Building Better Cabinets in the Shop!

by makewithjake in Workshop > Woodworking

20982 Views, 168 Favorites, 0 Comments

Building Better Cabinets in the Shop!

.gif)

I was just building this cabinet to organize all of the garden supplies in the garage, and I thought this would be a great opportunity to share a few cabinet building tips so you can make your next cabinet better, faster and stronger!

So follow along and check out these 10+ tips for building better cabinets!

Let's get started!

Supplies

As always, be sure to check out my Woodworker's Notebook! This book is great for jotting down notes, or sketching out a new project! (each purchase helps support me as I make more content, just like this 'ible!)

Plan Your Build!

I already have all my parts cut and labeled with sticky notes so that I don't mix them up. Plywood is crazy expensive these days, So I made a sketch of my project to ensure that I'd get the most out of each panel. And because I'm not as smart as a robot, I used this web based app called Cut List Optimizer, which automatically calculates the most efficient way to get all the parts I need out of each sheet of plywood.

Use Pre-finished Plywood!

You might be asking yourself,

“Jake, is there a particular type of plywood that I should be using to build cabinets?”

Well, Yes. Yes there is.

There are ton of different plywood options available, ranging from construction grade to fine woodworking quality plywood with a walnut veneer. I wont get into the different types of plywoods in this video, but I recommend you stick with a plywood that has a birch, maple, or oak veneer - or even better, baltic birch plywood which is made of a bunch of layers and is the go to choice for most cabinet projects, although, it is typically a little more expensive.

For this project, Ill be using a pre-finished birch plywood that has a clear but super durable finish already applied to the surface.

Using prefinished plywood can save a ton of time and energy, all you need to do is cut the wood to size and then assemble your cabinet! No need to get out any finishing supplies!

Prefinished ply is available at most home centers for just a few dollars more than regular plywood. If you figure in the effort it might take to apply finish, this stuff definitely pays for itself.

Batch Out the Toe Kicks!

I saw this next tip online recently, and it's so obvious, I can't believe I didn't think of it earlier. Most cabinets feature a toe kick on the bottom front of the case. A toe kick provides clearance for your feet when you are standing close to the cabinet or countertop. And since it is at floor level, it tends to get kicked and scuffed, so by insetting it, we hide the scuff marks and keep the cabinet looking fresh.

I used to always mark out each of my toe cuts on the side panels, and then cut each side individually with a jigsaw.

But get this…If your project has toe kicks, clamp both of your side panels together so that you can cut the toe kicks at the same time!

This is way easier! With the side panels clamped together, you can use a jig saw or circular saw to cut out the toe kicks at the same time. Not only ensuring that they are the same, but saving a bit of time in the process!

Use Edgebanding!

Before we start assembling this cabinet, Im thinking it would be a nice upgrade if we added some edge banding. Edge banding on plywood levels up the design aesthetic of your project and makes for a much nicer finished looking product.

Also, plywood edges are easily damaged if bumped or hit, and not to mention, if plywood edges are exposed to moisture, they can start to expand and delaminate.

Edge banding can be made from solid hardwood, but unless I'm making a fancy pants cabinet, I prefer to stick with the iron on edge banding. This stuff is low cost and really easy to apply.

I highly recommend sticking on your edge banding first, it is way faster and means you can use one of these handy dandy edge trimmers. It does quick work and leaves a near perfect edge on the plywood.

(Photo Credit: Finewoodworking.com)

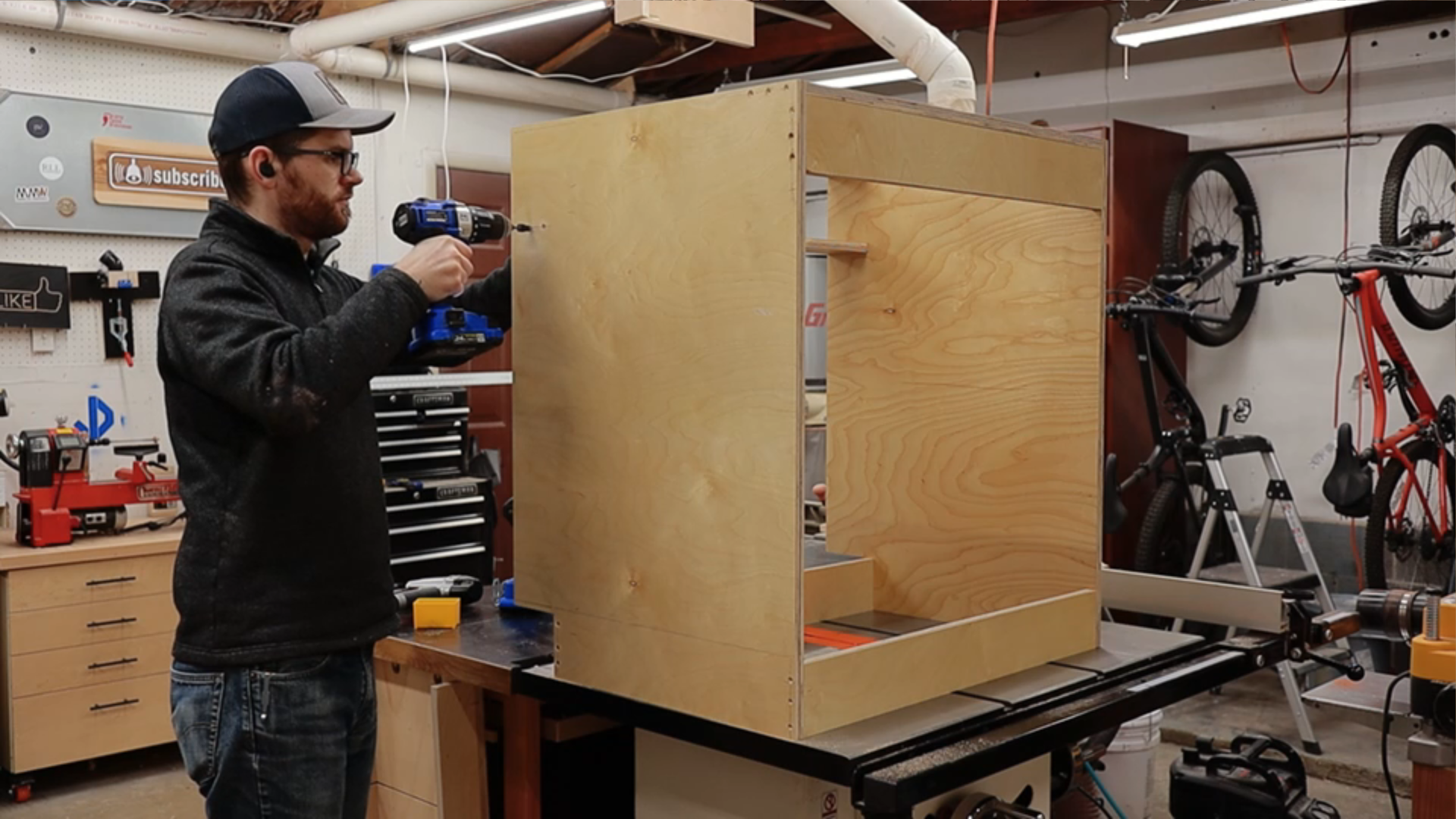

Pin the Box for Easier Assembly!

Alright, now we can start assembling this cabinet!

When I assemble cabinets like this one, I try to clamp each piece where it needs to go, and then use my brad nailer to pin the parts in place. The brad nails will hold the box together while I spend the extra time to make sure my box is perfectly square. Then I can go ahead and drive in some screws to hold everything together.

And that brings us to my next tip….

Don't Use Pocket Holes!

Look, Im as big a fan of pocket holes as the next guy, but the reality is, they take longer to set up than a simple countersunk screw. In the case of a cabinet, especially one where the sides of the cabinet aren't going to be visible, I like to use counter sunk flat head screws. This saves a ton of time that I would have had to spend marking out and pre-drilling a bunch of pocket holes.

Plus, pocket holes can sometimes cause parts of your box to slide around. This is not particularly optimal, and countersunk screws solve this problem.

Bonus Tip: And here is a bonus tip for ya! Drywall screws have a rough black surface that is meant to grab drywall (obviously) and hold it in place. But, if you are using them for woodworking projects, be sure to add a little bit of wax to the threads. This will help them go in much easier, allowing for a tighter joint that doesnt overstress the screw.

Add Sacrificial Skids

Here's a pro tip I just saw over on Crafted Workshops channel:

Add a couple of sacrificial boards to the bottoms of your base cabinets. This allows you to slide the cabinet around on the shop floor without damaging your fancy new cabinet!

This is definitely something I am going to start doing on all of my future cabinet builds!

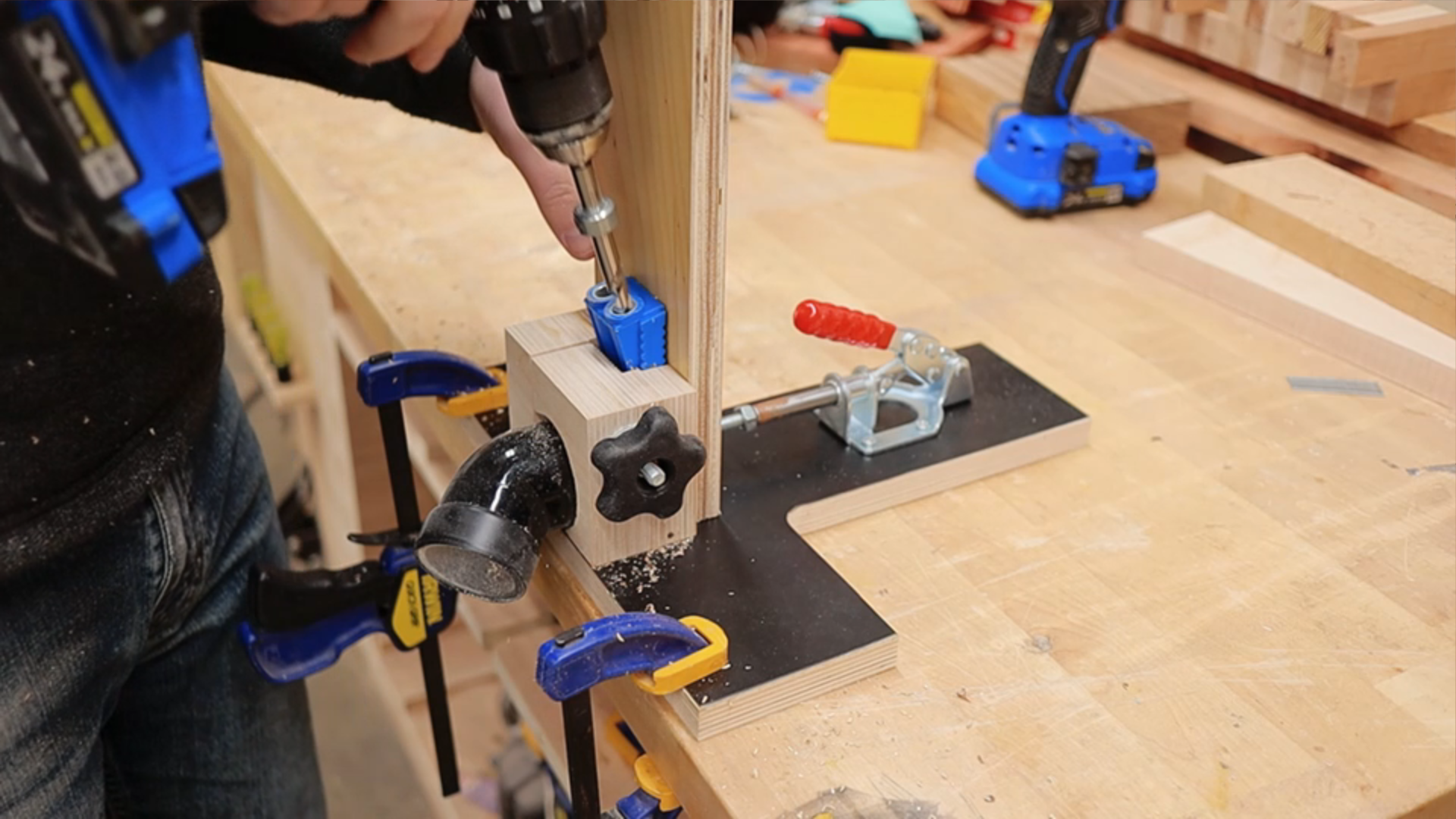

Clamp Free Pocket Hole Joints!

Building cabinet drawers is probably one of the worst parts of any cabinet build. It can get repetitive, cutting a bunch of the same identical pieces, clamping parts together…on and on and on!

Well, Ive found the absolute best way to build drawer boxes, fast and easy. Here goes:

With all my pieces cut to length, I set up my pocket hole jig and get to work. This is probably the most time consuming part of building boxes, but I like the clean look of hidden fasteners.

In order to assemble the drawer boxes, you would typically need to use clamps to hold everything super tight, otherwise the pocket holes will cause the joint to slide around

No, heres a killer trick for clamp free pocket hole joints. Use your brad nailer to pin the joint in place, then, just drive in your pocket hole screws! The nails keep the joint from sliding around, while the pocket hole screws clamp everything tight!

No need to spend money on fancy pocket hole clamps!

Standardize!

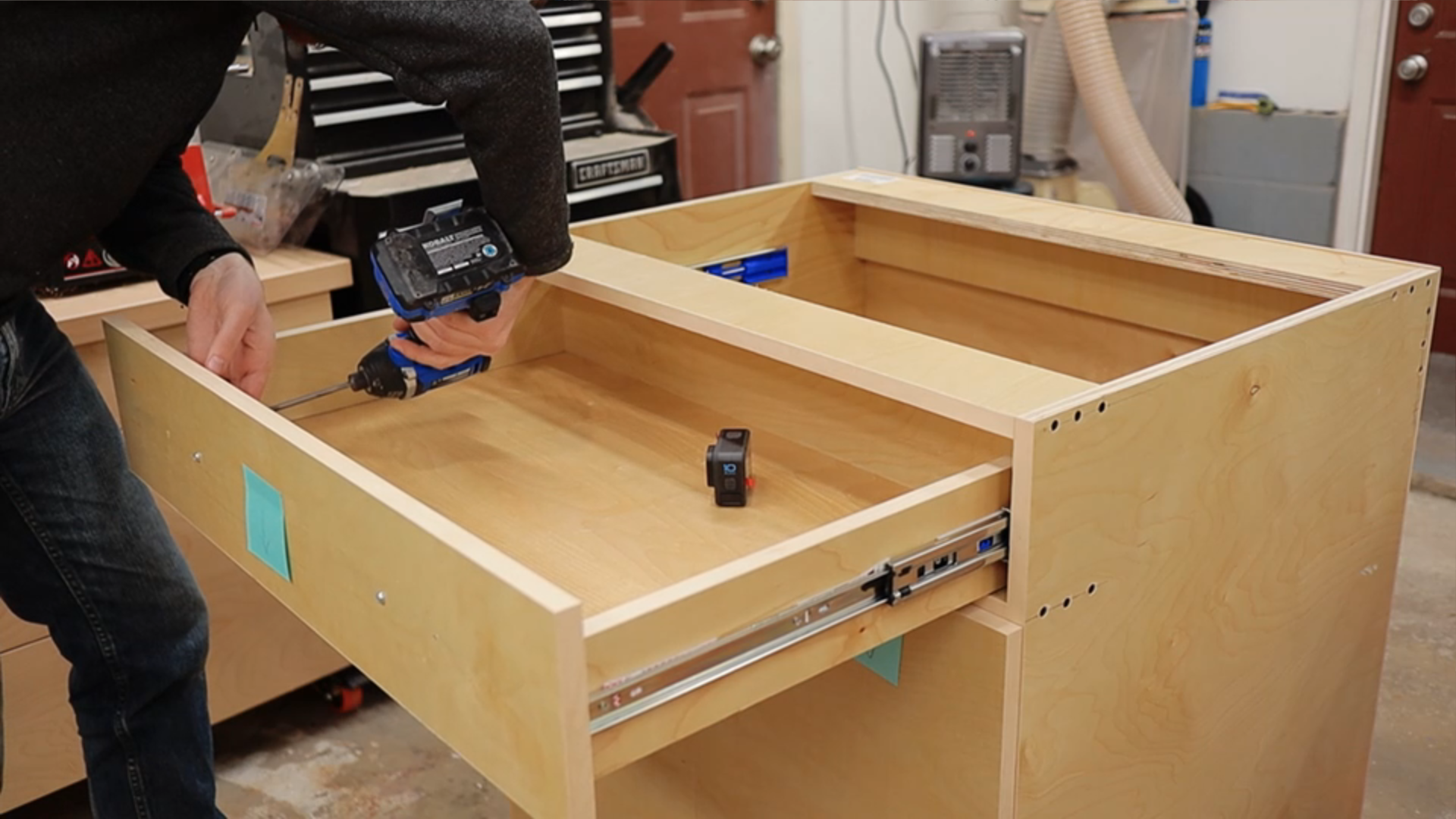

Now, getting drawer glides aligned consistently with each of the drawers requires some thought, and can be pretty difficult. Each glide needs to be at exactly the same height on each side, otherwise, you'll have wonky drawers!

(and you dont want wonky drawers!)

To solve these potentially disastrous issues, here’s what to do:

On each of the drawers, use your square to make a line 2” from the bottom of the drawer. Then, install each of your glide rails along this line. This keeps each of the drawer glides straight and consistent across all of your drawer boxes.

Next, I use a spacer to set the height of each of the glide bearings inside of the cabinet box. I try to keep this consistent so that I can use the same spacer whenever possible.

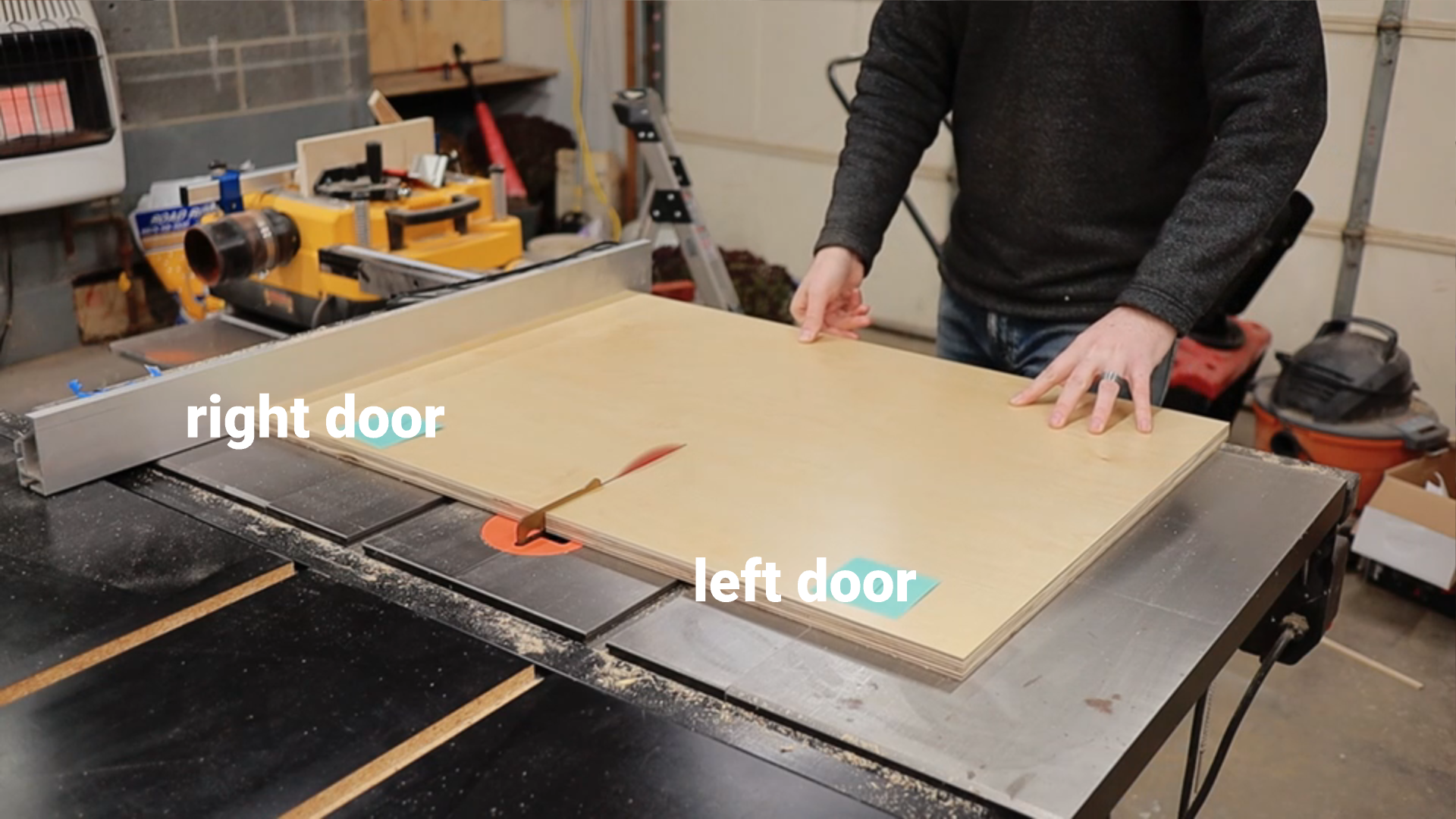

Matching Drawer Faces (waterfall Grain)

Whenever I build cabinets that won't be painted, and will have a simple plywood door or drawer front, I like to cut the door and drawer fronts out of a single piece of plywood. This does a few things for me. First, it makes it really easy to measure out how big each piece needs to be. I start by cutting down the entire sheet to leave a ⅛” reveal, relative to the box. Then, I simply divide the panel into the appropriate number of pieces that I need. Since I am using an ⅛” inch blade, all of my gaps will be spaced perfectly!

As a bonus, the plywood grain now flows across the entire cabinet piece, making for a really cool look.

Getting this to work doesnt take much extra planning, all I do is drop it into Cutlist Optimizer when I'm planning out the project and that is it!

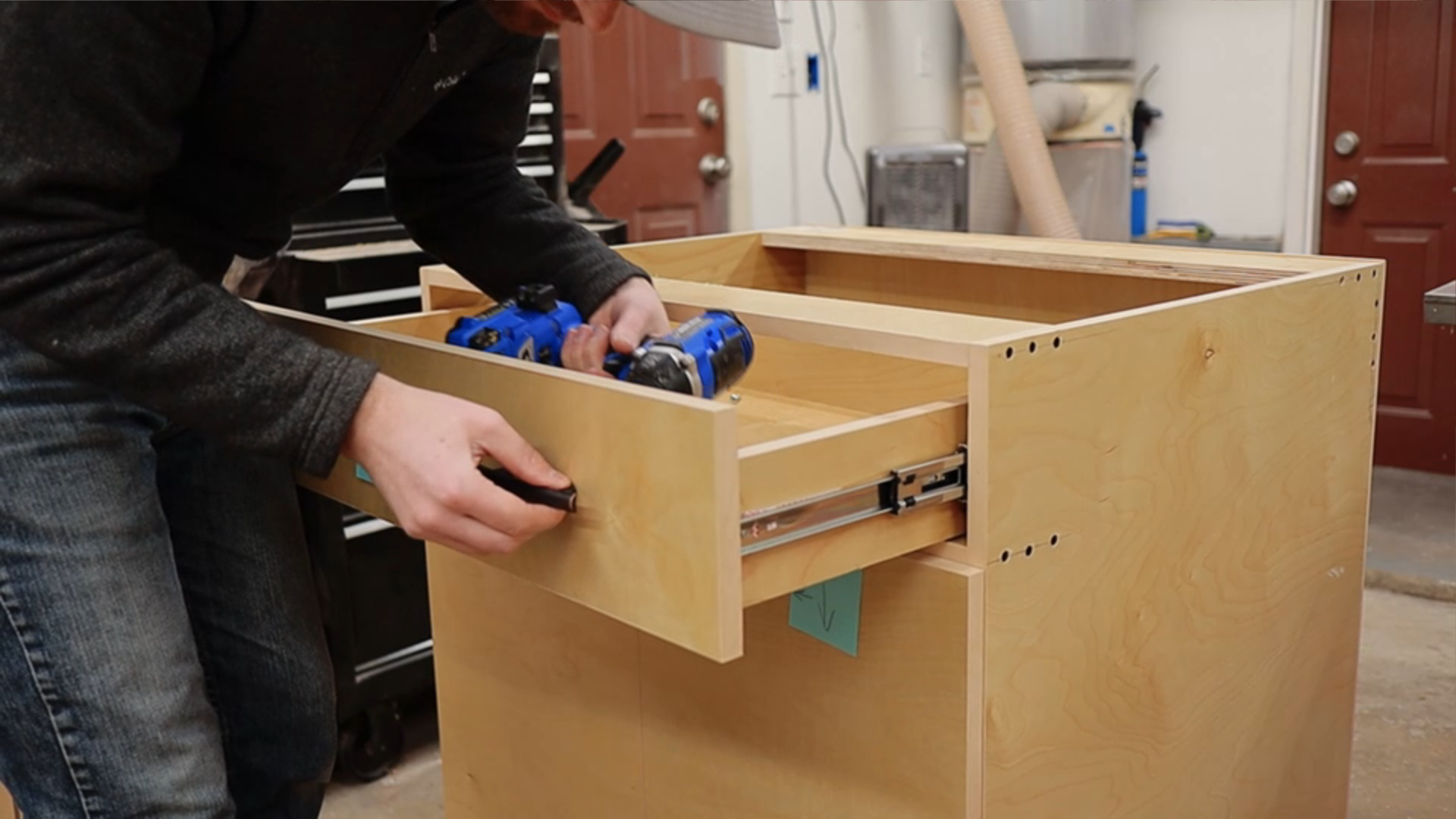

Perfectly Aligned Drawer Fronts

Of course, getting drawer fronts aligned perfectly is a little tricky, but I've using a clever technique that doesn't require any fancy jigs, double stick tape, or glue. All I do, is before installing my drawer fronts, I mark out and pre-drill the holes for my drawer pulls.

Marking out drawer pulls can be done manually with a ruler or you could use this fancy kreg jig.

So anyways, to install the drawer front, I line it up against the drawer box and then use 2 screws to fasten the front through these holes. Then, I open the drawer, and use 2 more screws from the inside to fasten on the front.

Time to Go Build Some Cabinets!

Now all I need to do is fill up this gardening cabinet with all the junk that has been cluttering my workshop!

I hope you learned a few tips and tricks about building better cabinets in the shop! If you have any other clever tips, share them in the comments down below so we can all learn from each other!

Thank you so much for reading, I'll see you in the next one!

----

Don't forget to pick up your Woodworker's Notebook!

Make with Jake LLC, Makewithjake.net, and Jake Drews is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com.