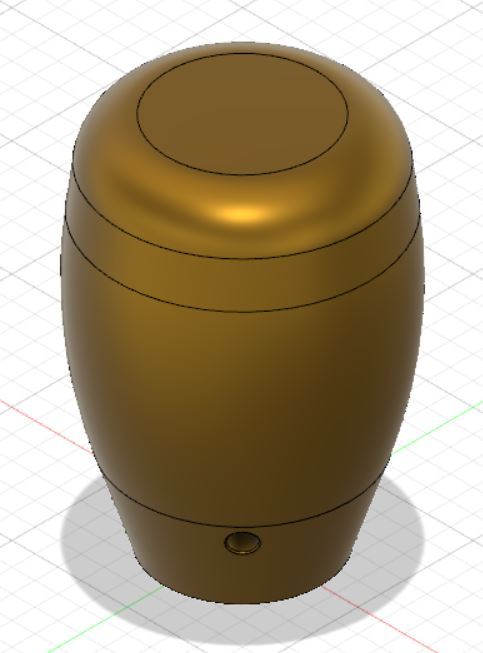

3D Printed Shifter Knob

This Instructable shows the design process of a 3D printed shifter knob. This shift knob is universal and can be altered from the provided dimensions to fit the users preferences.

Supplies

Things you will need:

- Dial Caliper

- Tape Measure

- CAD Software(I used Fusion 360)

- 3D Printer

- Pen and Paper

- 3/8x16 thread, 1/2 inch long set screw

- Tools necessary to remove and install shifter knob(varies by vehicle)

Step 1: Measure

Remove the old shifter knob and any hardwar underneath, revealing the bare shifter shaft.

Take precise measurements of the shaft inculidng: Diameter and height.

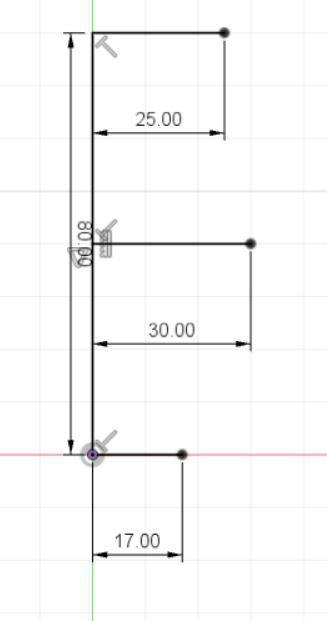

Step 2: Draw

Open CAD Software

Create a new sketch

Draw a vertical line with desired vertical dimension

Draw top and bottom perpendicular lines with half the value of their desire dimension (ie. I wanted my knob to have a width of 34mm so I drew a 17mm line)

Draw a third perpendicular line in the center of your vertical line. Make this line longer than the others

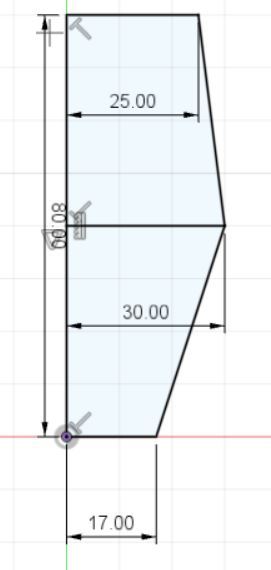

Step 3: Draw

Connect the three lines from end point to endpoint

Delete the middle line after connection, it was only for reference

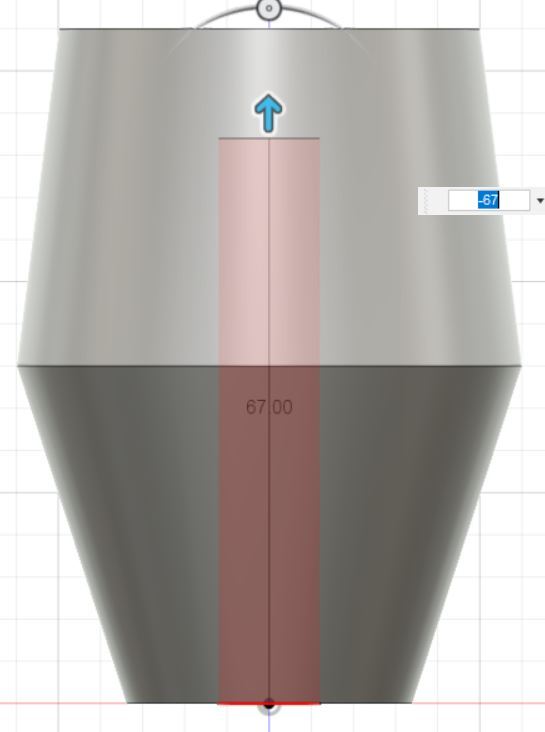

Step 4: Revolve

Select the revolve command

Select the face that's been drawn and the inside axis

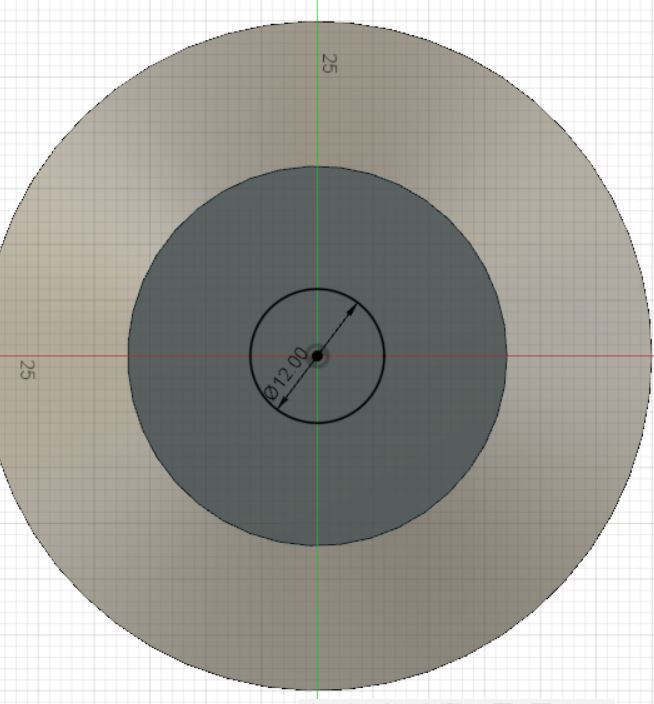

Step 5: Draw Circle

Pan to the bottom face of your drawing.

Create a circle in the center of the piece with your the diameter dimension measured on the shaft.

Be sure to give this dimension a tolerance of .01-.05 mm, allowing plenty of room for the shifter to slide on butstill snug.

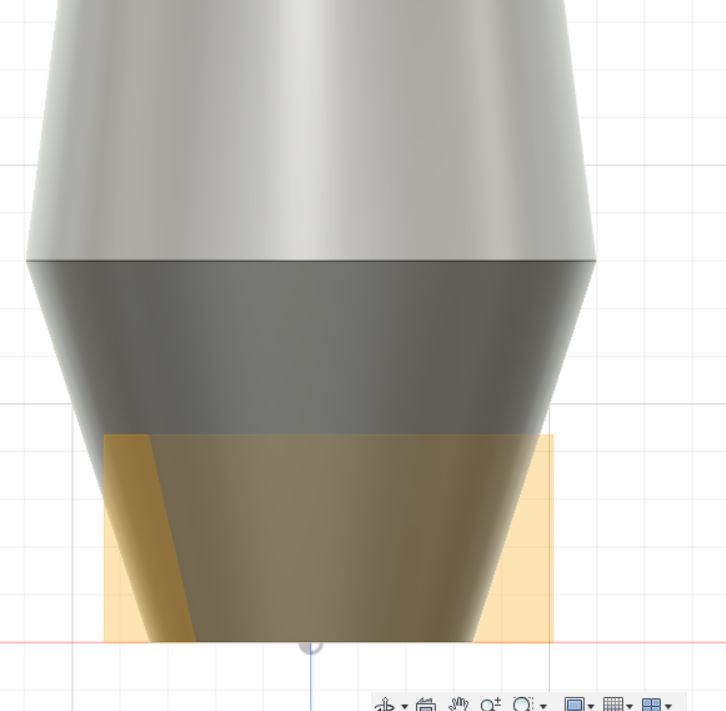

Step 6: Extrude

Extrude this circle upwards into the shifter.

Use the height dimension you measured on the shifter.

Step 7: Midplane

Create a midplane.

Have the midplane flush with the bottom of the part. Select both the XZ and YZ surfaces and hit OK.

To make the midplane larger, click and drag to edge of the plane.

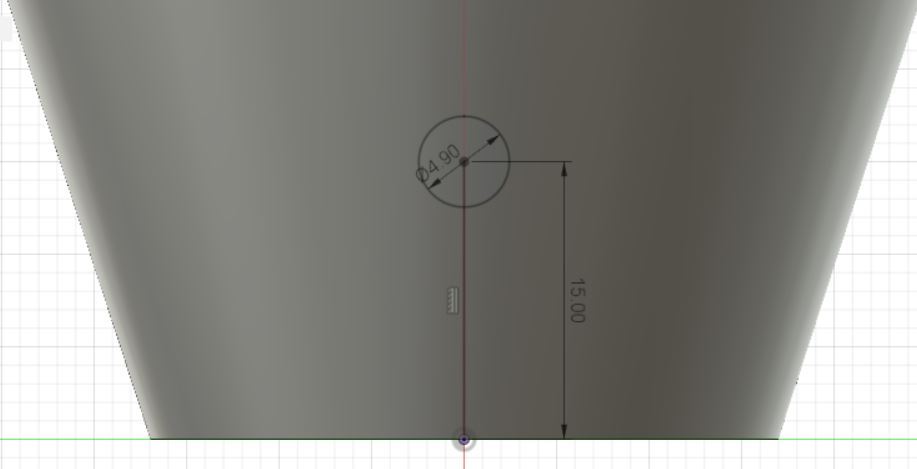

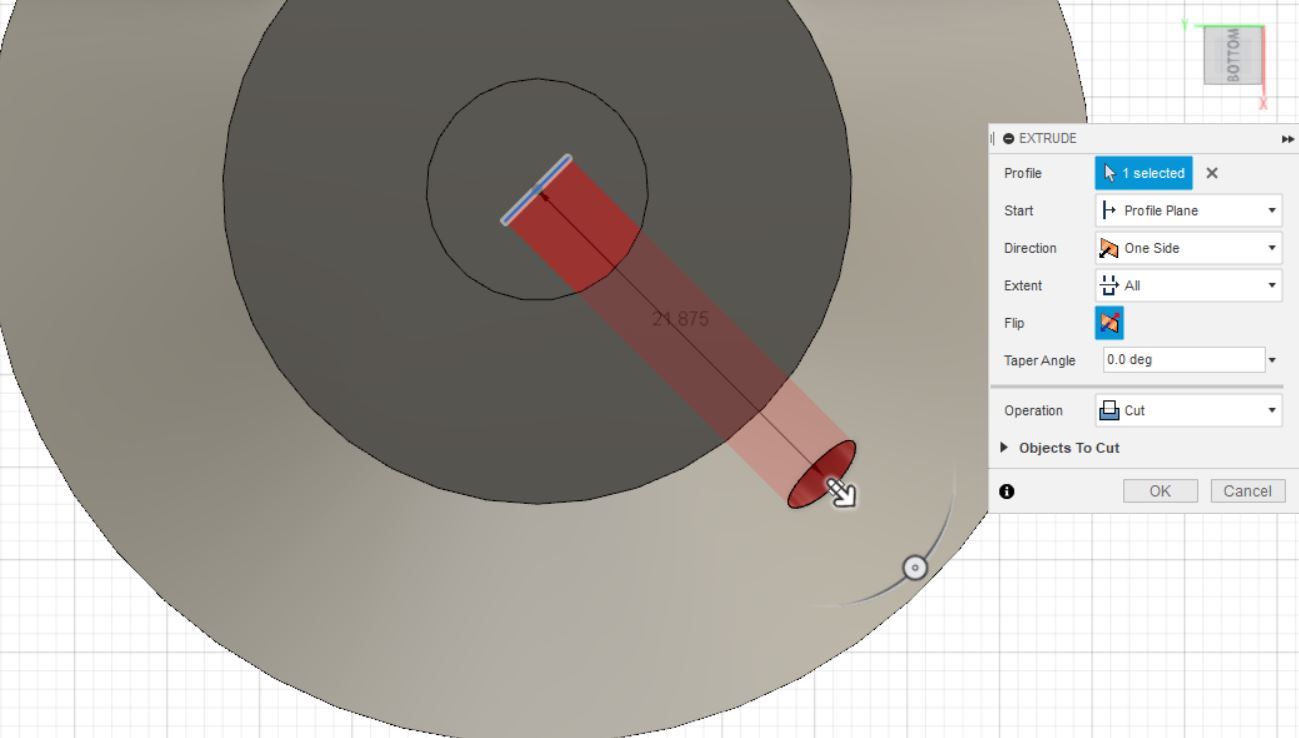

Step 8: Draw Circle

Create a sketch on the midplane.

From the base of the knob, draw a 15mm vertical line.

At the end of this line, draw a circle with a diameter of 4.9mm.

Extrude the circle through the outside of the knob.

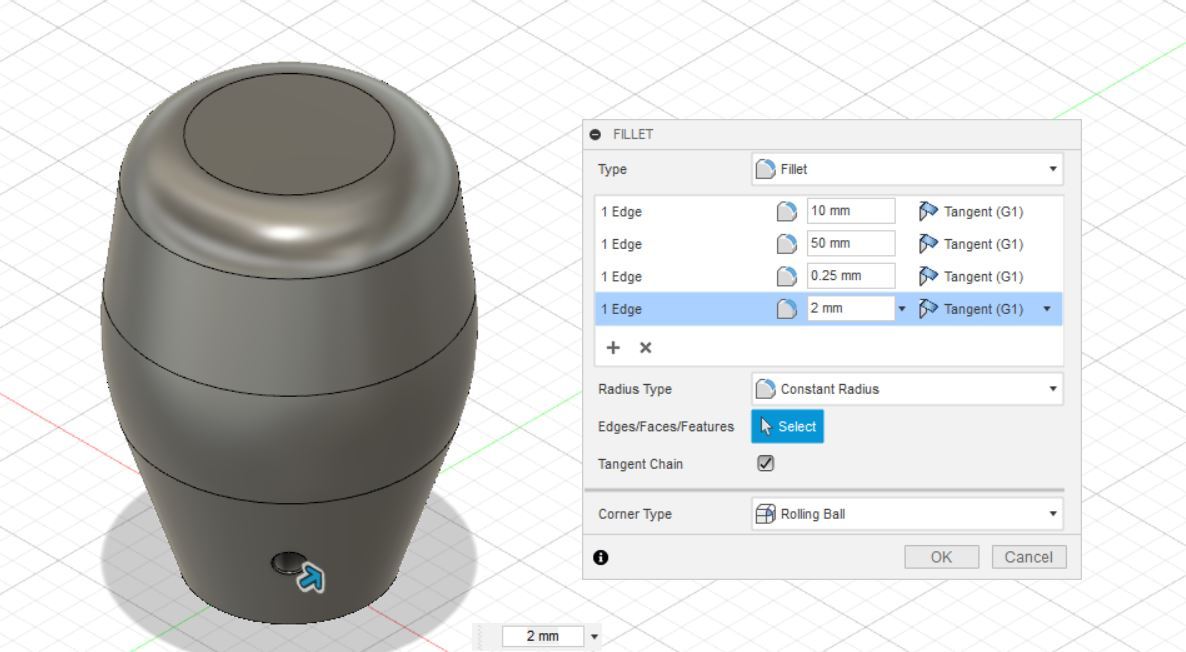

Step 9: Fillet

This is the final step.

Fillet the edges of the part. Type in different dimensions for each edge until the desired shape is aquired.

Be sure to fillet both holes, the bottom hole at 2mm and the set screw hole at .25mm.

Step 10: Make It

Print your final design.

Make sure to use thin layers and decent infill. Make it strong.

Enjoy bangin' gears.