An Easy Way to Create Professional Looking Labeled Project Panels

by abizar in Circuits > Electronics

34363 Views, 102 Favorites, 0 Comments

An Easy Way to Create Professional Looking Labeled Project Panels

Many of my homemade electronics projects have hand lettered labels. For a variable power supply, I decided to make a better looking set of labels. Popular approaches were using rub on letters, transferring ink jet printed text/graphics to a solid surface with glue, transferring laser printed text/graphics with a hot clothes iron, or melting laser-printed letters onto the solid surface with a solvent. I tried all of these, the last method worked the best.

I will describe how I used the solvent based method.

This will only work if your panel can withstand the solvent used (acetone, or nail polish remover, xylene). Metals and wood are ok, but some plastics such as acrylic/plexiglass will not work. Add a drop of the solvent onto your plastic material to see if it is affected or not.

I will describe how I used the solvent based method.

This will only work if your panel can withstand the solvent used (acetone, or nail polish remover, xylene). Metals and wood are ok, but some plastics such as acrylic/plexiglass will not work. Add a drop of the solvent onto your plastic material to see if it is affected or not.

Design and Print the Label

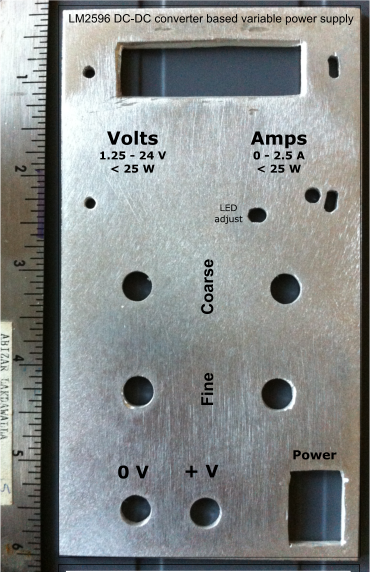

Take a photograph of your panel with a ruler next to it.

Import it into a drawing program or Powerpoint. I use Xara Extreme or Inkscape. Then change the size of the picture of the panel till it matches the ruler in your drawing program, That is the inch on the graphics ruler is the same size as the inch on the picture of your panel.

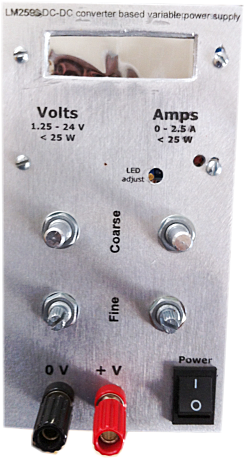

Now type/draw the text or other graphics you need on top of your panel picture. This helps place the lettering more precisely with the locations on your panel. The first image is a screen shot from the Xara software with the photo of my panel in the background and letters on top.

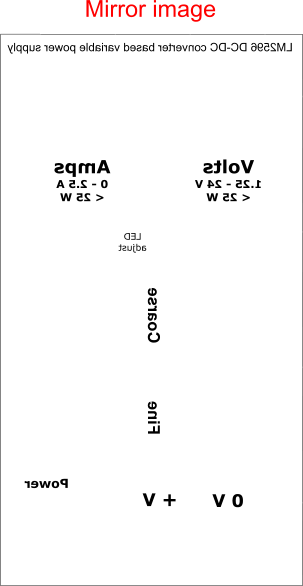

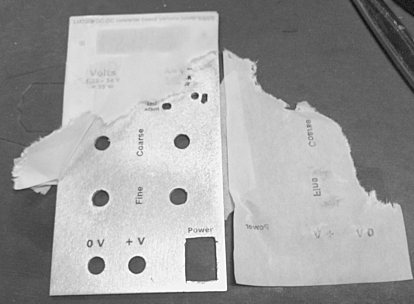

Delete the picture of your panel from the drawing program leaving only the lettering and graphics. Group (Ctrl-G on most softwares) the letters and graphics and then flip the 'group' (create a mirror image) so that the graphics are reversed. See the second image below.

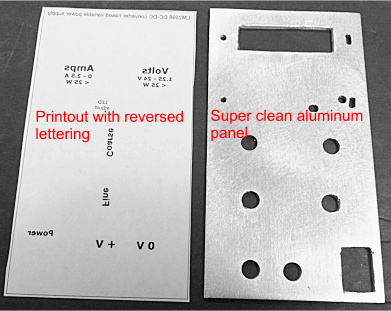

Print out the label you just created on a laser printer making sure that image is not re-sized during printing.

Import it into a drawing program or Powerpoint. I use Xara Extreme or Inkscape. Then change the size of the picture of the panel till it matches the ruler in your drawing program, That is the inch on the graphics ruler is the same size as the inch on the picture of your panel.

Now type/draw the text or other graphics you need on top of your panel picture. This helps place the lettering more precisely with the locations on your panel. The first image is a screen shot from the Xara software with the photo of my panel in the background and letters on top.

Delete the picture of your panel from the drawing program leaving only the lettering and graphics. Group (Ctrl-G on most softwares) the letters and graphics and then flip the 'group' (create a mirror image) so that the graphics are reversed. See the second image below.

Print out the label you just created on a laser printer making sure that image is not re-sized during printing.

Transfer the Print to the Panel

Prepare the panel

Clean the panel so that grease or dust does not remain on the panel. For the aluminum panel, I used a soap impregnated steel wool pad, followed by a nice scrubbing with dish-washing liquid, then with water, let dry and and finally wiped with rubbing alcohol (isopropanol).

Cut the laser printout (on paper) to the correct size and place this on the panel with the print side touching the panel. Tape a few edges with painters tape so that the paper will not slide.

Pour a bit of acetone (I used Cutex nail polish remover) onto the paper and use a roller to squeeze the bubbles out. Make sure that the paper does not shift.

Rub the paper with the back of a spoon to help transfer the letters from the paper to the panel. The acetone evaporates quite quickly so you may need to add more when you are rubbing with the spoon. If you have a set of rollers, it might be easier to squeeze the paper/panel sandwich through these rollers to help transfer the letters. Again, be careful about the paper not sliding.

The print transfers with surprising ease. The fused plastic powder which makes up the 'ink' in laser printers melts and re-sticks to the other surface. Some residue seems to remain on the paper.

Lift of the paper. It is pretty fragile after the acetone and spoon rubs so my tear.

The lettering should have transferred to the panel.

Rub with wet fingers to remove any sticking paper. The lettering is attached quite well and withstand the fingers,

Clean the panel so that grease or dust does not remain on the panel. For the aluminum panel, I used a soap impregnated steel wool pad, followed by a nice scrubbing with dish-washing liquid, then with water, let dry and and finally wiped with rubbing alcohol (isopropanol).

Cut the laser printout (on paper) to the correct size and place this on the panel with the print side touching the panel. Tape a few edges with painters tape so that the paper will not slide.

Pour a bit of acetone (I used Cutex nail polish remover) onto the paper and use a roller to squeeze the bubbles out. Make sure that the paper does not shift.

Rub the paper with the back of a spoon to help transfer the letters from the paper to the panel. The acetone evaporates quite quickly so you may need to add more when you are rubbing with the spoon. If you have a set of rollers, it might be easier to squeeze the paper/panel sandwich through these rollers to help transfer the letters. Again, be careful about the paper not sliding.

The print transfers with surprising ease. The fused plastic powder which makes up the 'ink' in laser printers melts and re-sticks to the other surface. Some residue seems to remain on the paper.

Lift of the paper. It is pretty fragile after the acetone and spoon rubs so my tear.

The lettering should have transferred to the panel.

Rub with wet fingers to remove any sticking paper. The lettering is attached quite well and withstand the fingers,

Seal the Labeling With Water Based Acrylic Varnish

Let the panel with letters from the previous step dry.

With a foam brush apply a water based acrylic varnish. A water based polyurethane varnish should also work. Oil based acrylic or polyurethanes may dissolve the lettering.

Let dry. You may put another coat on. I did not.

Now attach all the other goodies to your panel to complete your project!

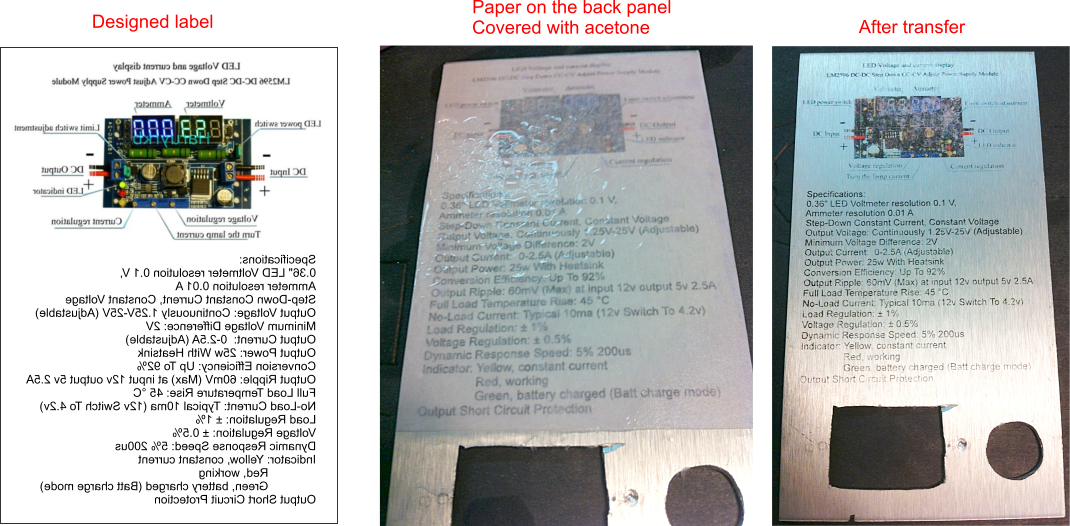

I went a bit crazy on the back panel. Printed out a mirror image of the circuit board graphic and performance specification and transferred that to the back panel.

With a foam brush apply a water based acrylic varnish. A water based polyurethane varnish should also work. Oil based acrylic or polyurethanes may dissolve the lettering.

Let dry. You may put another coat on. I did not.

Now attach all the other goodies to your panel to complete your project!

I went a bit crazy on the back panel. Printed out a mirror image of the circuit board graphic and performance specification and transferred that to the back panel.