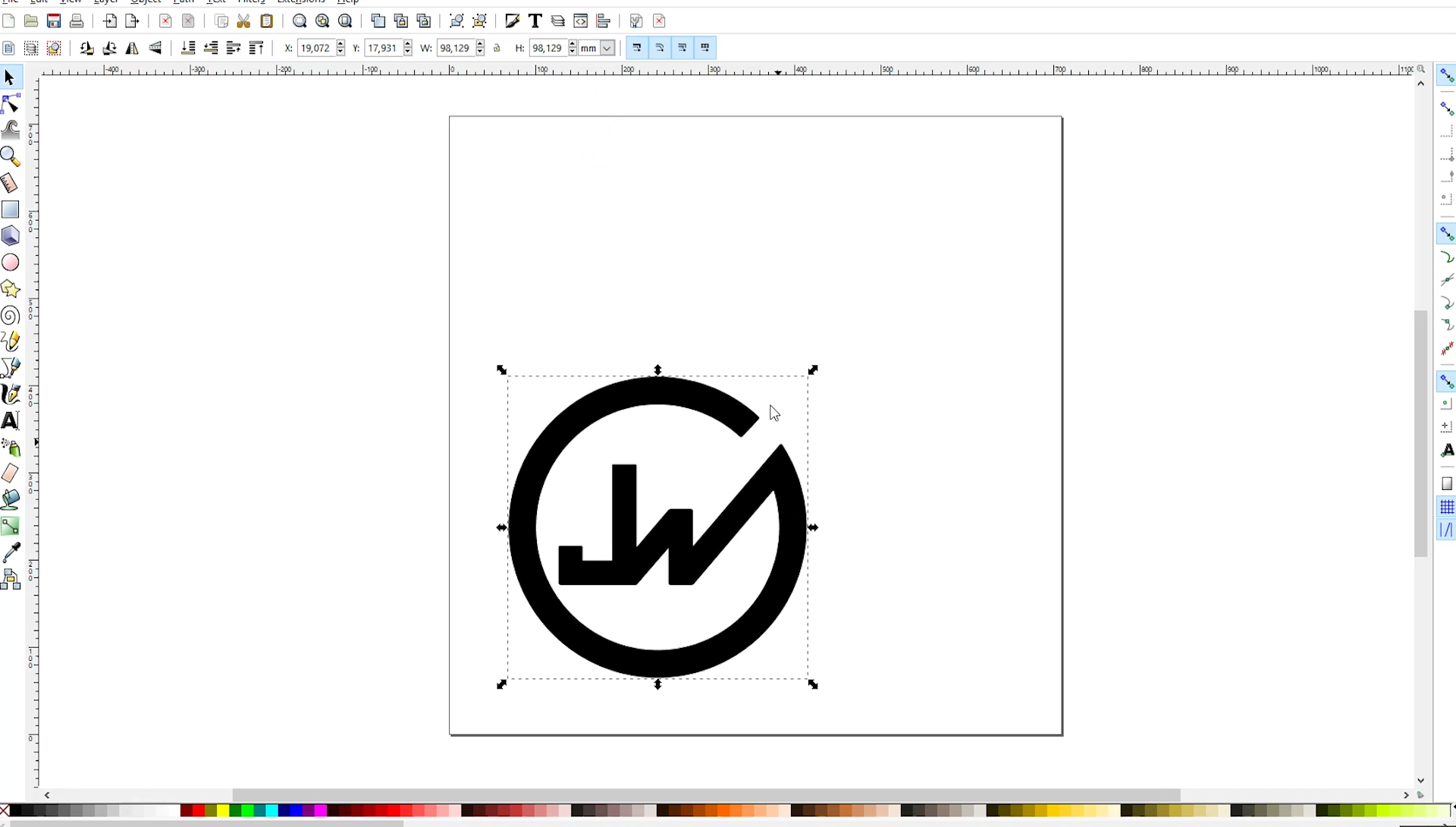

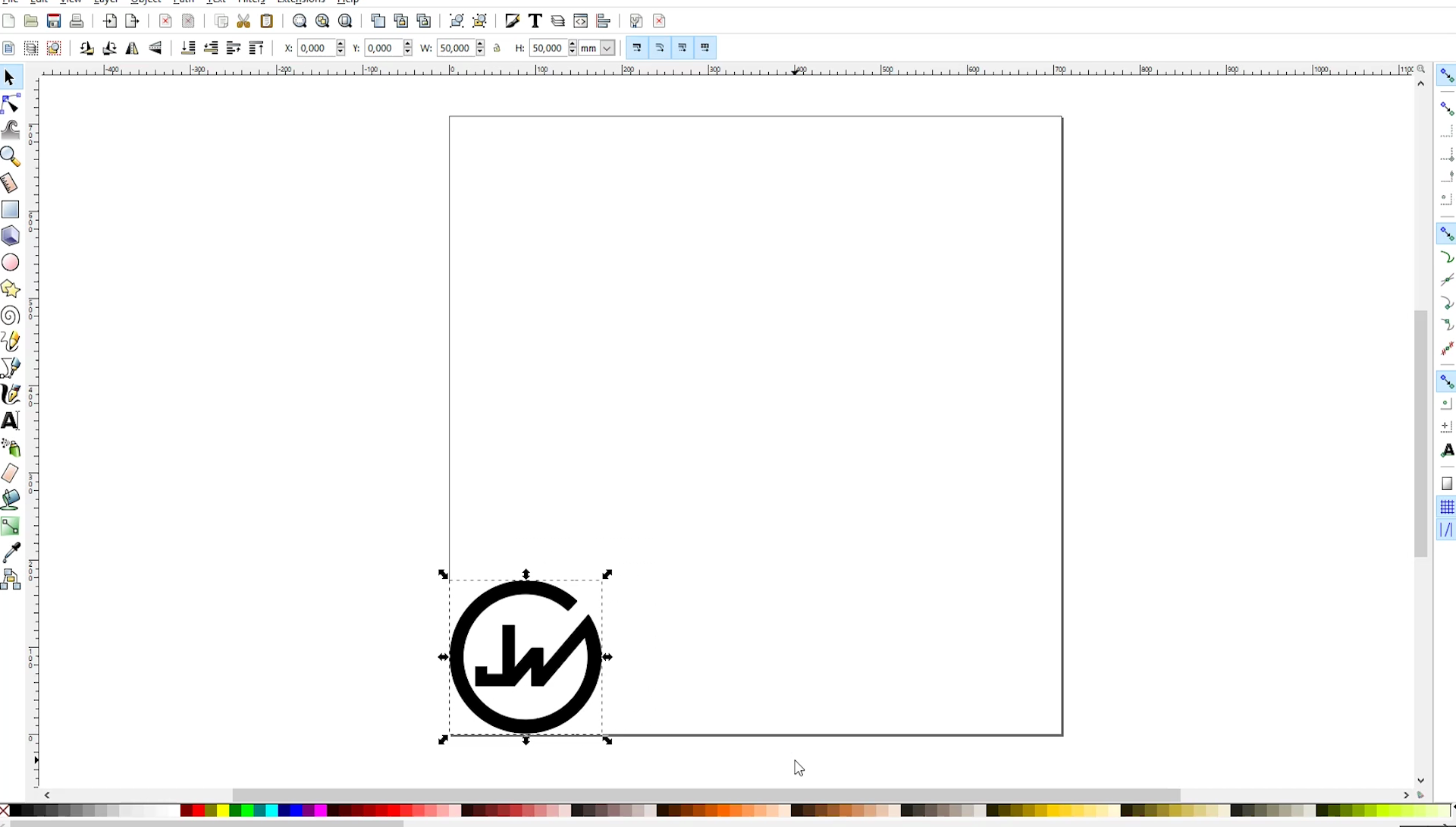

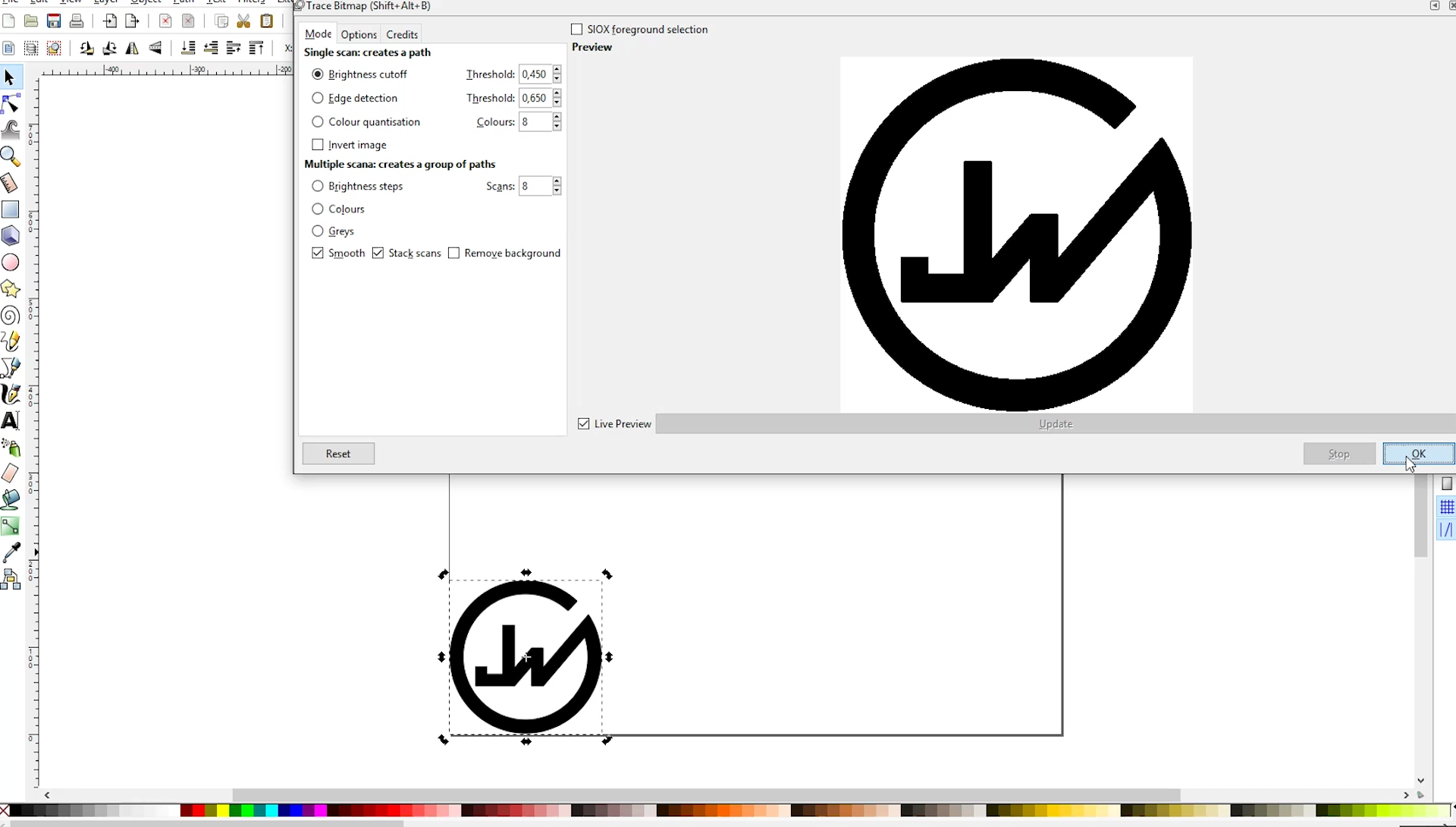

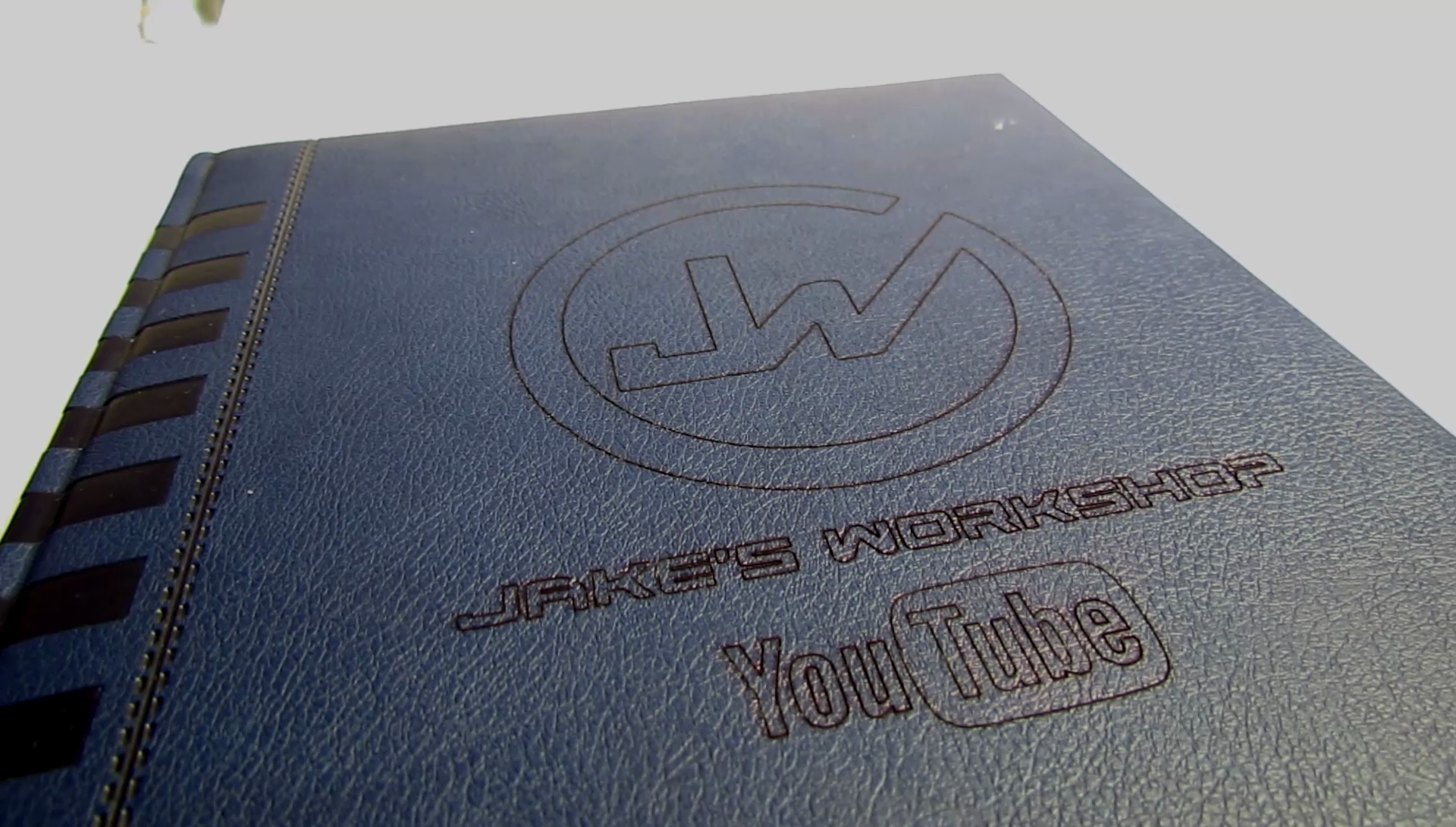

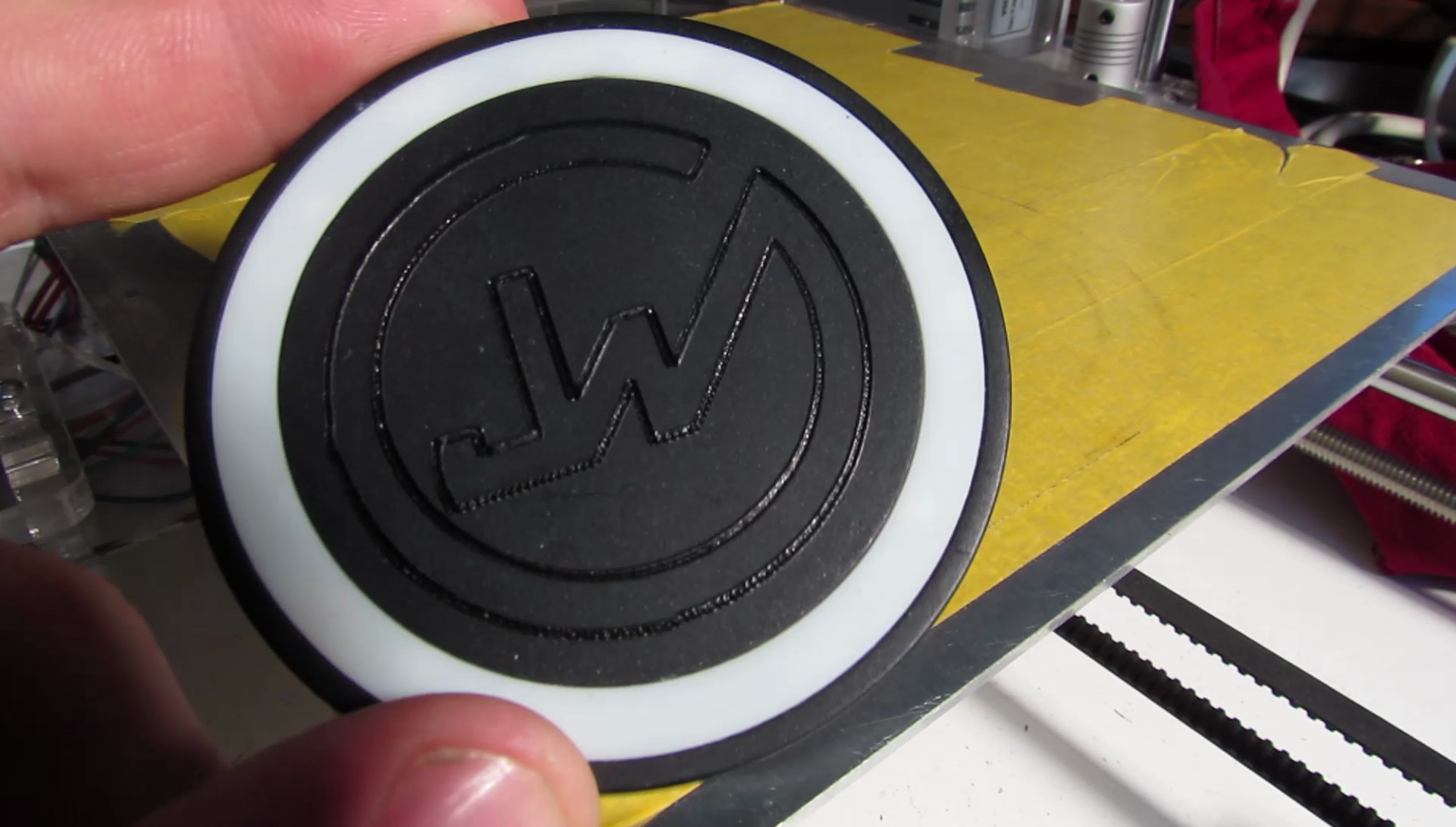

- In the program firstly define your printing bed diameters and drag desired logo that you want to engrave. Set it's x and y to 0 and vectorize the image using trace bitmap command: Path -> Trace Bitmap

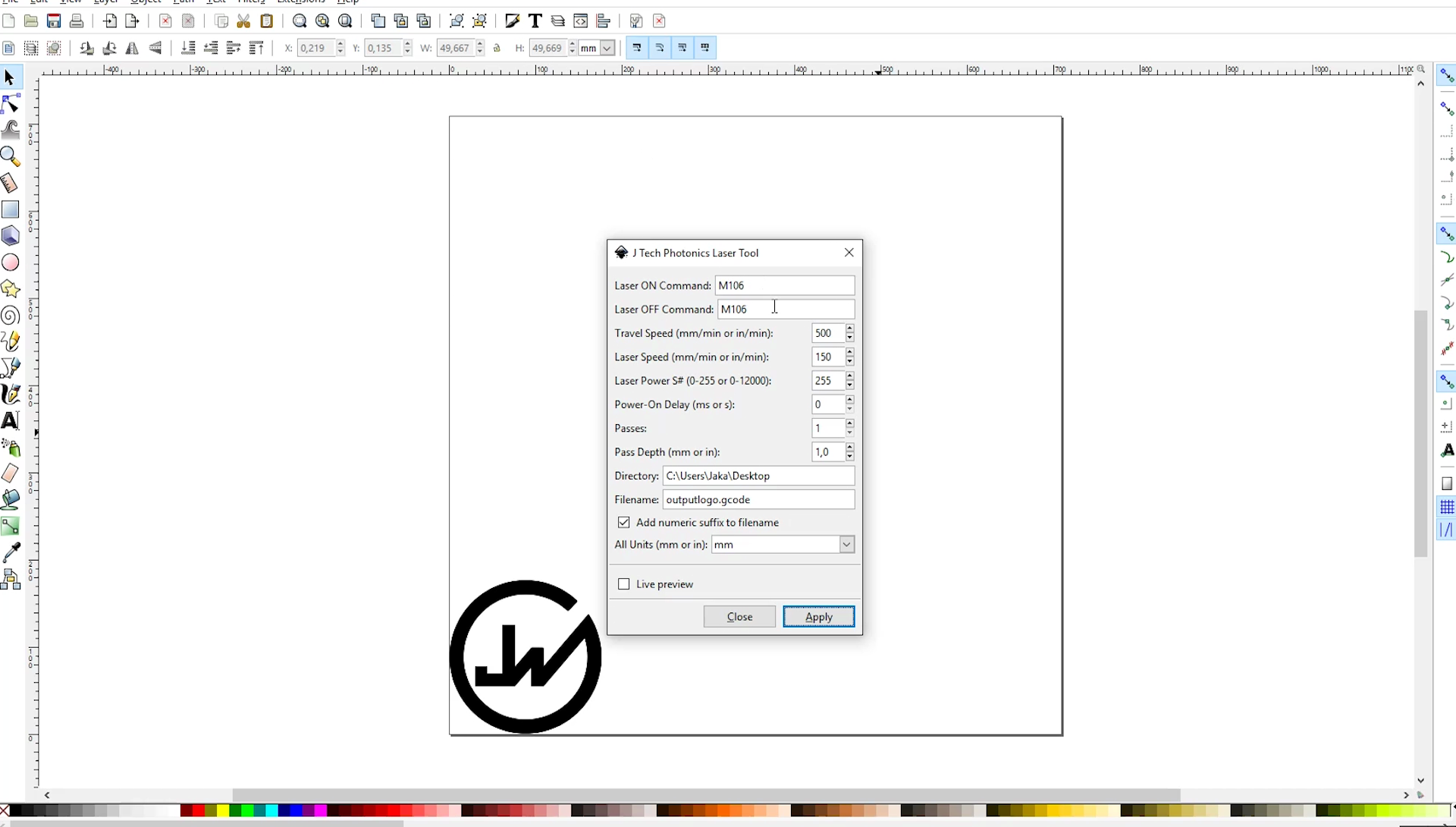

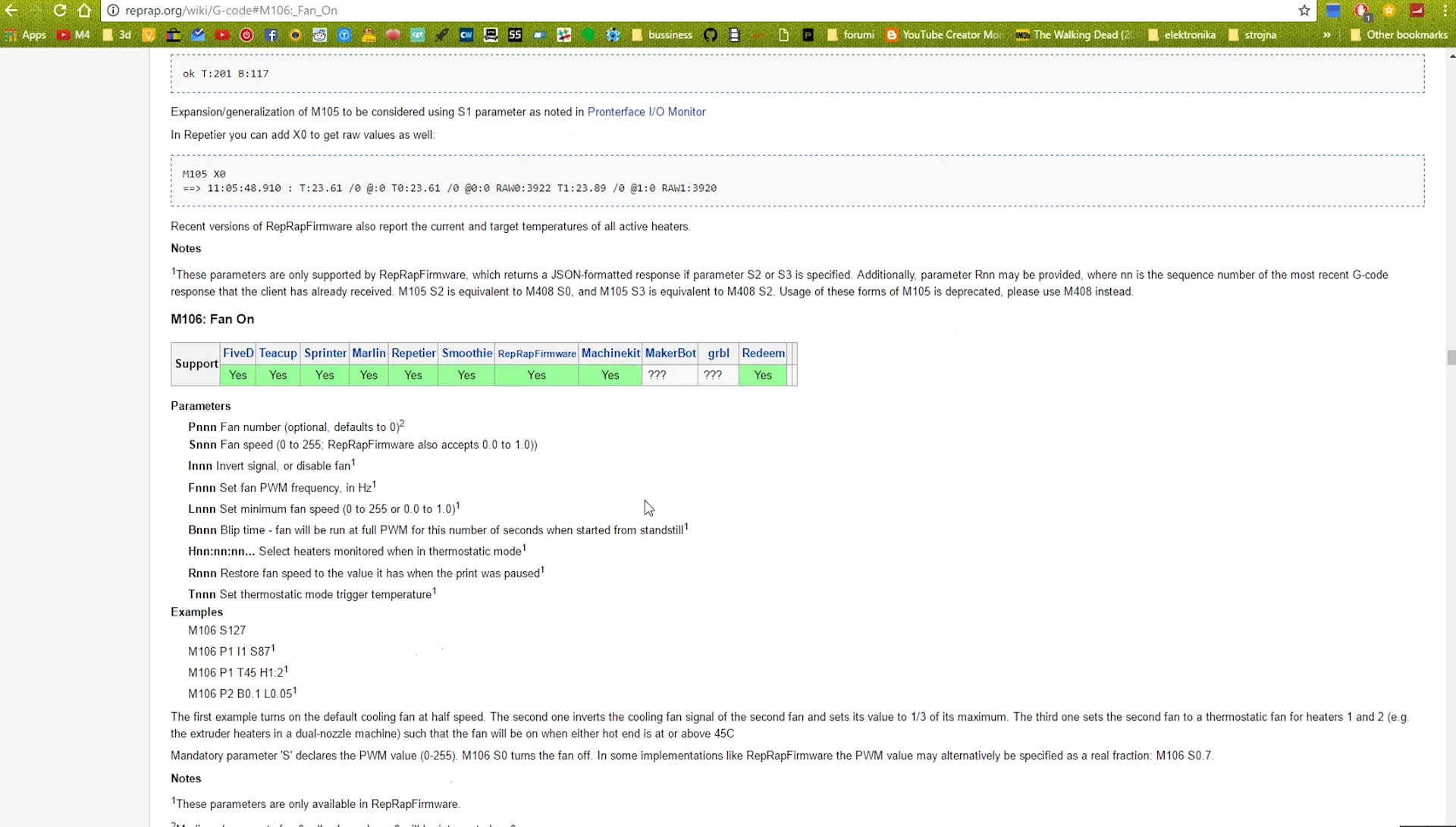

-Now simply go to: Extensions -> generate laser G-code -> J Tech... and set the laser on/off commands to M106 which is the command for turning on and off the fan port on which we connected our laser.

-Laser speed is also very important and I fount that the perfect speed is from 100 to 300 mm per minute.

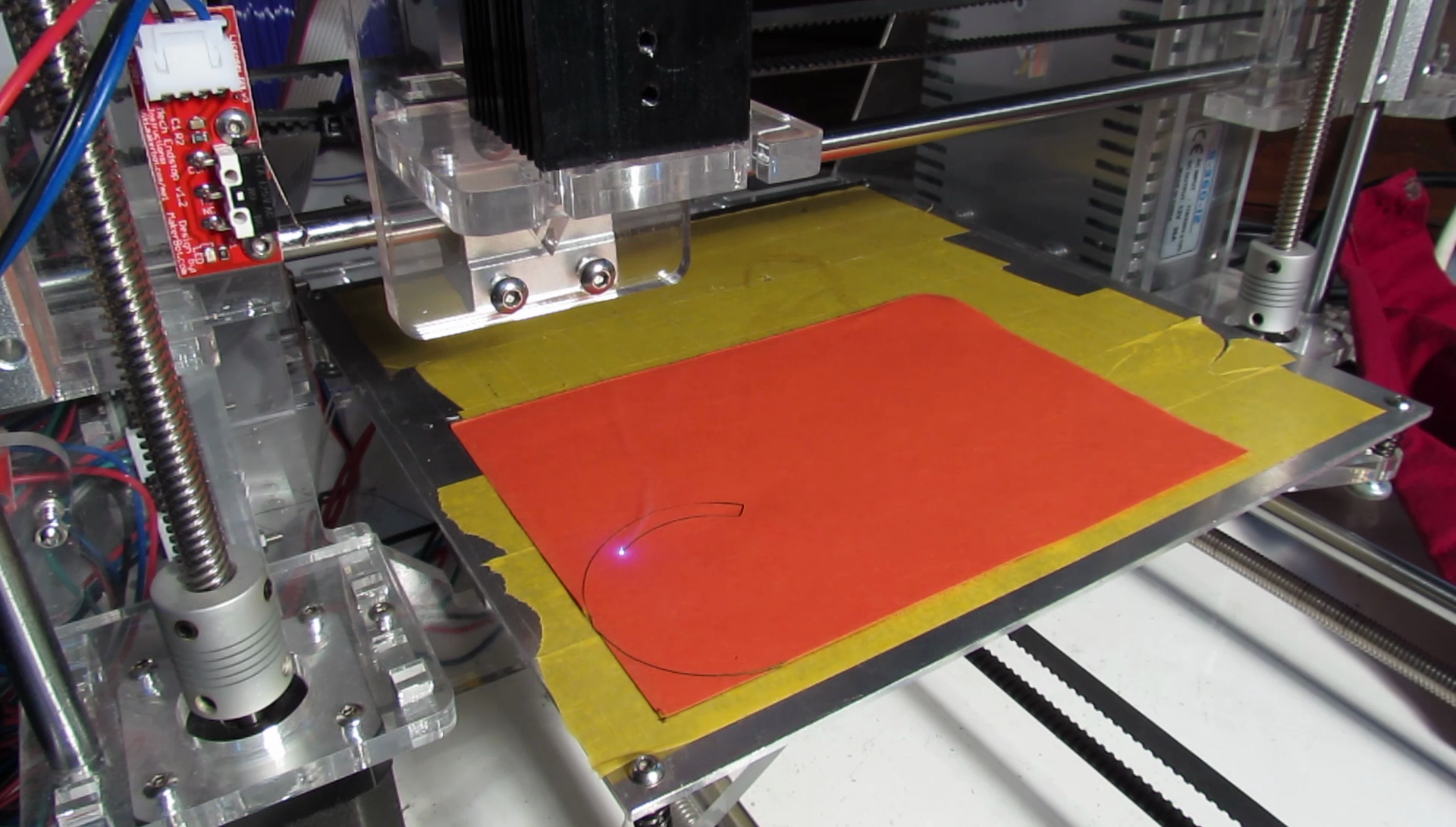

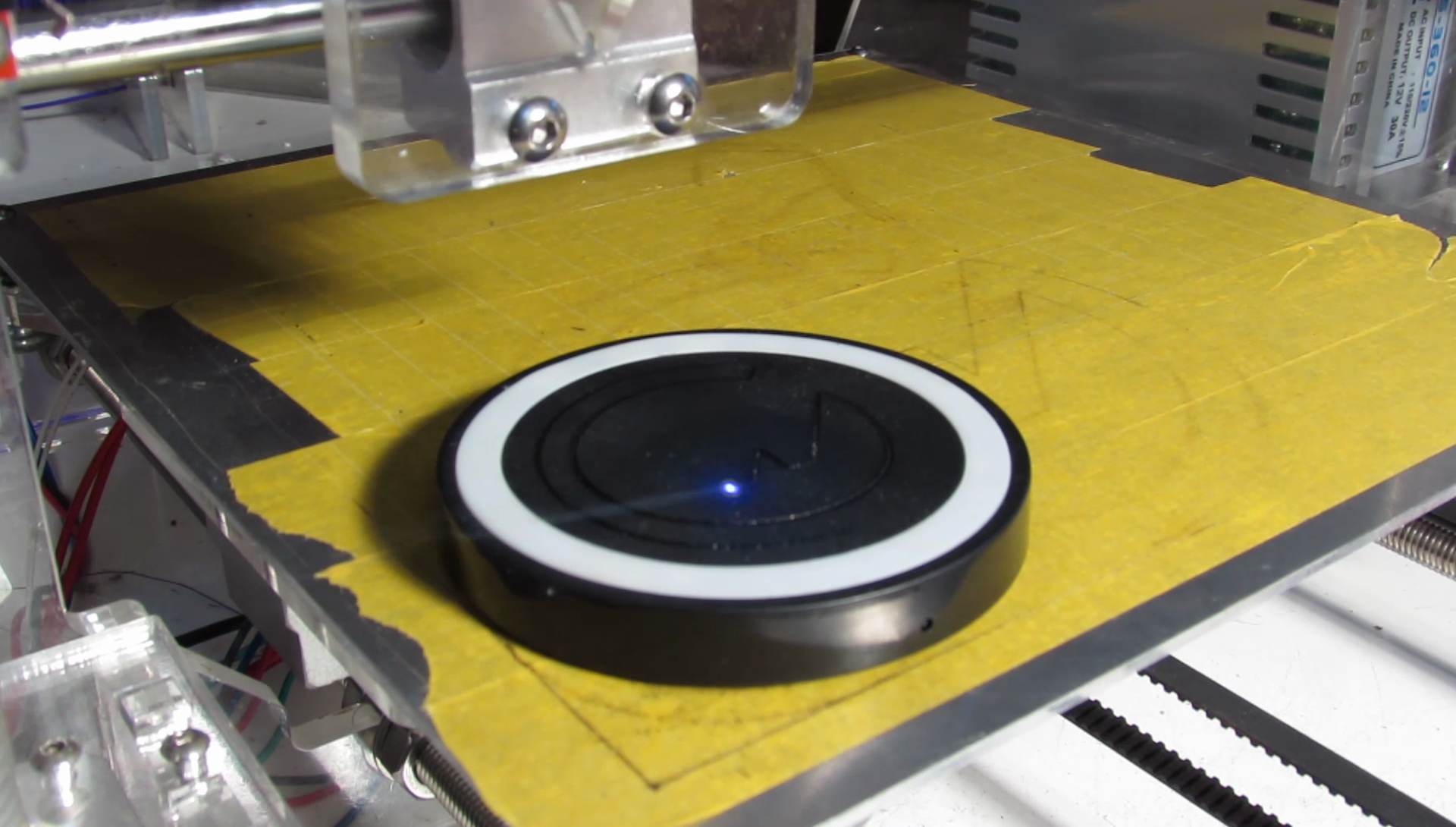

Testing and Engraving

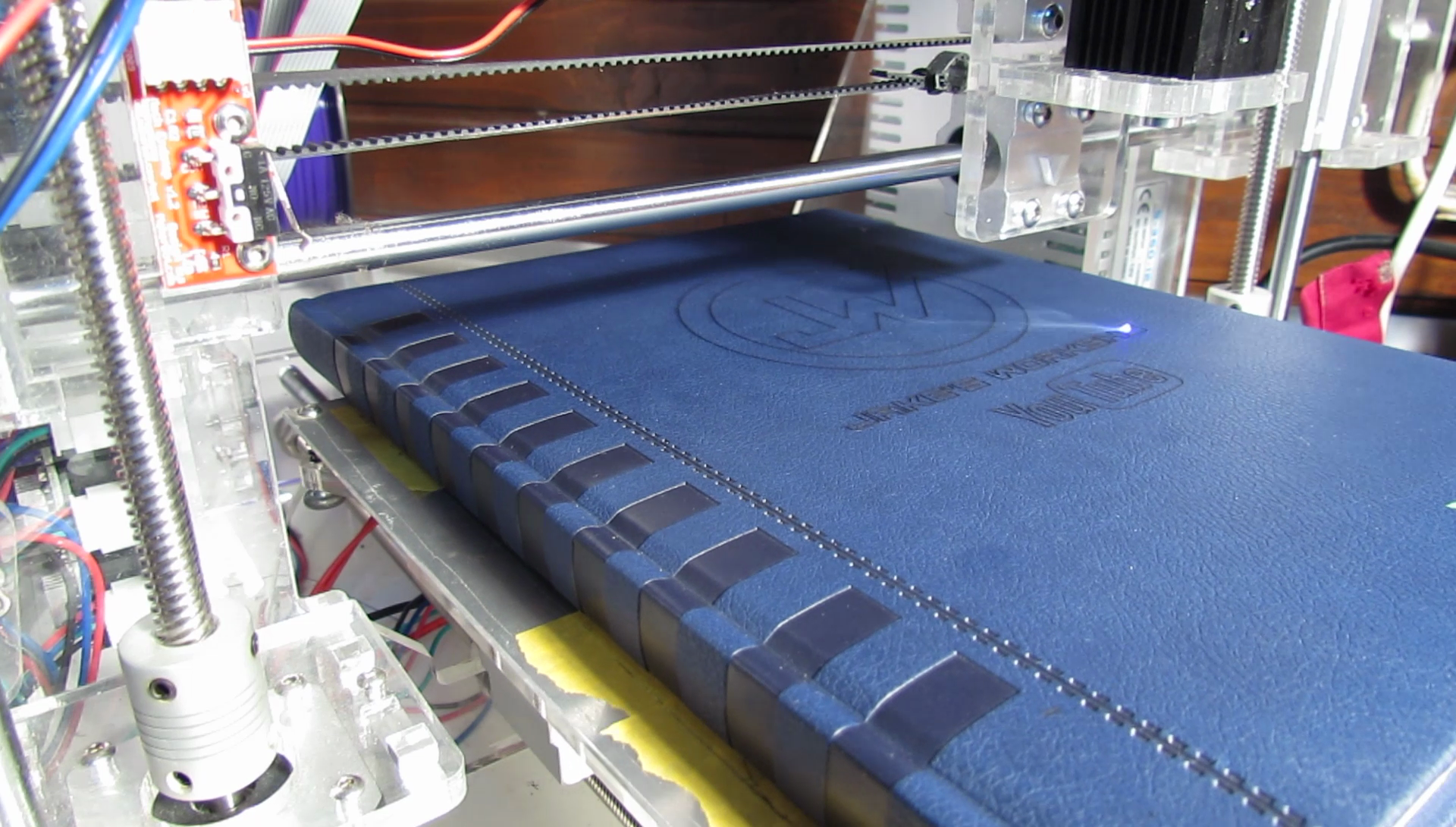

- When our G-code is ready, drag it to the Sdcard and print that G-code in the 3d printer menu.

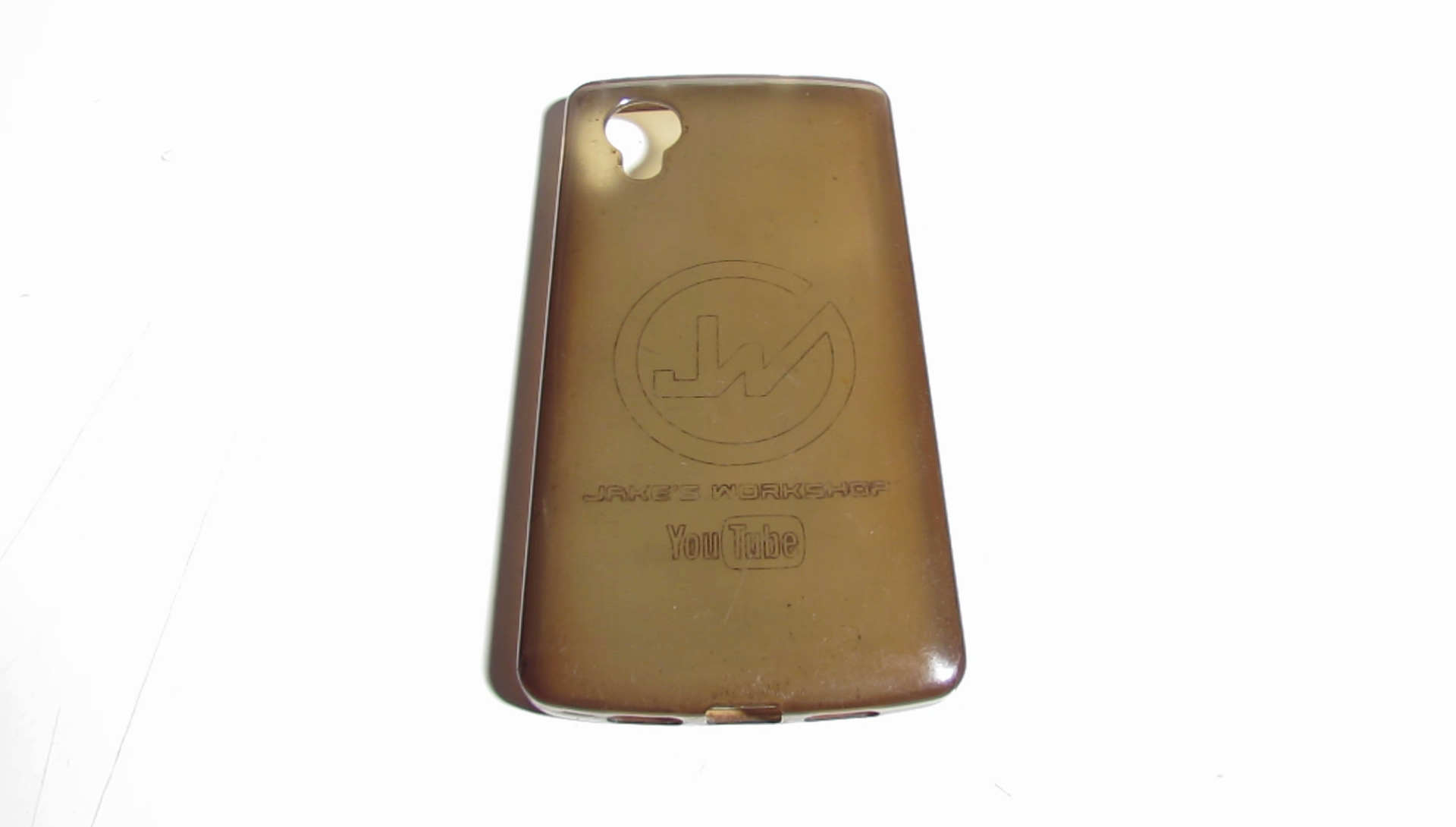

- We can easily cut any type of paper and the best part is that you can engrave your logo in any leather, wooden or plastic material.

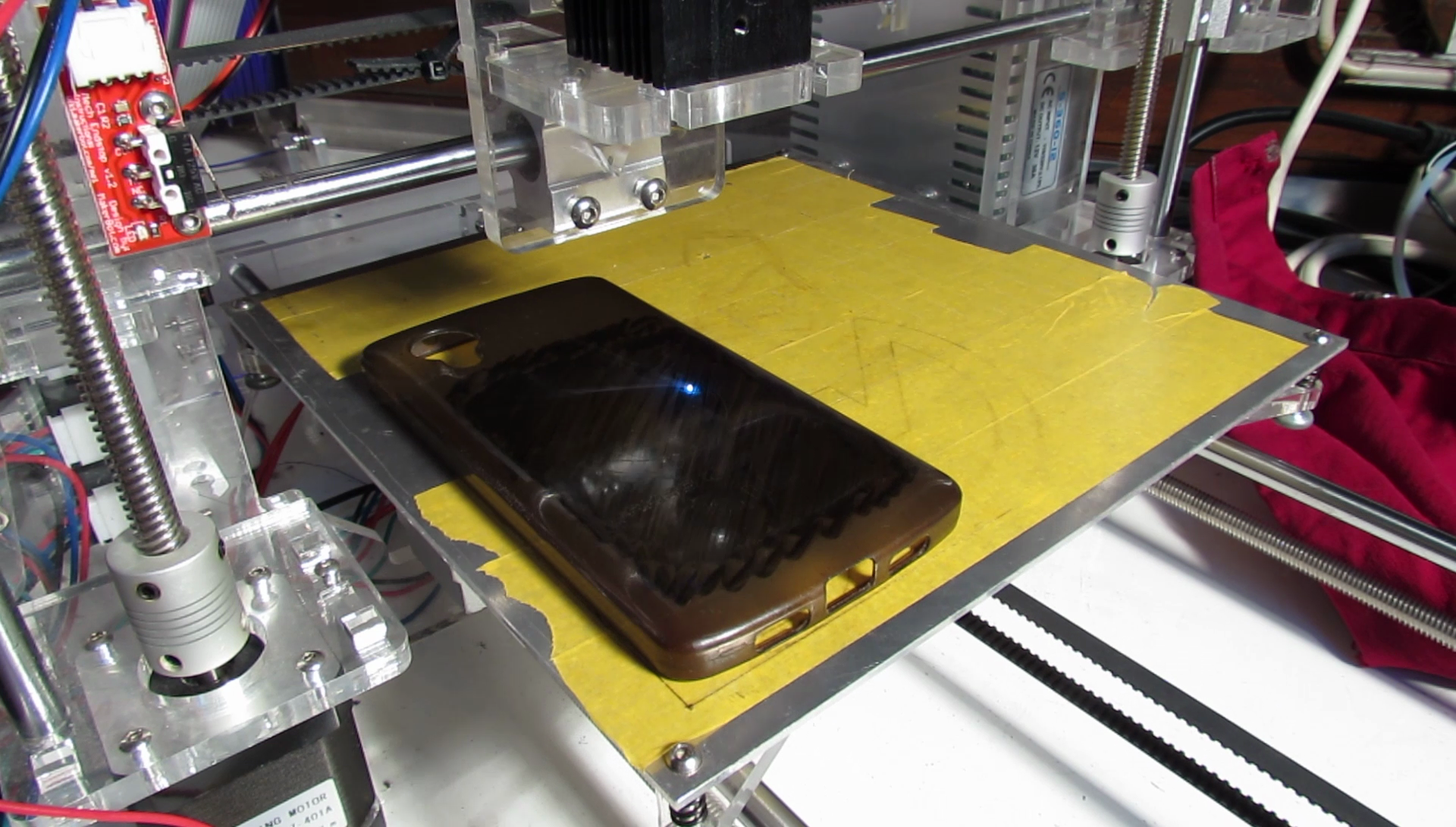

- You can also cut foam and engrave anything on your smartphone case or tablet.

- If you want to engrave faster there is always an option of buying even more powerful laser but It will also cost you twice as much money.

That would be all, thank you for reading this instructable, If you like it please also consider clicking on the video below of how I do it and enjoy the great music.

Thank you!!!