Build a Peg Board Tool Cart (by Brad Justinen)

by sensoryhouse in Workshop > Tools

186923 Views, 1250 Favorites, 0 Comments

Build a Peg Board Tool Cart (by Brad Justinen)

Build a $500+ Peg Board Cart for $30-$50.

Peg Board Cart @ Overstock.com

Are your tools completely out of control? Do you need a large organization system on the cheap? Then weld your own peg board tool cart for less than $50 (assuming you have a welder and some scrap metal). If you don't own a welder, go buy one. You can buy welders cheap at Harbor Freight and Sears for around $100-$150. You can also find amazing deals on Craiglist like me. I got my Lincoln Wire-Feed 140HD for $375 cash vs. $540 for the exact same welder at Lowe's, Home Depot, or Sears. Or better yet go buy a nice one with a warranty at one of those stores. It's a good investment and when your done you will know how to weld (kinda).

I purchased my welder about a month ago. In fact, this is my second real attempt at welding anything - so if i can do it, you can too. This welder cart was my first welding project.

MAKE SURE YOU READ UP ON THE DANGERS OF WELDING BEFORE ATTEMPTING TO WELD ANYTHING.

This storage isn't for everyone. For people who need to lock up their tools, it won't work. But in my situation it works great.

Click here to view the cart in HD

1. If someone borrows a tool, or I loose one, I can tell right away and go track it down.

2. I have so many tools, i often forget to use the best one for the job because, quite frankly, I forgot that i owned one. With the pegboard i can make a quick visual scan and find the right tool easily.

3. I can easily roll my entire tool collection (mostly) right up to my car or any other project i'm workin on. No more walking back and forth between my toolboxes and work area (i have a decent sized shop).

4. I can brag to all my friends and fellow toolmongers about my creation.

5. No more searching for hours to find one misplaced tool.

6. I'm pretty broke so it's nice that it was cheap.

7. It takes up minimal floor space.

OK, sorry for the rant, let's build it.

Peg Board Cart @ Overstock.com

Are your tools completely out of control? Do you need a large organization system on the cheap? Then weld your own peg board tool cart for less than $50 (assuming you have a welder and some scrap metal). If you don't own a welder, go buy one. You can buy welders cheap at Harbor Freight and Sears for around $100-$150. You can also find amazing deals on Craiglist like me. I got my Lincoln Wire-Feed 140HD for $375 cash vs. $540 for the exact same welder at Lowe's, Home Depot, or Sears. Or better yet go buy a nice one with a warranty at one of those stores. It's a good investment and when your done you will know how to weld (kinda).

I purchased my welder about a month ago. In fact, this is my second real attempt at welding anything - so if i can do it, you can too. This welder cart was my first welding project.

MAKE SURE YOU READ UP ON THE DANGERS OF WELDING BEFORE ATTEMPTING TO WELD ANYTHING.

This storage isn't for everyone. For people who need to lock up their tools, it won't work. But in my situation it works great.

Click here to view the cart in HD

1. If someone borrows a tool, or I loose one, I can tell right away and go track it down.

2. I have so many tools, i often forget to use the best one for the job because, quite frankly, I forgot that i owned one. With the pegboard i can make a quick visual scan and find the right tool easily.

3. I can easily roll my entire tool collection (mostly) right up to my car or any other project i'm workin on. No more walking back and forth between my toolboxes and work area (i have a decent sized shop).

4. I can brag to all my friends and fellow toolmongers about my creation.

5. No more searching for hours to find one misplaced tool.

6. I'm pretty broke so it's nice that it was cheap.

7. It takes up minimal floor space.

OK, sorry for the rant, let's build it.

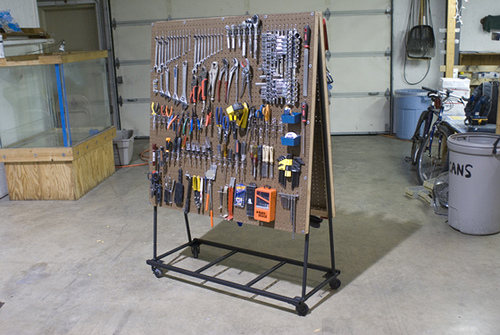

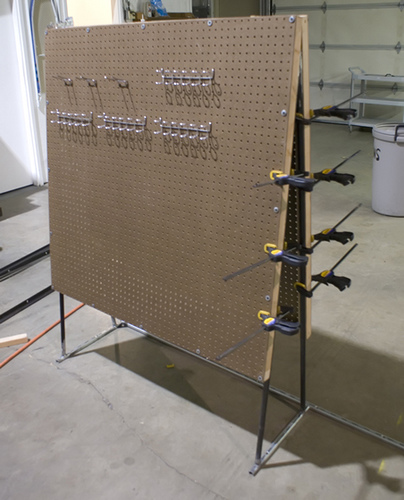

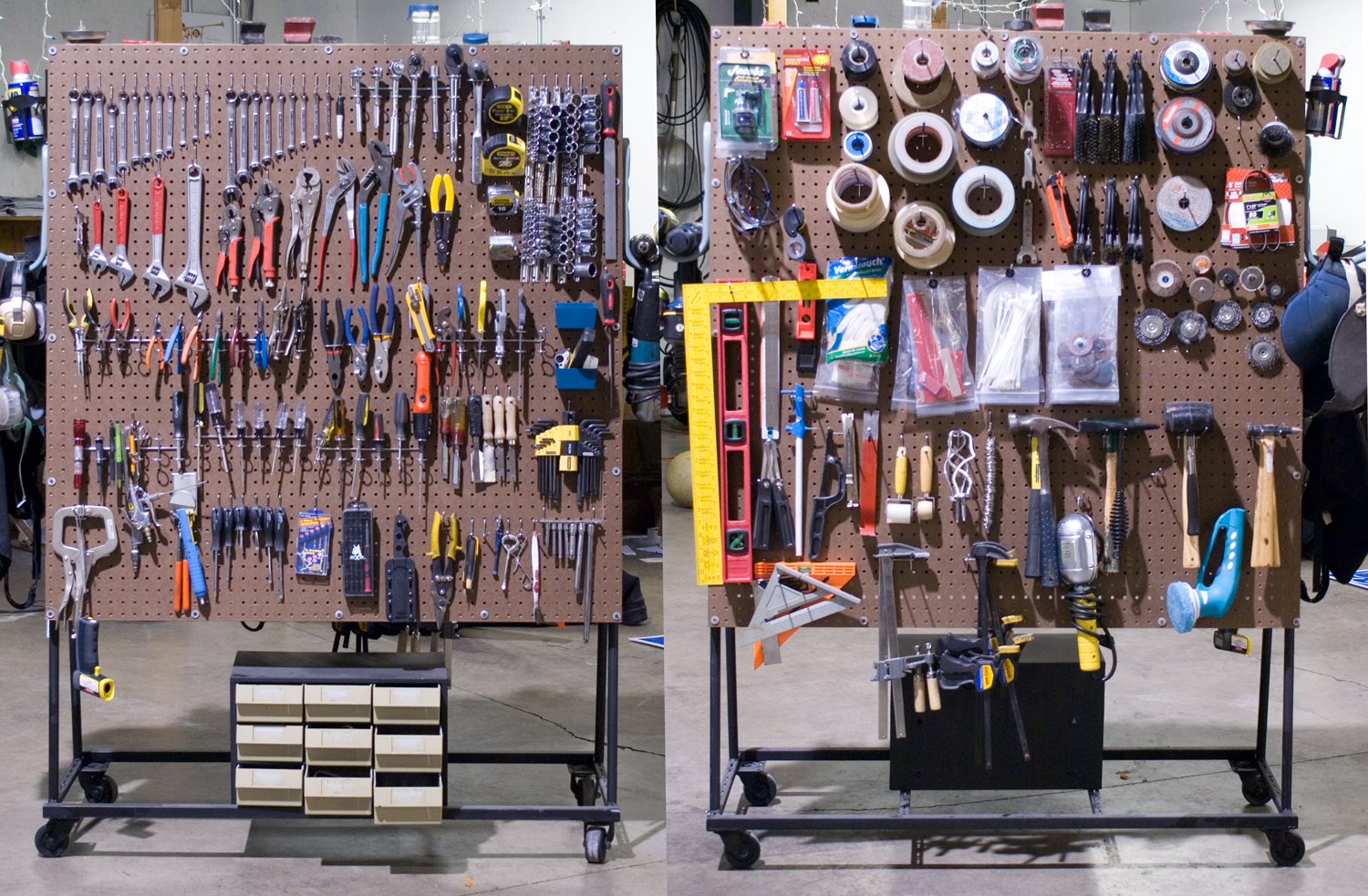

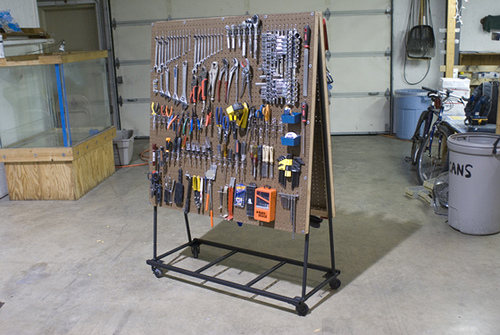

Visualize It!

1.

Take a good look, this is what we are going to build!

Take a good look, this is what we are going to build!

Get Your Tools in Check

For this project you will need:

POWER TOOLS:

Welder (Lincoln Electric Wire-Feed)

Wood Saw (Craftsman Radial Arm Saw)

Metal Saw (18v Ryobi Recip Saw)

Drill (18v Ryobi & Pnuematic Ingersoll-Rand)

Grinder (Variable Speed Makita)

Air Compressor (Craftsman) (optional)

Die Grinder (Harbor Freight) (optional)

OTHER TOOLS AND ACESSORIES:

Square

Drill Bits

Screw Driver Bits (That match screws)

6" Hex Bit Extension

Wire Cutters (for wire feed welder)

Saftey Glasses

Welding Mask

Leather Gloves

Metal Grinding Wheel

Wire Brush

Clamps (bar, spring)

Vise-Grips

Spray Paint

Face Shield (optional, but highly recommend)

Respirator (optional)

Sandpaper flap disc (optional)

Bench Vise (optional)

Saw horses or or work bench (optional)

POWER TOOLS:

Welder (Lincoln Electric Wire-Feed)

Wood Saw (Craftsman Radial Arm Saw)

Metal Saw (18v Ryobi Recip Saw)

Drill (18v Ryobi & Pnuematic Ingersoll-Rand)

Grinder (Variable Speed Makita)

Air Compressor (Craftsman) (optional)

Die Grinder (Harbor Freight) (optional)

OTHER TOOLS AND ACESSORIES:

Square

Drill Bits

Screw Driver Bits (That match screws)

6" Hex Bit Extension

Wire Cutters (for wire feed welder)

Saftey Glasses

Welding Mask

Leather Gloves

Metal Grinding Wheel

Wire Brush

Clamps (bar, spring)

Vise-Grips

Spray Paint

Face Shield (optional, but highly recommend)

Respirator (optional)

Sandpaper flap disc (optional)

Bench Vise (optional)

Saw horses or or work bench (optional)

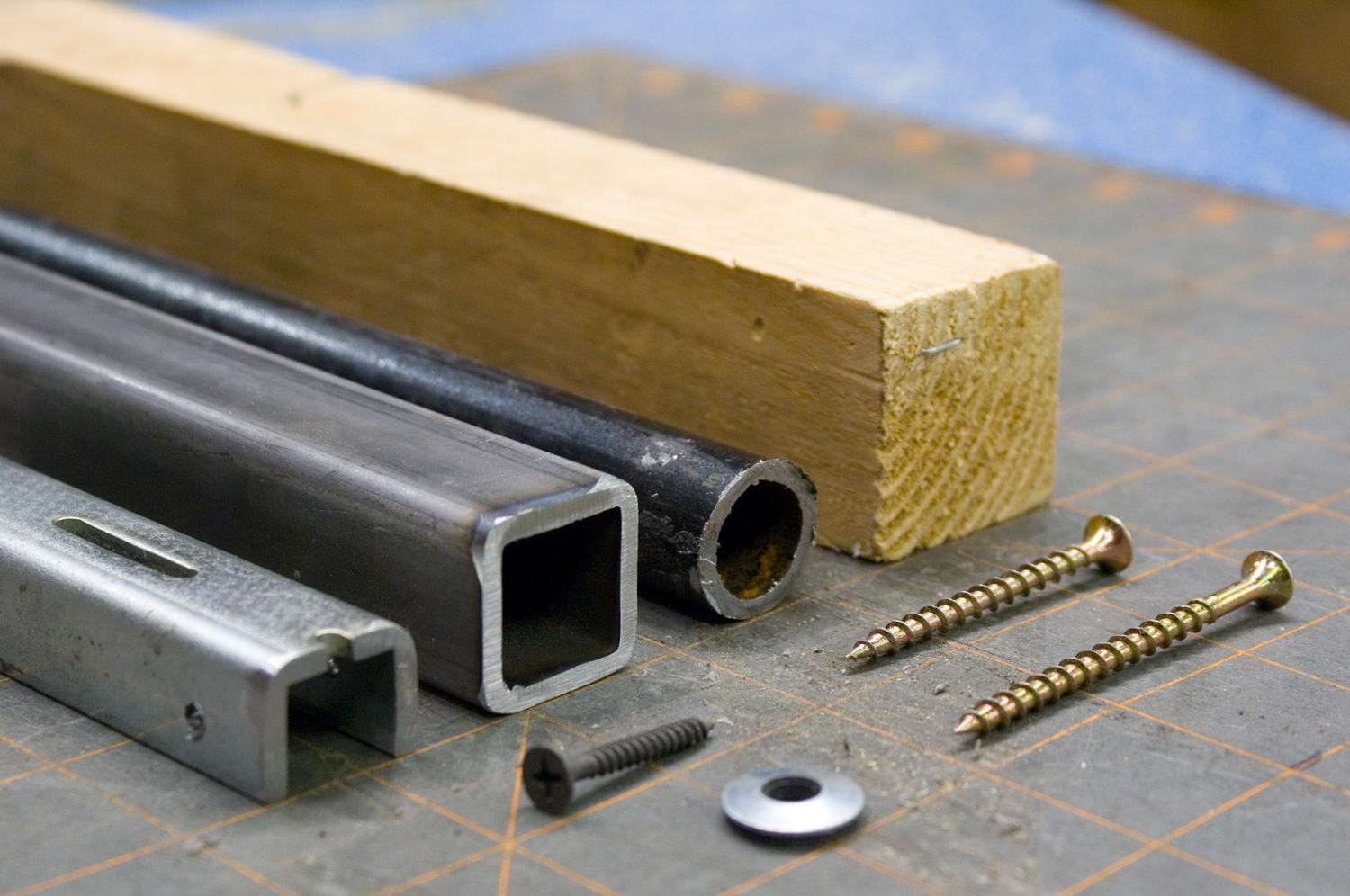

Get Your Materials in Check

For this project you will also need:

MATERIAL:

35 feet of steel

32 feet of 2x2 lumber

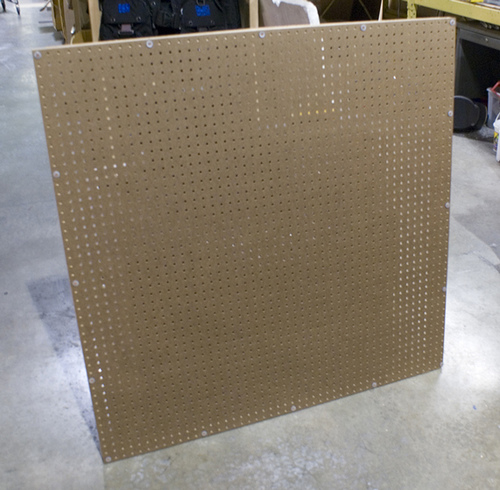

2 4'x4' sheets of peg board

4 heavy duty wheels

Approx. 40 1" wood screws

Approx. 40 washers (for 1" screws)

Approx. 20 2" wood screws

1 short piano hinge

8 3" wood screws

MATERIAL:

35 feet of steel

32 feet of 2x2 lumber

2 4'x4' sheets of peg board

4 heavy duty wheels

Approx. 40 1" wood screws

Approx. 40 washers (for 1" screws)

Approx. 20 2" wood screws

1 short piano hinge

8 3" wood screws

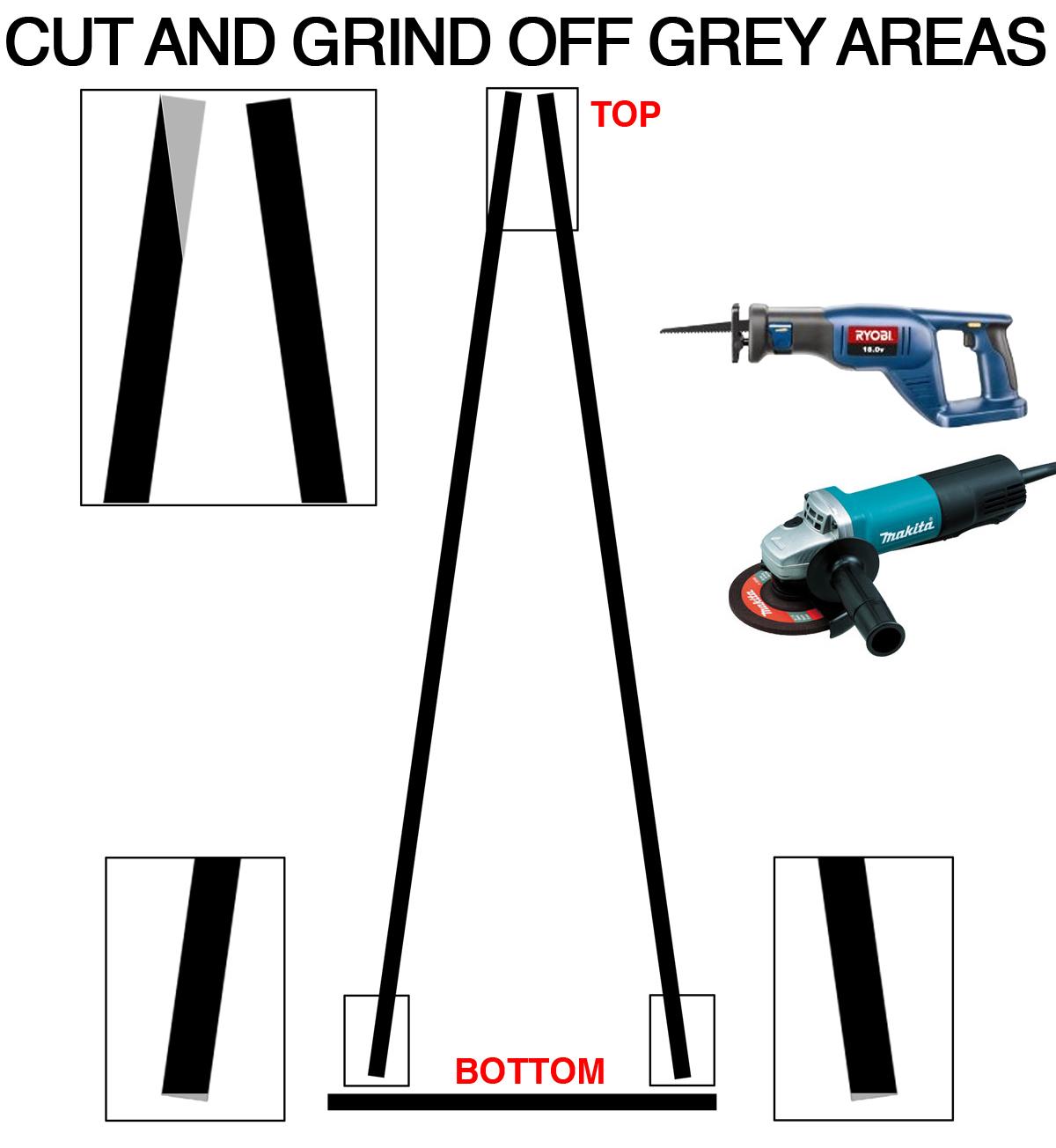

Cut and Grind Your Metal

Since the peg boards are 4'x4' the side supports don't HAVE to be any taller than that. I made mine about 5'6" so I could add a shelf at the bottom to store tool boxes. If you want to make yours exactly like mine use these directions.

1.

Cut your metal. You can use any scrap as long as it is roughly 1-1.5 inches diameter. I used scrap 1" steel conduit for the longer side pieces and some cut up shelf tracking for the bottom pieces.

Cut: 4 pieces at 5 ft.

2 pieces at 18.5 inches'

2.

Take two of the longer pieces and cut a sliver off the top of both of them (See Diagram). The degree of this cut will determine the angle of your pegboard. Use a sawzall or hacksaw to cut it off. Then Use a grinder to perfect your angle

Make sure you don't shorten the overall length of steel though. It should come to a point a 5 feet. Take your time and just remove a little metal at a time until you have the angle that fits nicely. Its better to make a smaller cut and grind it down than then have to cut another 5 footer.

3.

You will also need to grind the bottoms of all four of the longer pieces - so they will sit straight on the bottom piece. See Diagram

1.

Cut your metal. You can use any scrap as long as it is roughly 1-1.5 inches diameter. I used scrap 1" steel conduit for the longer side pieces and some cut up shelf tracking for the bottom pieces.

Cut: 4 pieces at 5 ft.

2 pieces at 18.5 inches'

2.

Take two of the longer pieces and cut a sliver off the top of both of them (See Diagram). The degree of this cut will determine the angle of your pegboard. Use a sawzall or hacksaw to cut it off. Then Use a grinder to perfect your angle

Make sure you don't shorten the overall length of steel though. It should come to a point a 5 feet. Take your time and just remove a little metal at a time until you have the angle that fits nicely. Its better to make a smaller cut and grind it down than then have to cut another 5 footer.

3.

You will also need to grind the bottoms of all four of the longer pieces - so they will sit straight on the bottom piece. See Diagram

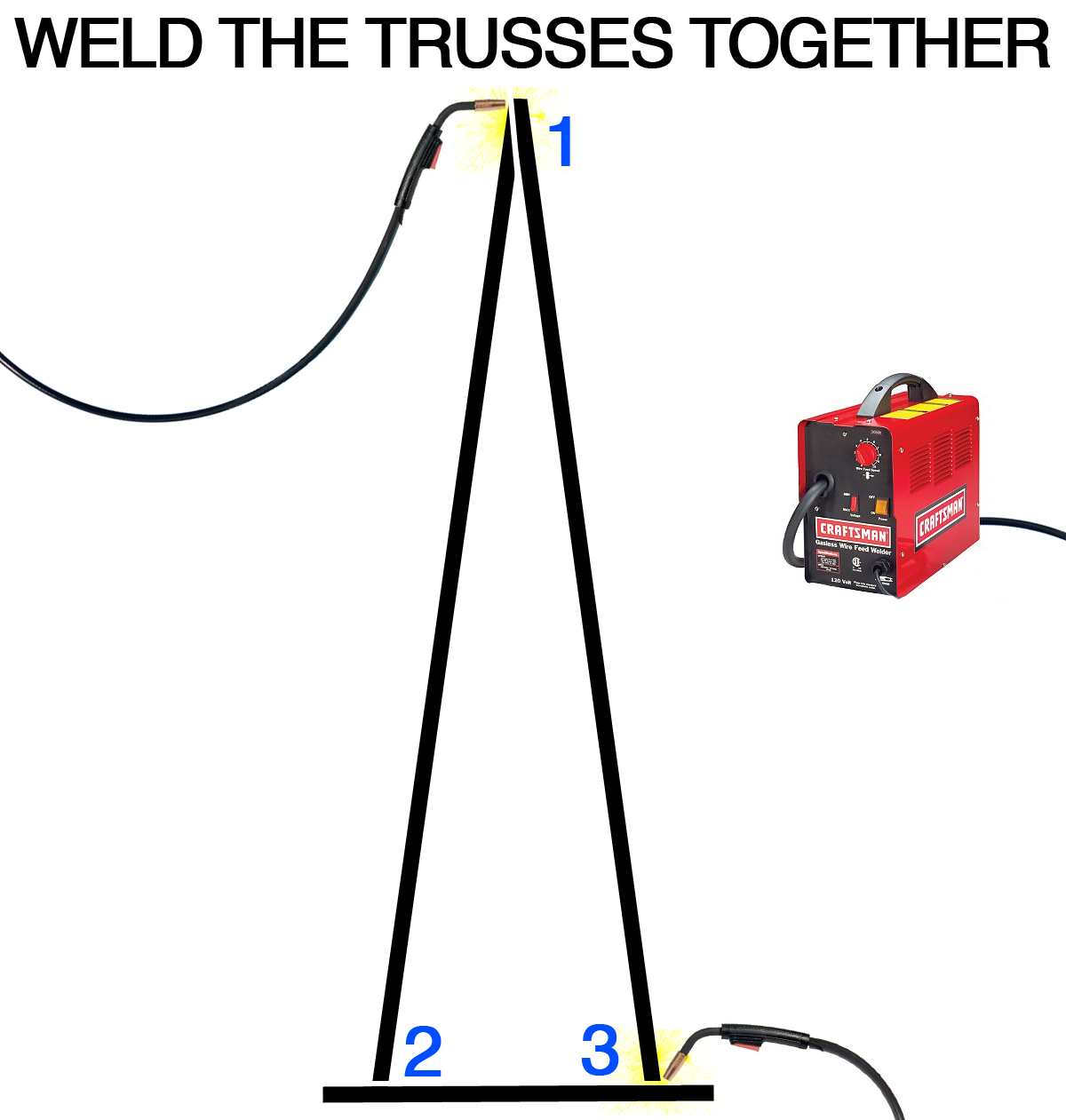

Weld the Trusses

1.

IF YOU'RE A NOOB, MAKE SURE YOU READ UP BEFORE PRACTICING AND ESPECIALLY BEFORE STARTING A PROJECT. IN MY PROJECT I USED SOME GALVANIZED STEEL WHICH GIVES OFF DANGEROUS FUMES. I MADE SURE I KEPT MY WORK AREA WELL VENTILATED WHILE WELDING - PLUS I USED A RESPIRATOR. BE RESPONSIBLE. PROTECT YOUR EYES AND LUNGS.'

2.

Weld everything together. I laid my pieces on the ground to fit everything. I use the first frame as a template to make the second one exactly the same.

3.

If you are worried about the look of the final product (which you should be) you should paint the trusses now. This is so you don't have to worry about painting them once the peg boards have been secured. Don't paint within a foot of the bottom though because we have some more welding to do.

4.

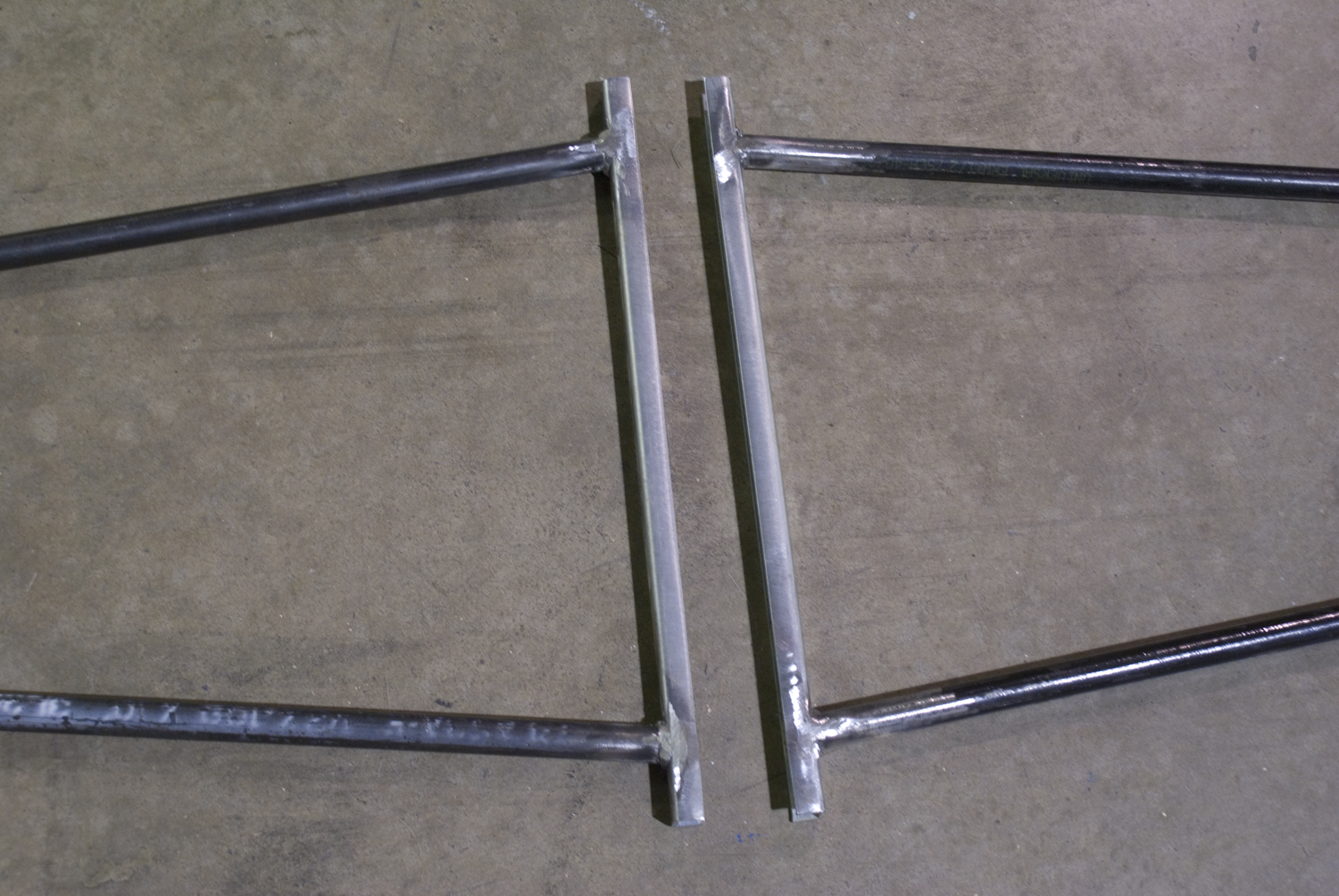

NOOB ALERT! Please don't make fun of my welds. I know they suck.

IF YOU'RE A NOOB, MAKE SURE YOU READ UP BEFORE PRACTICING AND ESPECIALLY BEFORE STARTING A PROJECT. IN MY PROJECT I USED SOME GALVANIZED STEEL WHICH GIVES OFF DANGEROUS FUMES. I MADE SURE I KEPT MY WORK AREA WELL VENTILATED WHILE WELDING - PLUS I USED A RESPIRATOR. BE RESPONSIBLE. PROTECT YOUR EYES AND LUNGS.'

2.

Weld everything together. I laid my pieces on the ground to fit everything. I use the first frame as a template to make the second one exactly the same.

3.

If you are worried about the look of the final product (which you should be) you should paint the trusses now. This is so you don't have to worry about painting them once the peg boards have been secured. Don't paint within a foot of the bottom though because we have some more welding to do.

4.

NOOB ALERT! Please don't make fun of my welds. I know they suck.

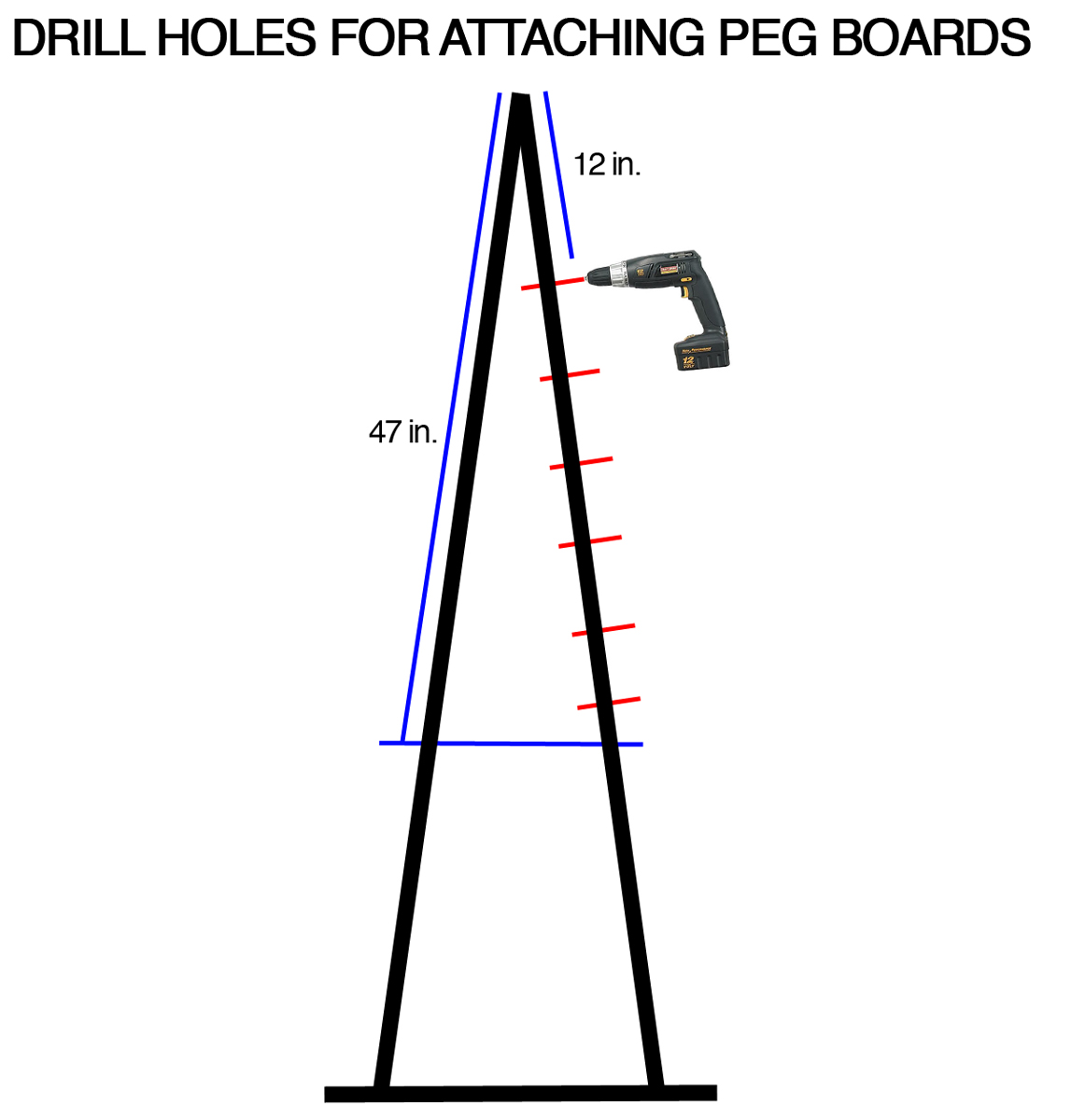

Drill Holes for Attaching the Peg Boards

Now drill some holes where we will attach to the peg board in Step 4.

1.

Drill a hole at about 13 inches from the top and add 5 more holes down to 47 inches.

2.

Do this on each side of both trusses. 24 holes in all.

1.

Drill a hole at about 13 inches from the top and add 5 more holes down to 47 inches.

2.

Do this on each side of both trusses. 24 holes in all.

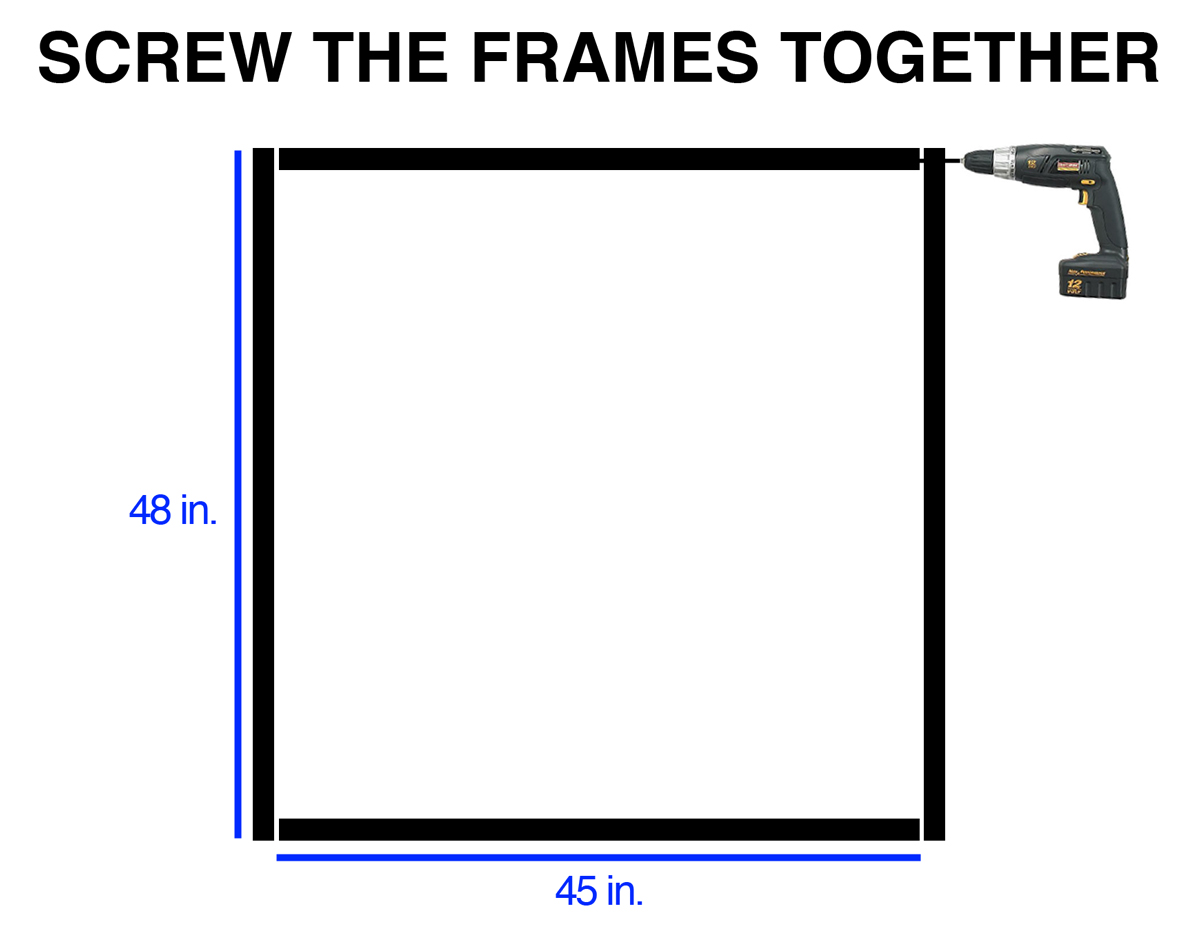

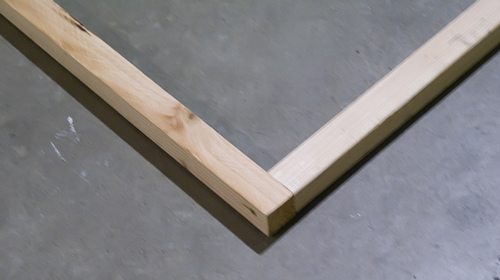

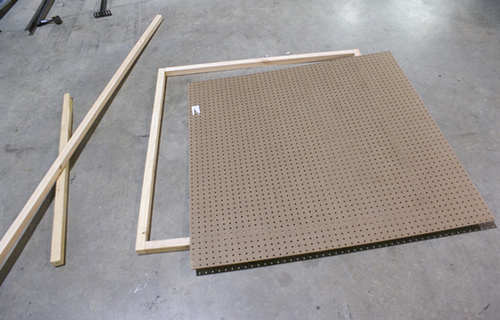

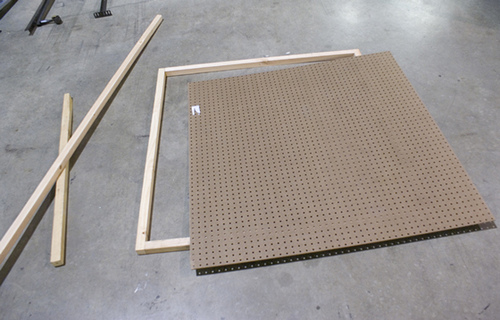

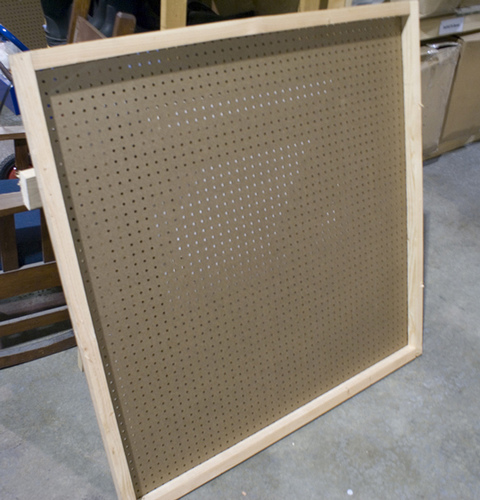

Make the 2x2 Peg Board Frames

1.

Cut your wood. You will need approximetally 36 feet of 2"x2" lumber and 2 4"x4" sheets of peg board - you can get the peg board at any Home Depot or Lowes.

Cut: 4 2x2's at 48 inches

4 2x2's at 45 inches'

NOTE: I always like to drill pilot holes for my screws. This is to ensure that I don't spilt the wood.

2. Screw together the frames using 2 1/2 to 3 inch screws. See Diagram

Cut your wood. You will need approximetally 36 feet of 2"x2" lumber and 2 4"x4" sheets of peg board - you can get the peg board at any Home Depot or Lowes.

Cut: 4 2x2's at 48 inches

4 2x2's at 45 inches'

NOTE: I always like to drill pilot holes for my screws. This is to ensure that I don't spilt the wood.

2. Screw together the frames using 2 1/2 to 3 inch screws. See Diagram

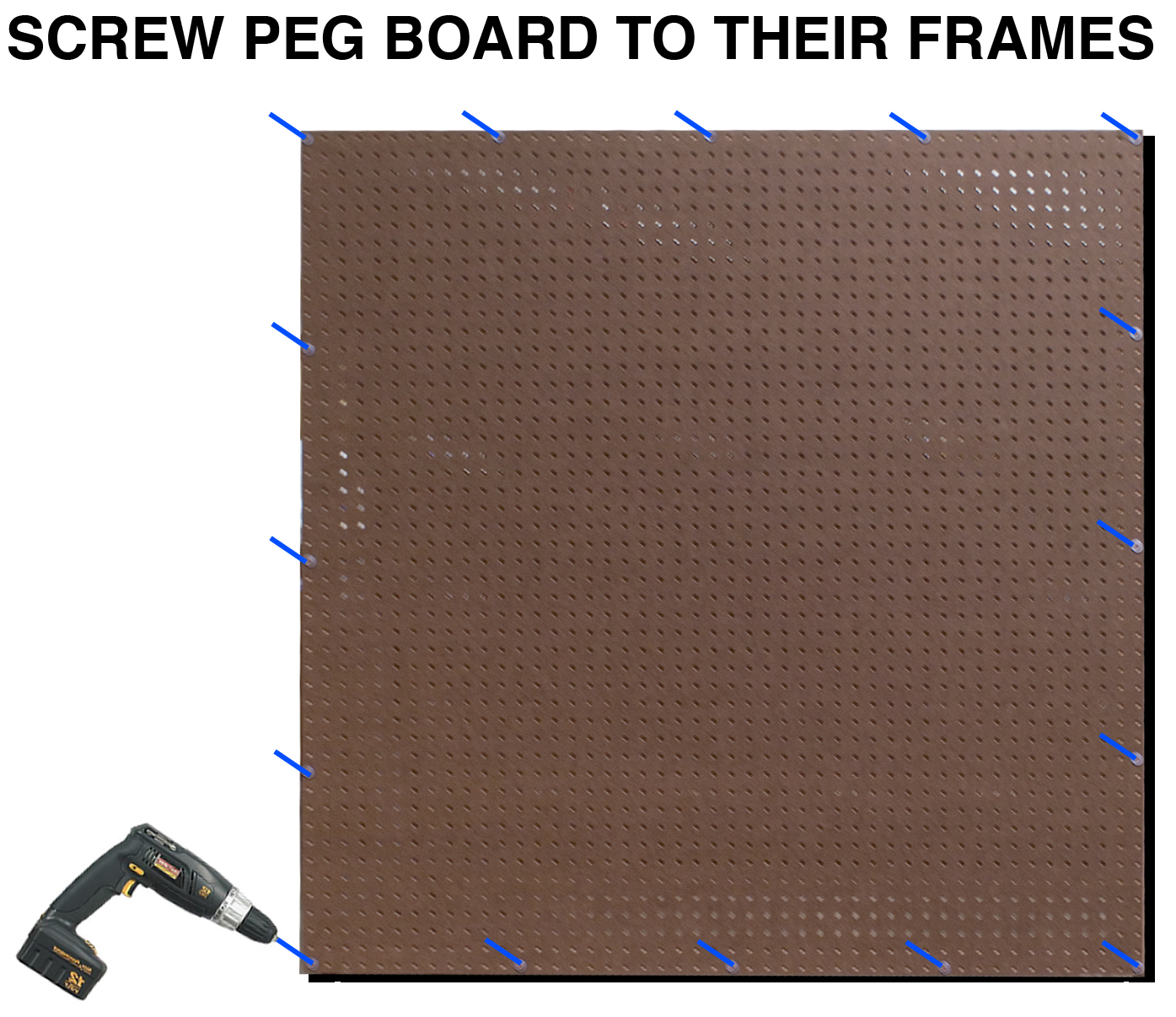

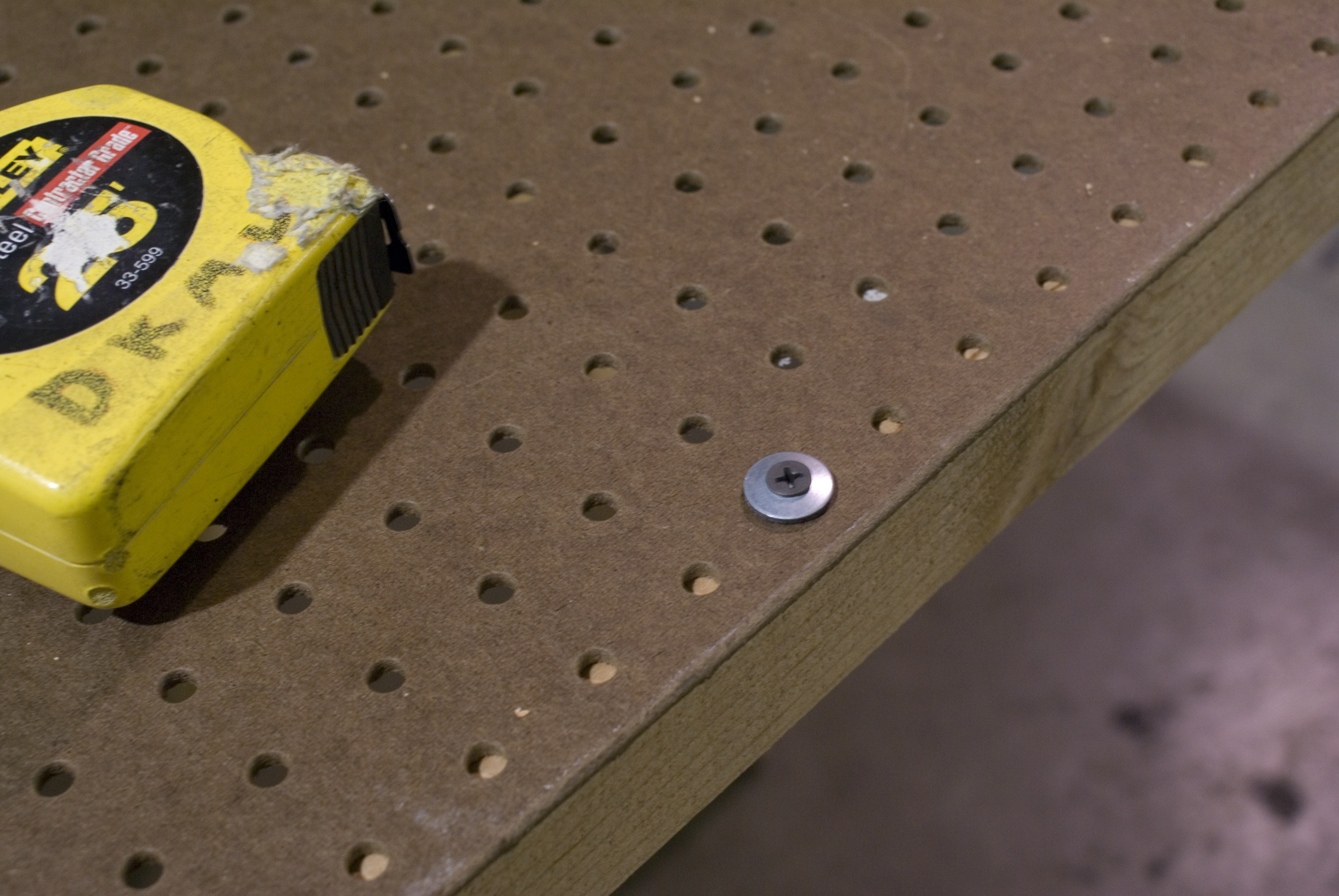

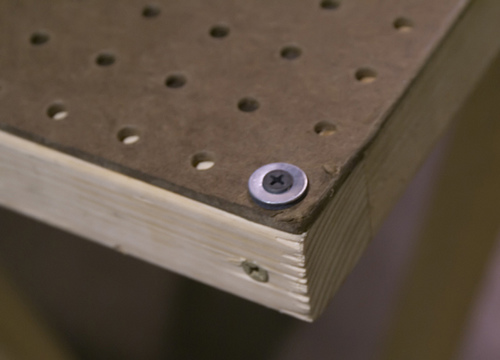

Screw the Peg Board to Their Wooden Frames

1.

Lay the frame flat (either on a table or on the ground) and lay the peg board onto it. Make sure its square. Clamp it if need be.

2.

Using the 1" screws and washers. Fasten the pegboards to their frames making sure everything is square. See Diagram.

Lay the frame flat (either on a table or on the ground) and lay the peg board onto it. Make sure its square. Clamp it if need be.

2.

Using the 1" screws and washers. Fasten the pegboards to their frames making sure everything is square. See Diagram.

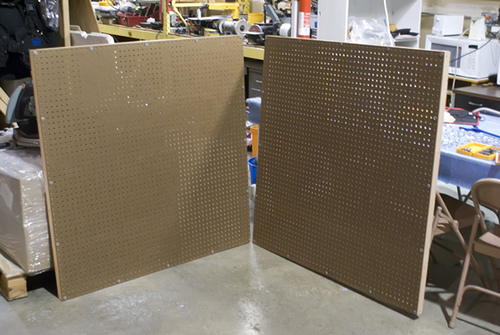

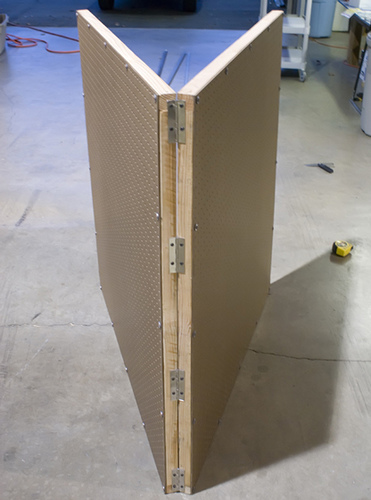

Fasten the Two Peg Boards Together

Once you have finished assembling both peg boards its time to fasten them together.

1.

Place the first peg board face down.

2.

Place the second peg board on top of that face up. See Pics

NOTE: I always like to drill pilot holes for my screws. This is to ensure that I don't spilt the wood.

3.

Then fasten a couple hinges along one side. This will add stability and make the rest of the project and future repairs easier. I used a piano hinge and cut it up into 5 hinges. You could use and old door or cabinet hinge.

1.

Place the first peg board face down.

2.

Place the second peg board on top of that face up. See Pics

NOTE: I always like to drill pilot holes for my screws. This is to ensure that I don't spilt the wood.

3.

Then fasten a couple hinges along one side. This will add stability and make the rest of the project and future repairs easier. I used a piano hinge and cut it up into 5 hinges. You could use and old door or cabinet hinge.

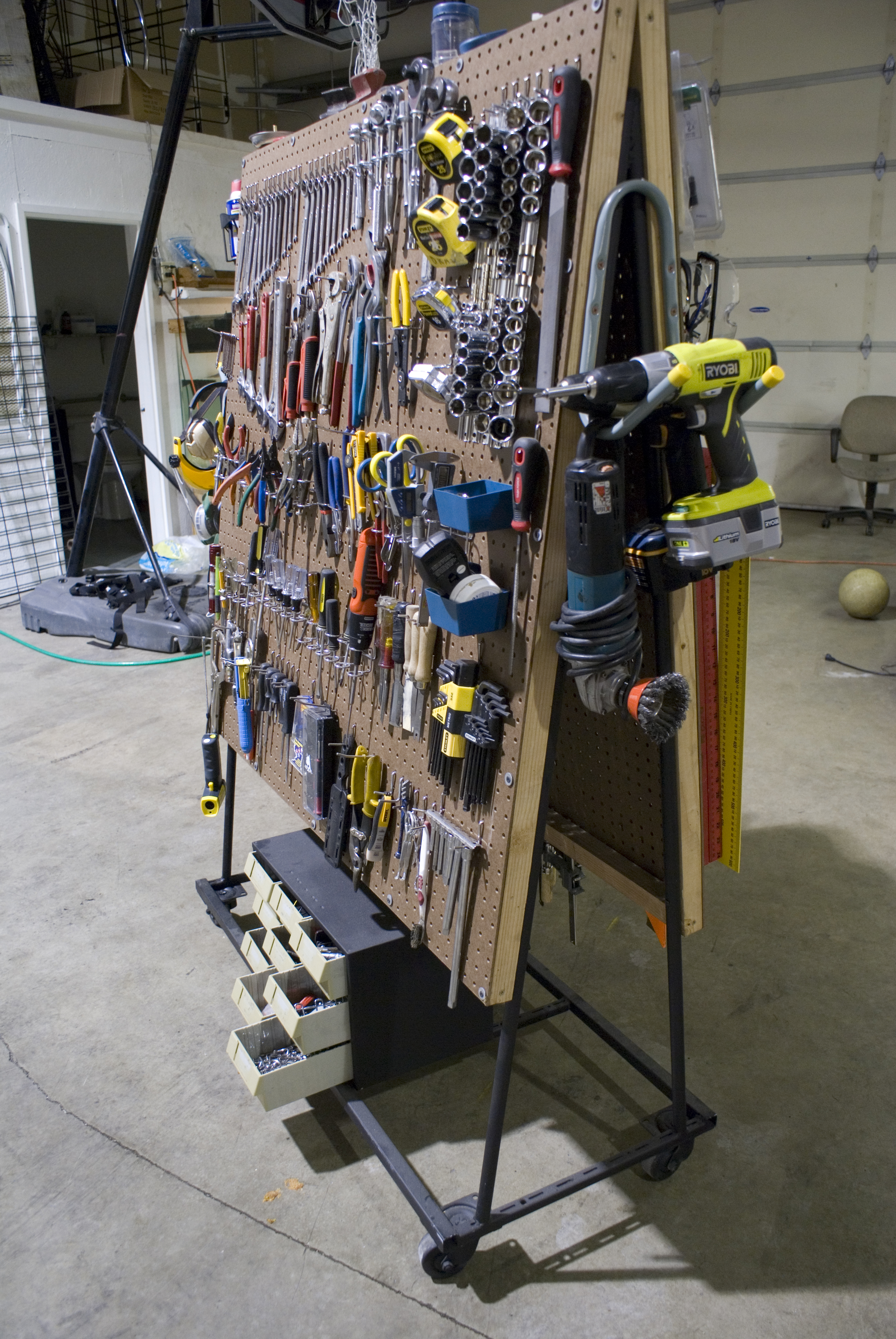

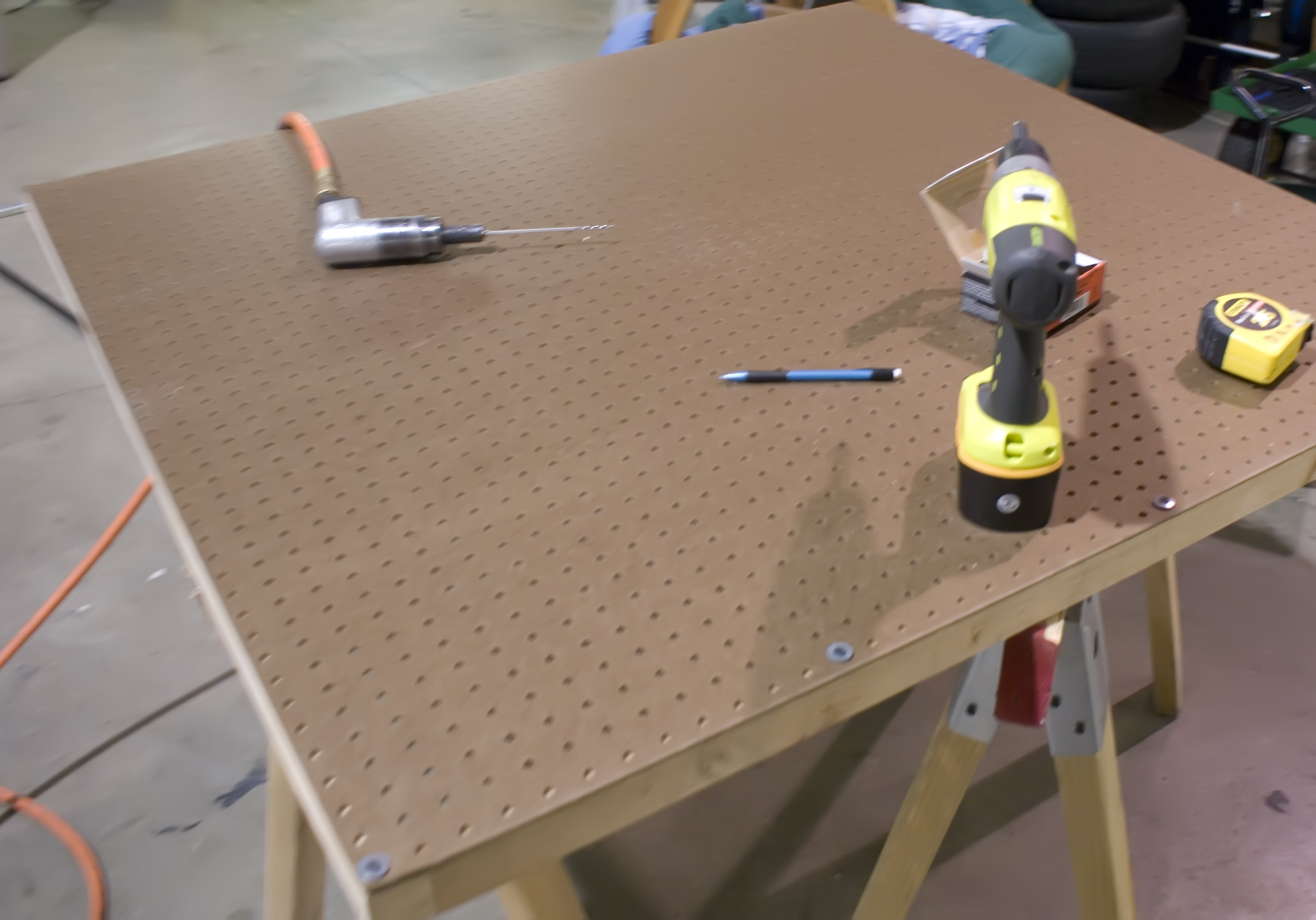

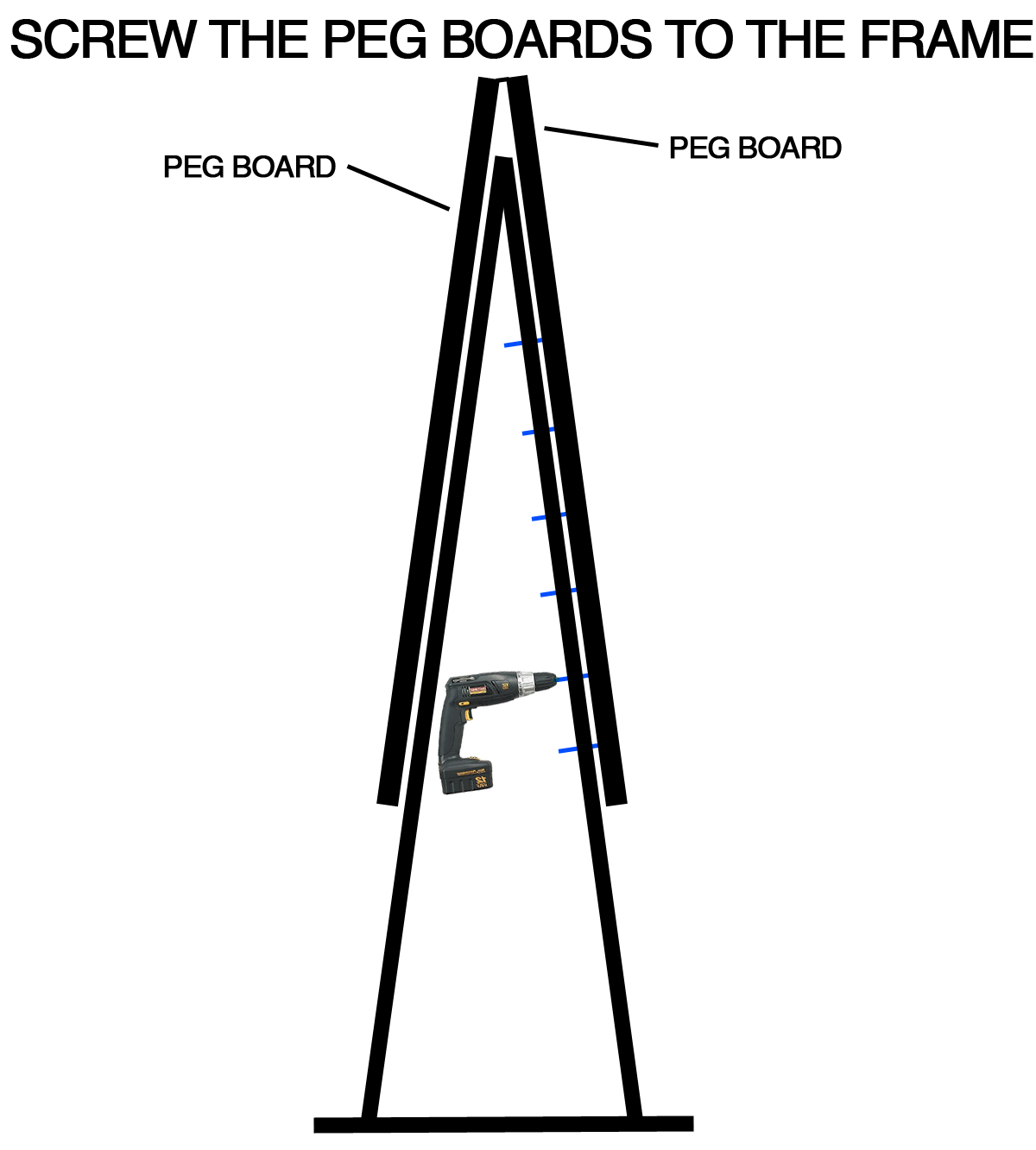

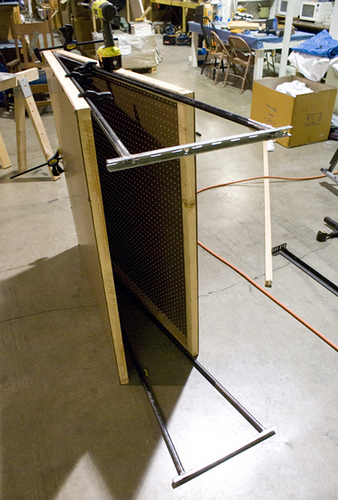

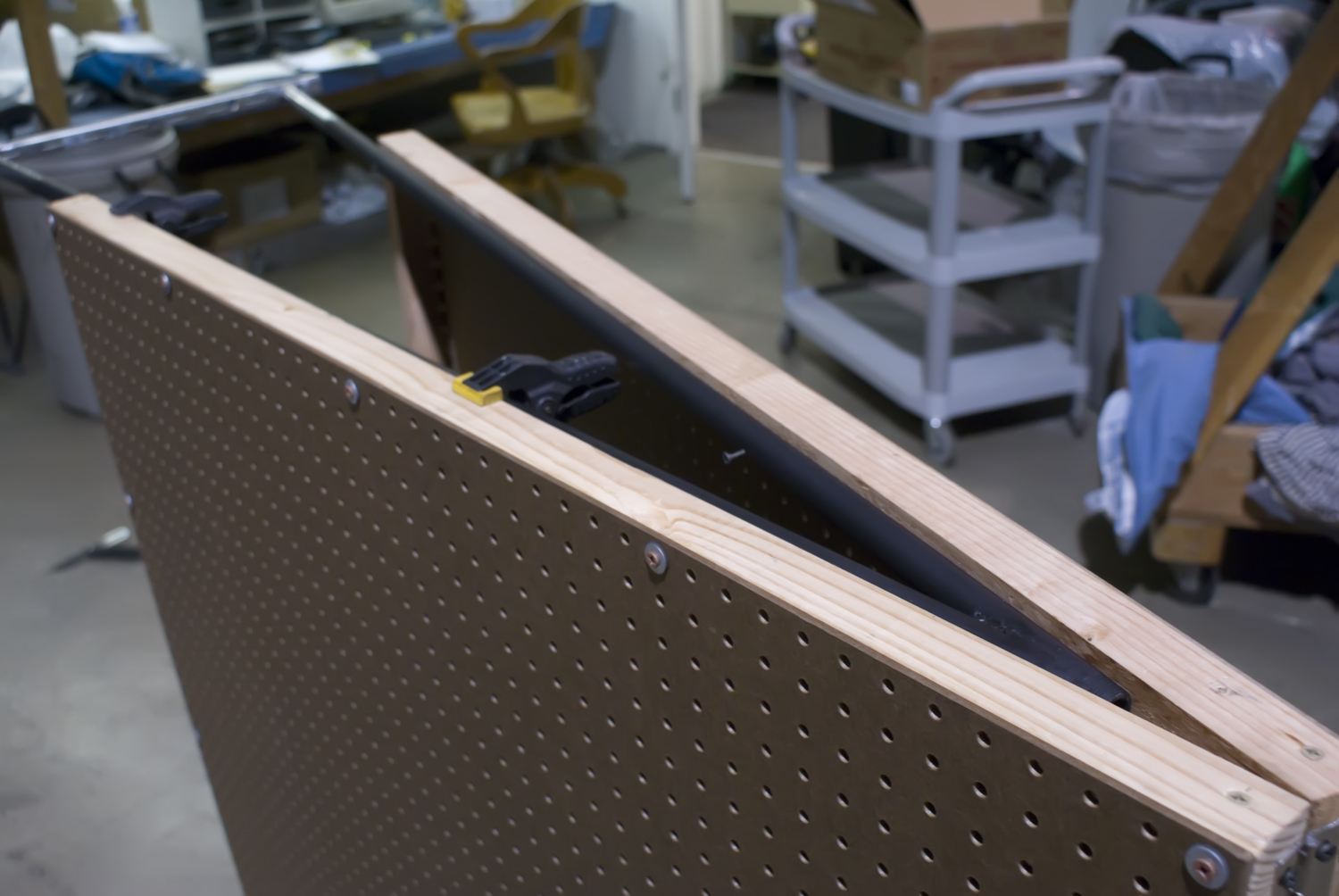

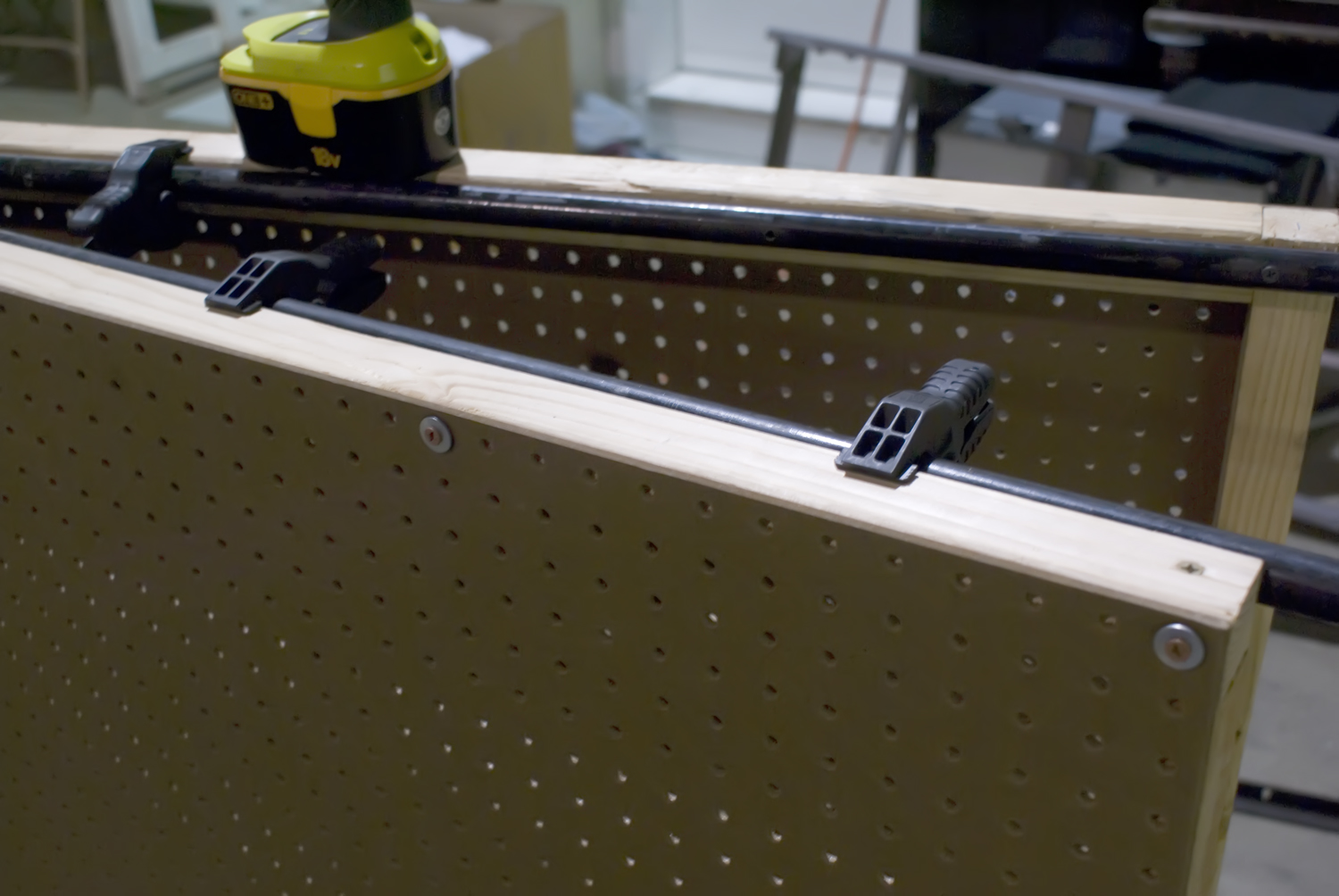

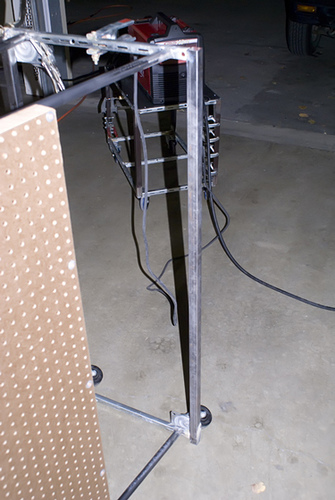

Clamp and Screw the Peg Boards to the Frame

1.

With the peg boards on their side (See Pics) clamp the first truss into place.

2.

Taken some screws (2 inch in my case) and fasten the frame to the pegboard. Again, try to make sure everything is square at all times.

NOTE: You may need to use either a stubby screwdriver, 6"+ hex driver extension, or 90 degree drill driver to get a couple of the screws in - because of the close quarters towards the top of the truss. See Pics.

3.

Once attached, turn it over attach the other frame to the other side.

With the peg boards on their side (See Pics) clamp the first truss into place.

2.

Taken some screws (2 inch in my case) and fasten the frame to the pegboard. Again, try to make sure everything is square at all times.

NOTE: You may need to use either a stubby screwdriver, 6"+ hex driver extension, or 90 degree drill driver to get a couple of the screws in - because of the close quarters towards the top of the truss. See Pics.

3.

Once attached, turn it over attach the other frame to the other side.

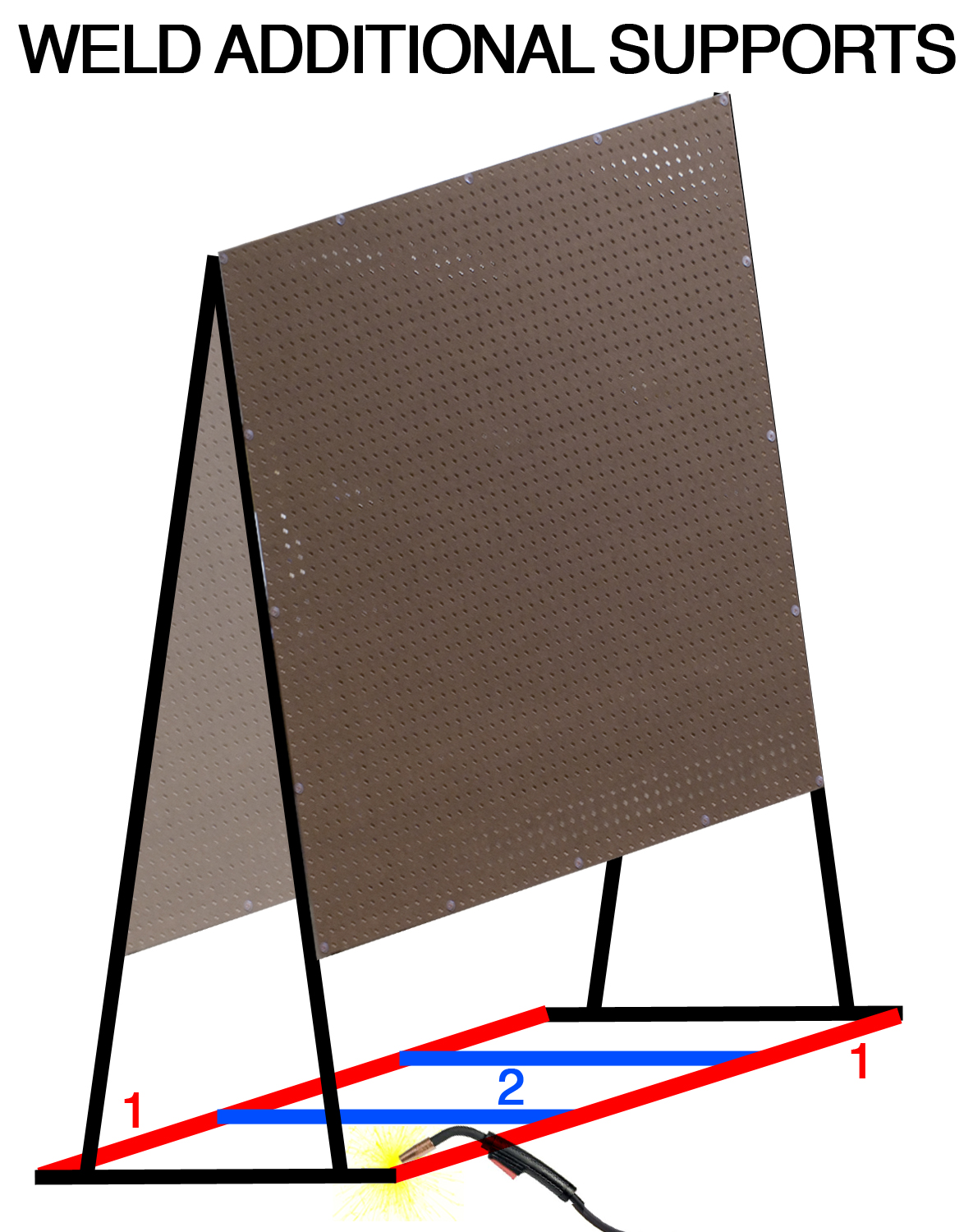

Weld the Two Trusses Together

Once both side trusses are attached you can you can weld the entire thing together.

See Diagram

1:

Cut your metal. You can use any scrap as long as it is roughly 1-1.5 inches diameter. I used some scrap 1" steel tubing for the side pieces and some donated, cut up shelf tracking for the middle pieces.

Cut: 2 pieces at 4 ft.

2 pieces at 18.5 inches'

2.

Weld the longer pieces in between the two trusses (1). (See Diagram)

3.

Then weld the two shorter supports in (2).

See Diagram

1:

Cut your metal. You can use any scrap as long as it is roughly 1-1.5 inches diameter. I used some scrap 1" steel tubing for the side pieces and some donated, cut up shelf tracking for the middle pieces.

Cut: 2 pieces at 4 ft.

2 pieces at 18.5 inches'

2.

Weld the longer pieces in between the two trusses (1). (See Diagram)

3.

Then weld the two shorter supports in (2).

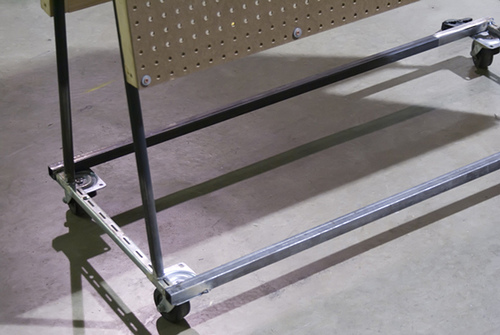

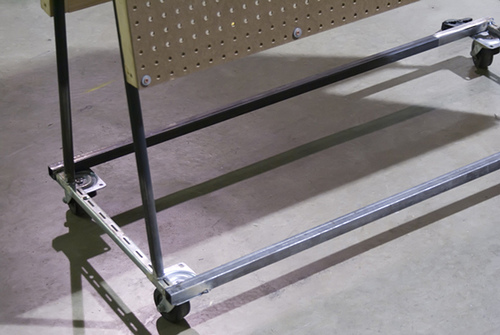

Add Wheels

Once everything is welded together its time to make it mobile.

1.

Do yourself a favor and buy new wheels. I used wheels from an old cart and I regret it every day. It's not as smooth riding as i'd like. So splurge and spend $10 on some new wheels. You know where to get them...........right?

2.

Clamp a wheel - one at a time - to the bottom of each corner of the cart (i used vise-grips) and weld 'em on.

The people over a Make Magazine feature this cart on their blog. They said they would have welded plates to the cart and then bolted the casters to plates. NO BRAINER. I should have done this. It would have made changing a bad wheel much easier.

1.

Do yourself a favor and buy new wheels. I used wheels from an old cart and I regret it every day. It's not as smooth riding as i'd like. So splurge and spend $10 on some new wheels. You know where to get them...........right?

2.

Clamp a wheel - one at a time - to the bottom of each corner of the cart (i used vise-grips) and weld 'em on.

The people over a Make Magazine feature this cart on their blog. They said they would have welded plates to the cart and then bolted the casters to plates. NO BRAINER. I should have done this. It would have made changing a bad wheel much easier.

Paint

Painting is 95% preperation and 5% spraying. A little prep will save you from a ruined finish.

1.

Grind and sand everything nice and smooth.

2.

Wipe all the metal down with soapy water or solvent.

3.

Spray paint it. I used flat black Rustoleum.

1.

Grind and sand everything nice and smooth.

2.

Wipe all the metal down with soapy water or solvent.

3.

Spray paint it. I used flat black Rustoleum.

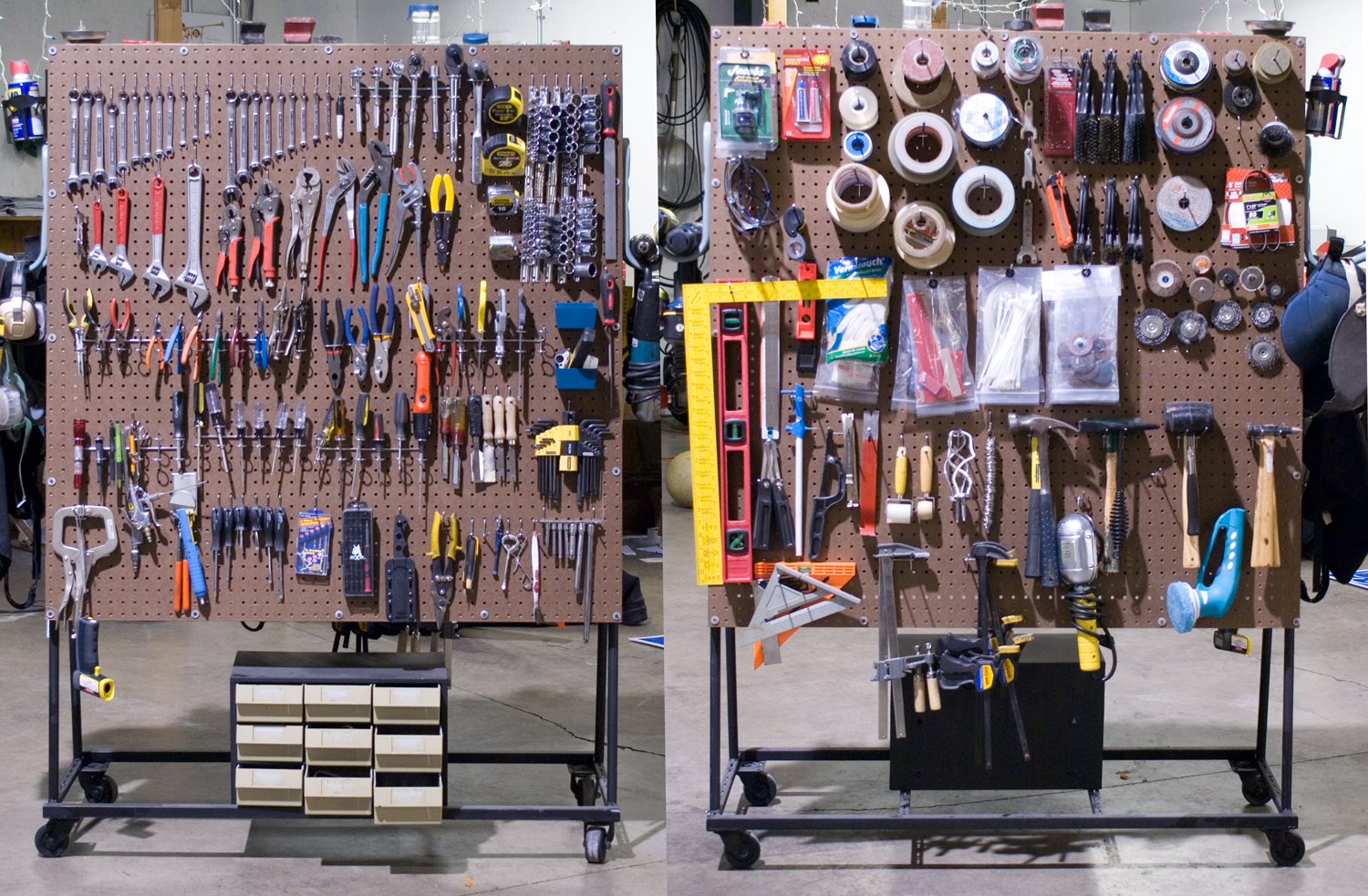

Stock It Up!

Its all about the layout, aesthetics, and ergonomics. Don't be afraid to pull every single hook off and start all over.

It has to look as good as it works. IMO!

Note: You can get peg board hardware at pretty much any hardware store. I needed about 6-7 multi-packs to stock my cart. I like to wait until they go on sale at Harbor Freight. You can get a big box of hooks for $4.

The hooks can be the most expensive part of the project if you don't shop smart.

It has to look as good as it works. IMO!

Note: You can get peg board hardware at pretty much any hardware store. I needed about 6-7 multi-packs to stock my cart. I like to wait until they go on sale at Harbor Freight. You can get a big box of hooks for $4.

The hooks can be the most expensive part of the project if you don't shop smart.

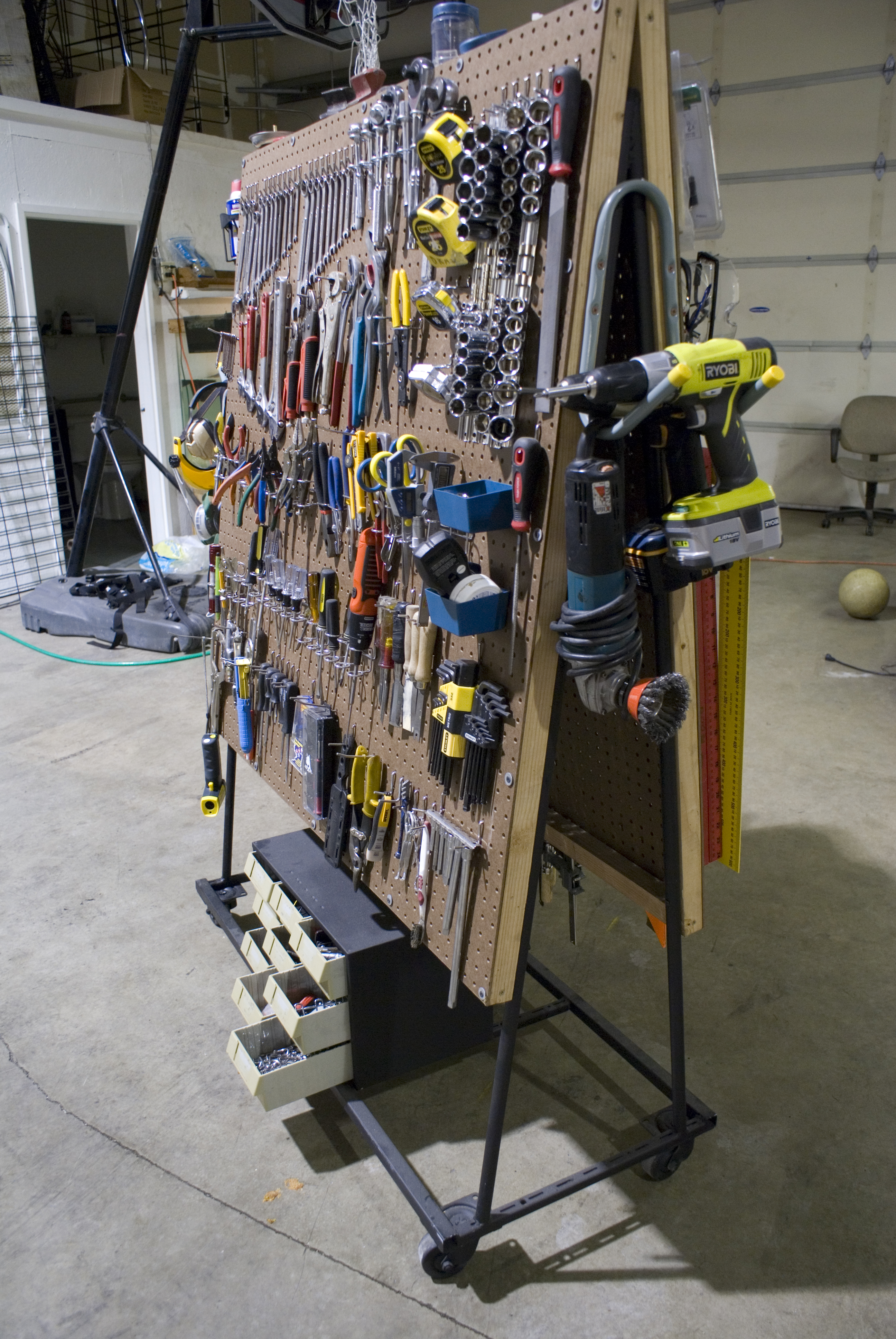

Add More Accessories

Because the pegboard has a wood frame I can screw all kinds of hooks, handles, and holders onto the side.

My buddy thinks i should screw a power strip to it and add an extension cord. I think i'll do it!

Why not?

My buddy thinks i should screw a power strip to it and add an extension cord. I think i'll do it!

Why not?

Update

Now that I have used the cart for 3 months I can give you an honest toolmongers opinion about the cart.

IT ROCKS.

Yes, I lose a hook every now and then.

but

It helps me stay organized.

It's saves me time.

It's super sturdy.

It has room for expansion.

It holds 90% of the tools I need for any given project.

It may not meet the needs of an automotive or aircraft mechanic, but it's more than enough for a hobbyist like myself.'

IF YOU MAKE ONE PLEASE SEND ME A PHOTO!

More photos at my Flickr Page

or this Photo Set

THANKS TO EVERYONE WHO VOTED, RATED, AND COMMENTED!!!!!!

Brad Justinen (sensoryhouse)

Here is the tool cart via:

Instructables Jan 8, 2009 Newsletter

Make Magazine

Google

dailydiy.com

motherearthnews.com

advrider.com

furgowv.org

Here are some cool peg board videos:

The Pegboard Shelf Solution

Installing a Pegboard in a Workshop

IT ROCKS.

Yes, I lose a hook every now and then.

but

It helps me stay organized.

It's saves me time.

It's super sturdy.

It has room for expansion.

It holds 90% of the tools I need for any given project.

It may not meet the needs of an automotive or aircraft mechanic, but it's more than enough for a hobbyist like myself.'

IF YOU MAKE ONE PLEASE SEND ME A PHOTO!

More photos at my Flickr Page

or this Photo Set

THANKS TO EVERYONE WHO VOTED, RATED, AND COMMENTED!!!!!!

Brad Justinen (sensoryhouse)

Here is the tool cart via:

Instructables Jan 8, 2009 Newsletter

Make Magazine

dailydiy.com

motherearthnews.com

advrider.com

furgowv.org

Here are some cool peg board videos:

The Pegboard Shelf Solution

Installing a Pegboard in a Workshop