AUTOmelette - Automated Omelette Cooking Articulated Robot

by automelette_2021mid in Workshop > 3D Printing

994 Views, 7 Favorites, 0 Comments

AUTOmelette - Automated Omelette Cooking Articulated Robot

As we are aware that, a large number of young individuals stay away from their home for higher education, jobs & other stuff.

We often imagine how working individuals are busy in their hectic daily schedule, meanwhile they tend to get exhausted while returning from their jobs and then end up buying online food which is quite expensive or in some cases unhealthy too.

Same applies to Hostellers or abroad studying college students who have to either make their own food after returning from a tiresome day from their college or have to depend on mess for breakfast or brunch.

But it is costly and unhealthy to eat online food or stale food at mess.

Thus, we decided to research and work on a project using which we can overcome this problem.

Hence, we came up with an idea of automating this cooking process, so that every individual can enjoy homemade food which will eventually be prepared by a robot in a hygiene surrounding.

Also, we took it to the next step by accepting the challenge to start the cooking process by accepting command through Google Assistant and serving the food hot when the respective person reaches home.

Supplies

- 3 x 20 Kgcm High Torque Servo Motors (Robokits)

- 2 x MG996R motors with 10Kgcm.

- SG90 motor with 2kgcm (locking system.)

- Robokits servo motor controller board.

- ESP8266-01 module.

- Jumper Cables

- Induction cooktop.

- 0-12 Volts Variable Power Supply

- Steel Spatula

- Silicon Brush(for oil)

- Steel Measure Cup(60ml)

Implementation

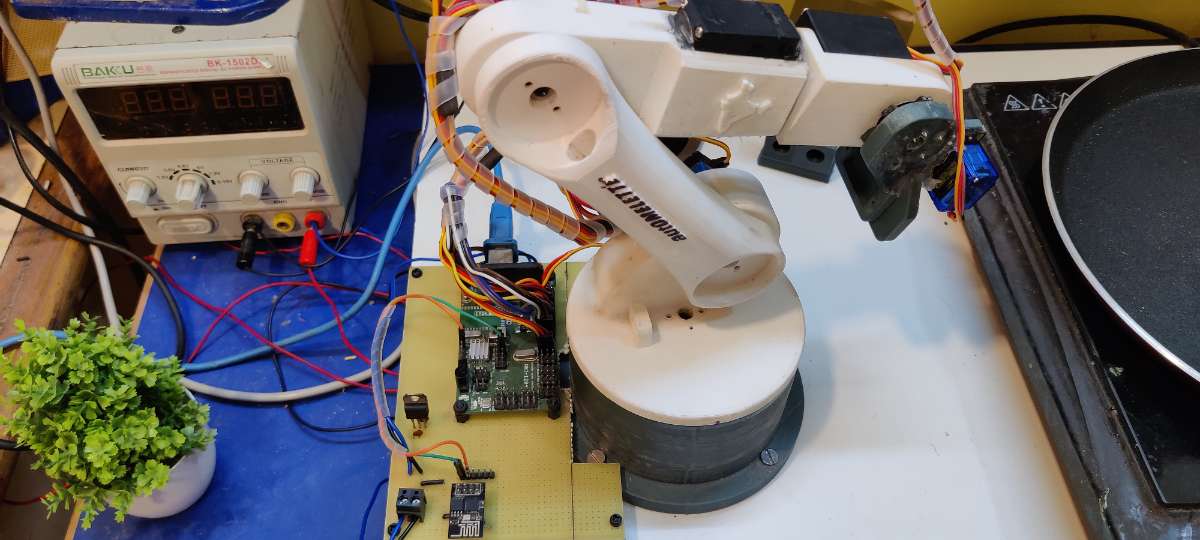

First, we did research on this project including its need, components requirement and its overall budget. Then we designed the 3D parts of the robotic arm using a reference model. After thoroughly checking the dimensions of arm we built a “. step” file of the design.

Then this file was sent to the local 3D printing service provider for printing the designed parts, as our system must deal with lot of heat so we used ABS material for printing.

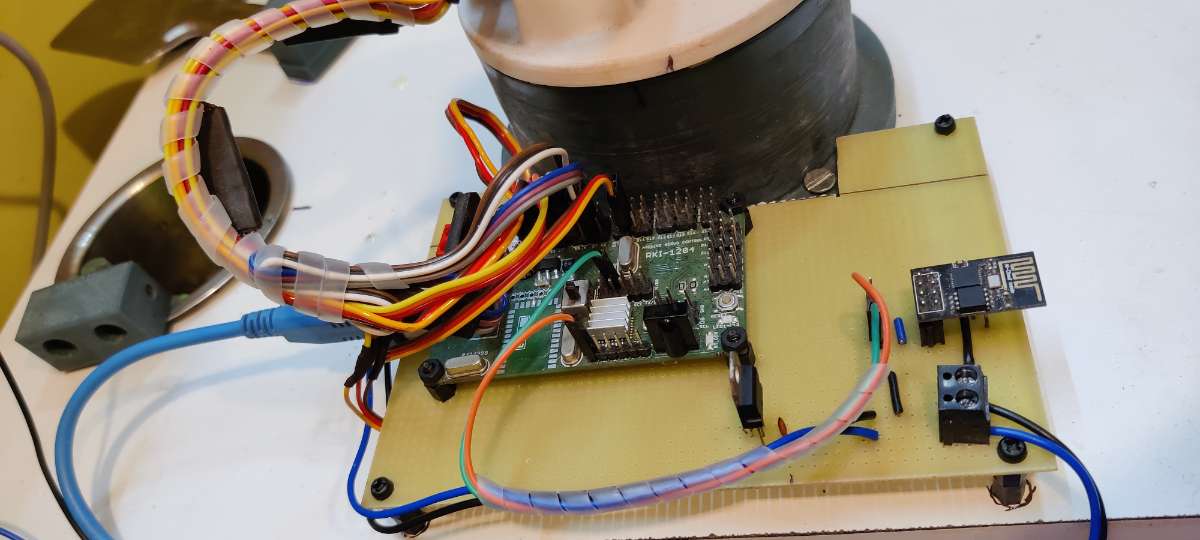

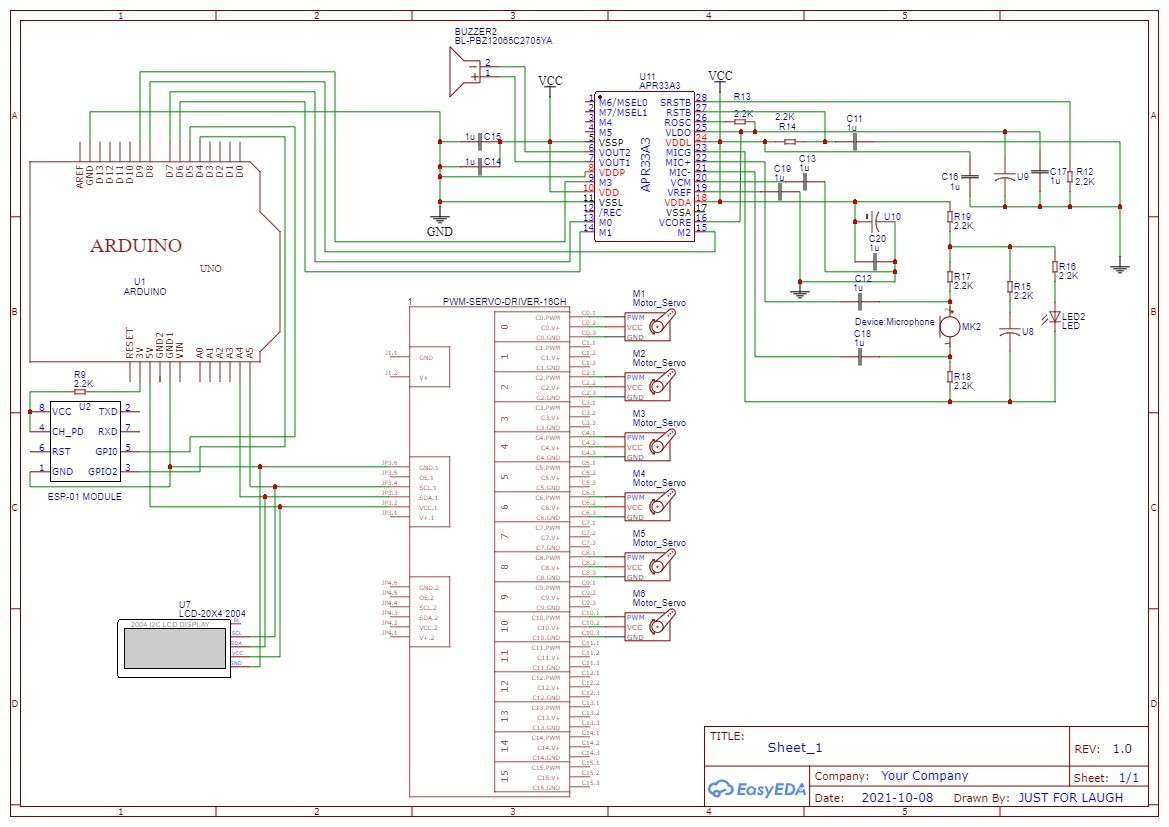

Meanwhile we designed the circuitry using EasyEDA software.

On arrival of 3D printed parts all the parts were assembled. We also attached the servos to their respective positions on the Arm.

We interfaced the controller and servos using cables and then we went on with the programming of Arm as per the cooking process.

We also interfaced an esp01 with the controller for commanding the cooking process remotely using the concept of Geo location tracking.

We accepted the command through Google Assistant and triggered the controller whenever the person enters a predefined radius making it possible to serve hot food until the person reaches home.

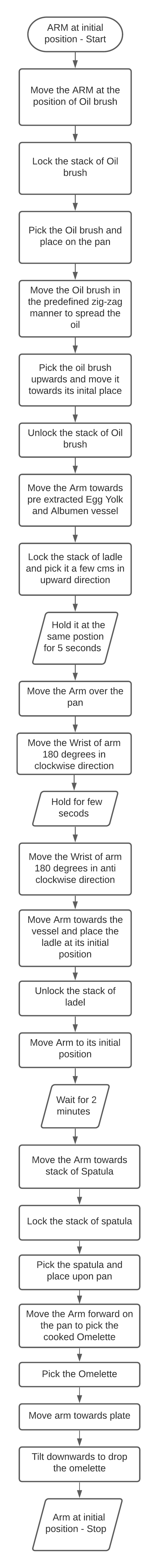

Flow of Operations

1) ARM at initial position - Start.

2) Move the ARM at the position of Oil brush.

3) Lock the stack of Oil brush.

4) Pick the Oil brush and place on the pan.

5) Move the Oil brush in the predefined zig-zag manner to spread the oil.

6) Pick the oil brush upwards and move it towards its inital place.

7) Unlock the stack of Oil brush.

8) Move the Arm towards pre extracted Egg Yolk and Albumen vessel.

9) Lock the stack of ladle and pick it a few cms in upward direction.

10) Hold it at the same postion for few seconds.

11) Move the Arm over the pan.

12) Move the Wrist of arm 180 degree in clockwise direction.

13) Hold for few secods.

14) Move the Wrist of arm 180 degree in anti clockwise direction.

15) Move Arm towards the vessel and place the ladle at its initial position.

16) Unlock the stack of ladel.

17) Move Arm to its initial position.

18) Wait for 2 minutes.

19) Move the Arm towards stack of Spatula.

20) Lock the stack of spatula.

21) Pick the spatula and place upon pan.

22) Move the Arm forward on the pan to pick the cooked Omelette.

23) Pick the Omelette.

24) Move arm towards plate.

25) Tilt downwards to drop the omelette.

26) Arm at initial position - Stop.

Hardware Selection

Motors Selection :-

While designing we considered stepper Motors as our first preference as the required torque was high, but these are quite bulky and robust, which results to huge cost of motors, also it was not possible to design an arm consisting of stepper motors with low budget. Thus, we went for Servo Motors which would go in our budget.

We have selected 3 * 20 Kgcm high torque motors from which 1 motor is at the base for 1st axial rotation of the arm and other 2 motors are used for 2nd and 3rd axial movement of upper and lower arm.

2 * 10Kgcm is used for axial movement of wrist of the Arm.

One 2Kgcm motors is used for locking mechanism of attachable equipment like Spoon, Oil brush and Spatula.

Controller Selection :-

At the beginning, we selected Arduino Uno as our main control board, but it was not feasible to control the positions of arm in real-time which would also take large amount of time for programming the same.

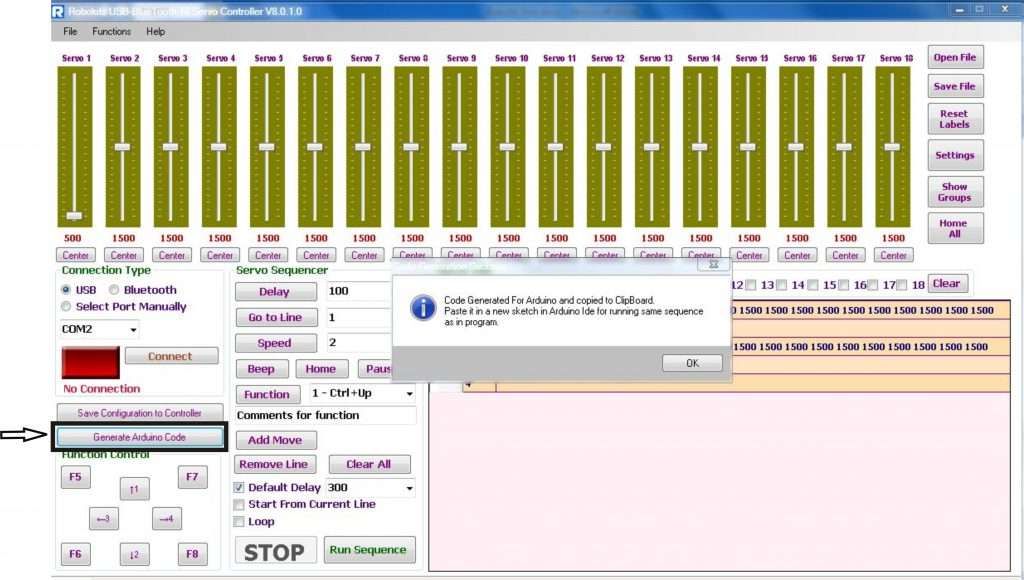

Thus, we changed to ARDUINO UNO BASED USB 18 SERVO CONTROLLER which consist of Onboard ATMEGA 328p chip with I2C interface for up to 18 servos. This board was easy to program with a GUI for controlling each servo in real-time which eventually saved our time for programming.

Also, an ESP8266-01 is interfaced with this controller board for communication with ADAFRUIT cloud.

Whenever the order is placed by user the ESP sends signal to controller to begin the cooking process.

Software Selection

Solidworks :–

We found the best software till now for creating 3d models is SolidWorks, Hence as we were familiar with it since diploma, we choose solid works as main.

EasyEDA :–

It is used for building the schematic diagram of our system.

Robokit servo controller software :–

It is GUI used to control servos in realtime.

Arduino IDE :-

It is an Integrated Development Environment software used to compile and upload codes to any Arduino boards.

Google Assistant :–

It is an artificial intelligence powered virtual assistant developed by Google which can take commands or questions (commands for our project) and respond to it accordingly. In our project it triggers the IFTTT on saying – “Hey Google” and then “Prepare an omelette i am hungry” command.

IFTTT :–

We have used it as a mediator between Google Assistant and Adafruit service. Whenever the Google Assistant receives a predefined command, it triggers the IFTTT which in turn triggers the adafruit io button. Also, we have used the geo location tracking service to trigger the adafruit button when the user enters a predefined area.

Adafruit IO :–

It responds to the trigger of IFTTT by setting the button as HIGH which is further read by ESP01 which is constantly observing the state of buttons.

Circuit Diagram

The following Circuit is explained below.

Explanation :

All the servo motors are connected to Arduino via servo control board. But we have used Arduino Uno Based USB 18 Servo Controller board practically which is capable of interfacing servos.

Esp8266-01 controller is used to for IOT part of our project, the GPIO 2 pin is connected to D4 pin of Arduino. The pin is high when esp01 receives command from adafruit io which is read by Arduino and further cooking processes are carried out.

In order to provide a good user experience an LCD and Voice playback module can be interfaced with the controller.

LCD will display the current cooking process being carried out and also the time remaining to complete the cooking process.

An APR33A3 Voice Record & Playback Module can be used to provide audio playback of the cooking process being carried out, also it can inform user after the completion of cooking process.

Conclusion :

This is a prototype model, real ones need a little high investment, but through completions like this, we hope we would stand better in the future & keep working on this research. Further, we are eager to work on this, more deeply & dive into AI Kitchens driven by Robots. This invention, which is now in the prototype phase, would benefit people living out of their city, college students, college campuses, industry areas, meeting rooms, conference halls, etc. It's just like a Coffee machine fitted everywhere, the same way this robot can also be taken into applications in a variety of areas in a few bucks.

Code

#include <ESP8266WiFi.h>

#include "config.h"

#include "Adafruit_MQTT.h"

#include "Adafruit_MQTT_Client.h"

#define ToCont 2

int GoogleAssistant;

int Loc_State;

int GA_State;

#define WLAN_SSID "AME" // Your SSID

#define WLAN_PASS "tushar007" // Your password

/************************* Adafruit.io Setup *********************************/

#define AIO_SERVER "io.adafruit.com" //Adafruit Server

#define AIO_SERVERPORT 1883

#define AIO_USERNAME "Automelette"

#define AIO_KEY "aio_qKuB11XwBqowiAs3nVdxk1cNPPhD"

//WIFI CLIENT

WiFiClient client;

Adafruit_MQTT_Client mqtt(&client, AIO_SERVER, AIO_SERVERPORT, AIO_USERNAME, AIO_KEY);

Adafruit_MQTT_Subscribe Loc = Adafruit_MQTT_Subscribe(&mqtt, AIO_USERNAME"/feeds/Location"); // Feeds name should be same everywhere

Adafruit_MQTT_Subscribe GA = Adafruit_MQTT_Subscribe(&mqtt, AIO_USERNAME"/feeds/google-assistant");

Adafruit_MQTT_Publish photocell = Adafruit_MQTT_Publish(&mqtt, AIO_USERNAME "/feeds/google-assistant");

void MQTT_connect();

void setup() {

Serial.begin(9600);

pinMode(ToCont, OUTPUT);

// Connect to WiFi access point.

Serial.println(); Serial.println();

Serial.print("Connecting to ");

Serial.println(WLAN_SSID);

WiFi.begin(WLAN_SSID, WLAN_PASS);

while (WiFi.status() != WL_CONNECTED) {

delay(500);

Serial.print(".");

}

Serial.println();

Serial.println("WiFi connected");

Serial.println("IP address: ");

Serial.println(WiFi.localIP());

mqtt.subscribe(&Loc);

mqtt.subscribe(&GA);

}

uint32_t x=0;

int laststate = 0, currentstate = 0;

void loop() {

MQTT_connect();

Adafruit_MQTT_Subscribe *subscription;

while ((subscription = mqtt.readSubscription(20000))) {

if (subscription == &Loc) {

Serial.println(F("Got_Loc: "));

Serial.println((char *)Loc.lastread);

Loc_State = atoi((char *)Loc.lastread);

}

if (subscription == &GA) {

Serial.print(F("Got_GA: "));

Serial.println((char *)GA.lastread);

GA_State = atoi((char *)GA.lastread);

Serial.println("Received from GA");

}

Send_Out();

}

Send_Out();

}

void Send_Out() {

if(GA_State && Loc_State == 1)

{

digitalWrite(ToCont,HIGH);

Serial.println("ToCont HIGH");

}

else{

digitalWrite(ToCont,LOW);

Serial.println("ToCont LOW");

}

if(Loc_State == 1)

{

currentstate = 1;

}

else

{

currentstate = 0;

}

if(currentstate != laststate)

{

}

if( currentstate == 0 && laststate == 1)

{

Serial.print(F("\nSending val ToCont"));

Serial.print(x);

Serial.print("...");

if (! photocell.publish(0)) {

Serial.println(F("Failed"));

}

else {

Serial.println(F("OK!"));

}

}

Serial.println("HEre am I");

Serial.print("Loca State");

Serial.println(Loc_State);

Serial.print("Current");

Serial.println(currentstate);

Serial.print("Last");

Serial.println(laststate);

laststate = currentstate;

}

void MQTT_connect() {

int8_t ret;

if (mqtt.connected()) {

return;

}

Serial.print("Connecting to MQTT... ");

uint8_t retries = 3;

while ((ret = mqtt.connect()) != 0) {

Serial.println(mqtt.connectErrorString(ret));

Serial.println("Retrying MQTT connection in 5 seconds...");

mqtt.disconnect();

delay(5000);

retries--;

if (retries == 0) {

while (1);

}

}

Serial.println("MQTT Connected!");

}

...................................................................................................................................

/* ROBOKITS ARDUINO USB/BLUETOOTH 18 SERVO CONTROLLER FIRMWARE

This code is generated from Robokits Arduino Bluetooth/USB Servo Controller software.

The hardware consist of 2 AVRs out of which one is Master and has Arduino bootloader. The second one is slave and runs all servo routines.

The master controls slave through I2C and slave operates all servos.

Many pins of the main controller are free and can be used for connecting other peripherals and interfaces.

Firmware contains 2 parts (functions in void loop()) - 1. Run in PC controlled Mode and 2. Run User Code

The code is selected through a Jumper on Servo controller board.

You can change the user code as per your need.

This code is generated for Arduino UNO board profile and the same should be chosed while programming with Arduino IDE.

Arduino IDE veersion 1.6.5 + is recommended.

If the code is moved to other servo base platform like a robot, offsets must be set properly so that servos will move correctly as per program.

*/

#include <Wire.h>

#define servo1 (16>>1)

#define servo2 (18>>1)

#define UART_BAUD_RATE 115200

#define LED 13

#define SERIAL_BUFFER_SIZE 256

void I2C_SERVOSET(unsigned char servo_num,unsigned int servo_pos);

void I2C_SERVOREVERSE(unsigned char servo_num,unsigned char servo_dir);

void I2C_SERVOOFFSET(unsigned char servo_num,int value);

void I2C_SERVOSPEED(unsigned char value);

void I2C_SERVONUTRALSET(unsigned char servo_num,unsigned int servo_pos);

void I2C_SERVOMIN(unsigned char servo_num,unsigned int servo_pos);

void I2C_SERVOMAX(unsigned char servo_num,unsigned int servo_pos);

char I2C_SERVOEND(void);

int I2C_SERVOGET(int servo_num);

int I2C_SERVOGETOFFSET(int servo_num);

void CheckEndMovement(void);

void PCControlledCode(void);

void UserCode(void);

void LEDToggle(void);

volatile int cnt,c,servoval;

volatile char state,servobuf[36],bytecnt;

int interval=100;

unsigned long previousMillis=0;

unsigned long currentMillis = millis();

char runCode =0; //1 for PC controlled, 0 for user controlled

char LEDState=0;

#define State_Start 0

#define State_Command 1

#define State_Servoposition 2

#define State_Speed 3

#define State_Servomin 4

#define State_Servomax 5

#define State_Servooffset 6

#define State_Servoreverse 7

#define State_Servonutral 8

#define State_ReadOffsets 9

#define ipfromesp D4

int ipstate;

void setup()

{

cnt=0;

int i;

unsigned int x;

char buffer[10],tmp,tmp1;

float range;

Serial.begin(UART_BAUD_RATE);

Serial.write('S');

Serial.write('r');

pinMode(13, OUTPUT);

pinMode(2, OUTPUT);

pinMode(8, INPUT);

digitalWrite(8,1);

delay(500);

sei();

Wire.begin();

TWSR = 3; // no prescaler

TWBR = 18; //Set I2C speed lower to suite I2C Servo controller

pinMode(2,OUTPUT);

digitalWrite(2,HIGH);

delay(500);

state=State_Start;

if (digitalRead(8))

{

runCode=1;

}

else

{

runCode=0;

}

}

void loop()

{

if (runCode ==1)

{

PCControlledCode();

}

else

{

UserCode();

LEDToggle();

}

}

void PCControlledCode(void)

{

currentMillis = millis();

if(Serial.available()>0)

{

c=Serial.read();

previousMillis = currentMillis;

if(state==State_Start)

{

if(c==170)

state=State_Command;

}

else if(state==State_Servoposition)

{

servobuf[bytecnt]=c;

bytecnt++;

if(bytecnt==36)

{

for(int i=1;i<19;i++)

{

servoval=servobuf[(i*2)-1]<<7;

servoval=servoval+servobuf[(i*2)-2];

I2C_SERVOSET(i,servoval);

}

bytecnt=0;

state=State_Start;

Serial.write('r');

CheckEndMovement();

previousMillis = currentMillis;

}

}

else if(state==State_Speed)

{

I2C_SERVOSPEED(c);

state=State_Start;

Serial.write("rs");

CheckEndMovement();

}

else if(state==State_Servomin)

{

servobuf[bytecnt]=c;

bytecnt++;

if(bytecnt==36)

{

for(int i=1;i<19;i++)

{

servoval=servobuf[(i*2)-1]<<7;

servoval=servoval+servobuf[(i*2)-2];

I2C_SERVOMIN(i,servoval);

delay(20);

}

bytecnt=0;

state=State_Start;

Serial.write("rn");

CheckEndMovement();

previousMillis = currentMillis;

}

}

else if(state==State_Servomax)

{

servobuf[bytecnt]=c;

bytecnt++;

if(bytecnt==36)

{

for(int i=1;i<19;i++)

{

servoval=servobuf[(i*2)-1]<<7;

servoval=servoval+servobuf[(i*2)-2];

I2C_SERVOMAX(i,servoval);

delay(20);

}

bytecnt=0;

state=State_Start;

Serial.write("rx");

CheckEndMovement();

previousMillis = currentMillis;

}

}

else if(state==State_Servooffset)

{

servobuf[bytecnt]=c;

bytecnt++;

if(bytecnt==36)

{

for(int i=1;i<19;i++)

{

servoval=servobuf[(i*2)-1]<<7;

servoval=servoval+servobuf[(i*2)-2];

I2C_SERVOOFFSET(i,servoval);

delay(20);

}

bytecnt=0;

state=State_Start;

Serial.write("ro");

CheckEndMovement();

previousMillis = currentMillis;

}

}

else if(state==State_Servoreverse)

{

servobuf[bytecnt]=c;

bytecnt++;

if(bytecnt==18)

{

for(int i=1;i<19;i++)

{

I2C_SERVOREVERSE(i,servobuf[(i-1)]);

delay(20);

}

bytecnt=0;

state=State_Start;

Serial.write("rv");

CheckEndMovement();

previousMillis = currentMillis;

}

}

else if(state==State_Servonutral)

{

servobuf[bytecnt]=c;

bytecnt++;

if(bytecnt==36)

{

for(int i=1;i<19;i++)

{

servoval=servobuf[(i*2)-1]<<7;

servoval=servoval+servobuf[(i*2)-2];

I2C_SERVONUTRALSET(i,servoval);

}

bytecnt=0;

state=State_Start;

Serial.write("rn");

CheckEndMovement();

previousMillis = currentMillis;

}

}

else if(state==State_ReadOffsets)

{

Serial.write("O");

for(int i=1;i<19;i++)

{

Serial.print(I2C_SERVOGETOFFSET(i));

Serial.write(",");

delay(1);

}

Serial.write("F");

state=State_Start;

Serial.write('r');

CheckEndMovement();

previousMillis = currentMillis;

}

else if(state==State_Command)

{

if(c==8)

state=State_Speed;

if(c==10)

state=State_Servoposition;

if(c==11)

state=State_Servomin;

if(c==12)

state=State_Servomax;

if(c==13)

state=State_Servooffset;

if(c==14)

state=State_Servoreverse;

if(c==15)

state=State_Servonutral;

if(c==21)

state=State_ReadOffsets;

bytecnt=0;

}

else

{

Serial.write('e');

CheckEndMovement();

}

}

else

{

if ((unsigned long)(currentMillis - previousMillis) >= interval)

{

Serial.write('i');

Serial.write('r');

CheckEndMovement();

previousMillis = currentMillis;

}

}

}

void CheckEndMovement(void)

{

if(I2C_SERVOEND())

Serial.write('X');

else

Serial.write('G');

LEDToggle();

}

void I2C_SERVOSET(unsigned char servo_num,unsigned int servo_pos)

{

if(servo_pos<500)

servo_pos = 500;

else if(servo_pos>2500)

servo_pos=2500;

if(servo_pos>501)

servo_pos=(((servo_pos-2)*2)-1000);

else

servo_pos=0;

if(servo_num<19)

Wire.beginTransmission(servo1);

else

Wire.beginTransmission(servo2);

Wire.write(servo_num-1);

Wire.write(servo_pos>>8);

Wire.write(servo_pos & 0XFF);

Wire.endTransmission();

}

void I2C_SERVOMIN(unsigned char servo_num,unsigned int servo_pos)

{

if(servo_pos<500)

servo_pos = 500;

else if(servo_pos>2500)

servo_pos=2500;

servo_pos=((servo_pos*2)-1000);

if(servo_num<19)

Wire.beginTransmission(servo1);

else

Wire.beginTransmission(servo2);

Wire.write((servo_num-1)+(18*4));

Wire.write(servo_pos>>8);

Wire.write(servo_pos & 0XFF);

Wire.endTransmission();

delay(20);

}

void I2C_SERVOMAX(unsigned char servo_num,unsigned int servo_pos)

{

if(servo_pos<500)

servo_pos = 500;

else if(servo_pos>2500)

servo_pos=2500;

servo_pos=((servo_pos*2)-1000);

if(servo_num<19)

Wire.beginTransmission(servo1);

else

Wire.beginTransmission(servo2);

Wire.write((servo_num-1)+(18*3));

Wire.write(servo_pos>>8);

Wire.write(servo_pos & 0XFF);

Wire.endTransmission();

delay(20);

}

void I2C_SERVONUTRALSET(unsigned char servo_num,unsigned int servo_pos)

{

if(servo_pos<500)

servo_pos = 500;

else if(servo_pos>2500)

servo_pos=2500;

servo_pos=((servo_pos*2)-1000);

if(servo_num<19)

Wire.beginTransmission(servo1);

else

Wire.beginTransmission(servo2);

Wire.write((servo_num-1)+(18*5));

Wire.write(servo_pos>>8);

Wire.write(servo_pos & 0XFF);

Wire.endTransmission();

}

void I2C_SERVOSPEED(unsigned char value)

{

Wire.beginTransmission(servo1);

Wire.write(18*2);

Wire.write(value);

Wire.write(0);

Wire.endTransmission();

Wire.beginTransmission(servo2);

Wire.write(18*2);

Wire.write(value);

Wire.write(0);

Wire.endTransmission();

delay(20);

}

void I2C_SERVOOFFSET(unsigned char servo_num,int value)

{

value=3000-value;

value=value-1500;

if (value<-500)

value=-500;

else if (value>500)

value=500;

if(value>0)

value=2000+(value*2);

else if(value<=0)

value=-value*2;

if(servo_num<19)

Wire.beginTransmission(servo1);

else

Wire.beginTransmission(servo2);

Wire.write((servo_num-1)+(18*6));

Wire.write(value>>8);

Wire.write(value & 0XFF);

Wire.endTransmission();

delay(20);

}

void I2C_SERVOREVERSE(unsigned char servo_num,unsigned char servo_dir)

{

if(servo_dir>0)

servo_dir=1;

if(servo_num<19)

Wire.beginTransmission(servo1);

else

Wire.beginTransmission(servo2);

Wire.write((servo_num-1)+(18*7));

Wire.write(servo_dir);

Wire.write(0);

Wire.endTransmission();

delay(20);

}

char I2C_SERVOEND(void)

{

int i, n;

char buffer;

Wire.beginTransmission(servo1);

n = Wire.write(181);

if (n != 1)

return (-10);

n = Wire.endTransmission(false);

if (n != 0)

return (n);

delayMicroseconds(350);

Wire.requestFrom(servo1, 1, true);

while(Wire.available())

buffer=Wire.read();

return(buffer);

}

int I2C_SERVOGET(int servo_num)

{

int i, n, error;

uint8_t buffer[2];

Wire.beginTransmission(servo1);

n = Wire.write((servo_num-1)+(18*8));

if (n != 1)

return (-10);

n = Wire.endTransmission(false);

if (n != 0)

return (n);

delayMicroseconds(240);

Wire.requestFrom(servo1, 2, true);

i = 0;

while(Wire.available() && i<2)

{

buffer[i++]=Wire.read();

}

if ( i != 2)

return (-11);

return (((buffer[0]*256 + buffer[1])+4)/2 +500);

}

int I2C_SERVOGETOFFSET(int servo_num)

{

int i, n, error;

uint8_t buffer[2];

Wire.beginTransmission(servo1);

n = Wire.write((servo_num-1)+(182));

if (n != 1)

return (-10);

n = Wire.endTransmission(false);

if (n != 0)

return (n);

delayMicroseconds(240);

Wire.requestFrom(servo1, 2, true);

i = 0;

while(Wire.available() && i<2)

{

buffer[i++]=Wire.read();

}

if ( i != 2)

return (-11);

i=((buffer[0]*256 + buffer[1]));

if(i>2000)

return(3000-(((i-2000)/2)+1500));

else

return(3000-((-i/2)+1500));

}

void ServoSetAll(unsigned int Servo1, unsigned int Servo2, unsigned int Servo3, unsigned int Servo4, unsigned int Servo5, unsigned int Servo6, unsigned int Servo7, unsigned int Servo8, unsigned int Servo9, unsigned int Servo10, unsigned int Servo11, unsigned int Servo12, unsigned int Servo13, unsigned int Servo14, unsigned int Servo15, unsigned int Servo16, unsigned int Servo17, unsigned int Servo18)

{

if (Servo1 >= 500) {I2C_SERVOSET(1,Servo1);}

if (Servo2 >= 500) {I2C_SERVOSET(2,Servo2);}

if (Servo3 >= 500) {I2C_SERVOSET(3,Servo3);}

if (Servo4 >= 500) {I2C_SERVOSET(4,Servo4);}

if (Servo5 >= 500) {I2C_SERVOSET(5,Servo5);}

if (Servo6 > 500) {I2C_SERVOSET(6,Servo6);}

if (Servo7 >= 500) {I2C_SERVOSET(7,Servo7);}

if (Servo8 >= 500) {I2C_SERVOSET(8,Servo8);}

if (Servo9 >= 500) {I2C_SERVOSET(9,Servo9);}

if (Servo10 >= 500) {I2C_SERVOSET(10,Servo10);}

if (Servo11 >= 500) {I2C_SERVOSET(11,Servo11);}

if (Servo12 >= 500) {I2C_SERVOSET(12,Servo12);}

if (Servo13 >= 500) {I2C_SERVOSET(13,Servo13);}

if (Servo14 >= 500) {I2C_SERVOSET(14,Servo14);}

if (Servo15 >= 500) {I2C_SERVOSET(15,Servo15);}

if (Servo16 >= 500) {I2C_SERVOSET(16,Servo16);}

if (Servo17 >= 500) {I2C_SERVOSET(17,Servo17);}

if (Servo18 >= 500) {I2C_SERVOSET(18,Servo18);}

while (!I2C_SERVOEND())

{

delay(1);

}

LEDToggle();

}

void LEDToggle(void)

{

if (LEDState == 0)

LEDState = 1;

else

LEDState = 0;

digitalWrite(LED, LEDState);

}

void MoveServos(void)

{

//------------------------------OIL SPREADING PROCESS------------------------------

delay(1000); // Line # 0

ServoSetAll(2195,1246,2169,1350,1842,1500,1503,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500); // Line # 5

delay(300); //Default Delay

delay(800); // Line # 6

ServoSetAll(2195,1201,1980,1350,1704,1500,1503,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500); // Line # 7

delay(300); //Default Delay

delay(800); // Line # 8

ServoSetAll(2195,1174,1920,1350,1713,1500,1503,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500); // Line # 9

delay(300); //Default Delay

delay(200); // Line # 10

ServoSetAll(2195,1174,1920,1350,1713,1500,1503,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500,2067); // Line # 11

delay(300); //Default Delay

delay(600); // Line # 12

ServoSetAll(2195,1279,1920,1350,1656,1500,1503,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500,2069); // Line # 13

delay(300); //Default Delay

delay(600); // Line # 14

ServoSetAll(2195,1722,1920,1350,1554,1500,1503,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500,2069); // Line # 15

delay(300); //Default Delay

delay(800); // Line # 16

ServoSetAll(1688,1546,1743,1350,1401,1500,1503,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500,2087); // Line # 17

delay(300); //Default Delay

delay(1000); // Line # 18

ServoSetAll(1688,1792,2109,1350,1221,1500,1503,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500,2087); // Line # 19

delay(300); //Default Delay

delay(600); // Line # 20

ServoSetAll(1622,1711,2070,1350,1203,1500,1503,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500,2087); // Line # 21

delay(300); //Default Delay

delay(100); // Line # 22

delay(100); // Line # 23

delay(100); // Line # 24

ServoSetAll(2195,1279,1920,1350,1656,1500,1503,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500,2093); // Line # 25

delay(300); //Default Delay

delay(800); // Line # 26

ServoSetAll(2195,1174,1920,1350,1713,1500,1503,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500); // Line # 27

delay(300); //Default Delay

delay(600); // Line # 28

ServoSetAll(2195,1246,2169,1350,1842,1500,1503,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500); // Line # 29

delay(300); //Default Delay

delay(800); // Line # 30

ServoSetAll(1781,1500,1500,1350,943,1500,1503,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500,1500); // Line # 31

delay(300); //Default Delay

delay(1000);

//------------------------------EGG SPREADING PROCESS------------------------------

delay(1000); // Line # 0

I2C_SERVOSPEED(82); // Line # 7

ServoSetAll(1500,2045,0,2500,1500,0,955,0,0,500,0,0,0,0,0,0,0,0); // Line # 8

delay(300); //Default Delay

delay(100); // Line # 9

ServoSetAll(554,1742,0,2500,1500,0,1231,0,0,500,0,0,0,0,0,0,0,0); // Line # 10

delay(300); //Default Delay

delay(100); // Line # 11

ServoSetAll(569,1335,0,2500,1500,0,1582,0,0,500,0,0,0,0,0,0,0,0); // Line # 12

delay(300); //Default Delay

delay(100); // Line # 13

ServoSetAll(590,1281,0,2374,1500,0,1543,0,0,500,0,0,0,0,0,0,0,0); // Line # 14

delay(300); //Default Delay

delay(100); // Line # 15

ServoSetAll(569,1254,0,2332,1500,0,1594,0,0,500,0,0,0,0,0,0,0,0); // Line # 16

delay(300); //Default Delay

delay(100); // Line # 17

ServoSetAll(569,1254,0,2332,1500,0,1594,0,0,1194,0,0,0,0,0,0,0,0); // Line # 18

delay(300); //Default Delay

delay(100); // Line # 19

ServoSetAll(569,1458,0,2383,1500,0,1429,0,0,1194,0,0,0,0,0,0,0,0); // Line # 20

delay(300); //Default Delay

delay(2000); // Line # 21

I2C_SERVOSPEED(20); // Line # 22

delay(2000); // Line # 23

ServoSetAll(611,1824,0,2134,1500,0,835,0,0,1194,0,0,0,0,0,0,0,0); // Line # 24

delay(300); //Default Delay

delay(2000); // Line # 25

delay(2000); // Line # 26

ServoSetAll(1539,1824,0,2134,1500,0,835,0,0,1194,0,0,0,0,0,0,0,0); // Line # 27

delay(300); //Default Delay

delay(100); // Line # 28

ServoSetAll(1539,1431,0,1729,1500,0,835,0,0,1194,0,0,0,0,0,0,0,0); // Line # 29

delay(300); //Default Delay

delay(100); // Line # 30

I2C_SERVOSPEED(80); // Line # 31

ServoSetAll(1710,1350,0,1829,500,0,835,0,0,1194,0,0,0,0,0,0,0,0); // Line # 32

delay(300); //Default Delay

delay(2000); // Line # 33

delay(100); // Line # 34

ServoSetAll(1539,1431,0,1729,1500,0,835,0,0,1194,0,0,0,0,0,0,0,0); // Line # 35

delay(300); //Default Delay

delay(100); // Line # 36

ServoSetAll(1539,1824,0,2134,1500,0,835,0,0,1194,0,0,0,0,0,0,0,0); // Line # 37

delay(300); //Default Delay

delay(100); // Line # 38

ServoSetAll(611,1824,0,2134,1500,0,835,0,0,1194,0,0,0,0,0,0,0,0); // Line # 39

delay(300); //Default Delay

delay(100); // Line # 40

ServoSetAll(569,1458,0,2383,1500,0,1429,0,0,1194,0,0,0,0,0,0,0,0); // Line # 41

delay(300); //Default Delay

delay(100); // Line # 42

ServoSetAll(587,1284,0,2335,1500,0,1528,0,0,1194,0,0,0,0,0,0,0,0); // Line # 43

delay(300); //Default Delay

delay(100); // Line # 44

ServoSetAll(587,1272,0,2362,1500,0,1528,0,0,1194,0,0,0,0,0,0,0,0); // Line # 45

delay(300); //Default Delay

ServoSetAll(587,1245,0,2362,1500,0,1528,0,0,1194,0,0,0,0,0,0,0,0); // Line # 46

delay(300); //Default Delay

delay(100); // Line # 47

ServoSetAll(587,1245,0,2362,1500,0,1528,0,0,500,0,0,0,0,0,0,0,0); // Line # 48

delay(300); //Default Delay

delay(100); // Line # 49

ServoSetAll(584,1269,0,2380,1500,0,1576,0,0,500,0,0,0,0,0,0,0,0); // Line # 50

delay(300); //Default Delay

delay(100); // Line # 51

ServoSetAll(584,1293,0,2410,1500,0,1546,0,0,500,0,0,0,0,0,0,0,0); // Line # 52

delay(300); //Default Delay

delay(100); // Line # 53

ServoSetAll(569,1335,0,2500,1500,0,1582,0,0,500,0,0,0,0,0,0,0,0); // Line # 54

delay(300); //Default Delay

delay(100); // Line # 55

ServoSetAll(1500,2045,0,2500,1500,0,955,0,0,500,0,0,0,0,0,0,0,0); // Line # 56

delay(300); //Default Delay

delay(1000);

//------------------------------SPATULA PICKING PROCESS------------------------------

delay(1000); // Line # 0

I2C_SERVOSPEED(75); // Line # 7

ServoSetAll(1500,2045,0,2500,1500,0,955,0,0,500,0,0,0,0,0,0,0,0); // Line # 8

delay(300); //Default Delay

delay(100); // Line # 9

ServoSetAll(2159,1715,0,2500,1500,0,1231,0,0,500,0,0,0,0,0,0,0,0); // Line # 10

delay(300); //Default Delay

delay(100); // Line # 11

ServoSetAll(2192,1398,0,2500,1500,0,1626,0,0,500,0,0,0,0,0,0,0,0); // Line # 12

delay(300); //Default Delay

delay(100); // Line # 13

ServoSetAll(2192,1248,0,2338,1500,0,1582,0,0,500,0,0,0,0,0,0,0,0); // Line # 14

delay(300); //Default Delay

delay(100); // Line # 15

ServoSetAll(2192,1230,0,2287,1500,0,1552,0,0,500,0,0,0,0,0,0,0,0); // Line # 16

delay(300); //Default Delay

delay(100); // Line # 17

ServoSetAll(2192,1230,0,2287,1500,0,1552,0,0,1178,0,0,0,0,0,0,0,0); // Line # 18

delay(300); //Default Delay

delay(100); // Line # 19

ServoSetAll(2192,1302,0,2311,1500,0,1540,0,0,1178,0,0,0,0,0,0,0,0); // Line # 20

delay(300); //Default Delay

I2C_SERVOSPEED(30); // Line # 21

delay(100); // Line # 22

ServoSetAll(2192,1779,0,2500,1500,0,1390,0,0,1178,0,0,0,0,0,0,0,0); // Line # 23

delay(300); //Default Delay

I2C_SERVOSPEED(50); // Line # 24

delay(100); // Line # 25

ServoSetAll(1645,1779,0,2500,1500,0,1390,0,0,1178,0,0,0,0,0,0,0,0); // Line # 26

delay(300); //Default Delay

delay(100); // Line # 27

I2C_SERVOSPEED(30); // Line # 28

ServoSetAll(1666,2180,0,2500,1500,0,527,0,0,1178,0,0,0,0,0,0,0,0); // Line # 29

delay(300); //Default Delay

delay(100); // Line # 30

ServoSetAll(1666,2000,0,2500,1500,0,527,0,0,1178,0,0,0,0,0,0,0,0); // Line # 31

delay(300); //Default Delay

ServoSetAll(1666,1973,0,2500,1500,0,617,0,0,1178,0,0,0,0,0,0,0,0); // Line # 32

delay(300); //Default Delay

ServoSetAll(1666,1856,0,2377,1500,0,662,0,0,1178,0,0,0,0,0,0,0,0); // Line # 33

delay(300); //Default Delay

ServoSetAll(1666,1823,0,2371,1500,0,698,0,0,1178,0,0,0,0,0,0,0,0); // Line # 34

delay(300); //Default Delay

ServoSetAll(1666,1745,0,2386,1500,0,998,0,0,1178,0,0,0,0,0,0,0,0); // Line # 35

delay(300); //Default Delay

ServoSetAll(1666,1685,0,2386,1500,0,1040,0,0,1178,0,0,0,0,0,0,0,0); // Line # 36

delay(300); //Default Delay

delay(100); // Line # 37

ServoSetAll(1639,1514,0,2212,1461,0,1163,0,0,1178,0,0,0,0,0,0,0,0); // Line # 38

delay(300); //Default Delay

delay(100); // Line # 39

ServoSetAll(1639,1679,0,2212,1461,0,1115,0,0,1178,0,0,0,0,0,0,0,0); // Line # 40

delay(300); //Default Delay

delay(100); // Line # 41

ServoSetAll(940,1679,0,2212,1461,0,1115,0,0,1178,0,0,0,0,0,0,0,0); // Line # 42

delay(300); //Default Delay

delay(100); // Line # 43

I2C_SERVOSPEED(45); // Line # 44

ServoSetAll(940,1451,0,2212,1461,0,893,0,0,1178,0,0,0,0,0,0,0,0); // Line # 45

delay(300); //Default Delay

delay(100); // Line # 46

ServoSetAll(940,1679,0,2212,1461,0,1115,0,0,1178,0,0,0,0,0,0,0,0); // Line # 47

delay(300); //Default Delay

delay(100); // Line # 48

ServoSetAll(1500,2045,0,2500,1500,0,955,0,0,1194,0,0,0,0,0,0,0,0); // Line # 49

delay(300); //Default Delay

ServoSetAll(2184,2045,0,2500,1500,0,955,0,0,1194,0,0,0,0,0,0,0,0); // Line # 50

delay(300); //Default Delay

delay(100); // Line # 51

ServoSetAll(2192,1241,0,2317,1500,0,1564,0,0,1194,0,0,0,0,0,0,0,0); // Line # 52

delay(300); //Default Delay

delay(100); // Line # 53

ServoSetAll(2192,1274,0,2317,1500,0,1564,0,0,1194,0,0,0,0,0,0,0,0); // Line # 54

delay(300); //Default Delay

delay(100); // Line # 55

ServoSetAll(2192,1241,0,2317,1500,0,1564,0,0,1194,0,0,0,0,0,0,0,0); // Line # 56

delay(300); //Default Delay

delay(100); // Line # 57

ServoSetAll(2192,1241,0,2317,1500,0,1564,0,0,500,0,0,0,0,0,0,0,0); // Line # 58

delay(300); //Default Delay

delay(100); // Line # 59

ServoSetAll(2192,1271,0,2395,1500,0,1555,0,0,500,0,0,0,0,0,0,0,0); // Line # 60

delay(300); //Default Delay

delay(100); // Line # 61

ServoSetAll(1500,2045,0,2500,1500,0,955,0,0,500,0,0,0,0,0,0,0,0); // Line # 62

delay(300); //Default Delay

delay(1000);

}

void UserCode(void)

{

//------------------------------Configuration------------------------------

I2C_SERVOMAX(1,2500); I2C_SERVOMAX(2,2500); I2C_SERVOMAX(3,2500); I2C_SERVOMAX(4,2500); I2C_SERVOMAX(5,2500); I2C_SERVOMAX(6,2500); I2C_SERVOMAX(7,2500); I2C_SERVOMAX(8,2500); I2C_SERVOMAX(9,2500); I2C_SERVOMAX(10,1194); I2C_SERVOMAX(11,2500); I2C_SERVOMAX(12,2500); I2C_SERVOMAX(13,2500); I2C_SERVOMAX(14,2500); I2C_SERVOMAX(15,2500); I2C_SERVOMAX(16,2500); I2C_SERVOMAX(17,2500); I2C_SERVOMAX(18,2500); //Maximum Values

I2C_SERVOMIN(1,500); I2C_SERVOMIN(2,500); I2C_SERVOMIN(3,500); I2C_SERVOMIN(4,500); I2C_SERVOMIN(5,500); I2C_SERVOMIN(6,500); I2C_SERVOMIN(7,500); I2C_SERVOMIN(8,500); I2C_SERVOMIN(9,500); I2C_SERVOMIN(10,500); I2C_SERVOMIN(11,500); I2C_SERVOMIN(12,500); I2C_SERVOMIN(13,500); I2C_SERVOMIN(14,500); I2C_SERVOMIN(15,500); I2C_SERVOMIN(16,500); I2C_SERVOMIN(17,500); I2C_SERVOMIN(18,500); //Minimum Values

I2C_SERVOOFFSET(1,1500); I2C_SERVOOFFSET(2,1500); I2C_SERVOOFFSET(3,1500); I2C_SERVOOFFSET(4,1500); I2C_SERVOOFFSET(5,1500); I2C_SERVOOFFSET(6,1500); I2C_SERVOOFFSET(7,1500); I2C_SERVOOFFSET(8,1500); I2C_SERVOOFFSET(9,1500); I2C_SERVOOFFSET(10,1500); I2C_SERVOOFFSET(11,1500); I2C_SERVOOFFSET(12,1500); I2C_SERVOOFFSET(13,1500); I2C_SERVOOFFSET(14,1500); I2C_SERVOOFFSET(15,1500); I2C_SERVOOFFSET(16,1500); I2C_SERVOOFFSET(17,1500); I2C_SERVOOFFSET(18,1500); //Offset Values

I2C_SERVOREVERSE(1,0); I2C_SERVOREVERSE(2,0); I2C_SERVOREVERSE(3,0); I2C_SERVOREVERSE(4,0); I2C_SERVOREVERSE(5,0); I2C_SERVOREVERSE(6,0); I2C_SERVOREVERSE(7,0); I2C_SERVOREVERSE(8,0); I2C_SERVOREVERSE(9,0); I2C_SERVOREVERSE(10,0); I2C_SERVOREVERSE(11,0); I2C_SERVOREVERSE(12,0); I2C_SERVOREVERSE(13,0); I2C_SERVOREVERSE(14,0); I2C_SERVOREVERSE(15,0); I2C_SERVOREVERSE(16,0); I2C_SERVOREVERSE(17,0); I2C_SERVOREVERSE(18,0); //Directions (Servo Reverse)

// Comment or remove the next 5 lines to run code in loop...

while(1)

{

ipstate = digitalRead(ipfromesp);

if(ipstate == HIGH)

{

MoveServos();

}

LEDToggle();

delay(100);

}

}

Video