CNC Machining: Setting Work Coordinate System

7922 Views, 4 Favorites, 0 Comments

CNC Machining: Setting Work Coordinate System

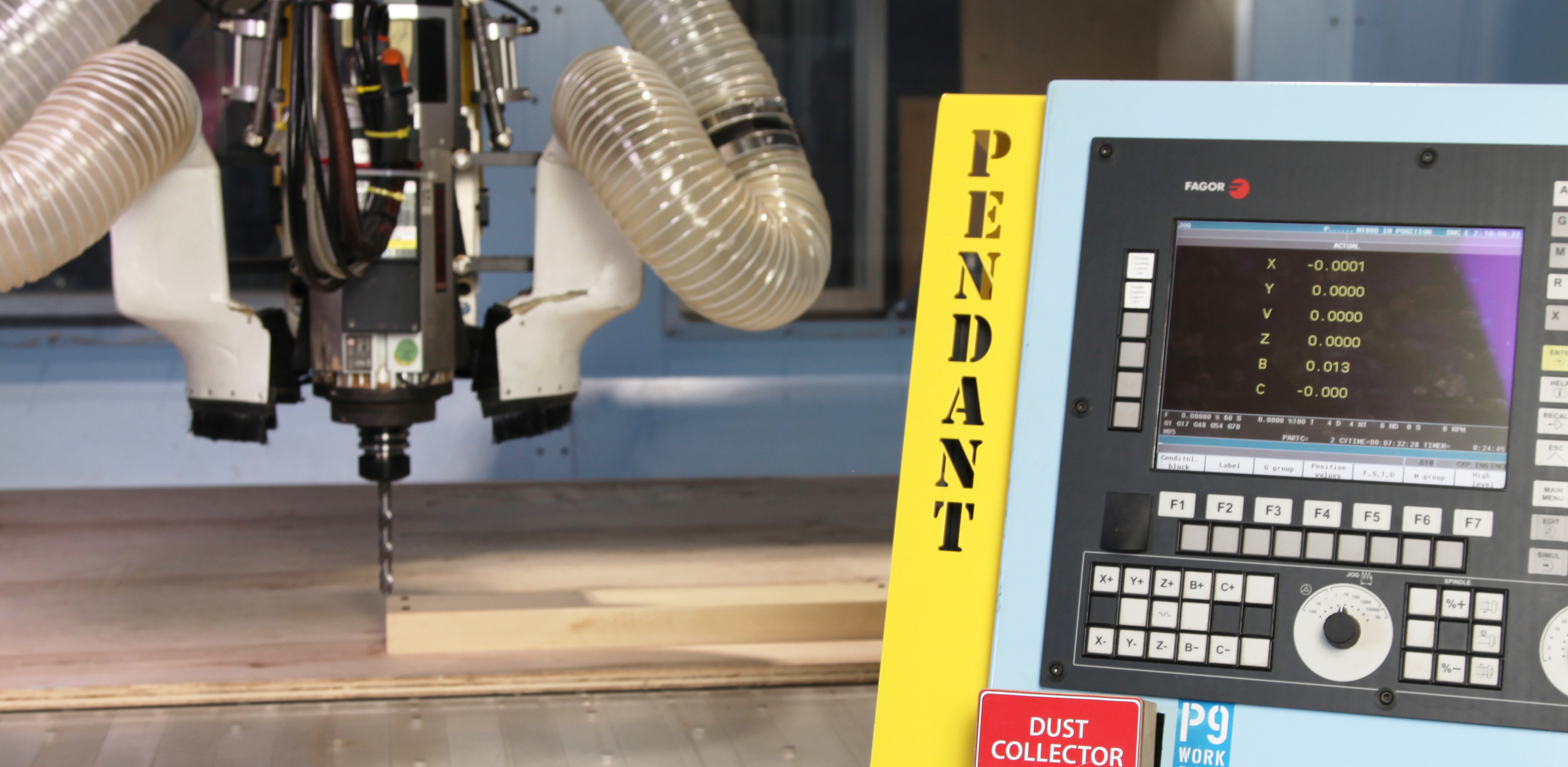

This lesson will teach you how to set your Work Coordinate System inside the DMS.

1) Perform a tool change to bring Tool 4 (1/2" drill) into the spindle.

If you have a drill in your program, it's useful to use it to establish your Work Coordinate System (WCS). Because this tool comes to a point, it is easier to visually ensure that the drill is in the correct location.

2) Jog the tool's tip to the exact back left corner of your stock--the location where you placed the WCS during Setup 1.

Check from the front and side that the tool is in the right position. Switch to incremental mode while jogging as you get close to the right spot.

3) Set X and Y G54 offsets (p. 11).

4) To set your Z offset, you will need to decide between two options.

You can choose between using the corner, which is fast, or using the interior of the part, which is more accurate. If doing the first, check the Z position of your tool tip one more time. Then continue immediately to setting your Z offset (p. 12).

If you would like to be more precise, you can use the "paper method". In this case, after setting X and Y G54 offsets, you will jog the tool over your stock, switch to incremental mode, and slowly lower the tool over a sheet of paper on the stock until the paper is lightly trapped. Then follow the steps in the Quickstart Guide to set your Z offset (p. 12).

5) Toggle back to the Machine Coordinate System (G53) coordinates by typing G53 and then pressing Cycle Start.

6) Take a picture of the Machine Coordinate System (G53) on the controller. This will be useful if you need to get back to this location at another time.

You can also find this information by selecting 'Tables' from the 'Main Menu'.

7) Go back to the WCS (G54) by typing G54 and then pressing Cycle Start. The coordinates should go back to zero.

Load Program

Here are a few more things to do before running G-code.

1) Warm up Spindle (p. 13).

2) Go through the pre-run checklist (p. 13).

3) Load your programs (p. 14).

Double check that your files are named 100001.PIM and 100002.PIM. If your files aren't six digits, the DMS won't detect them.