Basic Transformer Case

by girlsinthehall in Workshop > Laser Cutting

1719 Views, 15 Favorites, 0 Comments

Basic Transformer Case

This instructable gives you the directions for building a basic bare bones case that can then be modified to be perfect for any particular need that you have. It can be a jewelry case, a tool box, a first aid kit or a cosmetic case, by making small changes to this basic case. It can even be used for entertaining.

Follow me for more instructables that will guide you through modifications that will make it perfect for different specialized uses.

Materials for the Basic Transformer Case

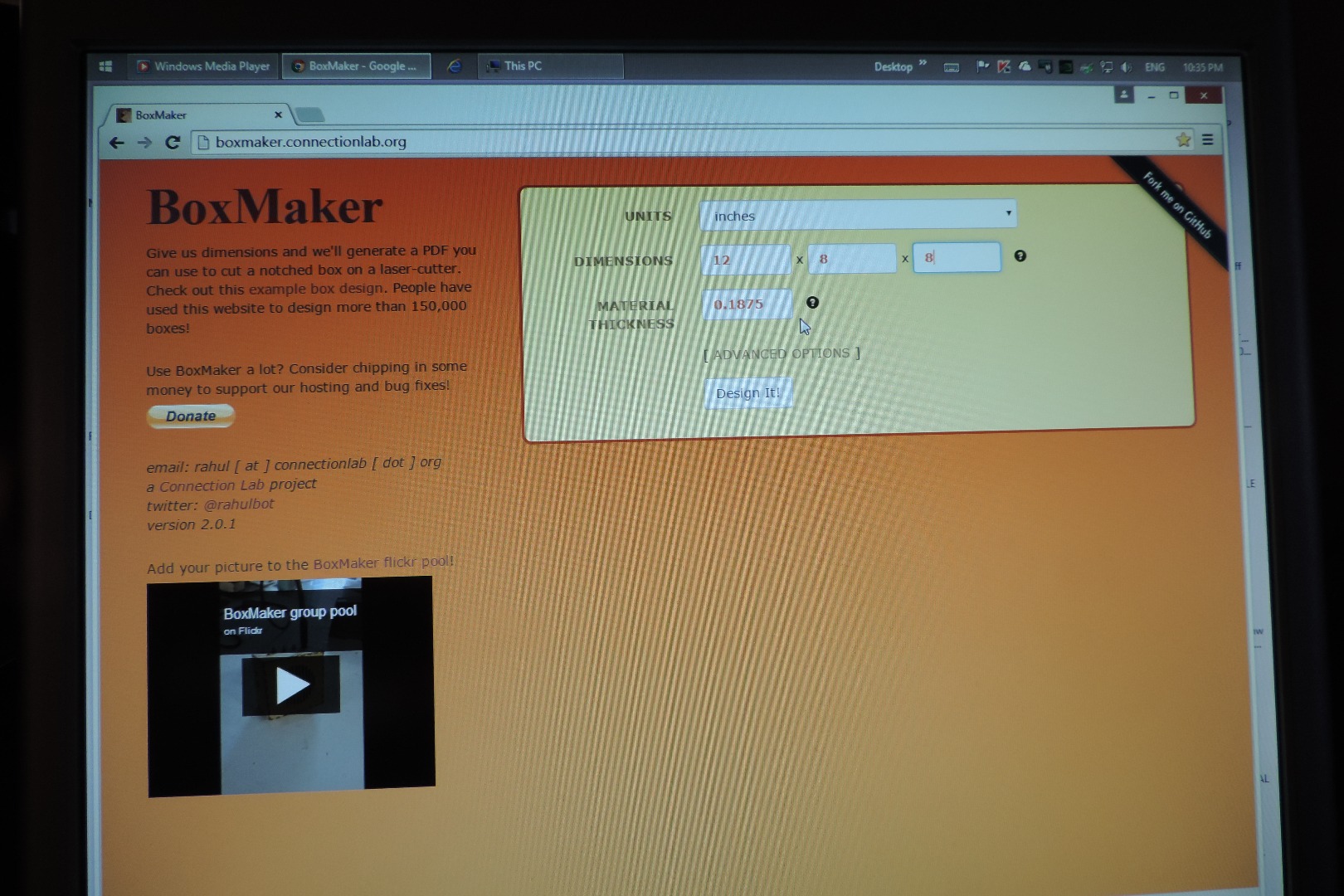

This case is easy to construct using the very user friendly Boxmaker.connectionlab.org. The dimensions of the case are input into the chart on the screen and the design is instantly forwarded to you. The dimensions used here are 11"x7"x7". You can input dimensions that suit your purposes. You might like to construct the first one and then look at how you can modify the basic case to serve certain needs. You might even consider making your first case out of cardboard to see how you might like to change the results in wood.

This box was constructed on an Epilog 60 watt Laser Cutter with a 20x32 inch bed.. The plywood is .188 cm and the glue used was E6000 and wood glue.

Requirements:

- CNC Laser Cutter with software, the one used here is an Epilog with a 20x32 inch bed

- Internet access to obtain boxmaker.connectionlab.org

- Cardboard from an appliance or bike shop

- Plywood .1888 cut into 20x30 inch pieces.

- A glue mat or some work surface that can tolerate some glue residue

- Glue sufficient for the weight the unit will be expected to carry

- Wood clamps sufficient to span the largest dimension of the case

- Masking tape, bands of elastic or other substitutes for clamps

- Skewers and cosmetic applicators

- A damp cloth

- Heavy weights if available

- Ruler, pencil and calipers

- Flash drive if the Boxmaker file needs to be transferred to a different computer

The Software Side of the Laser Cutter

Start by accessing boxmaker.connectionlab.org.

The dimensions shown here are W 11 inches, D 7 inches and H 7 inches. There are a few box making sites available and they may be better or worse than this one, but I have found boxmaker.connectionlab.org to be more than adequate for my needs. . For this project, .188 plywood is sufficient and happens to be the default setting on this site.

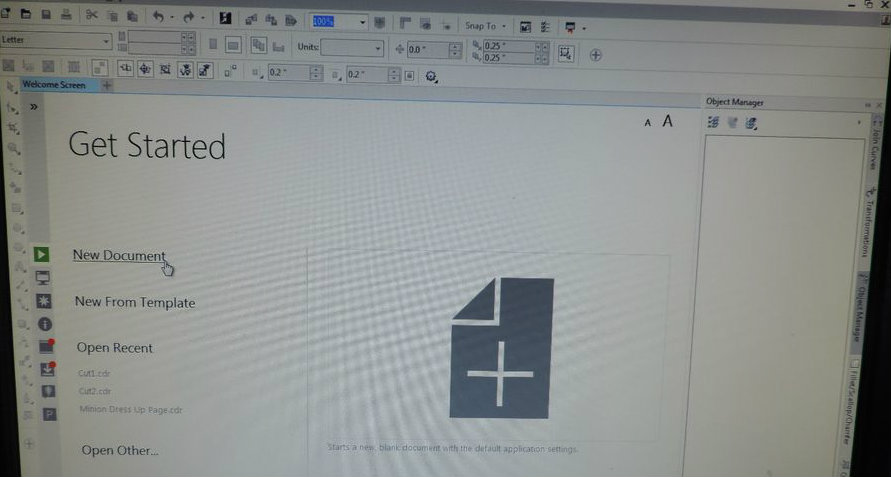

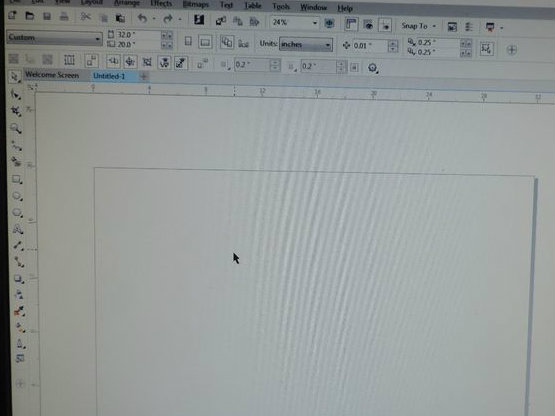

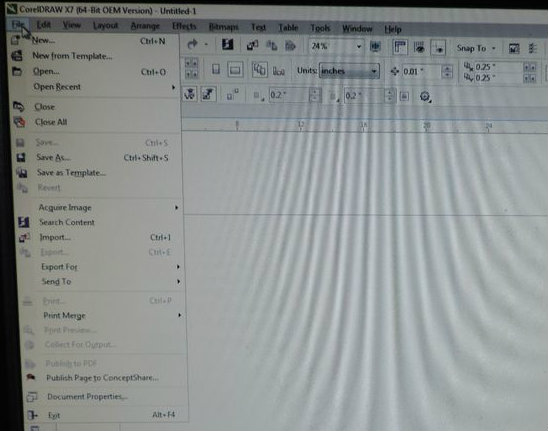

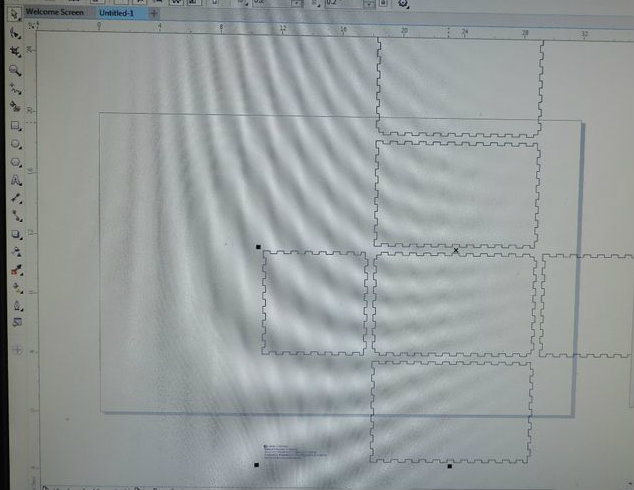

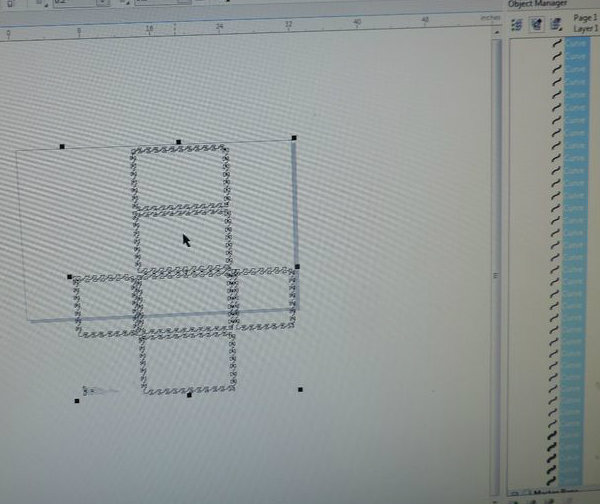

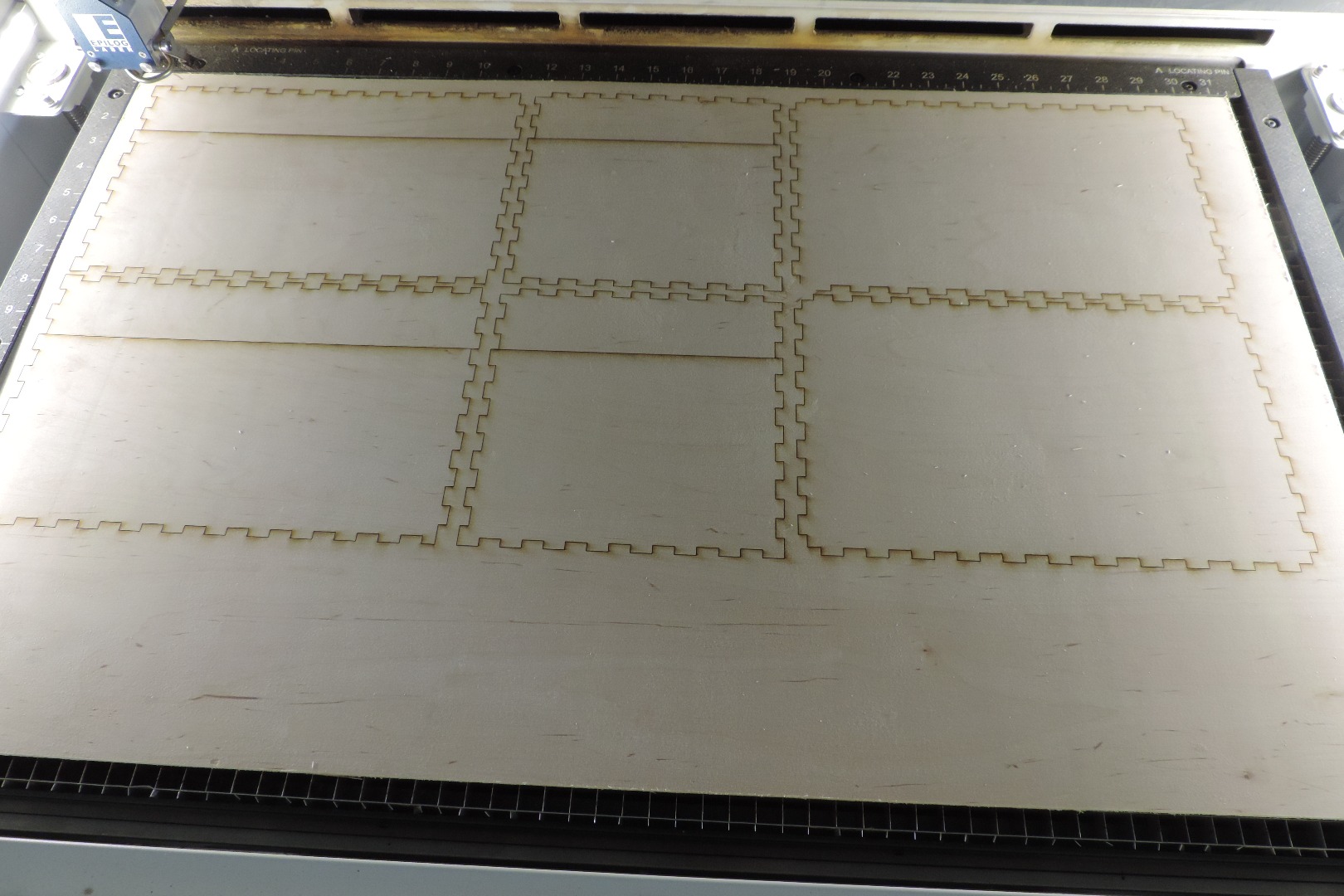

YuKonstruct (my local makerspace) has a laser cutter set up with Corel Draw x7. Once the Corel Draw is on the screen and a new document is shown on the workspace, go to file and click on import. Indicate that the source of your file. If the file is on your flash drive then you indicate that and click on import.

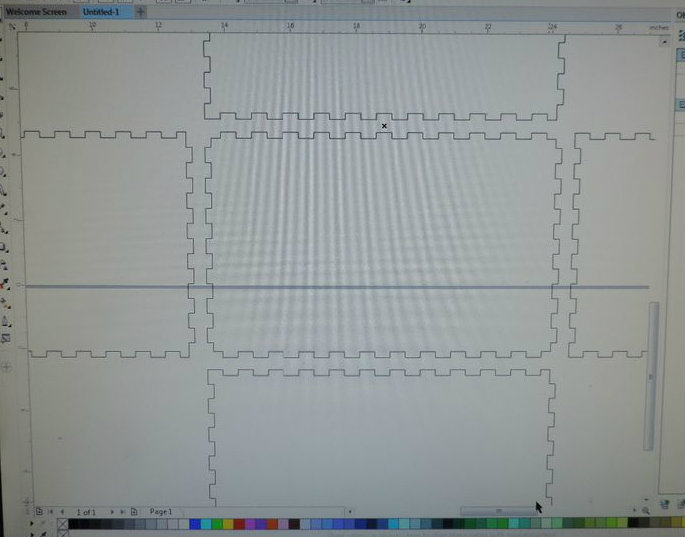

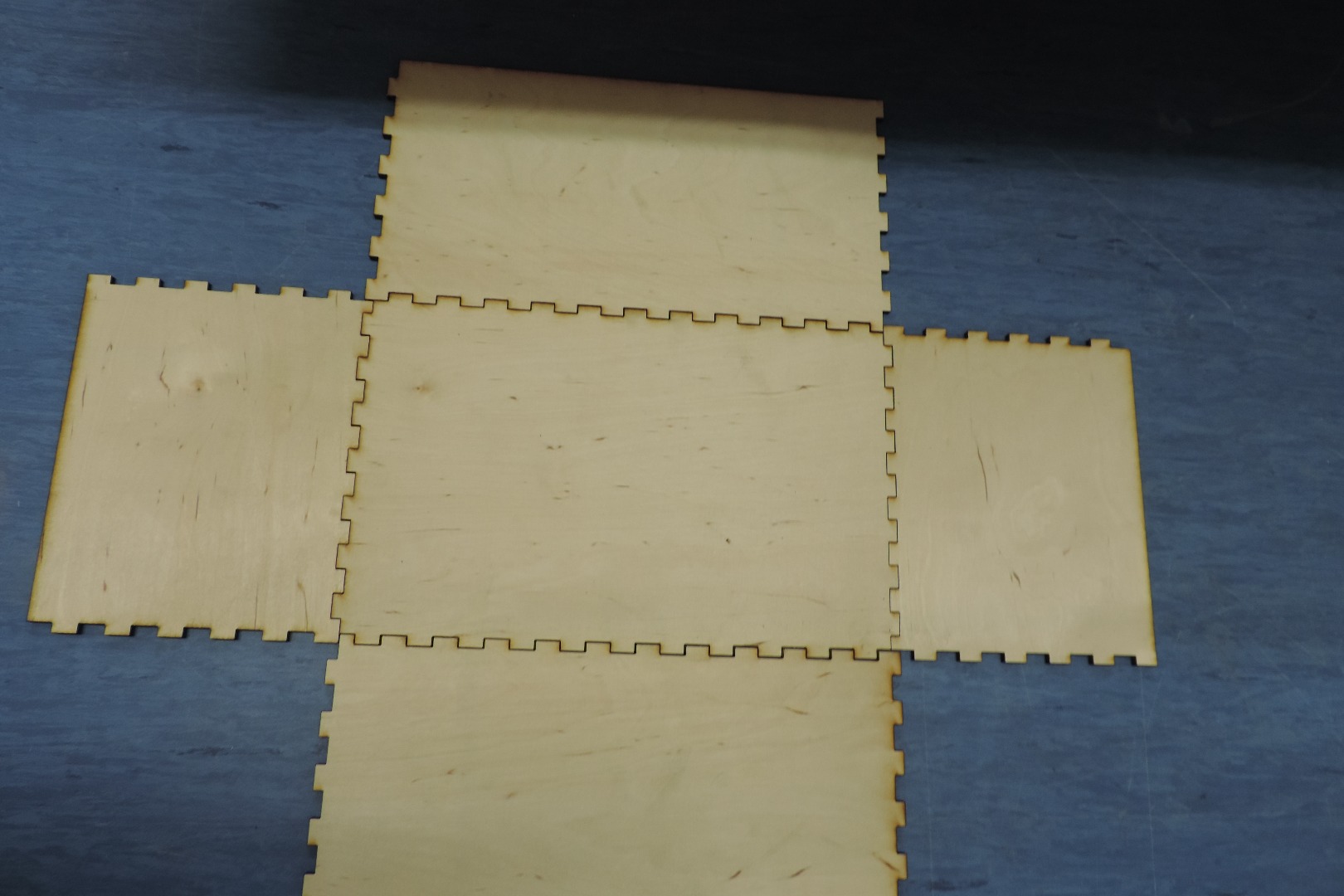

Identify each of the pieces of the case. The layout shows you by the position of each piece, just what part of the case each piece is. It is important that you keep each of these elements straight as to their placement in the case. For instance the element in the centre of the pieces will be the bottom and the element to the right and left, the sides, and those above and below, the bottom the front and back sides. The uppermost element is the top. Until you get used to the program, you might find it helpful to printout the layout and write the position names on the pieces as well as indicating which is the top of the piece. It might also help you to layout the pieces on the page to maximize your materials.

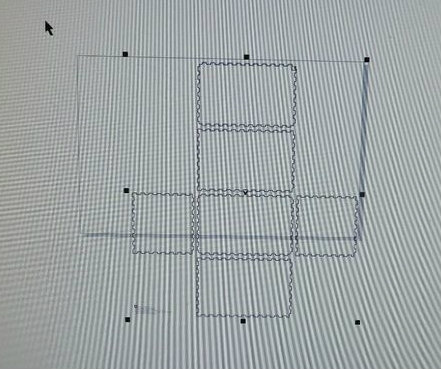

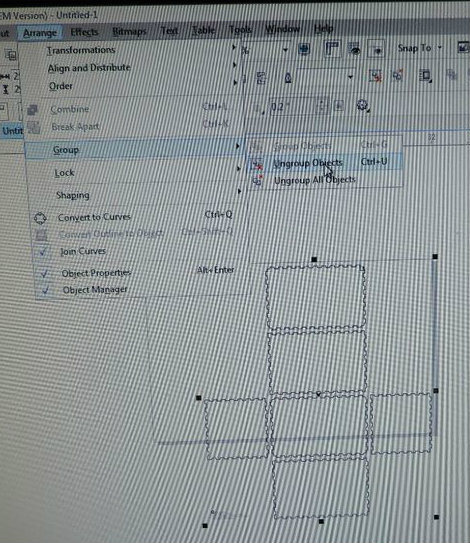

In Corel Draw, select all elements and ungroup. When they are ungrouped you can move each element around on the screen.

It is easier to work with the file when you zoom in and have it in the larger view.

Modifying the Case Parts

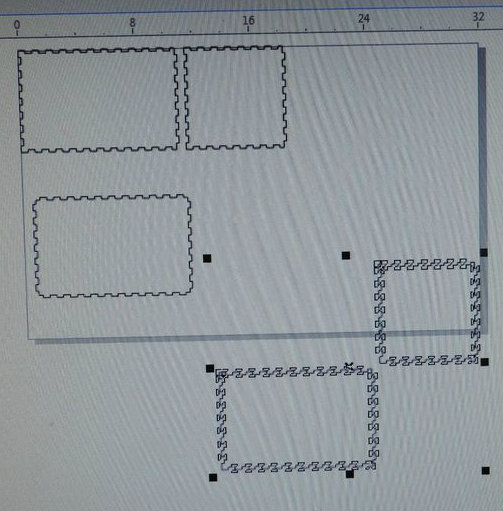

Start modifying the elements by separating them and placing them in certain places of the screen. Since the bottom and top elements are not going to be modified, move the element that is the top of the case to somewhere below the lowest element on the screen and delete the bottom element which was in the centre.

Next select the element that is now the highest on the screen which is the long side and move it to the top left hand corner of the workspace. Then select the lowest element on the screen which is the second long side and delete it. Leave the remaining two sides where they are. Take care to remember each of the parts.

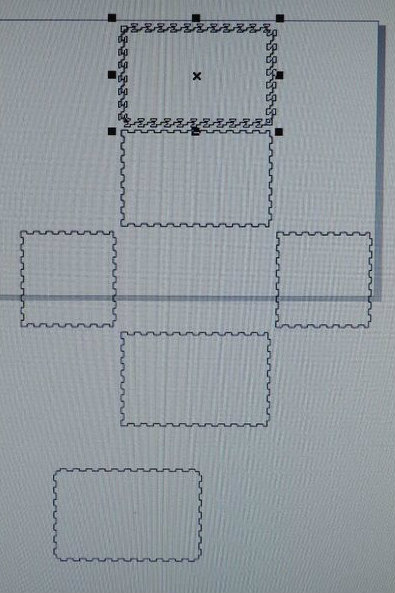

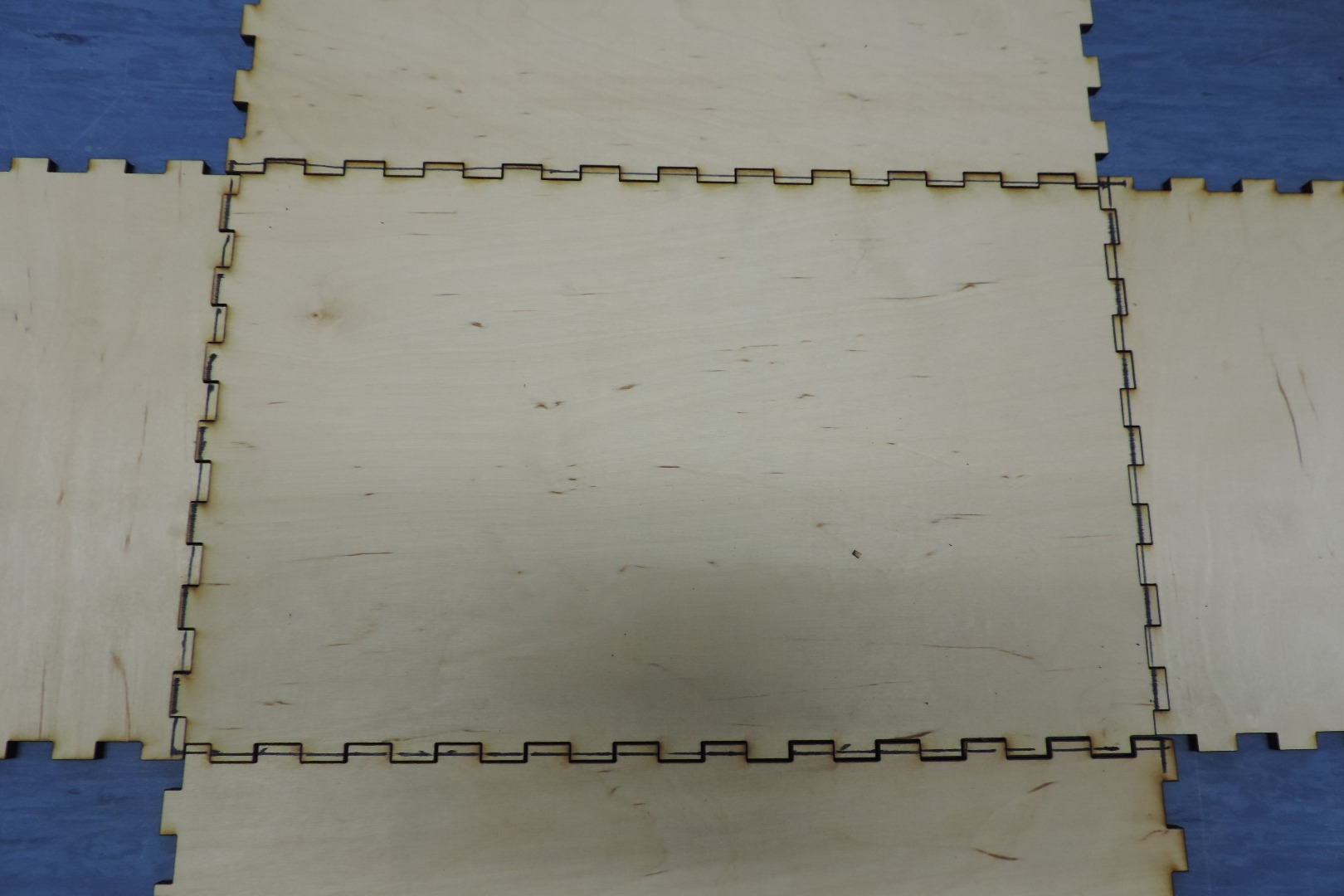

At this point you must determine the depth of the lid and the base of the case You can do this by measurement such as the lid is 2 inches deep or, preferably, you will go to the top of a finger closest to the desired depth of the lid. That is the system shown here. Select the side that is in the top left hand corner, that will be the long side, 11x7 inches. The top of the this side is at the top of the screen.

You will need to established a two point line across the piece at a point that would give you the lid depth that you want and the base of the case depth that you want. In select mode (the arrow cursor) draw a rectangle around the piece that is the long side. Click on the 2 point line and then click on the horizontal line on the left side of the piece at the top of the finger that will give you the dimensions of lid and base that you want. Drag your cursor across to the opposite side and when you reach the horizontal line at the top of the opposite finger, click connecting the line. Now check to see that the line thickness for that line is set to hairline. This is important.

Check that the cursor is again at the select tool and go to the left hand element of the remaining two elements from the original file. Select the LEFT element and delete it. Then select the right hand element. In its existing orientation, the side of the side element is actually the top of the side. Carefully rotate the side element so that the initial right hand side of the right hand element is uppermost. This is very important and why it is a good idea to use the print out as a guide and cardboard for a prototype. We will discuss cardboard prototypes later.

Determine the intersection of the finger on the side of this element that matches that of the first side and draw the line as before. It helps to place this side adjacent to the first side. That can help you to ensure that the new cut line will be at the same height as the first.

Once you have drawn these two cut lines, check to see that your cursor is again in select mode and select the first of the modified elements, the long side. Click on copy as shown in the photo and then below the selected element, click on paste. Then go back to the original of the copied element and drag the second copy down below the first. Do the same for the second element. You now have 4 SIDES on the screen. Go to the element at the bottom of the screen (this is the bottom/top) and copy, paste, drag so that you have two of this element as well.

Arrange the elements on the workspace that will best accommodate the piece of cardboard/wood in the Laser Cutter. These dimensions were chosen to show how to layout the pieces to maximize the wood. With these dimensions there will be a margin of about 6 inches left at the bottom. That wood will be used for interior supports for the lid.

Turn on the extractor system and the laser cutter.

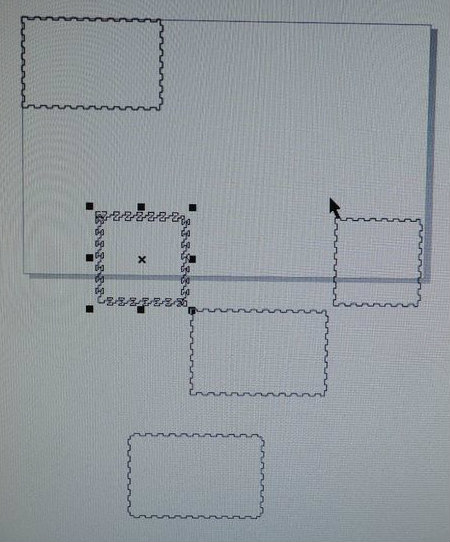

Ensure that all lines including the new lines are set at Hairline and that the placement of the elements is well within the dimensions of the cutter bed. You can save yourself some wood and frustration if you run your project through the laser cutter using cardboard. This way if you mistake a side for a bottom and put the cut line in the wrong place you won’t have to add your miscut to the scrap heap. Do not change the dimension of your final choice of material on the Boxmaker file if you do use cardboard but do remember to use the setting for cardboard when you set up the print commands.

Click on the printer icon. A page will come up that will give you any warnings that are needed, such as the file exceeds the cutter bed size etc. Assuming that there are no problems click on Preferences. This is essential as this is where you will input the commands regarding speed, power and frequency etc. As at this point you are only cutting and there is no engraving so you change the setting from combined to Vector only. If you are using cardboard (recommended) to print a trial run then consult the chart for the settings for cardboard. Insert these and the thickness of the cardboard. If you are very confident and are going straight to the wood ignore the cardboard speeds etc and input those for the wood you specified in boxmaker. When all of the commands are in place, click on Ok and when the next page comes up click on Assign and Ok. At this point the cutting instructions are sent to the laser cutter and on our equipment, a Job number will be shown along with the required time.

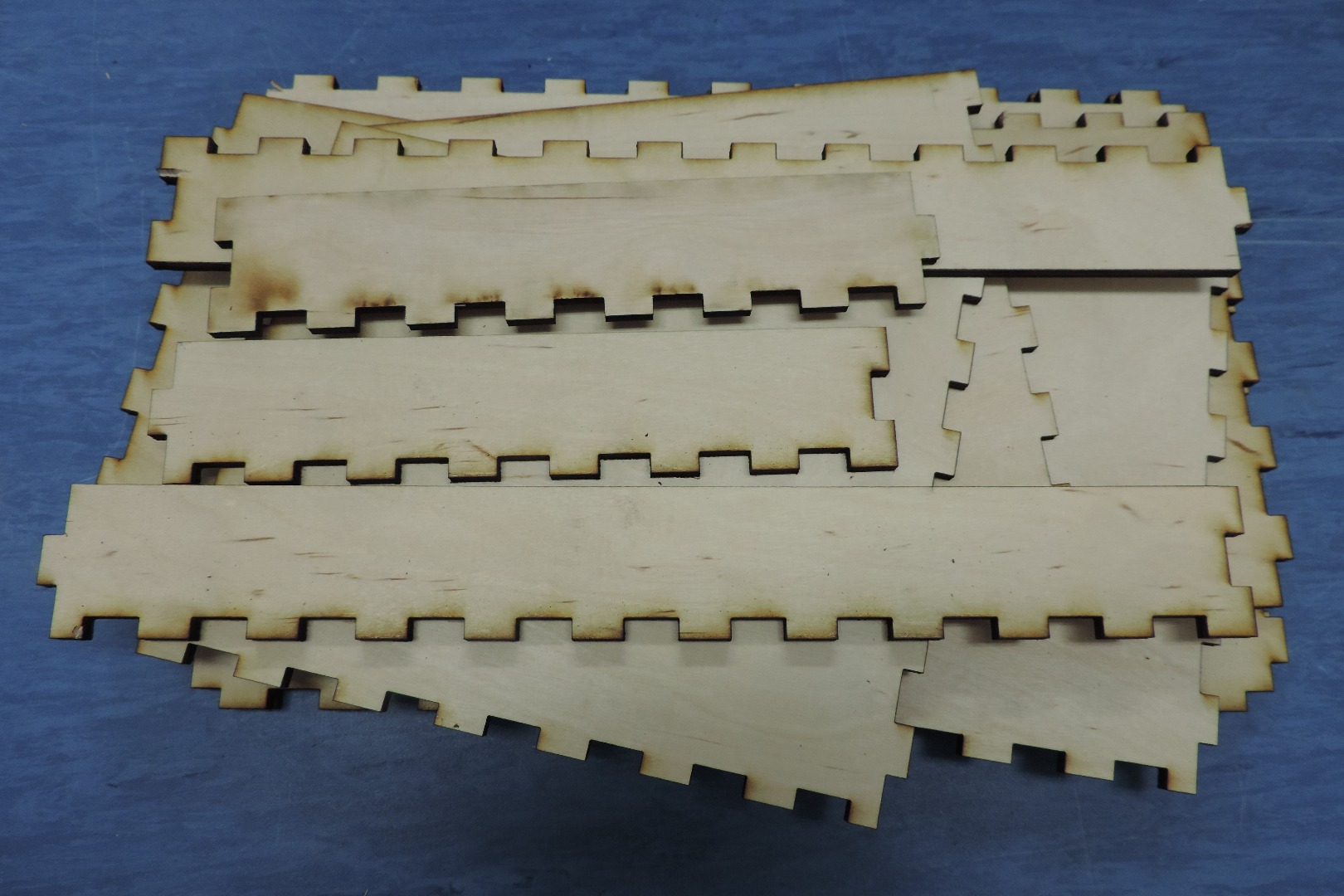

Cutting the Case

After you have sent the information to the Laser Cutter then you need to press GO on the cutter dashboard. When everything is cut out, put the remaining piece of wood or cardboard aside for other pieces of the case. I remain close to the cutter as it moves in its precise but peculiar manner until it is finished for safety sake.

Remove the finished pieces and move to a surface large enough to lay out the base with its sides. Now you are ready to assemble. Whether you are using the cardboard or the wood, put the elements together without glue to ensure that you put the cut lines where they were supposed to be. If all is great, proceed to do the same for the lid. If you are working with the wood cut outs and all is well then proceed to the gluing stage or if you used cardboard and all is fine, proceed through the steps for the wood pieces and proceed with the gluing. Keep the cardboard pieces if you think you might like to build another case. The cardboard model can assist you in designing your modifications. You might want to consider the ultimate use of your basic case in your choice of glue.

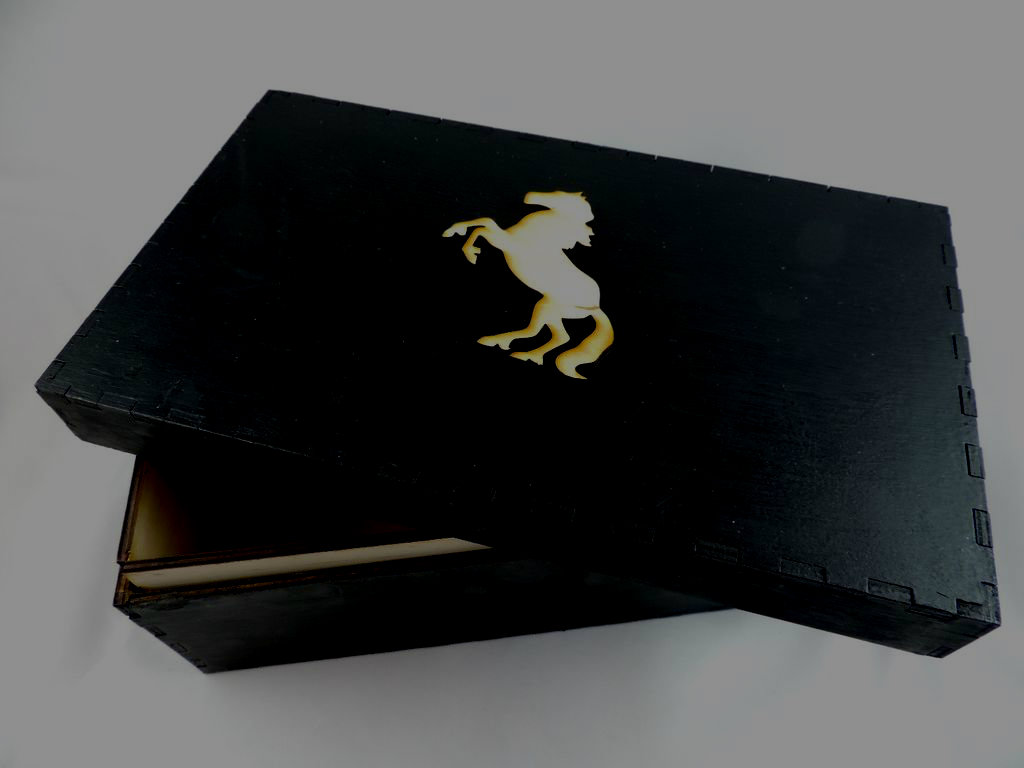

Note: If you want to decorate the box with engravings, the time to do that is after the cutting has been done but before the gluing stage. It is easier to do the cutting only and then setting up the engraving than trying to do both things at the same time. You can engrave the top and sides of the lid, and all around the the sides of the base. So you do the Vectoring only and then the Rastering only.

Gluing

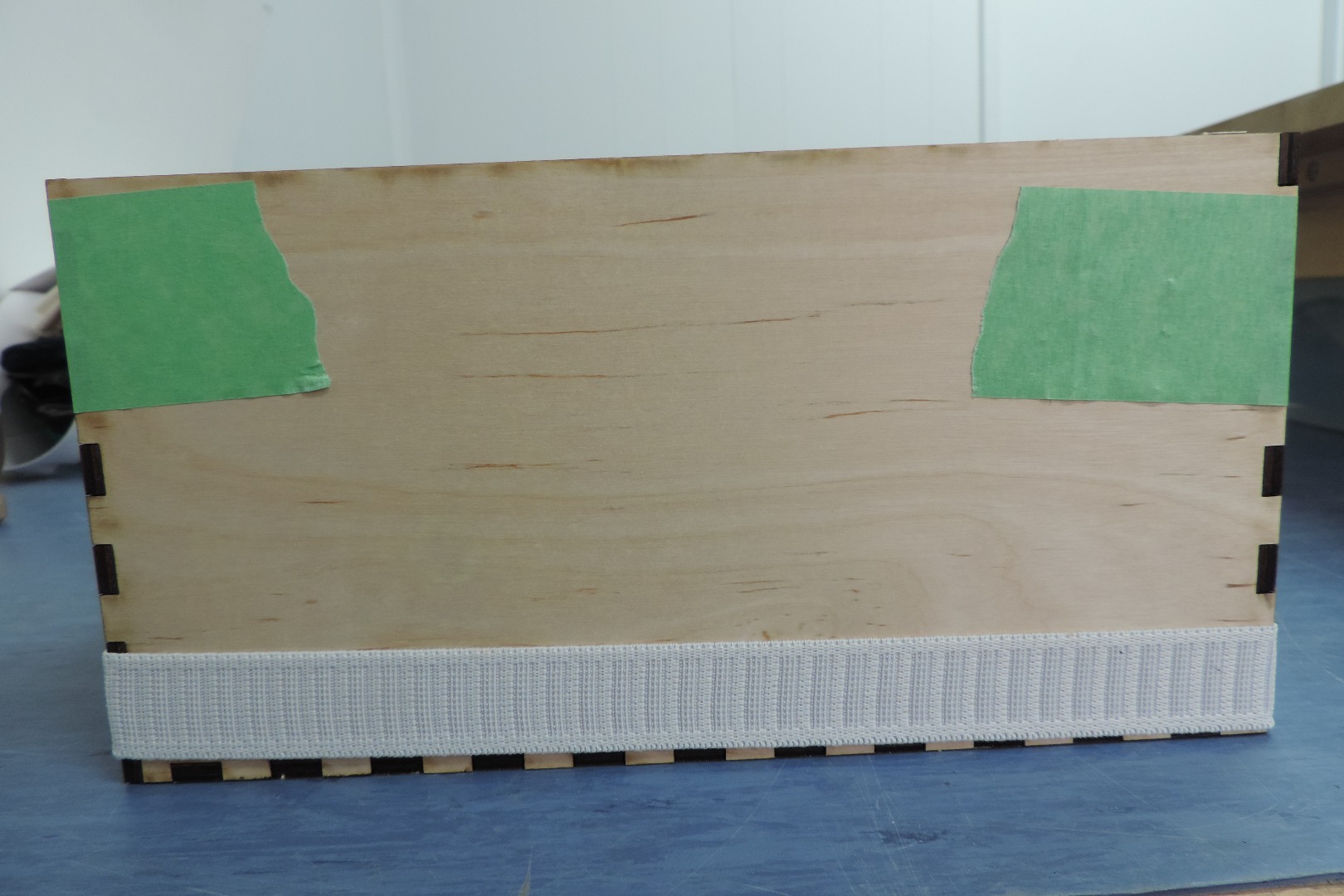

.JPG)

Sort the pieces of the base from the pieces of the lid and set the lid aside. Lay the bottom of the base in the middle of the work area. Locate the two long sides and lay them on each side of the bottom of the base with the fingers set inside of their matching slots. Do the same with the short sides. Lift all four sides and ensure that everything fits. Since everything should be fine, lay the sides down again with the fingers in the slots and run a line of glue around as should by black marker. This ensures that all areas have glue but if you run the glue line sparingly you will cut down on your clean up.

Again lift the sides into place one side at a time. After you have the first two adjacent sides in place, apply tape to the corner pulling firmly as you apply it to the two pieces. Continue raising the sides until all are in place and taped. At this point if you have clamps put them in place now but failing the availability of clamps, use any material that will keep the pieces tightly together. You can even use domestic elastic found in the sewing section. Run the elastic around the bottom edge pulling firmly and secure. Repeat this process for the lid.

If some glue has leaked out of the slots inside the box, take cotton applicators or a skewer with a damp cloth wound on its tip and work along the inside join. Inspect the outside areas and use a damp cloth to remove any excess glue. Allow the glue time to set. Check the label on your glue for curing times.

Because this is a basic transformer case, it will be finished without hinges or clasps because the modifications will call for the location and type of hardware to be suitable to the new design use. For this case it has a simple lip to secure the lid in place. This edge is made by cutting two pieces of .188 plywood the length of the inner dimension of the case. Then cut a piece the width of the inside of the case less 2 x .188 or 370 rounding the size to give the insert some ease. The depth of the piece will be the height of the inner wall of the case plus at least 1/4 inch. Here I have a 1/2 inch edge. Glue these pieces to the inside walls of the case. Lower the lid onto the base ensuring that everything is a good fit. Proceed to paint or stain the case.

Finishing

Paint the case and decorate as you wish. The example was painted with flat black Alkyd. The horse was cut on an Epilog laser cutter.