Ply Bathroom Storage (Laser Cut)

by HonorN in Workshop > Laser Cutting

1303 Views, 7 Favorites, 0 Comments

Ply Bathroom Storage (Laser Cut)

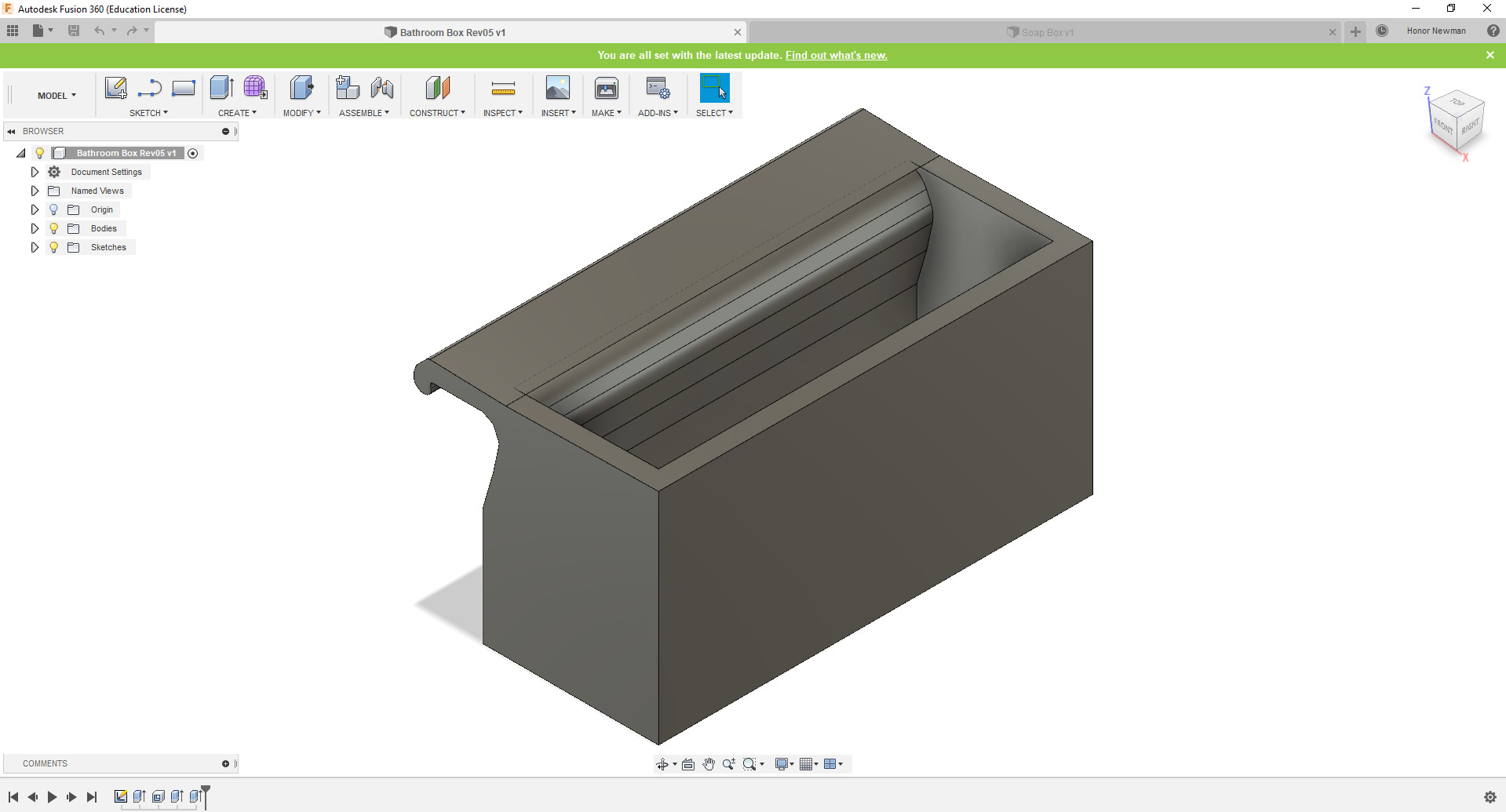

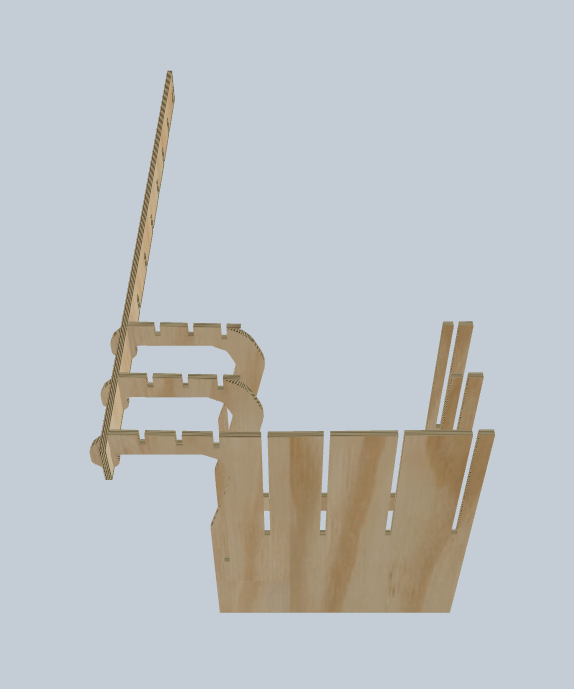

Hanging radiator storage box and soap dish.

I'm currently renting an apartment that is perfect in nearly all ways except for the shoe box of a bathroom. In my experience there is always some sort of compromise when renting. Minus the shower the bathroom is 1 square meter and it goes without saying storage is a huge problem. After months of saying I would get round to making something for the bathroom, I finally did. When my university lecturer set an assignment to use this new software I thought great I can finally design something for the bathroom. I made a ply storage box that hangs on the towel radiator.

"Wait but won't that burn?"

Well probably not since ply has a char temperature of 110° C and my towel radiator has a max temperature of 65° C but for caveat reasons I'm going to say it's best to use with the radiator turned right down/ off to be on the safe side.

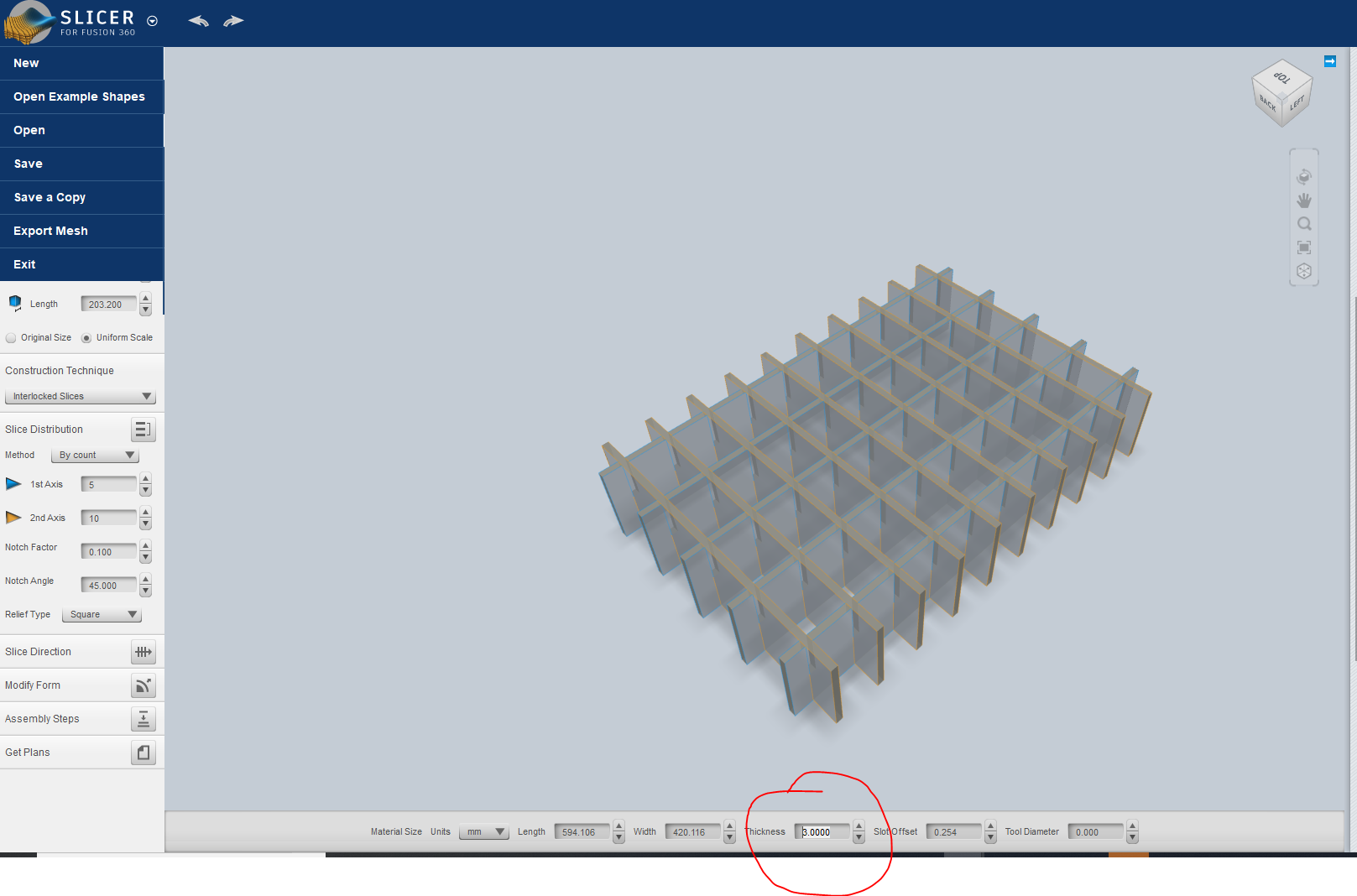

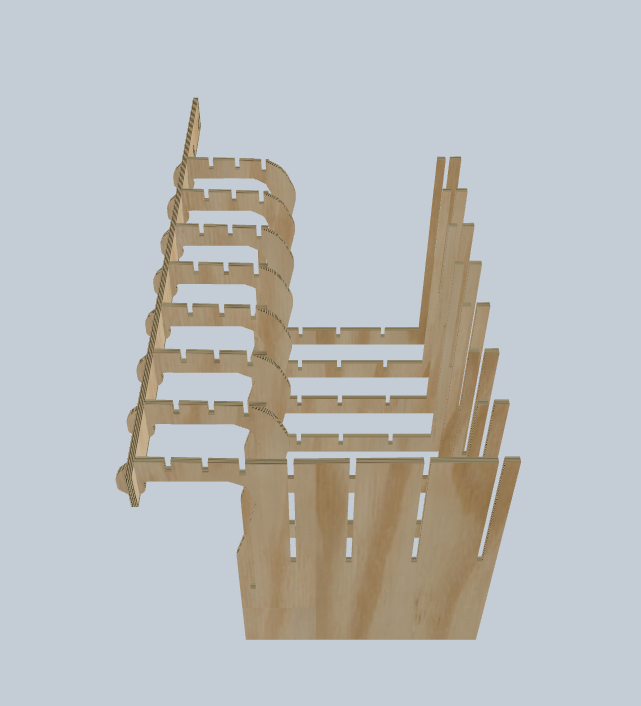

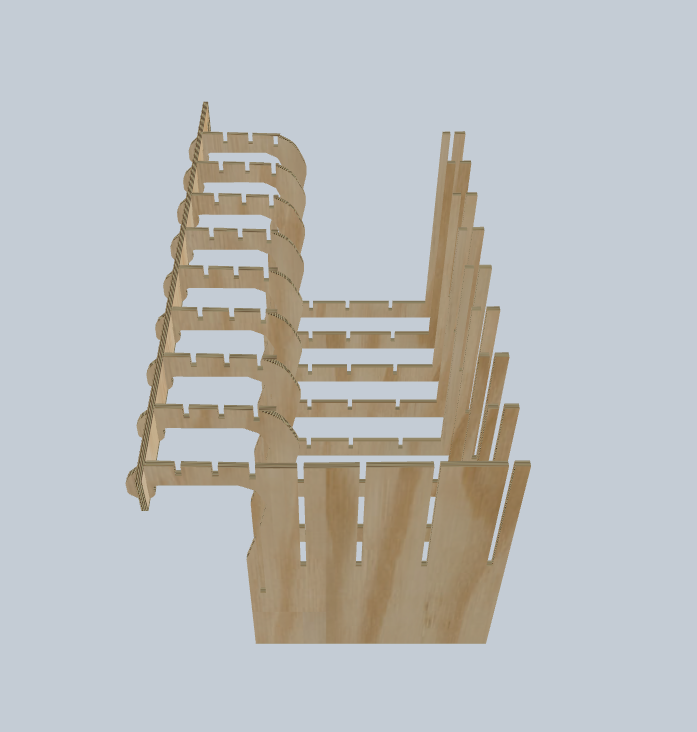

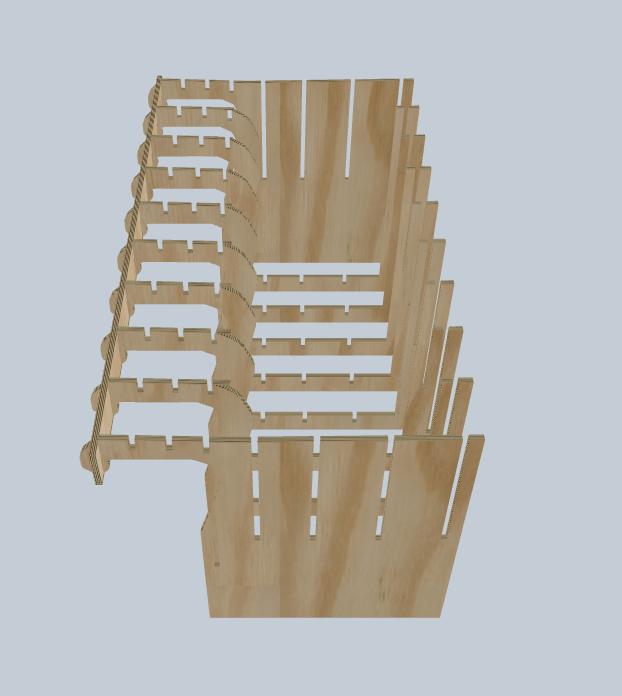

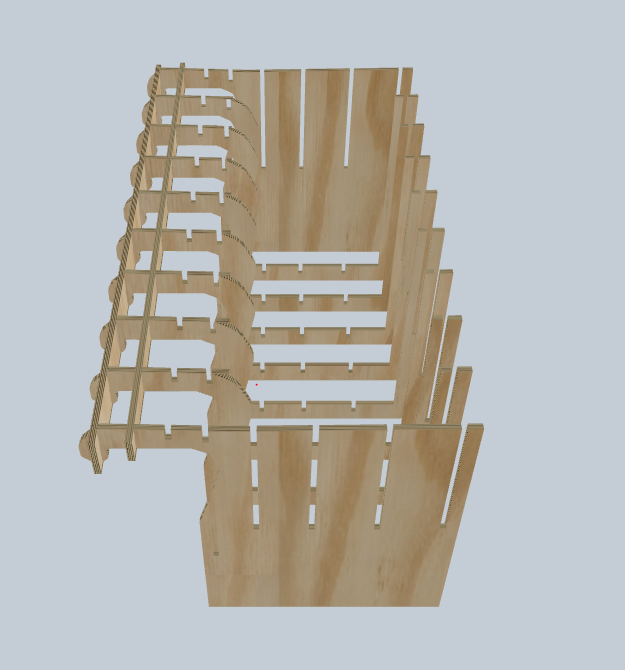

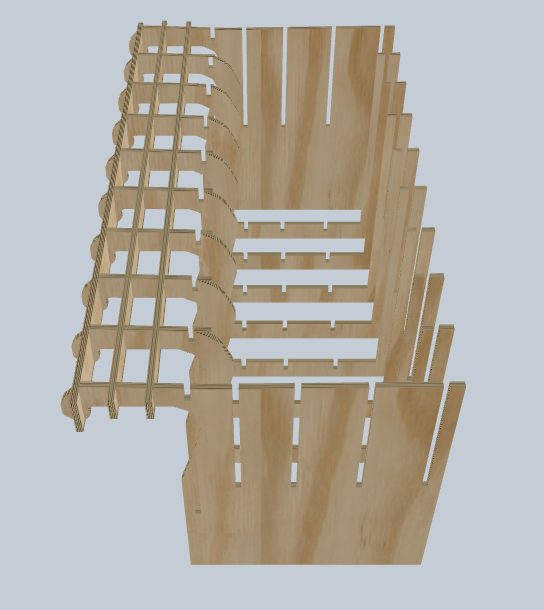

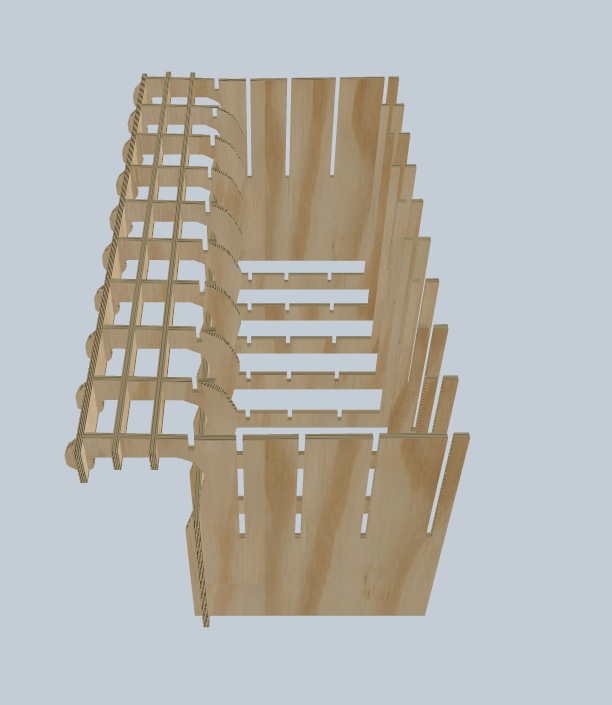

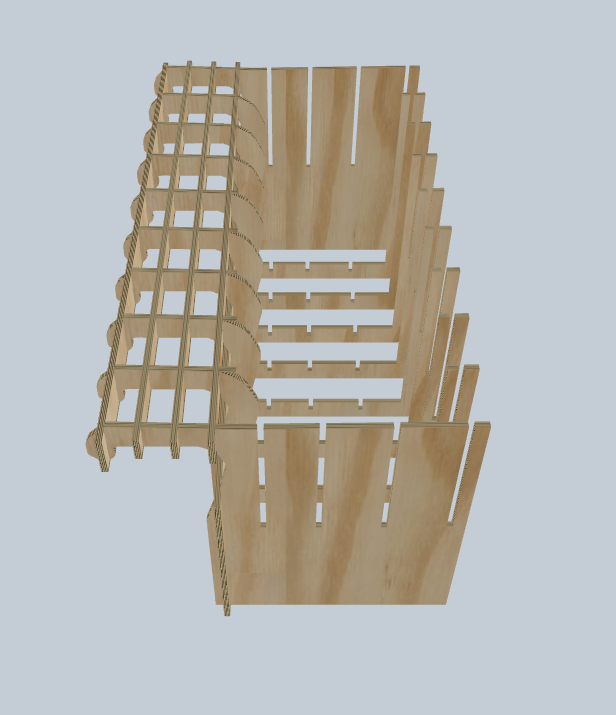

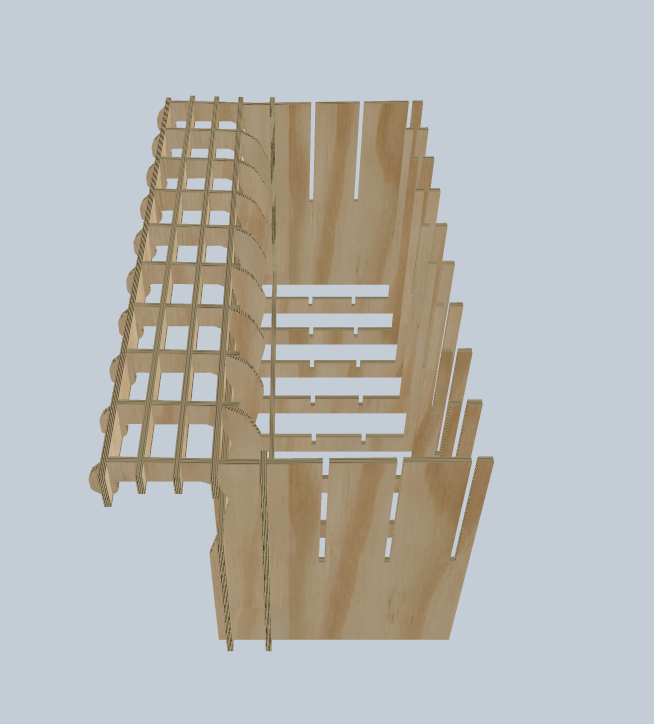

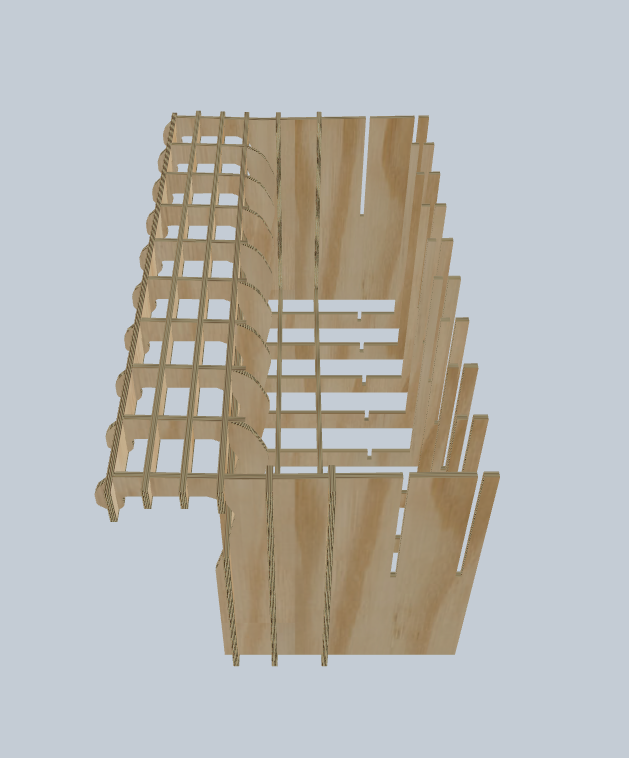

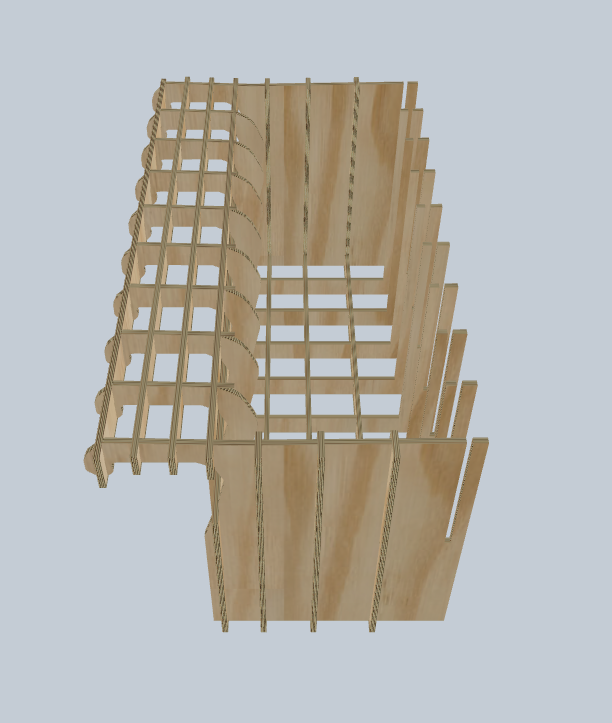

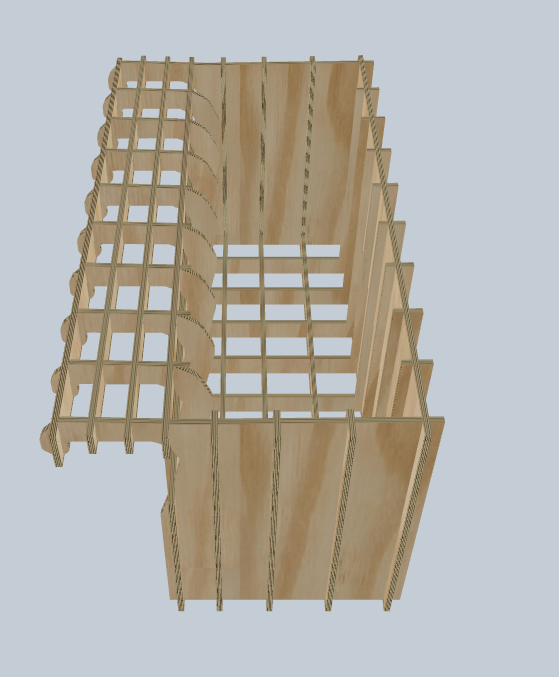

I used a new piece of software Autodesk Fusion 360 with the slicer addin. It is really easy to use if not a little limited. The slicer addin software on the other hand is a dream! it converted my 3D drawing in seconds into a 2D flat pack model which I laser cut in ply then assembled like a jigsaw puzzle.

It was so easy I decided to make a soap dish to go with it. My previous soap dish had no drain holes so water would pool in the dish making the soap mush. However this one keeps the soap well elevated and the sliced structure means it no longer gets soggy.

Materials

2No 400mm x 600mm x 3mm birch ply or similar material and dimensions.

Sand paper (optional but I like to sand the wood for a smooth finish and a splinter free life)

Find a Fab Lab and Laser Cutter

If you don't have access to a laser cutter follow the link below to find your nearest FabLab. They will have a machine you can use.

Download File

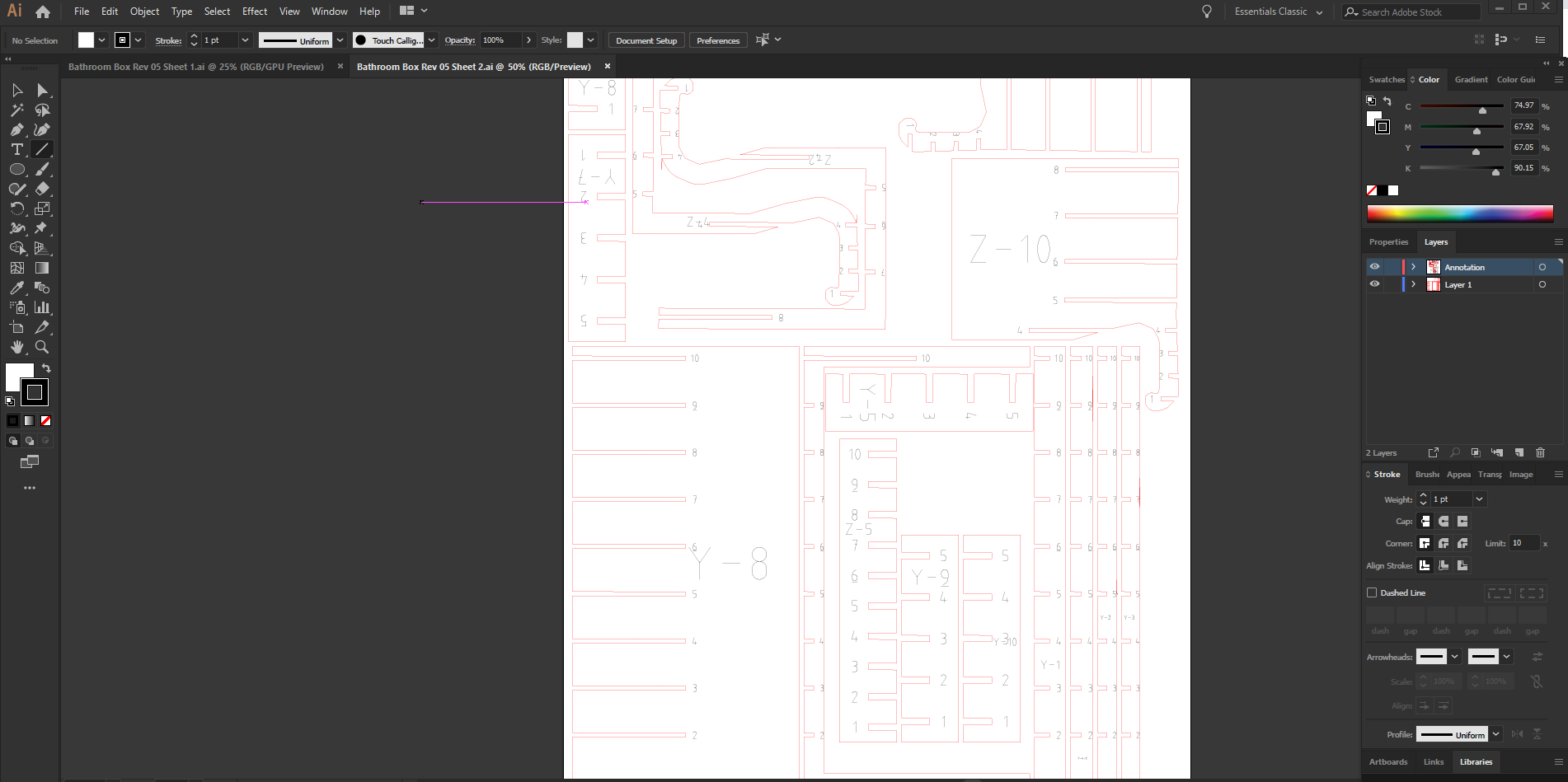

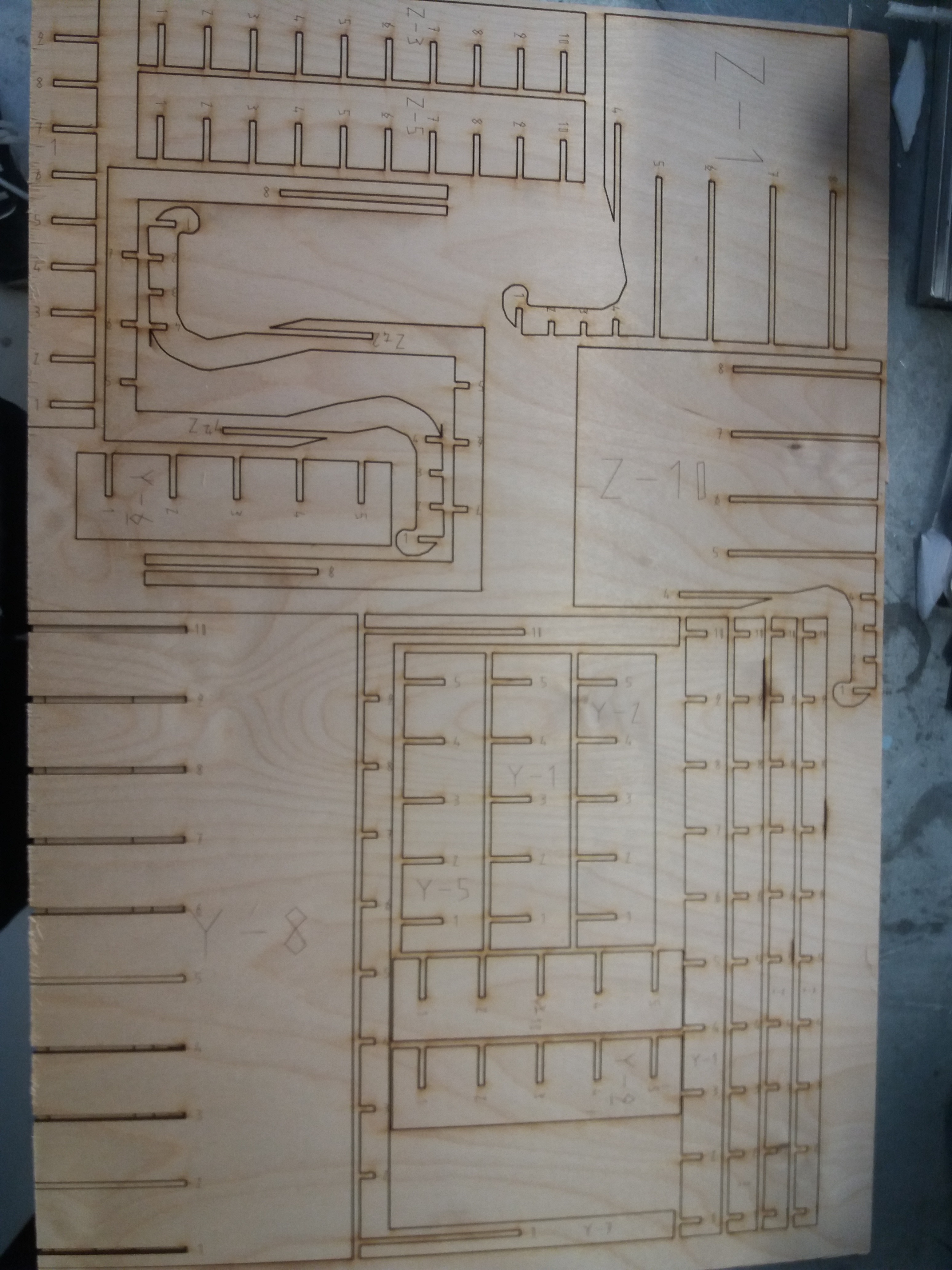

Download the Illustrator files (Bathroom Box Rev 06 Sheet 1 & 2) that includes the sliced hanging box and soap dish. This is already in a format that can be read by most laser cutters.

I have drawn the cut and kiss* lines with properties that are compatible with the laser machine I used. They are as follows:

Cut lines, stroke: 0.01mm, colour : RGB R=255, G=0, B=0.

Kiss Lines, stroke: 0.01mm, colour : RGB R=0, G=0, B=255.

Check with the laser cutter technician what colour and stroke properties are read by the machine you are using and if necessary change them in the illustrator file.

Note this is drawn for a 3mm piece of ply wood. If you want your box and soap dish to be made of a thicker wood then download the slicer files for the soap dish and box and change the thickness as circled in red in the photo.

If you want to make your own changes to the design please feel free to do so. you can access the fusion 360 files on the links below:

Soap dish: https://a360.co/2JscGzQ

*

Set Up the Laser Cutter

Place the ply in the machine.

Change the settings to the right material and thickness. Each machine is different so ask the technician.

Then send the file to the laser cutter normally by pressing print.

(The steps I followed were: check line colour and stroke, send to print, in print settings change the performance levels of the kissing to high and the cutting to high, change the material setting to medium wood birch ply, change the thickness to 3mm, then press go!)

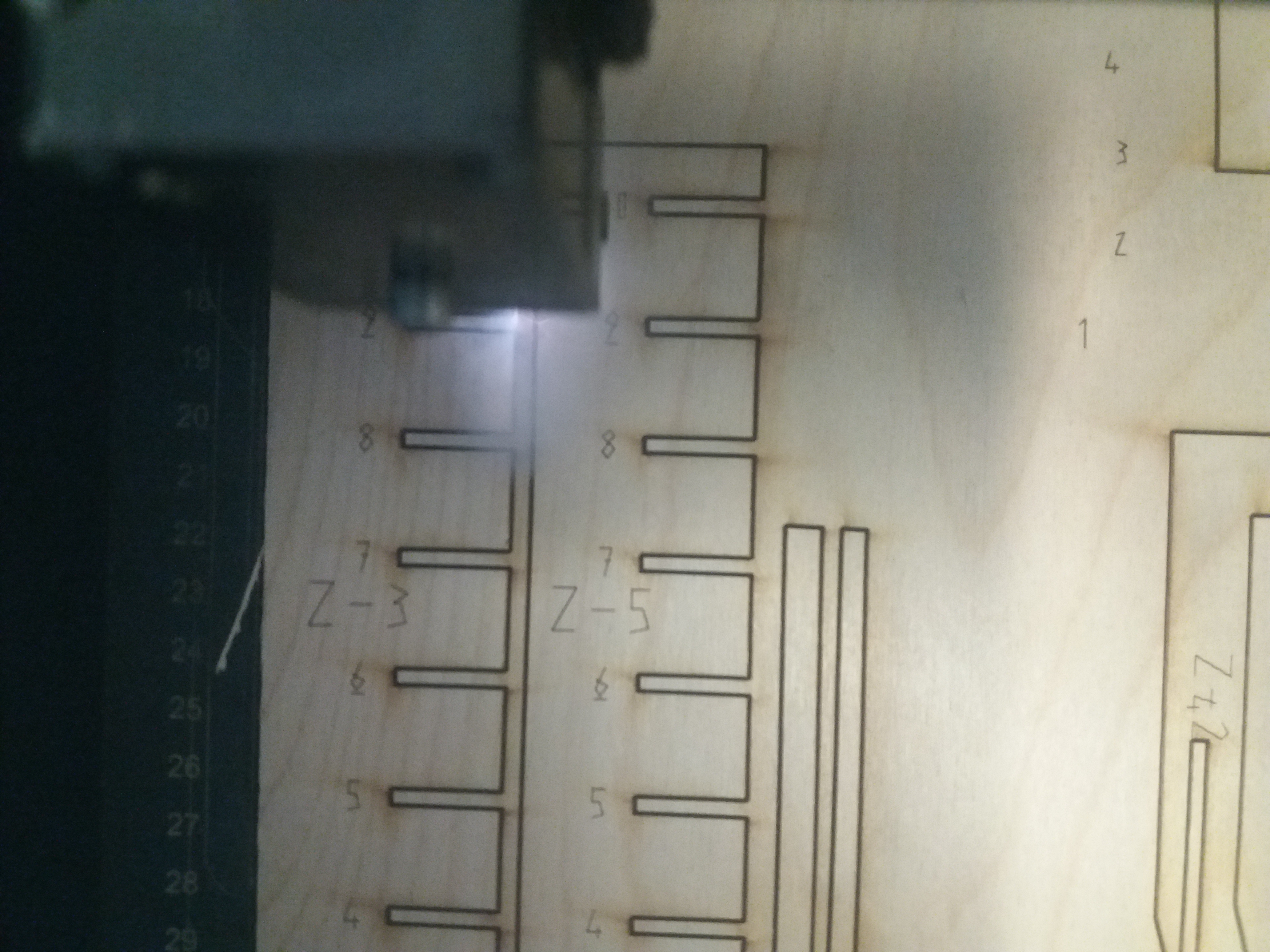

Watch the Magic Happen

Sit back and let the machine do the work.

Once done remove and clear the machine of any wood fragments.

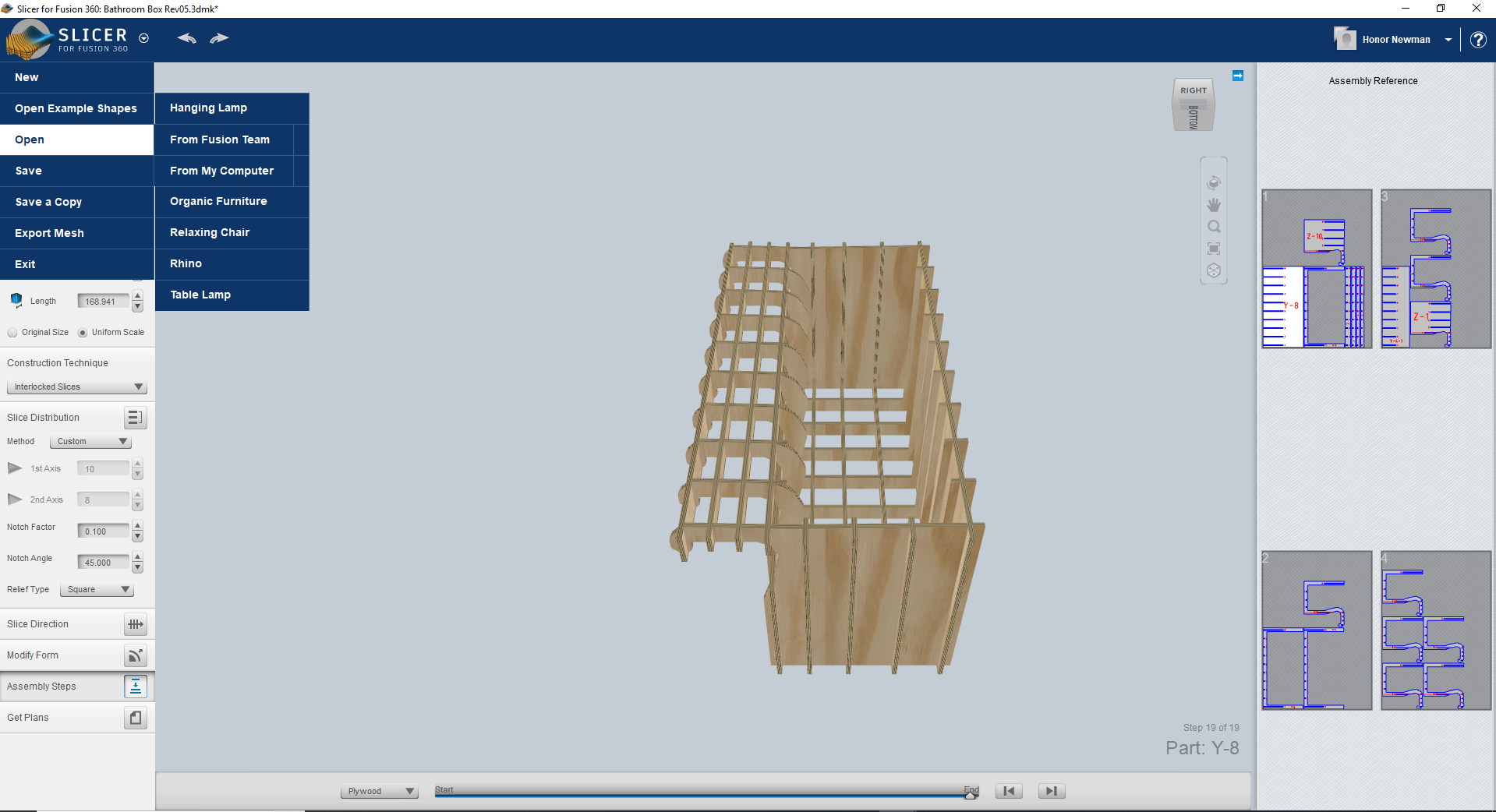

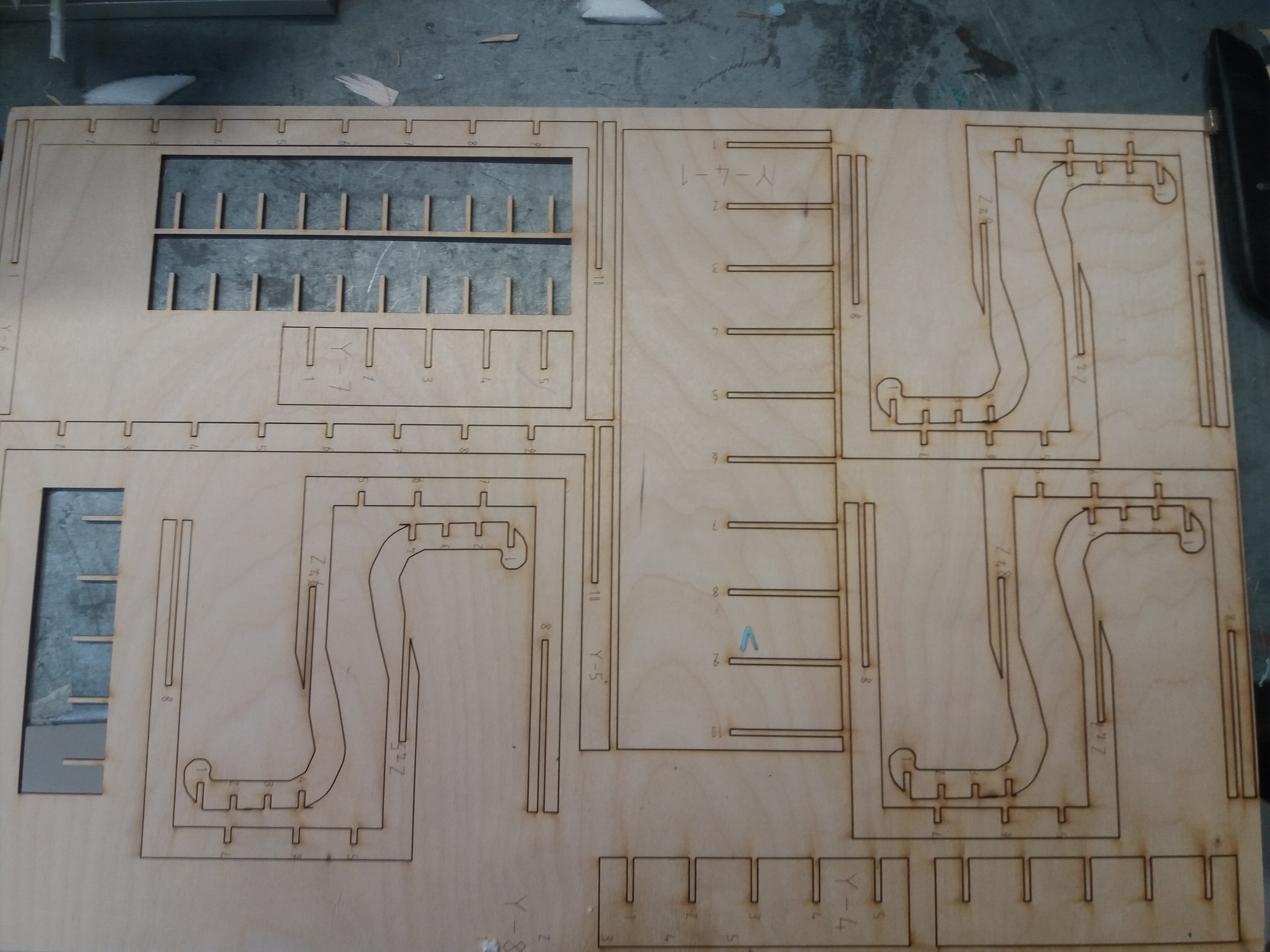

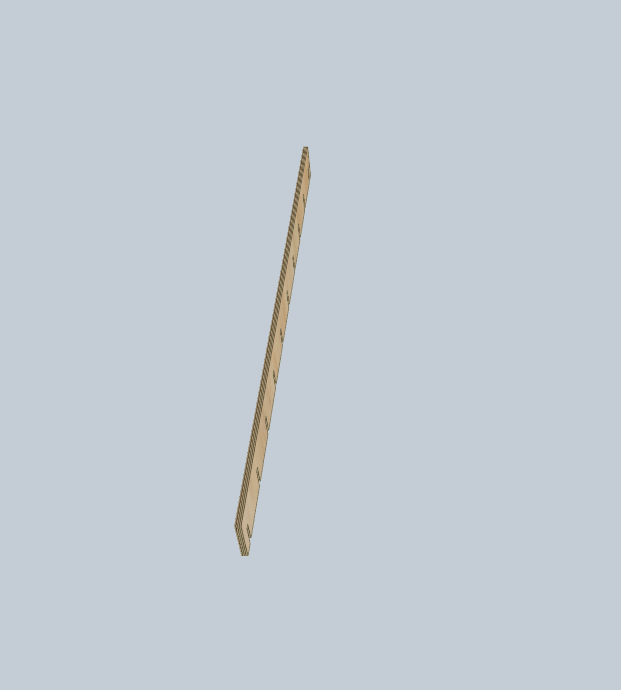

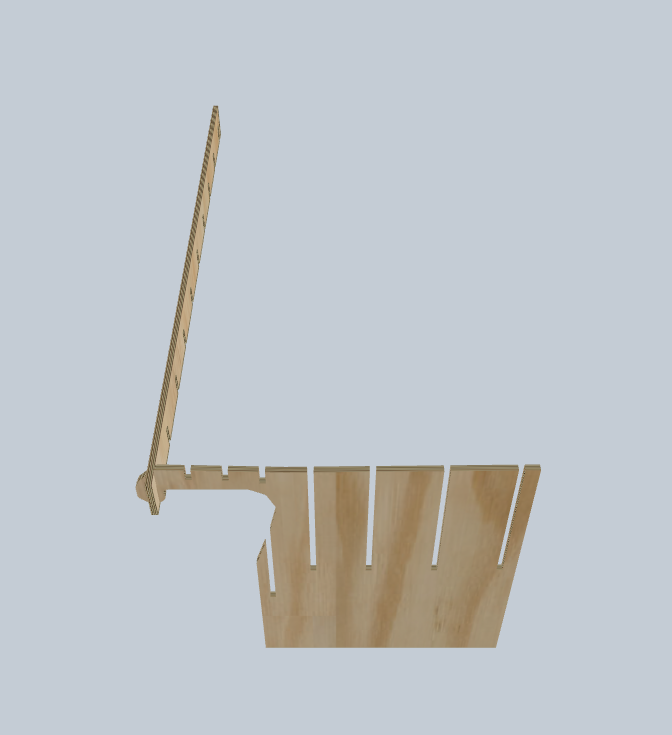

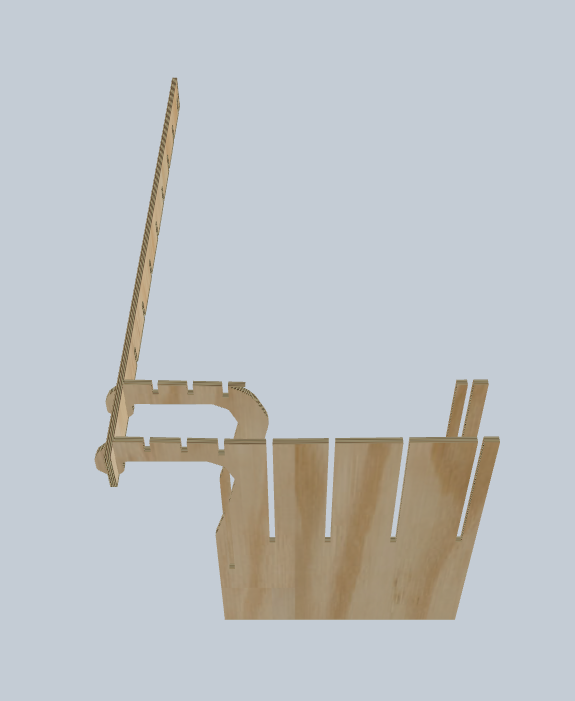

Assemble the Box.

Remove all the parts.

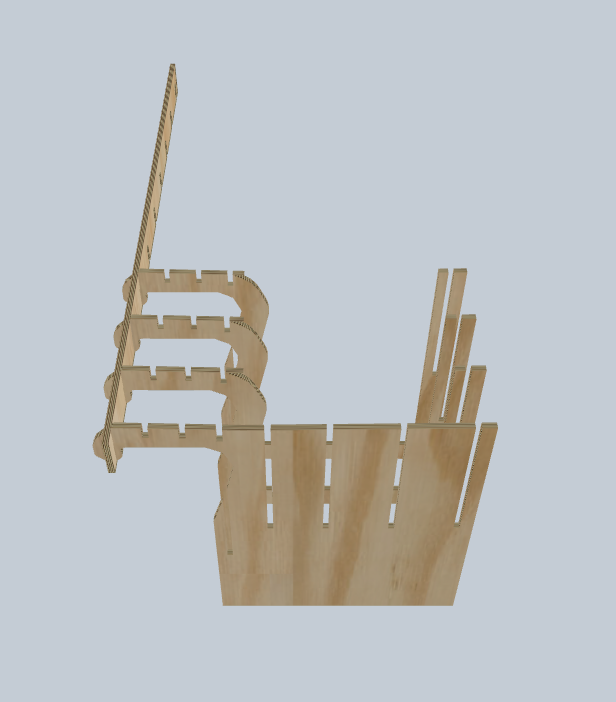

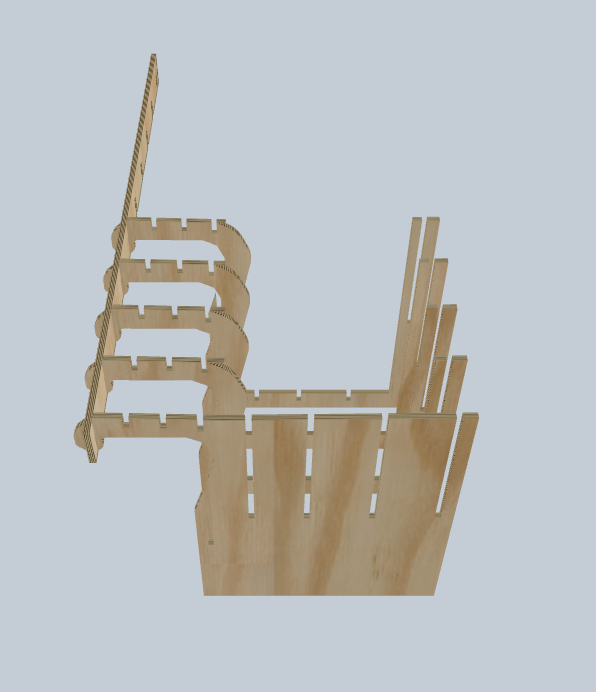

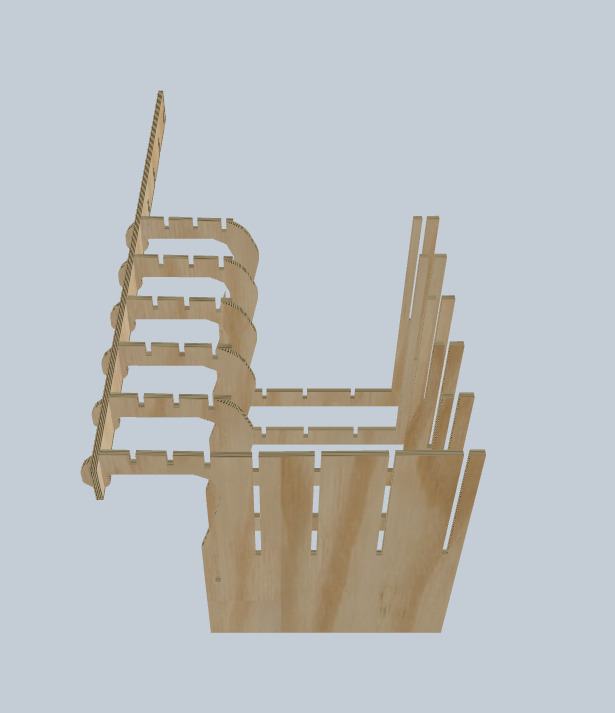

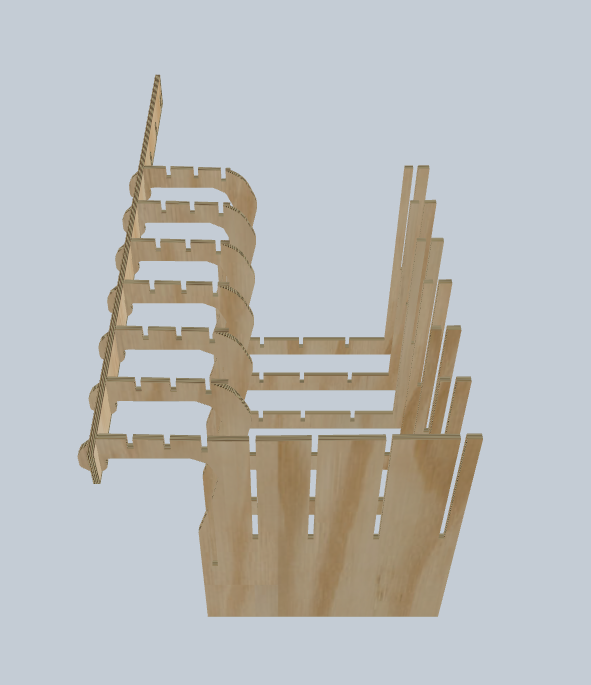

Assemble as in the step by step photos.

or

open the slicer document and follow the step by step video.

Finishes

Sand any rough patches.

Enjoy!